化工学报 ›› 2023, Vol. 74 ›› Issue (2): 893-903.DOI: 10.11949/0438-1157.20221406

收稿日期:2022-11-30

修回日期:2022-12-20

出版日期:2023-02-05

发布日期:2023-03-21

通讯作者:

叶光华

作者简介:孟金琳(1997—),男,硕士研究生,Y30200055@mail.ecust.edu.cn

基金资助:

Jinlin MENG( ), Yu WANG, Qunfeng ZHANG, Guanghua YE(

), Yu WANG, Qunfeng ZHANG, Guanghua YE( ), Xinggui ZHOU

), Xinggui ZHOU

Received:2022-11-30

Revised:2022-12-20

Online:2023-02-05

Published:2023-03-21

Contact:

Guanghua YE

摘要:

介孔结构的表征和分析对于介孔材料的开发至关重要,其中低温氮气吸脱附法是最常用的介孔表征方法之一。然而,目前氮气吸脱附法采用的分析模型仍基于平行孔假设,无法描述脱附过程堵孔现象,以及获取孔道连通性等重要孔结构信息。本文建立了低温氮气吸脱附的孔道网络模型,用于分析介孔结构对氮气等温吸脱附行为的影响。通过对比氧化铝材料的氮气吸脱附实验数据和模拟结果,证实了建立的孔道网络模型能很好地描述介孔材料中低温氮气吸脱附行为。模拟结果表明平均孔径较小时,毛细凝聚分压低,液氮堵孔效应显著,氮气吸脱附曲线回滞环的范围和面积较大;孔径分布较宽时,小孔和大孔数量均较多,毛细凝聚和堵孔效应显著,回滞环面积较大;孔道连通性不会影响吸附过程,但会通过改变堵孔效应显著影响脱附过程,连通性越差,堵孔效应越强。证实了堵孔效应对氮气脱附过程影响显著,因而氮气吸脱附法需要考虑堵孔效应,建立的孔道网络模型也可为介孔结构分析提供合理的模型工具。

中图分类号:

孟金琳, 汪宇, 张群锋, 叶光华, 周兴贵. 介孔材料低温氮气吸脱附的孔道网络模型[J]. 化工学报, 2023, 74(2): 893-903.

Jinlin MENG, Yu WANG, Qunfeng ZHANG, Guanghua YE, Xinggui ZHOU. Pore network model of low-temperature nitrogen adsorption-desorption in mesoporous materials[J]. CIESC Journal, 2023, 74(2): 893-903.

