化工学报 ›› 2025, Vol. 76 ›› Issue (11): 5980-5997.DOI: 10.11949/0438-1157.20250646

收稿日期:2025-06-15

修回日期:2025-07-07

出版日期:2025-11-25

发布日期:2025-12-19

通讯作者:

李双喜

作者简介:张家豪(1997—),男,博士研究生,zjh1592955102@163.com

基金资助:

Jiahao ZHANG( ), Zhichao GONG, Shuangxi LI(

), Zhichao GONG, Shuangxi LI( ), Kejian WANG, Fangjun LI

), Kejian WANG, Fangjun LI

Received:2025-06-15

Revised:2025-07-07

Online:2025-11-25

Published:2025-12-19

Contact:

Shuangxi LI

摘要:

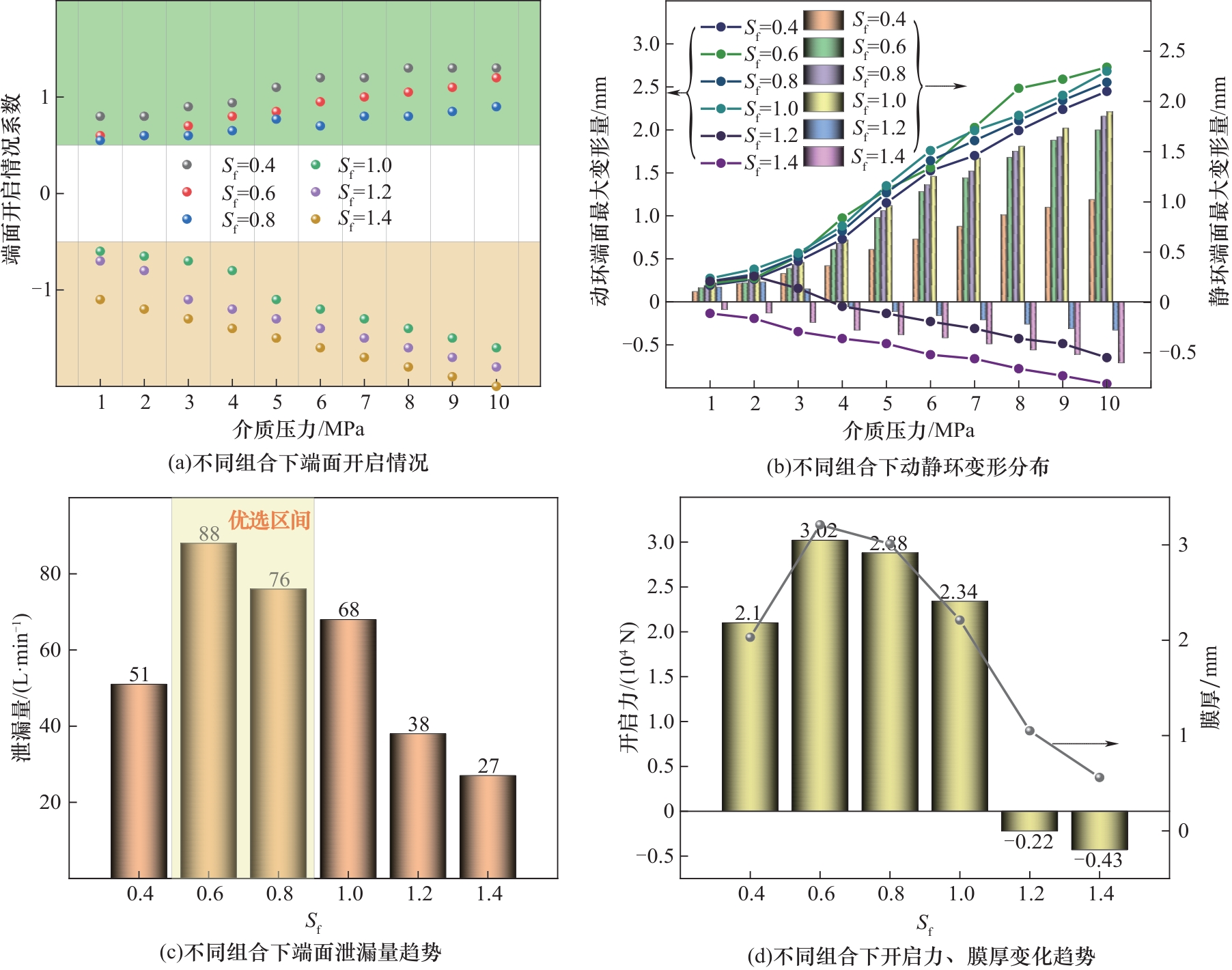

超高压干气密封作为极端工况下的非接触式密封,其性能显著受高温高压环境中的热力变形影响,热力变形研究对密封的长期稳定运转至关重要。针对高温高压高转速极端工况,建立流-固-热多物理场全耦合的性能分析模型,研究热力耦合变形对密封性能的影响,展开变形协调分析与优化研究,探究优化后的结构对密封性能的综合影响,得到超高压干气密封的适宜操作范围。建立高压密封试验装置,通过试验验证了模型的准确性。研究表明,当动环轴向厚度比Md为1.05~1.10,静环轴向厚度比Mf=1.20时,间隙近乎为理想平行型间隙,密封性能最好;当平衡直径处泛塞圈摩擦力与弹簧弹力之比Sf为0.6~0.8时,密封性能达到最佳;适宜操作的压力范围为0~14 MPa,线速度范围为30~160 m·s-1,温度范围为50~200℃。结果可为超高压干气密封结构参数和工况参数的设计提供理论参考。

中图分类号:

张家豪, 弓志超, 李双喜, 王克俭, 李方俊. 基于流-固-热全耦合数值方法的超高压干气密封的热力变形影响分析及变形协调研究[J]. 化工学报, 2025, 76(11): 5980-5997.

