化工学报 ›› 2020, Vol. 71 ›› Issue (5): 2440-2454.DOI: 10.11949/0438-1157.20191393

• 过程安全 • 上一篇

收稿日期:2019-12-10

修回日期:2020-03-05

出版日期:2020-05-05

发布日期:2020-05-05

通讯作者:

汪侃

作者简介:汪侃(1986—),男,博士,讲师,基金资助:

Kan WANG( ),Tingting SHI,Jinhui WANG,Xue ZHANG

),Tingting SHI,Jinhui WANG,Xue ZHANG

Received:2019-12-10

Revised:2020-03-05

Online:2020-05-05

Published:2020-05-05

Contact:

Kan WANG

摘要:

建立了危险化学品集装箱燃爆事故模型,针对事故形成的溢流火在相邻集装箱外立面受限空间内传播规律及温度场分布进行模拟研究。根据实地调研数据,分别设置了三种不同开口大小的危化品集装箱,同时研究了相邻间距为0.4、0.8、1.27 m等10余种不同工况的溢流火演化规律及温度场分布。研究提出了不同间距条件下发生火溢流行为的空气卷吸模型,并对溢流火焰高度进行了修正。研究结果表明,与燃爆集装箱开口相对的集装箱体对附近空气的卷吸效应具有限制作用,从而将影响开口溢流火行为的演化与发展。当相邻集装箱体间距小于一定值时,空气主要来自侧面卷吸,外部溢流火焰高度与温度均出现显著增加,此时对相邻叠加堆放的集装箱体损坏较大;随着相邻间距的增大,来自正面与侧面共同作用下的空气卷吸量增加,受限空间内的温度逐渐升高,溢流火焰高度逐渐降低,此时的破坏作用主要体现在对相邻集装箱体的热毁损破坏行为。

中图分类号:

汪侃, 时婷婷, 汪金辉, 张雪. 危化品集装箱燃爆溢流火在相邻空间内的火行为特征研究[J]. 化工学报, 2020, 71(5): 2440-2454.

Kan WANG, Tingting SHI, Jinhui WANG, Xue ZHANG. Study on flame behaviors induced by spill fire deflagration in adjacent space of hazardous chemical containers[J]. CIESC Journal, 2020, 71(5): 2440-2454.

| 开口大小(宽×高)/m2 | A1 | A2 | A3 | A4 | A5 | A6 | A7 | A8 | A9 | A10 |

|---|---|---|---|---|---|---|---|---|---|---|

| 1.2 m×2.4 m=2.88 m2 | 0.4 | 0.8 | 1.27 | 2.0 | 2.33 | 2.5 | 3.0 | 3.5 | 4.0 | 无遮挡 |

| 开口大小(宽×高)/ m2 | B1 | B2 | B3 | B4 | B5 | B6 | B7 | B8 | B9 | B10 |

| 1.8 m×2.4 m=4.32 m2 | 0.4 | 0.8 | 1.27 | 2.0 | 2.33 | 2.5 | 3.0 | 3.5 | 4.0 | 无遮挡 |

| 开口大小(宽×高)/ m2 | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | C10 |

| 2.2 m×2.4 m=5.28 m2 | 0.4 | 0.8 | 1.27 | 2.0 | 2.33 | 2.5 | 3.0 | 3.5 | 4.0 | 无遮挡 |

