化工学报 ›› 2020, Vol. 71 ›› Issue (4): 1696-1711.DOI: 10.11949/0438-1157.20190946

收稿日期:2019-08-20

修回日期:2019-12-08

出版日期:2020-04-05

发布日期:2020-04-05

通讯作者:

黄克谨

作者简介:臧立静(1994—),女,博士研究生,基金资助:

Lijing ZANG( ),Kejin HUANG(

),Kejin HUANG( ),Yang YUAN,Xing QIAN,Liang ZHANG,Shaofeng WANG,Haisheng CHEN

),Yang YUAN,Xing QIAN,Liang ZHANG,Shaofeng WANG,Haisheng CHEN

Received:2019-08-20

Revised:2019-12-08

Online:2020-04-05

Published:2020-04-05

Contact:

Kejin HUANG

摘要:

隔离壁蒸馏塔(DWC)的双塔多段拓扑结构导致蒸汽再压缩热泵(VRHP)的应用具有多种可能性,包括单VRHP、多VRHP、多级VRHP以及它们的相互组合等复杂结构,这显著加剧了蒸汽再压缩隔离壁蒸馏塔(DWC-VRHP)综合与设计的复杂性与烦琐性。为解决这一问题,针对轻组分绝对占优的三元宽沸点物系的分离问题推演了DWC-VRHP的最优拓扑结构,由此能够有效回避系统综合与设计过程中的结构搜索问题并显著降低模型化与搜索计算的工作强度。轻组分绝对占优与宽沸点物性导致了塔顶冷凝器与预分离蒸馏塔的提馏段是主要的热源与热阱,也决定了DWC-VRHP的最优拓扑结构,即一个二级VRHP与DWC的耦合系统。第一级VRHP用于进料预热,既充分利用温度提升跨度小的特点,又可以通过进料分流强化气液相间的物质传递。第二级VRHP用于加热预分离蒸馏塔的提馏段(或公共提馏段),能够最大限度地降低分离操作的非可逆性。采用苯/甲苯/邻二甲苯和正戊烷/正己烷/正庚烷两个物系的分离问题对所提出的DWC-VRHP的最优拓扑结构进行了分析与验证。通过与DWC以及DWC-VRHP其他潜在结构的系统性比较,显示了所提出系统结构在稳态性能方面的优越性。

中图分类号:

臧立静, 黄克谨, 苑杨, 钱行, 张亮, 王韶峰, 陈海胜. 轻组分绝对占优的蒸汽再压缩隔离壁蒸馏塔的最优拓扑结构[J]. 化工学报, 2020, 71(4): 1696-1711.

Lijing ZANG, Kejin HUANG, Yang YUAN, Xing QIAN, Liang ZHANG, Shaofeng WANG, Haisheng CHEN. Optimal topological structure of vapor recompressed dividing-wall columns for separation of light-component dominated mixtures[J]. CIESC Journal, 2020, 71(4): 1696-1711.

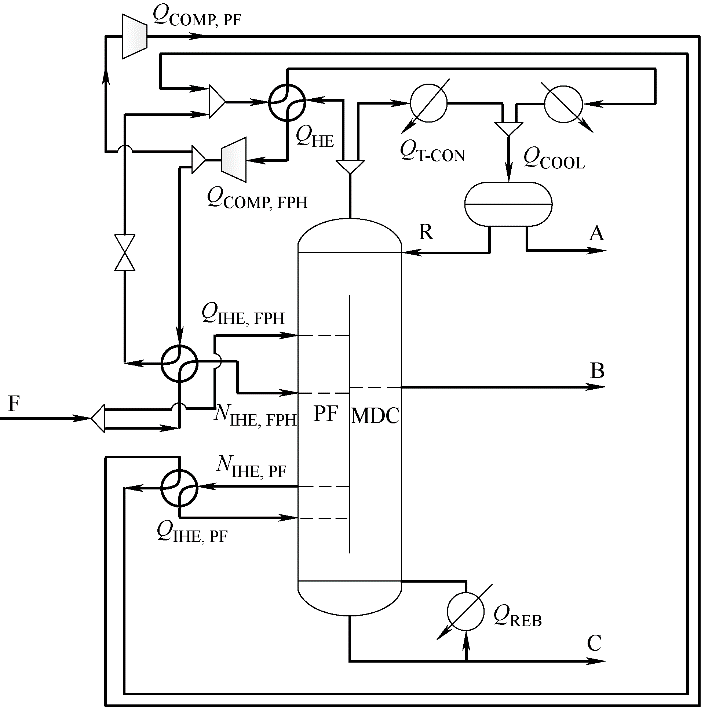

图2 分离轻组分绝对占优的三元宽沸点物系的DWC-VRHP的最优拓扑结构

Fig.2 Optimum topological configuration of DWC-VRHP for separation of light-component dominated and wide-boiling ternary mixtures