Jiahao ZHANG, Zhichao GONG, Shuangxi LI, Kejian WANG, Fangjun LI. Thermal deformation influence analysis and deformation compatibility research of ultra-high-pressure dry gas seal based on fluid-solid-thermal fully coupled numerical method[J]. CIESC Journal, 2025, 76(11): 5980-5997.

| 参数名称 | 数值/mm | 参数名称 | 数值/mm |

|---|---|---|---|

| 动环端面外径ro,r | 66.2 | 动环端面内径ri,r | 51.5 |

| 动环背部距压紧环最小距离Li1,min | 48.6 | 动环背部距压紧环最大距离Li1,max | 49 |

| 静环端面外径ro,s | 65.5 | 静环端面内径ri,s | 52 |

| 动环端面厚度Li | 14 | 静环端面厚度Ls | 11 |

| 压紧环内径ri,y | 39 | 动环背部泛塞圈密封内径ri,q | 59.8 |

| 平衡直径ri,p | 55.5 | 弹簧作用中心处内径ri,t | 67 |

| 泛塞圈轴向最大长度Lf1,max | 3.55 | 泛塞圈径向最大长度Lf2,max | 5 |

| 泛塞圈唇口长度Lf3 | 2.2 | 泛塞圈底部最小长度Lf4,min | 1.9 |

| 泛塞圈极限压缩宽度Lf5,max | 3.1 | 泛塞圈单边最大压缩量δf,max | 0.225 |

| 泛塞圈弹簧内径Ri,f | 1.0 | 泛塞圈单边壁厚Lf6 | 0.675 |

表1 超高压干气密封结构参数

Table 1 Structural parameters of ultra-high-pressure dry gas seal

| 参数名称 | 数值/mm | 参数名称 | 数值/mm |

|---|---|---|---|

| 动环端面外径ro,r | 66.2 | 动环端面内径ri,r | 51.5 |

| 动环背部距压紧环最小距离Li1,min | 48.6 | 动环背部距压紧环最大距离Li1,max | 49 |

| 静环端面外径ro,s | 65.5 | 静环端面内径ri,s | 52 |

| 动环端面厚度Li | 14 | 静环端面厚度Ls | 11 |

| 压紧环内径ri,y | 39 | 动环背部泛塞圈密封内径ri,q | 59.8 |

| 平衡直径ri,p | 55.5 | 弹簧作用中心处内径ri,t | 67 |

| 泛塞圈轴向最大长度Lf1,max | 3.55 | 泛塞圈径向最大长度Lf2,max | 5 |

| 泛塞圈唇口长度Lf3 | 2.2 | 泛塞圈底部最小长度Lf4,min | 1.9 |

| 泛塞圈极限压缩宽度Lf5,max | 3.1 | 泛塞圈单边最大压缩量δf,max | 0.225 |

| 泛塞圈弹簧内径Ri,f | 1.0 | 泛塞圈单边壁厚Lf6 | 0.675 |