表1 不同开口尺寸场景下相邻危化品集装箱箱体间距/m

Table 1 Spacing of hazardous chemical container under different opening sizes/m

| 开口大小(宽×高)/m2 | A1 | A2 | A3 | A4 | A5 | A6 | A7 | A8 | A9 | A10 |

|---|---|---|---|---|---|---|---|---|---|---|

| 1.2 m×2.4 m=2.88 m2 | 0.4 | 0.8 | 1.27 | 2.0 | 2.33 | 2.5 | 3.0 | 3.5 | 4.0 | 无遮挡 |

| 开口大小(宽×高)/ m2 | B1 | B2 | B3 | B4 | B5 | B6 | B7 | B8 | B9 | B10 |

| 1.8 m×2.4 m=4.32 m2 | 0.4 | 0.8 | 1.27 | 2.0 | 2.33 | 2.5 | 3.0 | 3.5 | 4.0 | 无遮挡 |

| 开口大小(宽×高)/ m2 | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | C10 |

| 2.2 m×2.4 m=5.28 m2 | 0.4 | 0.8 | 1.27 | 2.0 | 2.33 | 2.5 | 3.0 | 3.5 | 4.0 | 无遮挡 |

| 环境温度/℃ | 风速m/s | 风向 | 大气稳定度 | 湿度/% | 环境压力/kPa | 罐内压力/kPa | 可燃介质 | 点火源类型 | 点火源能量/mJ |

|---|---|---|---|---|---|---|---|---|---|

| 20.0 | 2.0 | 东北 | D | 64.0 | 101.325 | 4245.517 | 丙烷 | 静电火花 | 0.26 |

表2 数值模拟中的边界及初始条件参数

Table 2 Parameters of boundary condition and initial in numerical simulation

| 环境温度/℃ | 风速m/s | 风向 | 大气稳定度 | 湿度/% | 环境压力/kPa | 罐内压力/kPa | 可燃介质 | 点火源类型 | 点火源能量/mJ |