| 参数或变量 | 数值 |

|---|---|

| 氮气吸脱附温度(T)/K | 77 |

| 氮气临界温度(Tc)/K | 126 |

| 液氮密度(ρ)/( kg/m3) | 807 |

| 吸脱附相对压力区间(P/P0) | 0.10~0.95 |

| 平均孔径(dp)/nm | 5~20 |

| 孔径分布标准偏差(σ) | 0.2~0.8 |

| 孔道连通性(Z) | 4~8 |

表1 本工作中所用到的模型参数及变量

Table 1 Model parameters and variables used in this work

| 参数或变量 | 数值 |

|---|---|

| 氮气吸脱附温度(T)/K | 77 |

| 氮气临界温度(Tc)/K | 126 |

| 液氮密度(ρ)/( kg/m3) | 807 |

| 吸脱附相对压力区间(P/P0) | 0.10~0.95 |

| 平均孔径(dp)/nm | 5~20 |

| 孔径分布标准偏差(σ) | 0.2~0.8 |

| 孔道连通性(Z) | 4~8 |

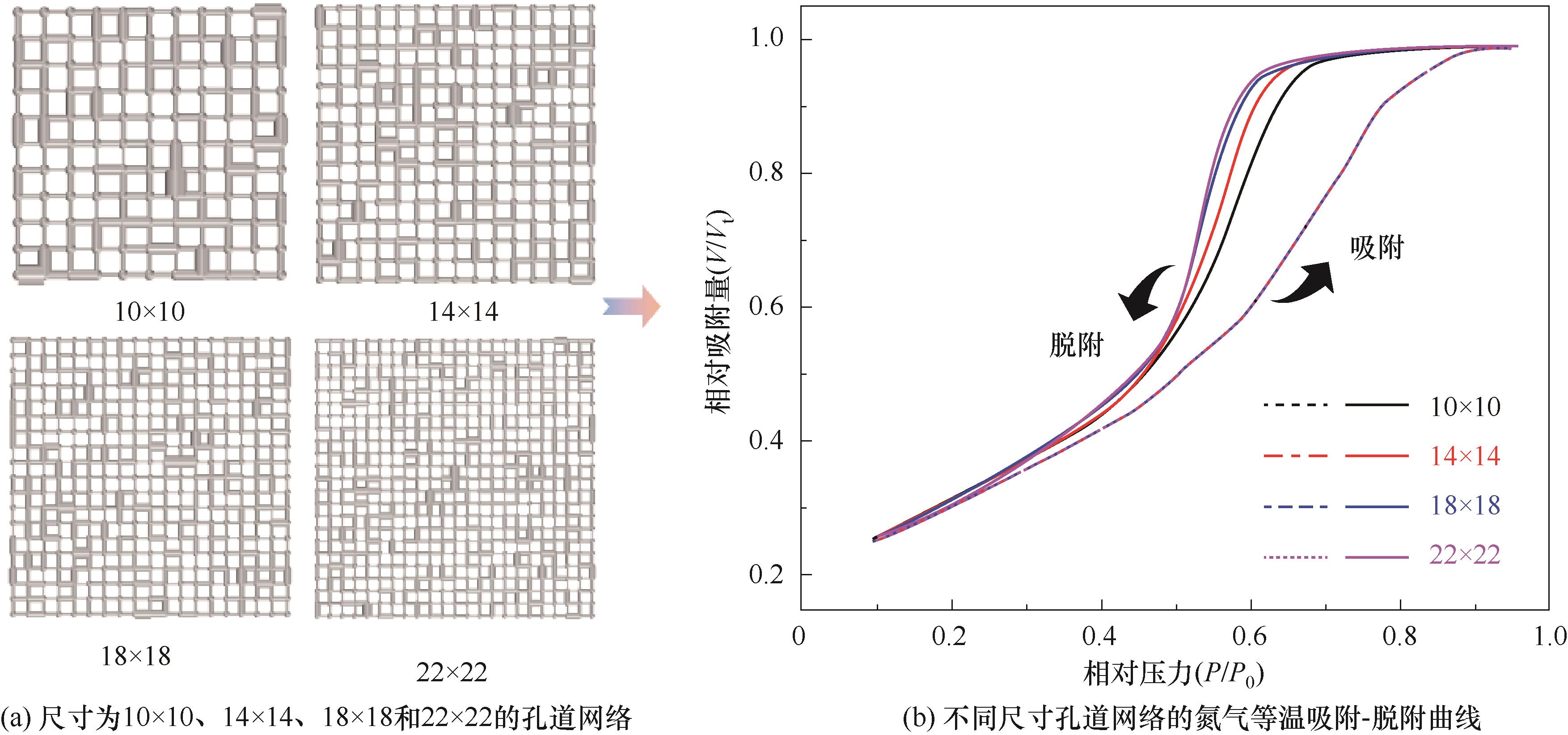

图5 孔道网络尺寸对氮气吸附-脱附曲线的影响(Z = 4,dp = 5 nm,σ = 0.5)

Fig.5 Effect of pore network size on the nitrogen adsorption-desorption isotherms(Z = 4, dp = 5 nm, σ = 0.5)