| 参数名称(高压侧) | 数值 | 参数名称(低压侧) | 数值 |

|---|---|---|---|

| 密封介质 | 空气 | 密封介质 | 空气 |

| 工作压力p1/MPa | 0~16 | 工作压力p2/MPa | 常压 |

| 工作温度T1/K | 0~600 | 工作温度T2/K | 常温 |

| 转速n1/(r·min-1) | 0~25000 | 转速n2/(r·min-1) | 0~25000 |

表2 超高压干气密封环境参数

Table 2 Ultra-high-pressure dry gas seal environmental parameters

| 参数名称(高压侧) | 数值 | 参数名称(低压侧) | 数值 |

|---|---|---|---|

| 密封介质 | 空气 | 密封介质 | 空气 |

| 工作压力p1/MPa | 0~16 | 工作压力p2/MPa | 常压 |

| 工作温度T1/K | 0~600 | 工作温度T2/K | 常温 |

| 转速n1/(r·min-1) | 0~25000 | 转速n2/(r·min-1) | 0~25000 |

| 材料属性 | 动静环(SiC) | 静环(M160K) | 壳体、环座 |

|---|---|---|---|

| 弹性模量E/GPa | 400 | 14 | 198 |

| 泊松比μ | 0.45 | 0.3 | 0.29 |

| 热导率k/(W·m-1·℃-1) | 90~110 | 140 | 17 |

| 固体比热容Cpt/(J·kg-1·℃-1) | 690 | 640 | 500 |

| 热膨胀系数α/(10-6℃-1) | 4.0 | 5 | 16.7 |

| 密度ρ/(kg·m-3) | 3080 | 1750 | 8446 |

表3 超高压干气密封材料参数

Table 3 Parameters of ultra-high-pressure dry gas sealing materials

| 材料属性 | 动静环(SiC) | 静环(M160K) | 壳体、环座 |

|---|---|---|---|

| 弹性模量E/GPa | 400 | 14 | 198 |

| 泊松比μ | 0.45 | 0.3 | 0.29 |

| 热导率k/(W·m-1·℃-1) | 90~110 | 140 | 17 |

| 固体比热容Cpt/(J·kg-1·℃-1) | 690 | 640 | 500 |

| 热膨胀系数α/(10-6℃-1) | 4.0 | 5 | 16.7 |

| 密度ρ/(kg·m-3) | 3080 | 1750 | 8446 |

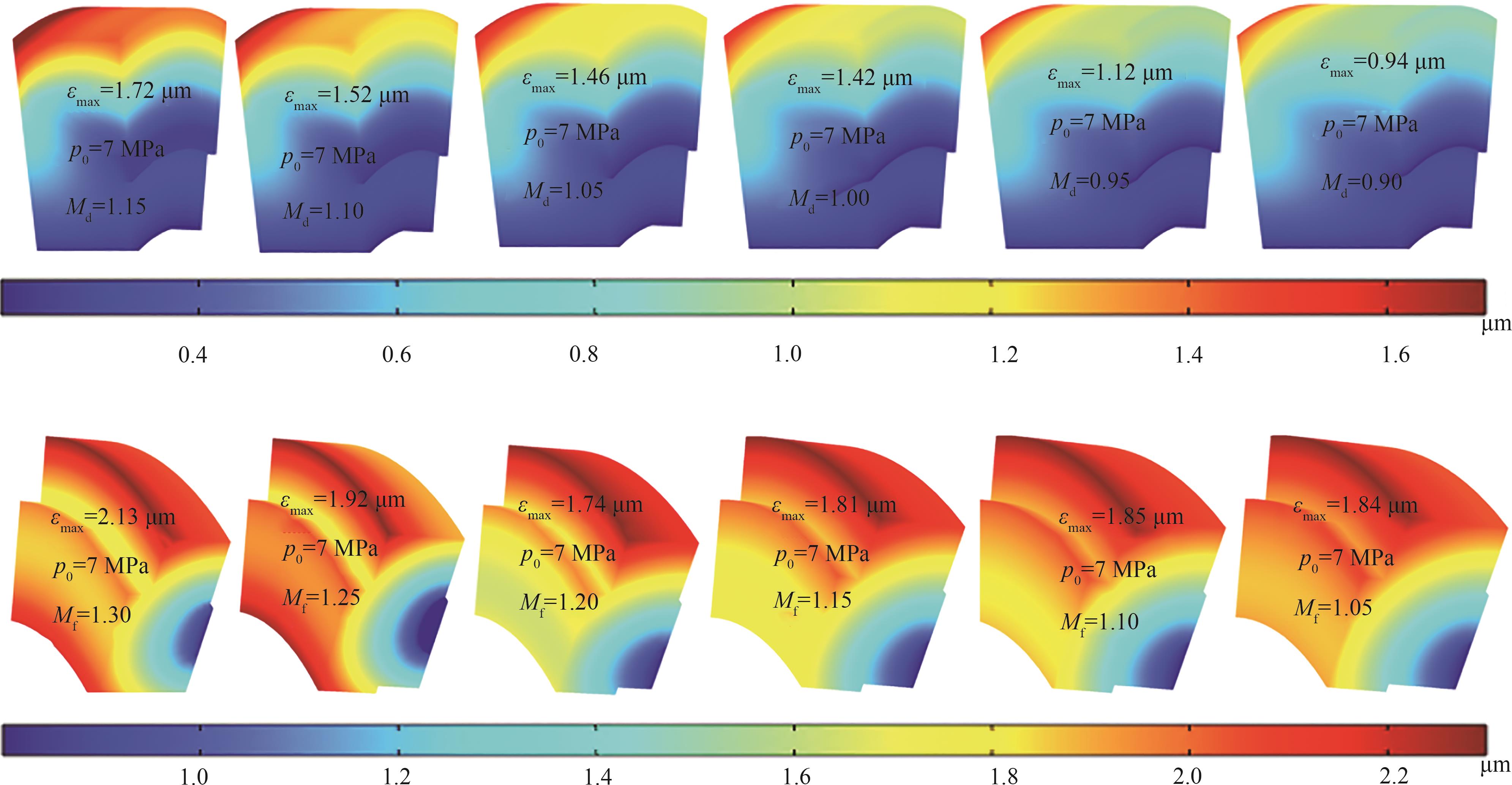

图8 不同动静环轴向厚度比下动静环端面最大变形云图

Fig.8 Maximum deformation of dynamic and static ring end face under different dynamic and static ring axial thickness ratios