|---|---|---|---|---|---|---|---|---|---|

| 20.0 | 2.0 | 东北 | D | 64.0 | 101.325 | 4245.517 | 丙烷 | 静电火花 | 0.26 |

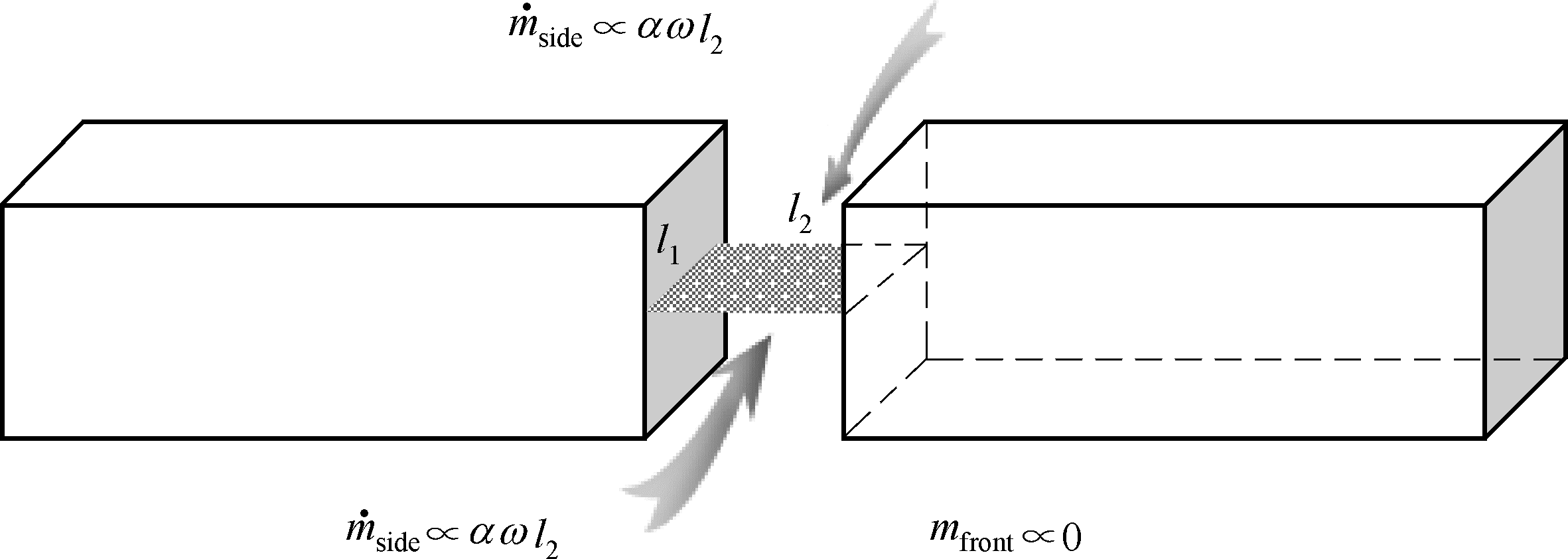

图9 不同相邻间距下危化品集装箱一侧开口溢流火的空气卷吸作用(D≤l2)

Fig.9 Entrainment behavior of open spill fire at difference distances in hazardous chemical container deflagrated side(D≤l2)

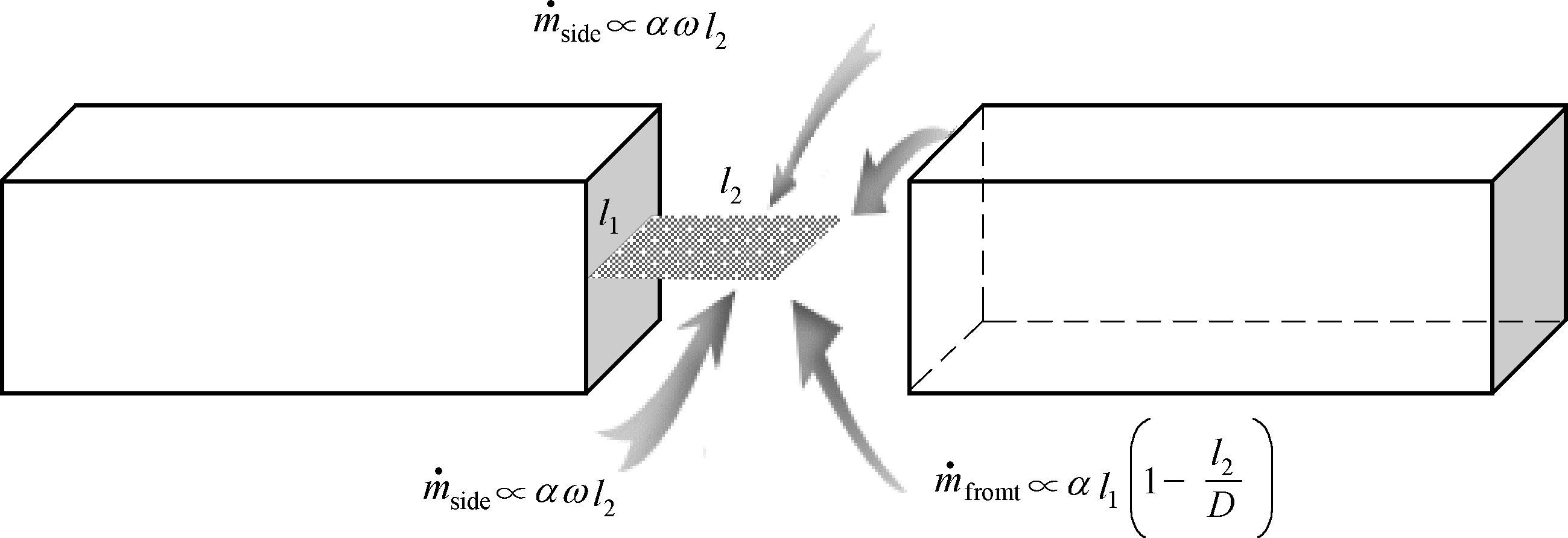

图10 不同相邻间距下危化品集装箱一侧开口溢流火的空气卷吸作用(D>l2)