| 参数 | 数值 | ||

|---|---|---|---|

| 塔顶压力/atm | 1.00 | ||

| 塔板压降/atm | 0.0068 | ||

| 进料流率/(kmol/h) | 1000 | ||

| 进料压力/atm | 1.088 | ||

| 进料温度(泡点)/K | 358.78 | ||

| 液/气相进料(FL/FV)组成/% (mol) | |||

| 苯 | 0.900 | ||

| 甲苯 | 0.050 | ||

| 邻二甲苯 | 0.050 | ||

| 产品规定/% (mol) | |||

| 塔顶产品(D) | 苯 | 0.995 | |

| 侧线产品(S) | 甲苯 | 0.995 | |

| 塔底产品(B) | 邻二甲苯 | 0.995 | |

表1 例Ⅰ的操作条件和产品规定

Table 1 Operating conditions and product specifications of Example Ⅰ

| 参数 | 数值 | ||

|---|---|---|---|

| 塔顶压力/atm | 1.00 | ||

| 塔板压降/atm | 0.0068 | ||

| 进料流率/(kmol/h) | 1000 | ||

| 进料压力/atm | 1.088 | ||

| 进料温度(泡点)/K | 358.78 | ||

| 液/气相进料(FL/FV)组成/% (mol) | |||

| 苯 | 0.900 | ||

| 甲苯 | 0.050 | ||

| 邻二甲苯 | 0.050 | ||

| 产品规定/% (mol) | |||

| 塔顶产品(D) | 苯 | 0.995 | |

| 侧线产品(S) | 甲苯 | 0.995 | |

| 塔底产品(B) | 邻二甲苯 | 0.995 | |

| 相关费用 | 过程设计 | ||||

|---|---|---|---|---|---|

| DWC | DWC-VRHP (FPH) | DWC-VRHP (FPH-PF) | DWC-VRHP (FPH-PF-MDC1) | DWC-VRHP (FPH-PF-MDC1-MDC2) | |

| 塔的投资费用/USD | 4543.89×103 | 4040.16×103 | 3749.25×103 | 3719.85×103 | 3793.62×103 |

| 再沸器的投资 费用/USD | 715.35×103 | 433.20×103 | 329.28×103 | 315.51×103 | 318.60×103 |

| 冷凝器的投资 费用/USD | 737.67×103 | 432.63×103 | 318.39×103 | 303.51×103 | 305.40×103 |

| 冷却器的投资 费用/USD | 0 | 80.07×103 | 101.94×103 | 104.76×103 | 105.48×103 |

| 压缩机的投资 费用/USD | 0 | 1172.22×103 | 1754.49×103 | 1864.47×103 | 2045.37×103 |

| 热交换器的投资 费用/USD | 0 | 161.28×103 | 204.90×103 | 210.75×103 | 243.54×103 |

| 中间再沸器的投资费用/USD | 0 | 949.74×103 | 1385.10×103 | 1548.00×103 | 1688.70×103 |

| 蒸汽费用/ (USD/a) | 3006.53×103 | 1375.56×103 | 902.07×103 | 844.69×103 | 857.37×103 |

| 冷却水费用/ (USD/a) | 41.53×103 | 19.60×103 | 13.36×103 | 12.64×103 | 12.76×103 |

| 电费/(USD/a) | 0 | 93.18×103 | 134.69×103 | 140.44×103 | 150.07×103 |

| QTUC/kW | 12534.66 | 6429.48(-48.71%) | 4764.83(-61.99%) | 4568.49(-63.55%) | 4693.08(-62.56%) |

| CI/USD | 5996.91×103 | 7269.30×103(+21.22%) | 7843.35×103(+30.79%) | 8066.85×103(+34.52%) | 8500.71×103(+41.75%) |

| OC/(USD/a) | 3048.06×103 | 1488.34×103(-51.17%) | 1050.12×103(-65.55%) | 997.77×103(-67.26%) | 1020.20×103(-66.53%) |

| TAC/(USD/a) | 5047.03×103 | 3911.44×103(-22.50%) | 3664.57×103(-27.39%) | 3686.72×103(-26.95%) | 3853.77×103(-23.64%) |