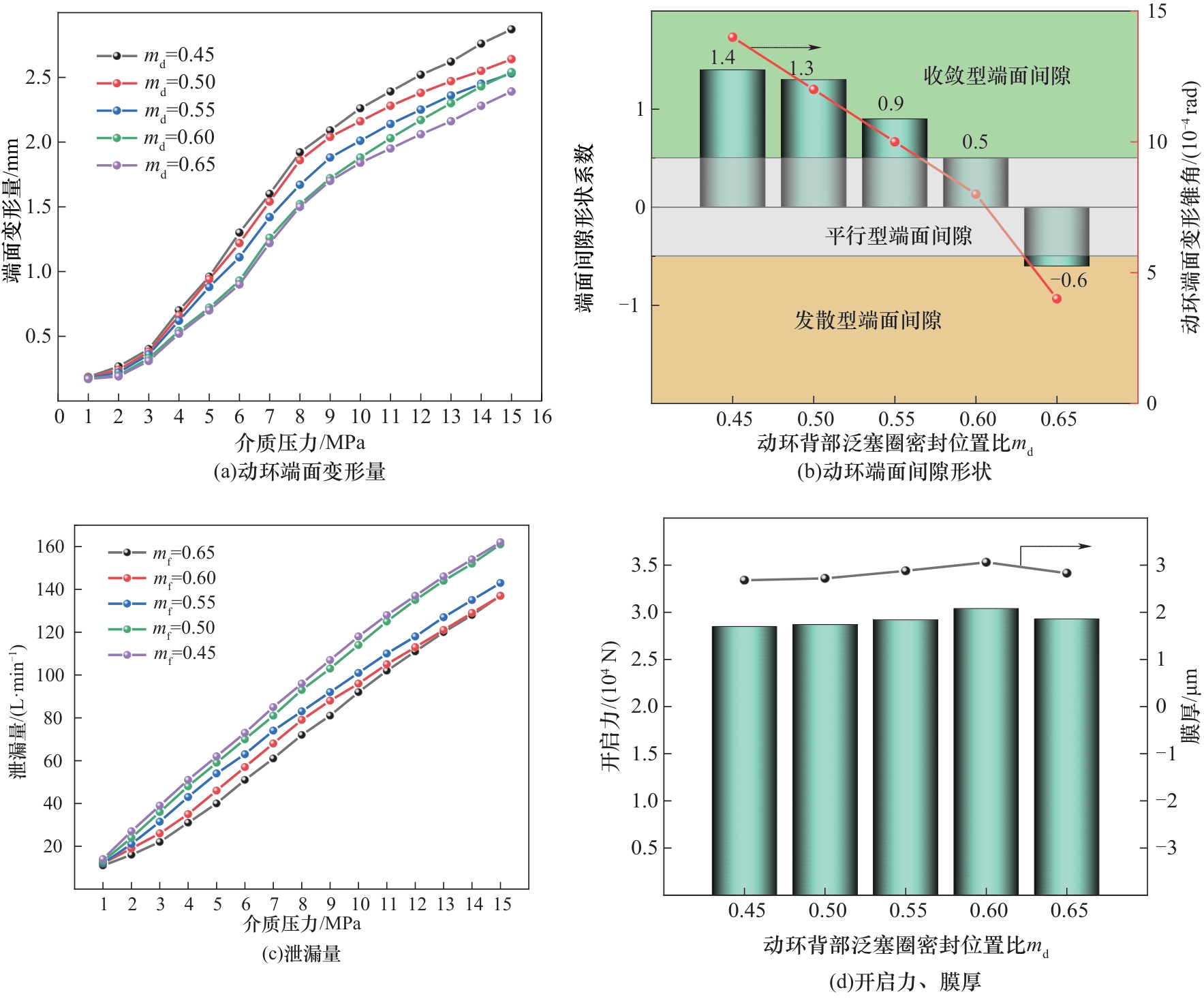

图11 动环背部泛塞圈密封位置比md对密封端面变形协调的影响

Fig.11 Influence of the ratio of the sealing position of the backside of the dynamic ring pan plug ring on the deformation compatibility of seal end face

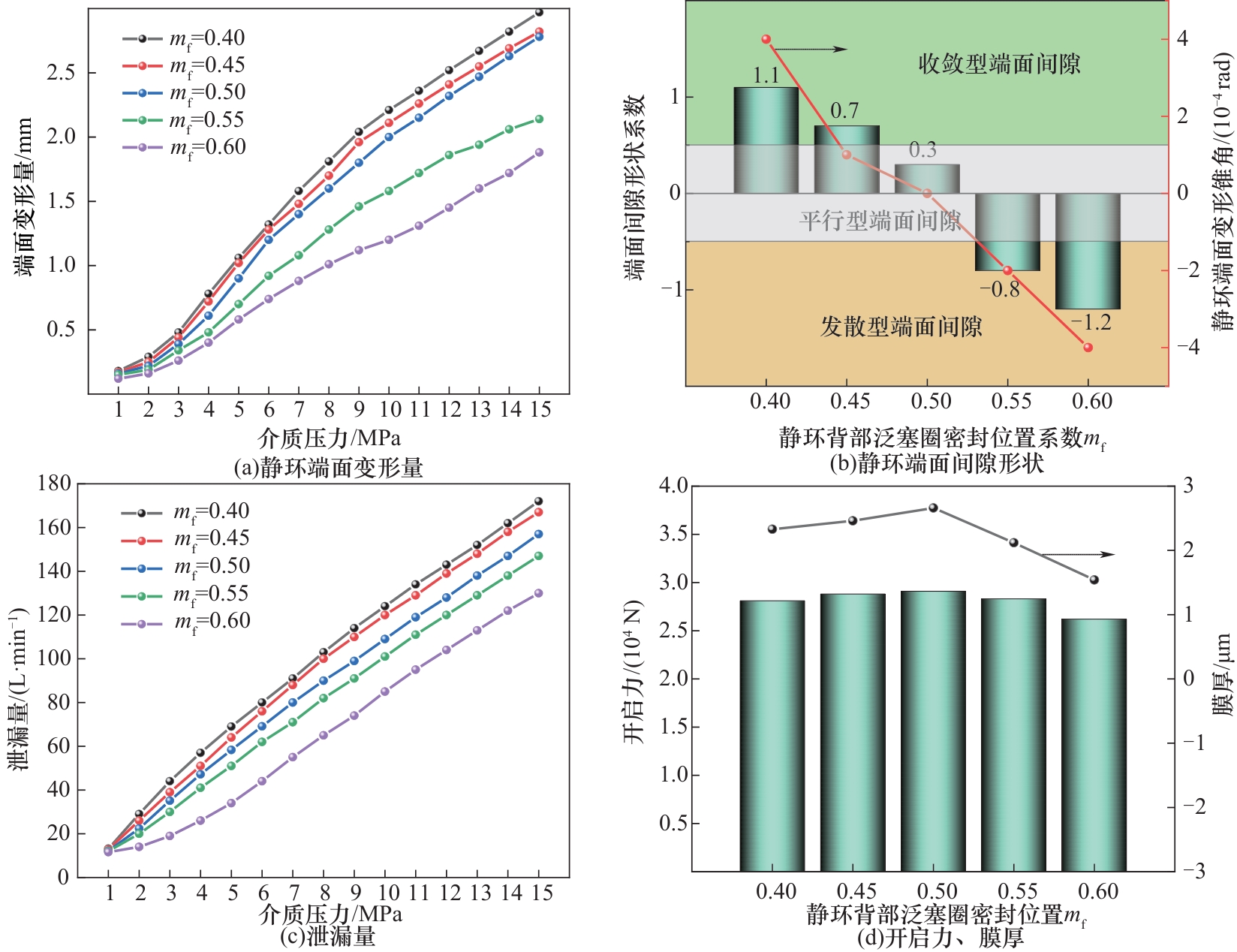

图12 静环背部泛塞圈密封位置之比mf对密封端面变形协调的影响

Fig.12 Influence of the ratio of the sealing position of the backside of the static ring pan plug ring on the deformation compatibility of the sealing end face