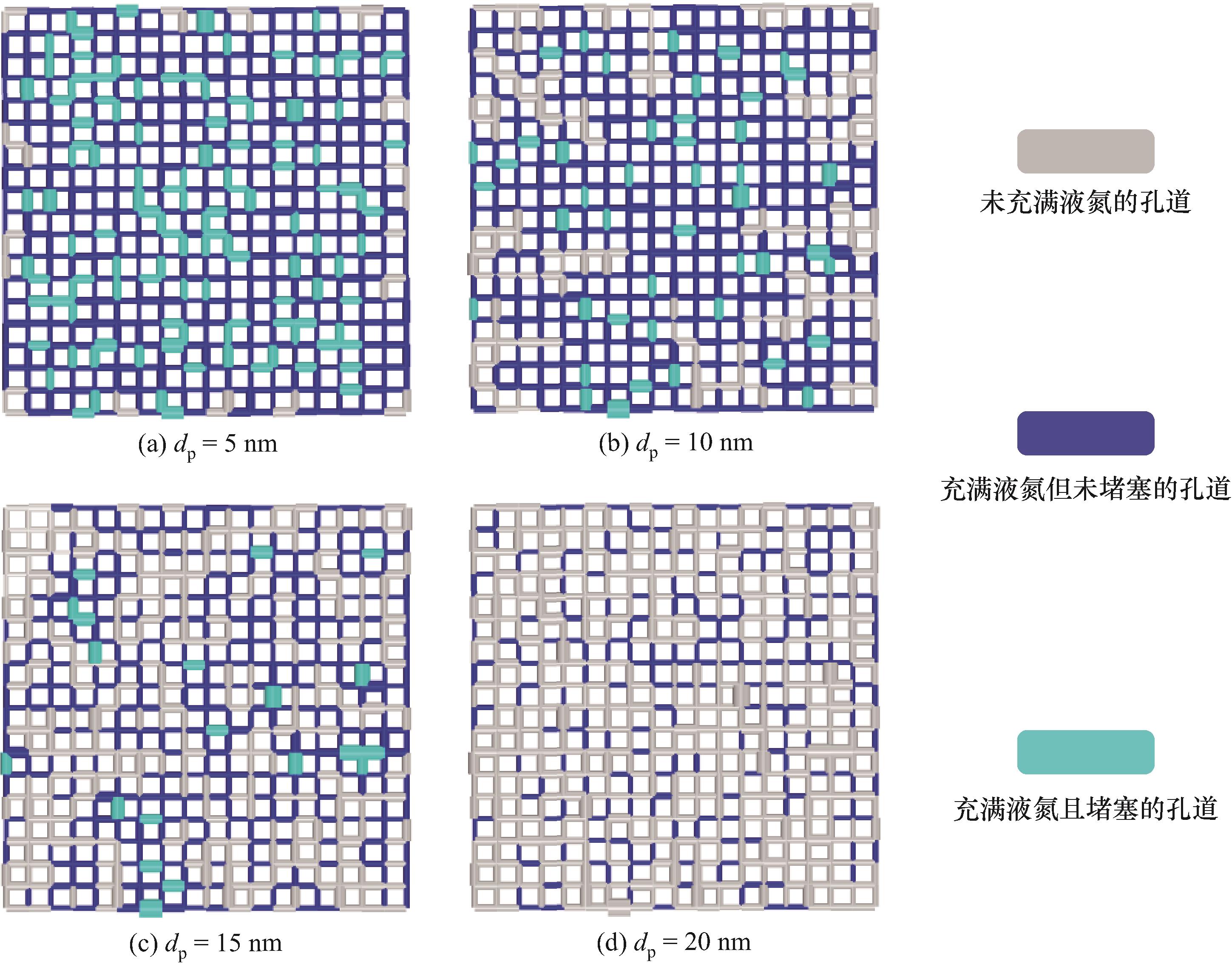

图7 不同平均孔径的孔道网络在脱附过程相对压力为0.60时的液氮分布

Fig.7 Liquid nitrogen distribution in pore networks with different average pore diameter at P/P0 = 0.60 during desorption