| βpbt/a | 3 | 3 | 3 | 3 | 3 |

表2 例Ⅰ中所有过程设计的结果

Table 2 Results of all process designs studied in Example Ⅰ

| 相关费用 | 过程设计 | ||||

|---|---|---|---|---|---|

| DWC | DWC-VRHP (FPH) | DWC-VRHP (FPH-PF) | DWC-VRHP (FPH-PF-MDC1) | DWC-VRHP (FPH-PF-MDC1-MDC2) | |

| 塔的投资费用/USD | 4543.89×103 | 4040.16×103 | 3749.25×103 | 3719.85×103 | 3793.62×103 |

| 再沸器的投资 费用/USD | 715.35×103 | 433.20×103 | 329.28×103 | 315.51×103 | 318.60×103 |

| 冷凝器的投资 费用/USD | 737.67×103 | 432.63×103 | 318.39×103 | 303.51×103 | 305.40×103 |

| 冷却器的投资 费用/USD | 0 | 80.07×103 | 101.94×103 | 104.76×103 | 105.48×103 |

| 压缩机的投资 费用/USD | 0 | 1172.22×103 | 1754.49×103 | 1864.47×103 | 2045.37×103 |

| 热交换器的投资 费用/USD | 0 | 161.28×103 | 204.90×103 | 210.75×103 | 243.54×103 |

| 中间再沸器的投资费用/USD | 0 | 949.74×103 | 1385.10×103 | 1548.00×103 | 1688.70×103 |

| 蒸汽费用/ (USD/a) | 3006.53×103 | 1375.56×103 | 902.07×103 | 844.69×103 | 857.37×103 |

| 冷却水费用/ (USD/a) | 41.53×103 | 19.60×103 | 13.36×103 | 12.64×103 | 12.76×103 |

| 电费/(USD/a) | 0 | 93.18×103 | 134.69×103 | 140.44×103 | 150.07×103 |

| QTUC/kW | 12534.66 | 6429.48(-48.71%) | 4764.83(-61.99%) | 4568.49(-63.55%) | 4693.08(-62.56%) |

| CI/USD | 5996.91×103 | 7269.30×103(+21.22%) | 7843.35×103(+30.79%) | 8066.85×103(+34.52%) | 8500.71×103(+41.75%) |

| OC/(USD/a) | 3048.06×103 | 1488.34×103(-51.17%) | 1050.12×103(-65.55%) | 997.77×103(-67.26%) | 1020.20×103(-66.53%) |

| TAC/(USD/a) | 5047.03×103 | 3911.44×103(-22.50%) | 3664.57×103(-27.39%) | 3686.72×103(-26.95%) | 3853.77×103(-23.64%) |

| βpbt/a | 3 | 3 | 3 | 3 | 3 |

图6 例Ⅰ中的DWC、DWC-VRHP(FPH)-FS和DWC-VRHP(FPH)-NFS的预分离蒸馏塔的温度分布

Fig.6 Temperature profiles of pre-fractionators for DWC, DWC-VRHP(FPH)-FS and DWC-VRHP(FPH)-NFS in Example Ⅰ