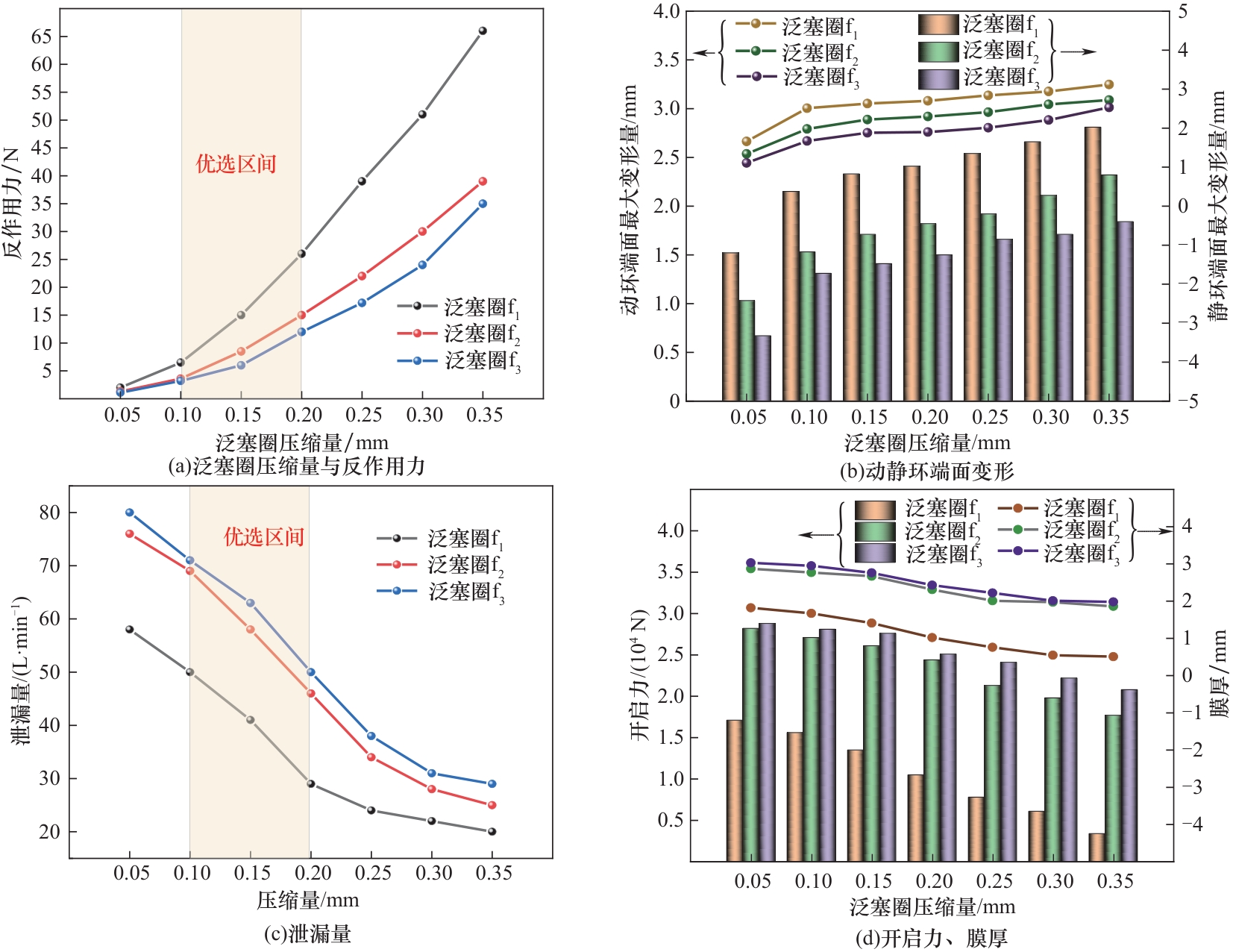

图13 不同泛塞圈结构压缩量对密封端面变形协调的影响

Fig.13 Influence of different compression amount of pan plug ring structure on the deformation compatibility of seal end face