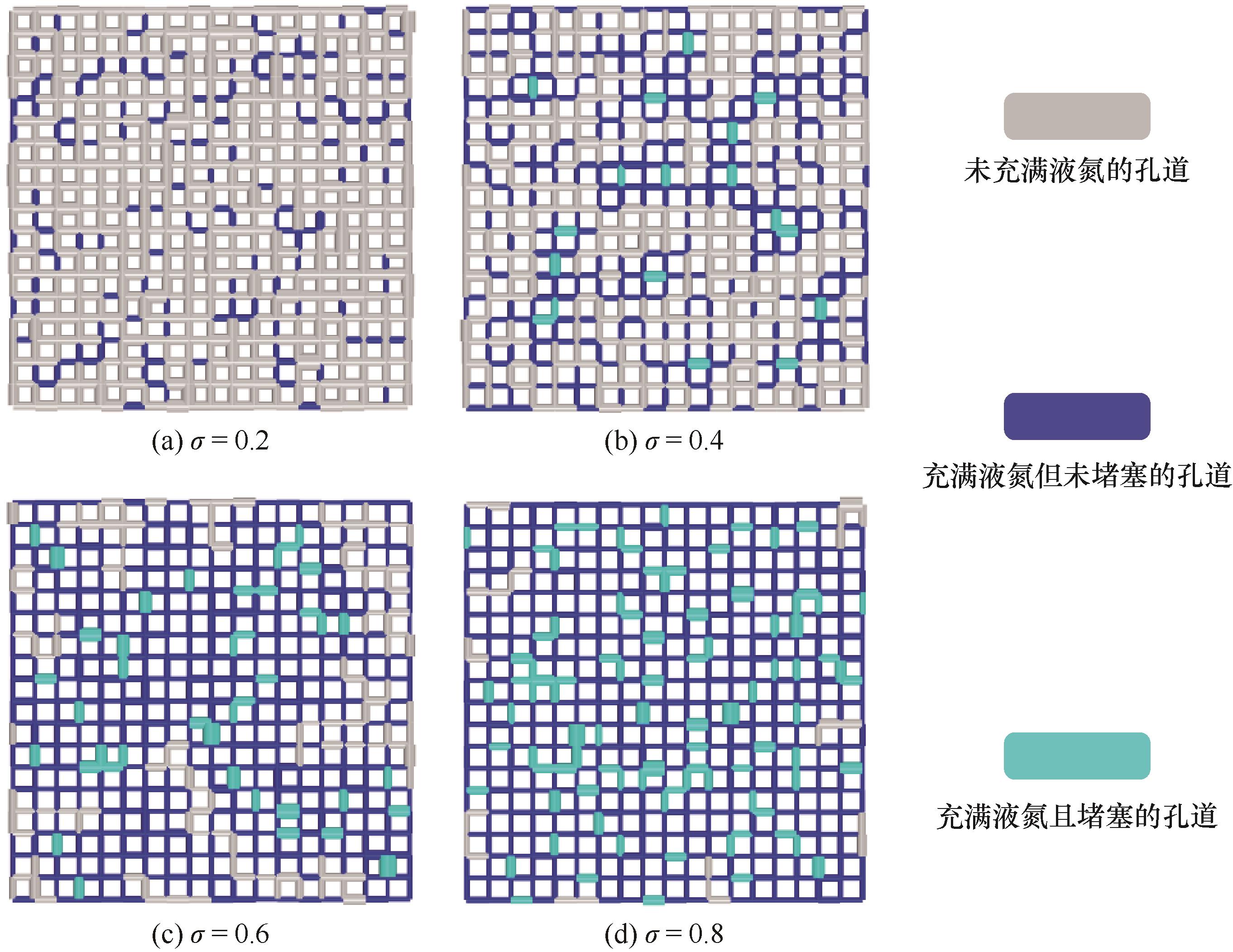

图9 不同孔径分布标准偏差的孔道网络在脱附过程相对压力为0.60时的液氮分布

Fig.9 Liquid nitrogen distribution in pore networks with different standard deviation at P/P0 = 0.60 during desorption