| 参数 | 数值 | |

|---|---|---|

| 塔顶压力/atm | 1.00 | |

| 塔板压降/atm | 0.0068 | |

| 进料流率/(kmol/h) | 1000 | |

| 进料压力/atm | 1.088 | |

| 进料温度(泡点)/K | 314.39 | |

| 液/气相进料(FL/FV)组成/% (mol) | ||

| 正戊烷 | 0.900 | |

| 正己烷 | 0.050 | |

| 正庚烷 | 0.050 | |

| 产品规定/% (mol) | ||

| 塔顶产品(D) | 正戊烷 | 0.995 |

| 侧线产品(S) | 正己烷 | 0.995 |

| 塔底产品(B) | 正庚烷 | 0.995 |

表3 例Ⅱ的操作条件和产品规定

Table 3 Operating conditions and product specifications of Example Ⅱ

| 参数 | 数值 | |

|---|---|---|

| 塔顶压力/atm | 1.00 | |

| 塔板压降/atm | 0.0068 | |

| 进料流率/(kmol/h) | 1000 | |

| 进料压力/atm | 1.088 | |

| 进料温度(泡点)/K | 314.39 | |

| 液/气相进料(FL/FV)组成/% (mol) | ||

| 正戊烷 | 0.900 | |

| 正己烷 | 0.050 | |

| 正庚烷 | 0.050 | |

| 产品规定/% (mol) | ||

| 塔顶产品(D) | 正戊烷 | 0.995 |

| 侧线产品(S) | 正己烷 | 0.995 |

| 塔底产品(B) | 正庚烷 | 0.995 |

| 相关费用 | 过程设计 | |||

|---|---|---|---|---|

| DWC | DWC-VRHP(FPH) | DWC-VRHP(FPH-PF) | DWC-VRHP(FPH-PF-MDC) | |

| 塔的投资费用/USD | 4223.58×103 | 3566.58×103 | 3358.68×103 | 3368.88×103 |

| 再沸器的投资费用/USD | 959.91×103 | 590.28×103 | 476.52×103 | 475.50×103 |

| 冷凝器的投资费用/USD | 806.31×103 | 476.82×103 | 372.42×103 | 370.80×103 |

| 冷却器的投资费用/USD | 0 | 101.04×103 | 124.74×103 | 127.65×103 |

| 压缩机的投资费用/USD | 0 | 1163.13×103 | 1675.32×103 | 1762.35×103 |

| 热交换器的投资费用/USD | 0 | 162.72×103 | 205.74×103 | 206.43×103 |

| 中间再沸器的投资费用/USD | 0 | 767.07×103 | 1081.71×103 | 1195.41×103 |

| 蒸汽费用/(USD/a) | 882.22×103 | 413.65×103 | 297.55×103 | 296.60×103 |

| 冷水费用/(USD/a) | 1243.57×103 | 606.66×103 | 452.87×103 | 452.95×103 |

| 电费/(USD/a) | 0 | 92.30×103 | 127.80×103 | 132.17×103 |

| QTUC/kW | 9651.61 | 5213.44(-45.98%) | 4207.90(-56.40%) | 4230.12(-56.17%) |

| CI/USD | 5989.80×103 | 6827.64×103(+13.99%) | 7295.13×103(+21.79%) | 7507.02×103(+25.33%) |

| OC/(USD/a) | 2125.79×103 | 1112.61×103(-47.66%) | 878.22×103(-58.69%) | 881.72×103(-58.52%) |

| TAC/(USD/a) | 4122.39×103 | 3388.49×103(-17.80%) | 3309.93×103(-19.71%) | 3384.06×103(-17.91%) |

| βpbt/a | 3 | 3 | 3 | 3 |

表4 例Ⅱ中所有过程设计的结果

Table 4 Results of all process designs studied in Example Ⅱ

| 相关费用 | 过程设计 | |||

|---|---|---|---|---|

| DWC | DWC-VRHP(FPH) | DWC-VRHP(FPH-PF) | DWC-VRHP(FPH-PF-MDC) | |

| 塔的投资费用/USD | 4223.58×103 | 3566.58×103 | 3358.68×103 | 3368.88×103 |

| 再沸器的投资费用/USD | 959.91×103 | 590.28×103 | 476.52×103 | 475.50×103 |

| 冷凝器的投资费用/USD | 806.31×103 | 476.82×103 | 372.42×103 | 370.80×103 |

| 冷却器的投资费用/USD | 0 | 101.04×103 | 124.74×103 | 127.65×103 |

| 压缩机的投资费用/USD | 0 | 1163.13×103 | 1675.32×103 | 1762.35×103 |

| 热交换器的投资费用/USD | 0 | 162.72×103 | 205.74×103 | 206.43×103 |

| 中间再沸器的投资费用/USD | 0 | 767.07×103 | 1081.71×103 | 1195.41×103 |

| 蒸汽费用/(USD/a) | 882.22×103 | 413.65×103 | 297.55×103 | 296.60×103 |

| 冷水费用/(USD/a) | 1243.57×103 | 606.66×103 | 452.87×103 | 452.95×103 |

| 电费/(USD/a) | 0 | 92.30×103 | 127.80×103 | 132.17×103 |

| QTUC/kW | 9651.61 | 5213.44(-45.98%) | 4207.90(-56.40%) | 4230.12(-56.17%) |

| CI/USD | 5989.80×103 | 6827.64×103(+13.99%) | 7295.13×103(+21.79%) | 7507.02×103(+25.33%) |

| OC/(USD/a) | 2125.79×103 | 1112.61×103(-47.66%) | 878.22×103(-58.69%) | 881.72×103(-58.52%) |

| TAC/(USD/a) | 4122.39×103 | 3388.49×103(-17.80%) | 3309.93×103(-19.71%) | 3384.06×103(-17.91%) |

| βpbt/a | 3 | 3 | 3 | 3 |

图13 例Ⅱ中的DWC、DWC-VRHP(FPH)-FS和DWC-VRHP(FPH)-NFS的预分离蒸馏塔的温度分布