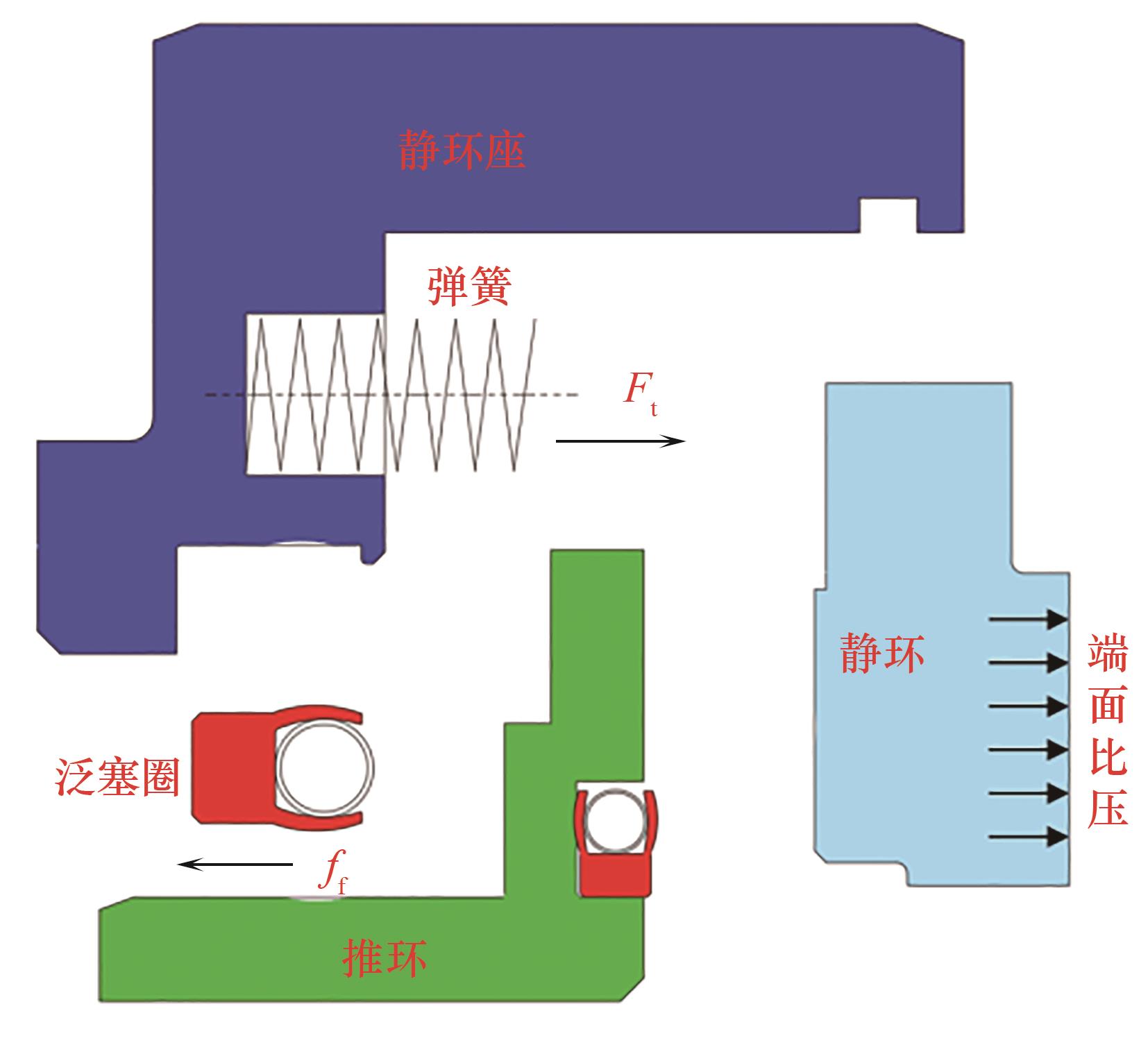

图14 平衡直径处泛塞圈与弹簧的组合结构对静环影响示意图

Fig.14 Schematic diagram of the effect of the combined structure of the pan plug ring and spring on the static ring at the equilibrium diameter

图15 平衡直径处泛塞圈的结构、压缩量与弹簧弹力的组合结构对密封变形协调的影响

Fig.15 Influence of the structure of the pan plug ring at the equilibrium diameter, the structure of the combination of compression and spring elasticity on the seal deformation compatibility

| [1] | 宁喜, 王维民, 张娅, 等. 离心式压缩机密封动态特性分析及稳定性评价[J]. 振动与冲击, 2013, 32(13): 153-158. |

| Ning X, Wang W M, Zhang Y, et al. Dynamic performance analysis of seals in a centrifugal compressor and rotor stability evaluation[J]. Journal of Vibration and Shock, 2013, 32(13): 153-158. | |

| [2] | Ullah T, Sobczak K, Liskiewicz G, et al. Numerical investigations of inlet recirculation in a turbocharger centrifugal compressor[J]. Energies, 2025, 18(4): 903. |

| [3] | 裴峻峰, 郑庆元, 姜海一, 等. 离心式压缩机定期维修周期及可靠性研究[J]. 中国石油大学学报(自然科学版), 2014, 38(6): 127-133. |

| Pei J F, Zheng Q Y, Jiang H Y, et al. Research on regular maintenance cycle and reliability for centrifugal compressors[J]. Journal of China University of Petroleum (Edition of Natural Science), 2014, 38(6): 127-133. | |

| [4] | 李双喜, 刘安, 刘志远, 等. 高速涡轮泵动静压混合式气体隔离密封扰动性能[J]. 化工学报, 2025, 76(1): 311-323. |

| Li S X, Liu A, Liu Z Y, et al. Disturbance performance of dynamic and static pressure hybrid gas isolation seal of high-speed turbopumps[J]. CIESC Journal, 2025, 76(1): 311-323. | |

| [5] | 李庆展, 郑娆, 李双喜, 等. 基于流固热耦合的油气两相动压密封追随动态特性[J]. 哈尔滨工业大学学报, 2020, 52(7): 122-132. |

| Li Q Z, Zheng R, Li S X, et al. Follows dynamic characteristics of oil-gas two-phase hydrodynamic seals based on fluid-solid-thermal coupling[J]. Journal of Harbin Institute of Technology, 2020, 52(7): 122-132. | |

| [6] | 丁雪兴, 陆俊杰, 刘勇, 等. 热耗散变形下干气密封系统轴向振动稳定性分析[J]. 振动工程学报, 2016, 29(1): 78-86. |

| Ding X X, Lu J J, Liu Y, et al. Stability analysis on axial vibration of dry gas seal system under the thermo-elastic deformation considering the thermal dissipation[J]. Journal of Vibration Engineering, 2016, 29(1): 78-86. | |

| [7] | Ding S J, Fang P, Li G, et al. Axial-torsional nonlinear vibration of bottom hole assembly in the air drilling technology[J]. Petroleum, 2024, 10(3): 446-461. |

| [8] | 刘蕴, 殷国富, 杜建媛, 等. 螺旋槽型干气密封系统轴向振动影响因素研究[J]. 四川大学学报(工程科学版), 2016, 48(S2): 155-160. |

| Liu Y, Yin G F, Du J Y, et al. Study on influencing factors of axial vibration of spiral groove dry gas sealing system[J]. Advanced Engineering Sciences, 2016, 48(S2): 155-160. | |

| [9] | 陈志, 赵鹏, 王金红, 等. 端面变形锥角对干气密封性能影响的数值模拟[J]. 工程科学与技术, 2018, 50(1): 203-210. |

| Chen Z, Zhao P, Wang J H, et al. Numerical simulation of the influence of the angle of end face gap on the performance of dry gas seal[J]. Advanced Engineering Sciences, 2018, 50(1): 203-210. | |

| [10] | 苏虹, 丁雪兴, 张海舟, 等. 力变形下螺旋槽干气密封气膜流场近似计算及分析[J]. 工程力学, 2013, 30(S1): 279-283. |

| Su H, Ding X X, Zhang H Z, et al. Gas membrane flow field approximate calculation and analysis of spiral groove dry gas seal on the force distortion[J]. Engineering Mechanics, 2013, 30(S1): 279-283. | |