Fig.10 Entrainment behavior of open spill fire at difference distances in hazardous chemical container deflagrated side(D>l2)

| 1 | 赵冰然. 危险品集装箱场站选址与箱区布置研究[D]. 大连: 大连海事大学, 2018. |

| Zhao B R. Study on site selection and layout of hazardous container terminal station[D]. Dalian: Dalian Maritime University, 2018. | |

| 2 | Kusiak A, Heragu S S. The facility layout problem[J]. European Journal of Operational Research, 1987, 29(3): 229-251. |

| 3 | Bernechea E J, Viger J A. Design optimization of hazardous substance storage facilities to minimize project risk[J]. Safety Science, 2013, 51(1): 49-62. |

| 4 | Antonio C C, Pacifico M P, Mario P, et al. Safety-based process plant layout using genetic algorithm[J]. Journal of Loss Prevention in the Process Industries, 2015, 34: 139-150. |

| 5 | Juan M G, Fabricio N R, José María P O, et al. Optimization of facility location and reallocation in an industrial plant through a multi-annual framework accounting for economic and safety issues[J]. Journal of Loss Prevention in the Process Industries, 2015, 33: 129-139. |

| 6 | Yokoi S. Study on the prevention of fire spread caused by hot upward current[R]. Japan: the Building Research Institute, 1960. |

| 7 | Thomas P H, Law M. The projection of flames from buildings on fire[J]. Fire Prevention Science and Technology, 1972, 10: 19-26. |

| 8 | Seigel L G. The projection of flames from burning buildings[J]. Fire Technology, 1969, 5(1): 43-51. |

| 9 | Oleszkiewicz I. Fire exposure to exterior walls and flame spread on combustible cladding[J]. Fire Technology, 1990, 26(4): 357-375. |

| 10 | Oleszkiewicz I. Heat transfer from a window fire plume to a building façade[J]. Asme Htd., 1989, 123: 163-170. |

| 11 | Oleszkiewicz I. Fire exposure to exterior walls and flame spread on combustible cladding[J]. Fire Technology, 1990, 26(4): 357-375. |

| 12 | Nakamichi A. Temperature profiles of window jet plume[J]. Journal of Applied Fire Science, 2004, 24(1): 55-66. |

| 13 | Klopovic S, Turan Ö F. Flames venting externally during full-scale flashover fires: two sample ventilation cases[J]. Fire Safety Journal, 1998, 31(2): 117-142. |

| 14 | Klopovic S, Turan Ö F. Comprehensive study of externally venting flames(Part Ⅰ): Experimental plume characteristics for through-draft and no-through-draft ventilation conditions and repeatability[J]. Fire Safety Journal, 2001, 36(2): 99-133. |

| 15 | Klopovic S, Turan Ö F. A comprehensive study of externally venting flames(Part Ⅱ): Plume envelope and centre-line temperature comparisons, secondary fires, wind effects and smoke management system[J]. Fire Safety Journal, 2001, 36(2): 135-172. |

| 16 | Himoto K, Tsuchihashi T, Tanaka Y, et al. Modeling thermal behaviors of window flame ejected from a fire compartment[J]. Fire Safety Journal, 2009, 44(2): 230-240. |

| 17 | Himoto K, Tsuchihashi T, Tanaka Y, et al. Modeling the trajectory of window flames with regard to flow attachment to the adjacent wall[J]. Fire Safety Journal, 2009, 44(2): 250-258. |

| 18 | Coutin M, Most J M, Delichatsios M A, et al. Flame heights in wall fires: effects of width, confinement and pyrolysis length[C]// Fire Safety Science: Proceedings of the 6th International Symposium, 2000: 729-740. |

| 19 | Lee Y P, Delichatsios M A, Silcock G W H. Heat fluxes and flame heights in facades from fires in enclosures of varying geometry[J]. Proceedings of the Combustion Institute, 2007, 31(2): 2521-2528. |

| 20 | Lee Y P. Heat fluxes and flame heights in external facade fires[D]. Belfast, Northern Ireland: University of Ulster, 2006. |