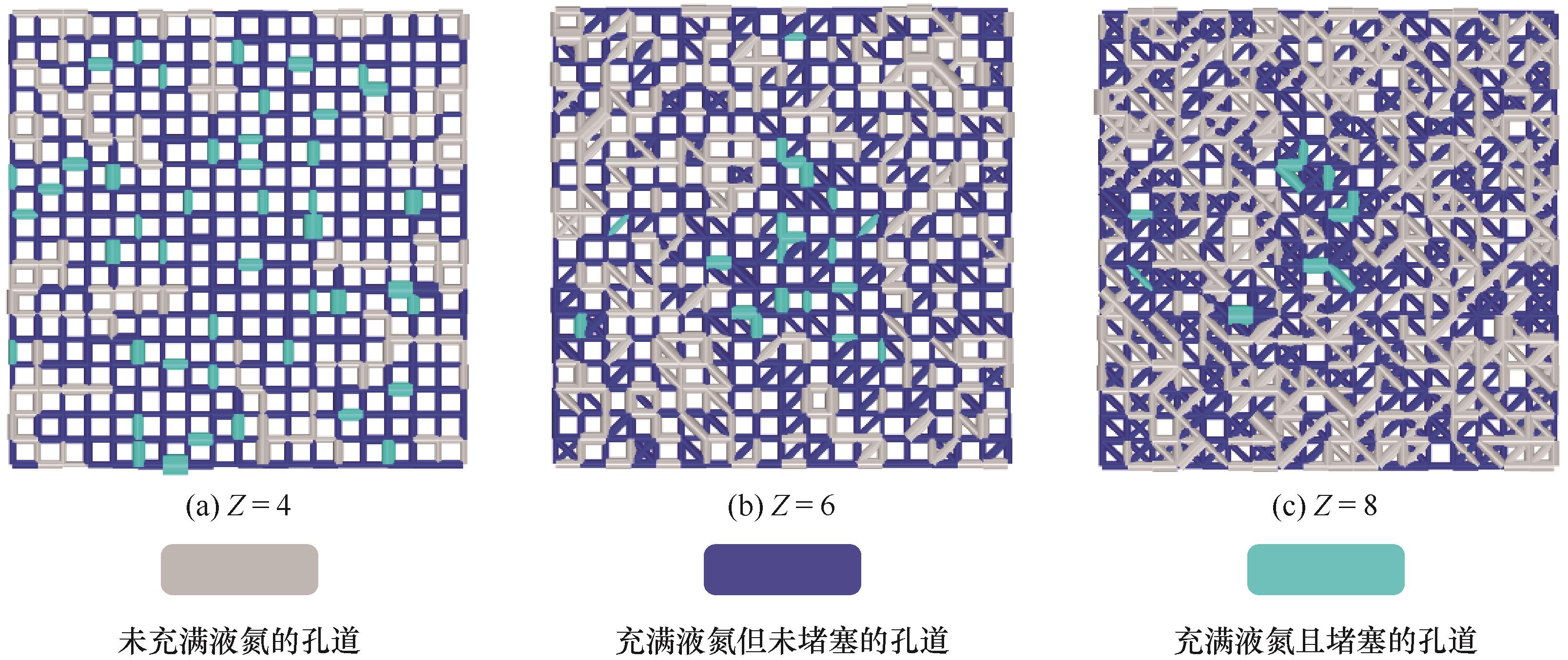

图11 不同孔道连通性的孔道网络在脱附过程相对压力为0.60时的液氮分布

Fig.11 Liquid nitrogen distribution in pore networks with different pore connectivity at P/P0 = 0.60 during desorption

| 1 | 李三妹, 陕绍云, 贾庆明, 等. 介孔分子筛改性研究进展[J]. 硅酸盐通报, 2013, 32(6): 1082-1086. |

| Li S M, Shan S Y, Jia Q M, et al. Process on modified mesoporous molecular sieve[J]. Bulletin of the Chinese Ceramic Society, 2013, 32(6): 1082-1086. | |

| 2 | 耿旺昌, 吉志强, 张秋禹. 介孔金属氧化物的研究进展[J]. 材料导报, 2010, 24(7): 16-19. |

| Geng W C, Ji Z Q, Zhang Q Y. Research progress of mesoporous metal oxides[J]. Materials Reports, 2010, 24(7): 16-19. | |