| [11] | 江锦波, 陈竹鑫, 肖洋溢, 等. 运行工况对超临界CO2干气密封端面热力过程及稳态性能影响研究[J]. 化工学报, 2025, 76(6): 2913-2928. |

| Jiang J B, Chen Z X, Xiao Y Y, et al. Study on the influence of operating conditions on the thermal process and steady state performance of supercritical CO2 dry gas seal end face[J]. CIESC Journal, 2025, 76(6): 2913-2928. | |

| [12] | 李雨诗, 陈源, 李运堂, 等. 新型柔性坝箔片端面气膜密封变形协调分析及性能智能优化[J]. 化工学报, 2025, 76(1): 324-334. |

| Li Y S, Chen Y, Li Y T, et al. Intelligent optimization and deformation analysis of novel flexible dam foil face gas seal[J]. CIESC Journal, 2025, 76(1): 324-334. | |

| [13] | 王云飞. 气体润滑理论与气体轴承设计[M]. 北京: 机械工业出版社, 1999. |

| Wang Y F. Gas Lubricated Theory and Design Manual of Gas Bearings[M]. Beijing: China Machine Press, 1999. | |

| [14] | Surovtcev S, Zadorozhnaya E, Khozenyuk N, et al. Building of a mathematical model for solving the elastic-gas-dynamic task of the gas lubrication theory for petal bearings[J]. Mathematics, 2023, 11(13): 2901. |

| [15] | 彭旭东, 赵艳凤, 江锦波, 等. 动静压气体端面润滑技术研究现状[J]. 润滑与密封, 2019, 44(1): 1-7. |

| Peng X D, Zhao Y F, Jiang J B, et al. Development status of hydrostatic-dynamic gas lubrication technology[J]. Lubrication Engineering, 2019, 44(1): 1-7. | |

| [16] | Liu Z Q, Tian J, Hao M M, et al. High-pressure miscible laser face shallow groove seal lubrication state change and performance analysis[J]. Tribology, 2024, 44(1): 49-59. |

| [17] | 朱芝, 许恒杰, 陈维, 等. 超临界二氧化碳螺旋槽干气密封热流耦合润滑临界阻塞特性研究[J]. 化工学报, 2024, 75(2): 604-615. |

| Zhu Z, Xu H J, Chen W, et al. Study on critical chocked characteristics of supercritical carbon dioxide spiral groove dry gas seal under thermal-fluid coupling lubrication[J]. CIESC Journal, 2024, 75(2): 604-615. | |

| [18] | 丁俊华, 俞树荣, 王世鹏, 等. 多重效应下超高速干气密封流场模拟及密封性能试验[J]. 化工学报, 2023, 74(5): 2088-2099. |

| Ding J H, Yu S R, Wang S P, et al. Flow simulation and sealing performance test of ultra-high speed dry gas seal under multiple effects[J]. CIESC Journal, 2023, 74(5): 2088-2099. | |

| [19] | 张俊杰, 陈源, 李运堂, 等. 超椭圆织构浮动坝箔片端面气膜密封动态性能分析与优化[J]. 化工学报, 2025, 76(1): 296-310. |

| Zhang J J, Chen Y, Li Y T, et al. Analysis and optimization of dynamic performance of super-elliptical hole floating seal dam compliant foil face gas seal[J]. CIESC Journal, 2025, 76(1): 296-310. | |

| [20] | Lee S C, Zheng X L. Analyses of both steady behavior and dynamic tracking of non-contacting spiral-grooved gas face seals[J]. Computers & Fluids, 2013, 88: 326-333. |

| [21] | Fairuz Z M, Jahn I, Abdul-Rahman R. The effect of convection area on the deformation of dry gas seal operating with supercritical CO2 [J]. Tribology International, 2019, 137: 349-365. |

| [22] | 陈滋新, 彭旭东, 赵文静, 等. 动压型分段式圆周密封变形特性及其调控策略研究[J]. 摩擦学学报, 2023, 43(2): 143-156. |

| Chen Z X, Peng X D, Zhao W J, et al. Deformation characteristics and control strategies of a dynamic segmented circumferential seal[J]. Tribology, 2023, 43(2): 143-156. | |

| [23] | 张书贵, 顾永泉. 机械密封环的温度场及变形[J]. 流体工程, 1993, 21(2): 5-10, 64. |

| Zhang S G, Gu Y Q. Temperature field and deformation in mechanical seal ring[J]. Fluid Machinery, 1993, 21(2): 5-10, 64. | |

| [24] | 顾永泉. 流体动密封[M]. 东营: 石油大学出版社, 1990. |

| Gu Y Q. Fluid Dynamic Seal [M]. Dongying: China University of Petroleum Press, 1990. | |

| [25] | 张书贵, 顾永泉. 机械密封变形的研究[J]. 石油大学学报(自然科学版), 1992, 16(2): 48-53. |

| Zhang S G, Gu Y Q. Study on the deformation of mechanical face seal[J]. Journal of the University of Petroleum, China, 1992, 16(2): 48-53. | |

| [26] | 王金红, 陈志, 刘凡, 等. 密封环支撑边界条件对机械密封端面变形的影响[J]. 化工学报, 2020, 71(4): 1744-1753. |

| Wang J H, Chen Z, Liu F, et al. Influence of support boundary conditions of a seal ring on deformation of mechanical seal end face[J]. CIESC Journal, 2020, 71(4): 1744-1753. | |

| [27] | 孟祥铠, 吴大转, 王乐勤. 辅助密封影响下机械密封端面变形行为的研究[J]. 润滑与密封, 2008, 33(1): 101-103, 121. |

| Meng X K, Wu D Z, Wang L Q. Study on deformation behavior of mechanical seal faces influenced by secondary seals[J]. Lubrication Engineering, 2008, 33(1): 101-103, 121. | |

| [28] | 胡航领, 丁雪兴, 张伟政, 等. 工况参数对超临界二氧化碳干气密封性能影响的试验研究[J]. 化工学报, 2023, 74(2): 665-674. |