Fig.13 Temperature profiles of pre-fractionators for DWC, DWC-VRHP(FPH)-FS, and DWC-VRHP(FPH)-NFS in Example Ⅱ

| 1 | 杨剑, 沈本强, 蔺锡钰, 等. 分壁精馏塔分离芳烃的稳态及动态研究[J]. 化工学报, 2014, 65(10): 3993-4003. |

| Yang J, Shen B Q, Lin X Y, et al. Steady state and dynamic control of divided-wall column for separating aromatics[J]. CIESC Journal, 2014, 65(10): 3993-4003. | |

| 2 | Ömer Y, Kiss A A, Kenig E Y. Dividing wall columns in chemical process industry: a review on current activities[J]. Separation and Purification Technology, 2011, 80(3): 403-417. |

| 3 | Xu L, Li M, Ge X, et al. Numerical simulation of dividing wall column with vapor recompression located at side product stage[J]. Chemical Engineering Research and Design, 2017, 120(Complete): 138-149. |

| 4 | Gao X, Ma Z, Ma J, et al. Application of three-vapor recompression heat-pump concepts to a dimethylformamide-water distillation column for energy savings[J]. Energy Technology, 2014, 2(3): 250-256. |

| 5 | Feng S, Lyu X, Ye Q, et al. Performance enhancement of reactive dividing-wall column via vapor recompression heat pump[J]. Industrial & Engineering Chemistry Research, 2016, 55(43): 11305-11314. |

| 6 | Li R, Ye Q, Suo X, et al. Improving the performance of heat pump-assisted azeotropic dividing wall distillation[J]. Industrial & Engineering Chemistry Research, 2016, 55(22): 6454-6464. |

| 7 | Tarjani A J, Toth A J, Nagy T, et al. Thermodynamic and exergy analysis of energy-integrated distillation technologies focusing on dividing-wall columns with upper and lower partitions[J]. Industrial & Engineering Chemistry Research, 2018, 57(10): 3678-3684. |

| 8 | Yang S B, Chien I L. Rigorous design and optimization of methyl glycolate production process through reactive distillation combined with a middle dividing-wall column[J]. Industrial & Engineering Chemistry Research, 2019, 58(13): 5215-5227 |

| 9 | Townsend D W, Brown K, Lic R. Dividing wall column with a heat pump: US8323457[P]. 2012. |

| 10 | Luo H, Bildea C S, Kiss A A. Novel heat-pump-assisted extractive distillation for bioethanol purification[J]. Industrial & Engineering Chemistry Research, 2015, 54(7): 2208-2213. |

| 11 | Aurangzeb M, Jana A K. Vapor recompression with interreboiler in a ternary dividing wall column: improving energy efficiency and savings, and economic performance[J]. Applied Thermal Engineering, 2019, 147: 1009-1023. |

| 12 | Navarro-Amoros M A, Ruiz-Femenia R, Caballero J A. A new technique for recovering energy in thermally coupled distillation using vapor recompression cycles[J]. AIChE Journal, 2013, 59(10): 3767-3781. |

| 13 | 李沐荣, 许良华, 辛春伟, 等. 热泵精馏隔壁塔分离宽沸程物系的模拟[J]. 化工学报, 2017, 68(5): 1906-1912. |

| Li M R, Xu L H, Xin C W, et al. Simulation of vapor recompression assisted dividing wall column for wide boiling mixture separation[J]. CIESC Journal, 2017, 68(5): 1906-1912. | |

| 14 | Xia M, Yu B, Wang Q, et al. Design and control of extractive dividing-wall column for separating methylal-methanol mixture[J]. Industrial & Engineering Chemistry Research, 2016, 51(49): 16016-16033. |

| 15 | Yang A, Wei R, Sun S, et al. Energy-saving optimal design and effective control of heat integration-extractive dividing wall column for separating heterogeneous mixture methanol/toluene/water with multiazeotropes[J]. Industrial & Engineering Chemistry Research, 2018, 57(23): 8036-8056. |