| 3 | 张宁, 李育珍, 夏云生, 等. 介孔碳材料的制备、功能化与应用研究进展[J]. 化学研究与应用, 2018, 30(7): 1048-1056. |

| Zhang N, Li Y Z, Xia Y S, et al. Preparation, functionalization and application of mesoporous carbon materials[J]. Chemical Research and Application, 2018, 30(7): 1048-1056. | |

| 4 | Linares N, Silvestre-Albero A M, Serrano E, et al. Mesoporous materials for clean energy technologies[J]. Chemical Society Reviews, 2014, 43(22): 7681-7717. |

| 5 | 梁振金, 洪梓博, 解明月, 等. 介孔炭材料应用于电化学催化的研究进展[J]. 新型炭材料, 2022, 37(1): 152-179. |

| Liang Z J, Hong Z B, Xie M Y, et al. Recent progress on mesoporous carbon materials used in electrochemical catalysis[J]. New Carbon Materials, 2022, 37(1): 152-179. | |

| 6 | 李刚, 华绍广, 吴将有. 硅基介孔材料及其改性对SO2的吸附效能研究[J]. 化学工程, 2020, 48(12): 25-30, 36. |

| Li G, Hua S G, Wu J Y. Adsorption efficiency of silica-based mesoporous materials and their modifications on sulfur dioxide[J]. Chemical Engineering (China), 2020, 48(12): 25-30, 36. | |

| 7 | 张文君, 梁喜龙, 吕江维, 等. 周期性介孔有机硅的合成及在生物医药领域的应用进展[J]. 精细化工, 2022, 39(2): 236-246. |

| Zhang W J, Liang X L, Lyu J W, et al. Synthesis and biomedicine application progress of periodic mesoporous organosilicas[J]. Fine Chemicals, 2022, 39(2): 236-246. | |

| 8 | Zhao C, Danish E, Cameron N R, et al. Emulsion-templated porous materials (PolyHIPEs) for selective ion and molecular recognition and transport: applications in electrochemical sensing[J]. Journal of Materials Chemistry, 2007, 17(23): 2446-2453. |

| 9 | Wargo E A, Kotaka T, Tabuchi Y, et al. Comparison of focused ion beam versus nano-scale X-ray computed tomography for resolving 3-D microstructures of porous fuel cell materials[J]. Journal of Power Sources, 2013, 241: 608-618. |

| 10 | Epting W K, Gelb J, Litster S. Resolving the three-dimensional microstructure of polymer electrolyte fuel cell electrodes using nanometer-scale X-ray computed tomography[J]. Advanced Functional Materials, 2012, 22(3): 555-560. |

| 11 | Litster S, Epting W K, Wargo E A, et al. Morphological analyses of polymer electrolyte fuel cell electrodes with nano-scale computed tomography imaging[J]. Fuel Cells, 2013, 13(5): 935-945. |

| 12 | Hoefner M L, Fogler H S. Pore evolution and channel formation during flow and reaction in porous media[J]. AIChE Journal, 1988, 34(1): 45-54. |

| 13 | Liu P S. Determining methods for aperture and aperture distribution of porous materials[J]. Titanium Industry Progress, 2006, 23(2): 29-34. |

| 14 | Roquerol F, Rouquerol J, Sing K. Adsorption by Powders and Porous Solids: Principles, Methodology, and Applications[M]. London: Academic Press, 1999. |

| 15 | Coasne B, Grosman A, Ortega C, et al. Adsorption in noninterconnected pores open at one or at both ends: a reconsideration of the origin of the hysteresis phenomenon[J]. Physical Review Letters, 2002, 88(25): 256102. |

| 16 | Cohan L H. Hysteresis and the capillary theory of adsorption of vapors1[J]. Journal of the American Chemical Society, 1944, 66(1): 98-105. |

| 17 | Horikawa T, Do D D, Nicholson D. Capillary condensation of adsorbates in porous materials[J]. Advances in Colloid and Interface Science, 2011, 169(1): 40-58. |