| Hu H L, Ding X X, Zhang W Z, et al. Experimental study on influence of working parameters on sealing performance of supercritical carbon dioxide dry gas seal[J]. CIESC Journal, 2023, 74(2): 665-674. | |

| [29] | Brunetière N, Tournerie B, Frêne J. TEHD lubrication of mechanical face seals in stable tracking mode(part 1): Numerical model and experiments[J]. Journal of Tribology, 2003, 125(3): 608-616. |

| [30] | Brunetière N, Tournerie B, Frêne J. TEHD lubrication of mechanical face seals in stable tracking mode(part 2): Parametric study[J]. Journal of Tribology, 2003, 125(3): 617-627. |

| [31] | 朱维兵, 王和顺, 徐昌学. 机械密封热变形研究进展[J]. 机械设计与制造, 2011 (12): 267-268. |

| Zhu W B, Wang H S, Xu C X. Researching progress in thermal deformation of mechanical seal[J]. Machinery Design & Manufacture, 2011(12): 267-268. | |

| [32] | 秦小屿, 李娜, 朱维兵, 等. 干气密封热变形影响因素分析[J]. 机械设计与制造, 2010 (11): 180-182. |

| Qin X Y, Li N, Zhu W B, et al. Influencing factor analysis on thermal deformation of dry gas seal[J]. Machinery Design & Manufacture, 2010(11): 180-182. | |

| [33] | Thomas S, Brunetière N, Tournerie B. Thermoelastohydrodynamic behavior of mechanical gas face seals operating at high pressure[J]. Journal of Tribology, 2007, 129(4): 841-850. |

| [34] | 张伟政, 席喜林, 李水平, 等. 热耗散变形下干气密封角向摆动稳定性的研究[J]. 振动与冲击, 2018, 37(14): 30-37, 50. |

| Zhang W Z, Xi X L, Li S P, et al. Analysis on the angular wobble of a dry gas seal system with thermal dissipation[J]. Journal of Vibration and Shock, 2018, 37(14): 30-37, 50. | |

| [35] | 杨小成, 丁雪兴, 陈金林. 考虑弹塑性变形阶段的干气密封接触模型[J]. 摩擦学学报, 2022, 42(6): 1237-1245. |

| Yang X C, Ding X X, Chen J L. Contact model of dry gas seal considering elastic-plastic deformation stage[J]. Tribology, 2022, 42(6): 1237-1245. | |

| [36] | 陈金林, 丁雪兴, 张伟政, 等. 干气密封动静环摩擦界面热弹法向接触刚度分形模型[J]. 振动与冲击, 2020, 39(14): 257-263, 284. |

| Chen J L, Ding X X, Zhang W Z, et al. Fractal prediction model for the thermo-elastic normal contact stiffness of frictional interfaces in dry gas seals[J]. Journal of Vibration and Shock, 2020, 39(14): 257-263, 284. | |

| [37] | 翁文豪, 胡航领, 江锦波, 等. 高压干气密封三体双向流固耦合模型及端面力变形规律研究[J]. 摩擦学学报, 2024, 44(11): 1540-1557. |

| Weng W H, Hu H L, Jiang J B, et al. Three-body two-way fluid-solid coupling model and end face mechanical deformation law of high pressure dry gas seal[J]. Tribology, 2024, 44(11): 1540-1557. | |

| [38] | 蒋小文, 顾伯勤. 螺旋槽干气密封端面间气膜特性[J]. 化工学报, 2005, 56(8): 1419-1425. |

| Jiang X W, Gu B Q. Characteristic of gas film between spiral groove dry gas seal faces[J]. Journal of Chemical Industry and Engineering (China), 2005, 56(8): 1419-1425. | |

| [39] | 张依婷, 何自福, 马高峰, 等. 干气密封润滑气膜在热-流-固耦合下对动环变形的影响[J]. 山东化工, 2024, 53(24): 161-163. |

| Zhang Y T, He Z F, Ma G F, et al. The influence of dry gas seal lubricating gas film on dynamic ring deformation under thermal fluid solid coupling[J]. Shandong Chemical Industry, 2024, 53(24): 161-163. | |

| [40] | 郑建科. 静压干气密封的动态特性及热变形研究[D]. 成都: 西华大学, 2013. |

| Zheng J K. Study on dynamic characteristics and thermal deformation of static dry gas seal[D]. Chengdu: Xihua University, 2013. | |

| [41] | 郭仁东, 温志梅, 相培. 流体力学[M]. 北京: 化学工业出版社, 2024. |

| Guo R D, Wen Z M, Xiang P. Hydromechanics[M]. Beijing: Chemical Industry Press, 2024. | |

| [42] | Ross C, Bird J, Little A. Mechanics of Solids[M]. London: CRC Press, 2021. |

| [43] | 邓元望, 袁茂强, 刘长青. 传热学[M]. 北京: 中国水利水电出版社, 2010. |

| Deng Y W, Yuan M Q, Liu C Q. Heat Transmission Science[M]. Beijing: China Water & Power Press, 2010. | |

| [44] | 黄柏淇. 航空发动机浅槽动压密封变形协调及密封性能研究[D]. 北京: 北京化工大学, 2023. |

| Huang B Q. Study on deformation coordination and sealing performance of aero-engine shallow groove dynamic pressure seal[D]. Beijing: Beijing University of Chemical Technology, 2023. |

| [1] | 李雨诗, 陈源, 李运堂, 彭旭东, 王冰清, 李孝禄. 新型柔性坝箔片端面气膜密封变形协调分析及性能智能优化[J]. 化工学报, 2025, 76(1): 324-334. |

| [2] | 谢玉汉, 孟祥铠, 赵文静, 王禹衡, 洪先志, 彭旭东. 高压工况上游泵送机械密封热力变形与密封性能分析[J]. 化工学报, 2023, 74(10): 4241-4251. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号