| 16 | Wu Y C, Lee H Y, Huang H P, et al. Energy-saving dividing-wall column design and control for heterogeneous azeotropic distillation systems[J]. Industrial & Engineering Chemistry Research, 2014, 53(4): 1537-1552. |

| 17 | Li Y, Xia M, Li W, et al. Process assessment of heterogeneous azeotropic dividing-wall column for ethanol dehydration with cyclohexane as an entrainer: design and control[J]. Industrial & Engineering Chemistry Research, 2016, 55(32): 8784-8801. |

| 18 | Chen M, Yu N, Cong L, et al. Design and control of a heat pump-assisted azeotropic dividing wall column for EDA/Water separation[J]. Industrial & Engineering Chemistry Research, 2017, 56(34): 9770-9777. |

| 19 | Aurangzeb M, Jana A K. Pressure-swing dividing wall column with multiple binary azeotropes: improving energy efficiency and cost savings through vapor recompression[J]. Industrial & Engineering Chemistry Research, 2018, 57(11): 4019-4032. |

| 20 | 朱怀工, 张荣檏, 马和旭,等. 隔板式反应精馏技术的研究进展[J]. 化学工业与工程, 2013, 30(6): 37-42. |

| Zhu H G, Zhang R P, Ma H X, et al. Progress in technology of reactive dividing-wall column[J]. Chemical Industry & Engineering, 2013, 30(6): 37-42. | |

| 21 | Li L, Sun L, Yang D, et al. Reactive dividing wall column for hydrolysis of methyl acetate: design and control[J]. Chinese Journal of Chemical Engineering, 2016, 24(10): 1360-1368. |

| 22 | Sharma S, Patle D S, Gadhamsetti A P, et al. Intensification and performance assessment of the formic acid production process through a dividing wall reactive distillation column with vapor recompression[J]. Chemical Engineering and Processing: Process Intensification, 2018, 123: 204-213. |

| 23 | Wonjoon J, Heecheon L, Jong-in H, et al. Energy-efficient reactive dividing wall column for simultaneous esterification of n-amyl alcohol and n-hexanol[J]. Industrial & Engineering Chemistry Research, 2019, 58(19): 8206-8219. |

| 24 | Li J, Zhang F, Pan Q, et al. Performance enhancement of reactive dividing wall column based on self-heat recuperation technology[J]. Industrial & Engineering Chemistry Research, 2019, 58(27): 12179-12191. |

| 25 | Kiss A A. Dividing-wall column[M]// Advanced Distillation Technologies: Design, Control and Applications. John Wiley & Sons, Ltd., 2013. |

| 26 | Lee J, Leyffer S. Mixed Integer Nonlinear Programming[M]. Springer, 2012. |

| 27 | Franke M B. Design of dividing‐wall columns by mixed‐integer nonlinear programming optimization[J]. Chemie Ingenieur Technik, 2017, 89(5): 582-597. |

| 28 | Yu J, Wang S J, Huang K, et al. Improving the performance of extractive dividing-wall columns with intermediate heating[J]. Industrial & Engineering Chemistry Research, 2015, 54(10): 2709-2723. |

| 29 | Shi L, Huang K, Wang S J, et al. Application of vapor recompression to heterogeneous azeotropic dividing-wall distillation columns[J]. Industrial & Engineering Chemistry Research, 2015, 54(46): 11592-11609. |

| 30 | Seider W D, Seader J D, Lewin D R, et al. Product and Process Design Principles Synthesis, Analysis, and Evaluation[M]. NJ:Wiley, Hoboken, 2010. |

| 31 | Douglas J M. Conceptual Design of Chemical Processes[M]. New York: McGraw-Hill, 1988. |

| 32 | Turton R, Bailie R C, Whiting W B, et al. Analysis, Synthesis, and Design of Chemical Processes[M]. Boston: Pearson Education, 2009. |

| [1] | 闻文, 王慧艳, 周静红, 曹约强, 周兴贵. 石墨负极颗粒对锂离子电池容量衰减及SEI膜生长影响的模拟研究[J]. 化工学报, 2023, (): 1-12. |

| [2] | 喻薇 周康根 吴运东 杜虎. 萃取工艺回收没食子酸[J]. CIESC Journal, 2013, 64(5): 0-0. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号