| 21 | Delichatsios M A, Lee Y P, Tofilo P. A new correlation for gas temperature inside a burning enclosure[J]. Fire Safety Journal, 2009, 44(8): 1003-1009. |

| 22 | Lee Y P, Delichatsios M A, Ohmiya Y, et al. Heat fluxes on opposite building wall by flames emerging from an enclosure[J]. Proceedings of the Combustion Institute, 2009, 32(2): 2551-2558. |

| 23 | Tang F, Hu L H, Delichatsios M A, et al. Experimental study on flame height and temperature profile of buoyant window spill plume from an under-ventilated compartment fire[J]. International Journal of Heat and Mass Transfer, 2012, 55(1/2/3): 93-101. |

| 24 | 唐飞. 不同外部边界及气压条件下建筑外立面开口火溢流行为特征研究[D]. 合肥: 中国科学技术大学, 2013. |

| Tang F. Studies on facade flame behavior ejected from opening of a building compartment under different external boundary and pressure conditions[D]. Hefei: University of Science and Technology of China, 2013. | |

| 25 | Tang F, Hu L H, Qiu Z W, et al. Window ejected flame height and heat flux along facade with air entrainment constraint by a sloping facing wall[J]. Fire Safety Journal, 2015, 71: 248-256. |

| 26 | Hu L H, Lu K H, Tang F, et al. A global non-dimensional factor characterizing side wall constraint effect on facade flame entrainment and flame height from opening of compartment fires[J]. International Journal of Heat and Mass Transfer, 2014, 75: 122-129. |

| 27 | Lu K H, Hu L H, Tang F, et al. Experimental investigation on window ejected facade flame heights with different constraint side wall lengths and global correlation[J]. International Journal of Heat and Mass Transfer, 2014, 78: 17-24. |

| 28 | Lu K H, Hu L H, Tang F, et al. Heat flux profile upon building facade with side walls due to window ejected fire plume: an experimental investigation and global correlation[J]. Fire Safety Journal, 2014, 70: 14-22. |

| 29 | Lu K H, Wang J, Hu L H. Vertical temperature profile of fire-induced facade thermal plume ejected from a fire compartment window with two adjacent side walls[J]. Applied Thermal Engineering, 2017, 113: 70-78. |

| 30 | Lee J Y, Lee J W, Ko J, et al. Optimization for allocating the explosive facilities in order to minimize the domino effect using nonlinear programming[J]. Korean Journal of Chemical Engineering, 2005, 22(5): 649-656. |

| 31 | Antioco L M, Richart V R, Mannan M S, et al. An approach for domino effect reduction based on optimal layouts[J]. Journal of Loss Prevention in the Process Industries, 2013, 26(5): 887-894. |

| 32 | Juliode L F, Richart V R, Antioco L M, et al. A MINLP approach for layout designs based on the domino hazard index[J]. Journal of Loss Prevention in the Process Industries, 2014, 30(1): 219-227. |

| 33 | 柏跃领. 外立面作用下的水平湍流浮力射流火焰特性研究[D]. 合肥: 中国科学技术大学, 2014. |

| Bai Y L. Study on flame characteristics of horizontal turbulent buoyant jet on facade wall[D]. Hefei: University of Science and Technology of China, 2014. | |

| 34 | Gao W, Liu N A, Delichatsios M, et al. Fire spill plume from a compartment with dual symmetric openings under cross wind[J]. Combustion and Flame, 2016, 167: 409-421. |

| 35 | Wang P G, Liu N A, Zhang L H, et al. Fire whirl experimental facility with no enclosure of solid walls: design and validation[J]. Fire Technology, 2015, 51: 951-969. |

| 36 | API. Recommended practice for fitness-for-service: API 579[S]. Washington DC: American Petroleum Institute, 2007. |

| No related articles found! |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号