| 18 | 张伟庆, 黄滨, 余小岚, 等. 对BJH方法计算孔径分布过程的解读[J]. 大学化学, 2020, 35(2): 98-106. |

| Zhang W Q, Huang B, Yu X L, et al. Interpretation of BJH method for calculating aperture distribution process[J]. University Chemistry, 2020, 35(2): 98-106. | |

| 19 | 近藤精一. 吸附科学[M]. 北京: 化学工业出版社, 2006: 32-34, 40-45, 72-80. |

| Kondo S. Adsorption Science[M]. Beijing: Chemical Industry Press, 2006: 32-34, 40-45, 72-80. | |

| 20 | 贾双珠, 吴林媛, 陈炷霖, 等. 微介孔材料的孔结构分析表征[J]. 分析测试技术与仪器, 2019, 25(3): 141-147. |

| Jia S Z, Wu L Y, Chen Z L, et al. Analysis and characterization of pore structure of micro-mesoporous materials[J]. Analysis and Testing Technology and Instruments, 2019, 25(3): 141-147. | |

| 21 | 浦群, 杨杰, 吴启强, 等. 含中孔和微孔的多孔炭的孔结构表征[J]. 实验技术与管理, 2015, 32(4): 52-55, 61. |

| Pu Q, Yang J, Wu Q Q, et al. Characterization of pore structure of carbons containing micro-and meso-pores[J]. Experimental Technology and Management, 2015, 32(4): 52-55, 61. | |

| 22 | Wheeler A. Reaction rates and selectivity in catalyst pores[J]. Advances in Catalysis, 1951, 3: 249-327. |

| 23 | Carman P C. Fluid flow through granular beds[J]. Chemical Engineering Research and Design, 1997, 75: S32-S48. |

| 24 | Wakao N, Smith J M. Diffusion in catalyst pellets[J]. Chemical Engineering Science, 1962, 17: 825-834. |

| 25 | Wakao N, Smith J M. Diffusion and reaction in porous catalysts[J]. Industrial and Engineering Chemistry Fundamentals, 1964, 3: 123-127. |

| 26 | Beeckman J W, Froment G F. Catalyst deactivation by site coverage and pore blockage: finite rate of growth of the carbonaceous deposit[J]. Chemical Engineering Science, 1980, 35(4): 805-815. |

| 27 | Reyes S, Jensen K F. Estimation of effective transport coefficients in porous solids based on percolation concepts[J]. Chemical Engineering Science, 1985, 40(9): 1723-1734. |

| 28 | Hollewand M P, Gladden L F. Modelling of diffusion and reaction in porous catalysts using a random three-dimensional network model[J]. Chemical Engineering Science, 1992, 47(7): 1761-1770. |

| 29 | Ding W, Li H, Pfeifer P, et al. Crystallite-pore network model of transport and reaction of multicomponent gas mixtures in polycrystalline microporous media[J]. Chemical Engineering Journal, 2014, 254: 545-558. |

| 30 | Kharaghani A, Metzger T, Tsotsas E. An irregular pore network model for convective drying and resulting damage of particle aggregates[J]. Chemical Engineering Science, 2012, 75: 267-278. |

| 31 | Blunt M J, Jackson M D, Piri M, et al. Detailed physics, predictive capabilities and macroscopic consequences for pore-network models of multiphase flow[J]. Advances in Water Resources, 2002, 25(8/12): 1069-1089. |

| 32 | El Hannach M, Prat M, Pauchet J. Pore network model of the cathode catalyst layer of proton exchange membrane fuel cells: analysis of water management and electrical performance[J]. International Journal of Hydrogen Energy, 2012, 37(24): 18996-19006. |

| 33 | Wu R, Liao Q, Zhu X, et al. Pore network modeling of cathode catalyst layer of proton exchange membrane fuel cell[J]. International Journal of Hydrogen Energy, 2012, 37(15): 11255-11267. |

| 34 | Ye G, Sun Y, Zhou X, et al. Method for generating pore networks in porous particles of arbitrary shape, and its application to catalytic hydrogenation of benzene[J]. Chemical Engineering Journal, 2017, 329: 56-65. |

| 35 | Zhou Z M, Cheng Z M, Li Z, et al. Determination of effectiveness factor of a partial internal wetting catalyst from adsorption measurement[J]. Chemical Engineering Science, 2004, 59(20): 4305-4311. |

| 36 | 汪蓉, 盛勇, 杨传路, 等. 液态低沸点气体的表面张力[J]. 化学物理学报, 2000, 13(3): 380-384. |

| Wang R, Sheng Y, Yang C L, et al. The surface tension of liquid gases for low-boiling point[J]. Chinese Journal of Chemical Physics, 2000, 13(3): 380-384. | |

| 37 | Yaws C L. Chemical Properties Handbook[M]. McGraw-Hill Education, 1999. |

| 38 | Androutsopoulos G P, Salmas C E. A new model for capillary condensation-evaporation hysteresis based on a random corrugated pore structure concept: prediction of intrinsic pore size distributions (part 1): Model formulation[J]. Industrial & Engineering Chemistry Research, 2000, 39(10): 3747-3763. |

| 39 | Pierce C. The Frenkel-Halsey-Hill adsorption isotherm and capillary condensation[J]. The Journal of Physical Chemistry, 1960, 64(9): 1184-1187. |

| 40 | Al-Futaisi A, Patzek T W. Extension of Hoshen-Kopelman algorithm to non-lattice environments[J]. Physica A: Statistical Mechanics and Its Applications, 2003, 321(3/4): 665- 678. |

| 41 | Murray K L, Seaton N A, Day M A. An adsorption-based method for the characterization of pore networks containing both mesopores and macropores[J]. Langmuir, 1999, 15(20): 6728-6737. |

| [1] | 乔国岳, 刘居陶, 孙剑飞, 徐琴琴, 银建中. 超临界CO2脱附作用调控负载纳米颗粒结晶动力学研究[J]. 化工学报, 2021, 72(11): 5849-5857. |

| [2] | 李伟斌, 宋超, 易贤, 马洪林, 杜雁霞. 动态结冰孔隙结构三维建模方法[J]. 化工学报, 2020, 71(3): 1009-1017. |

| [3] | 江罗, 陈标华, 张吉瑞, 傅吉全. 活性炭孔径分布对乙炔氢氯化低固汞催化剂性能的影响[J]. 化工学报, 2018, 69(1): 423-428. |

| [4] | 李静, 冯妍卉, 张欣欣, 王戈. 介孔复合材料内界面热阻及热导率[J]. 化工学报, 2016, 67(S1): 166-173. |

| [5] | 巩雁军, 刘汝庚, 赵晓萌, 张恒. 小角X射线散射在分子筛研究中的应用[J]. 化工学报, 2016, 67(8): 3146-3159. |

| [6] | 许承志, 郑美琴, 熊莹, 黄清明, 陈晓晖. 基于阻滞扩散模型估算柴油脱硫吸附剂的适宜孔径分布[J]. 化工学报, 2015, 66(9): 3611-3617. |

| [7] | 丁彬彬, 李朝林. 基于逾渗理论的多孔过滤介质孔径分布估计方法[J]. 化工学报, 2015, 66(5): 1690-1696. |

| [8] | 周建海, 赵会玲, 胡军, 刘洪来, 胡英. 氨基修饰微孔/介孔复合材料AM-5A-MCM-41对CO2吸附分离的分子模拟[J]. 化工学报, 2014, 65(5): 1680-1687. |

| [9] | 靖宇, 韦力, 王运东, 于燕梅. 混合胺改性SBA-15的二氧化碳吸附特性[J]. 化工学报, 2014, 65(1): 328-336. |

| [10] | 李春喜,熊佳丽,孟洪,陆颖舟. 从ILs到PILs:聚合离子液体介孔材料的制备性质及结构调控方法[J]. 化工进展, 2014, 33(08): 1941-1950. |

| [11] | 任瑞鹏 1,陈虎 1,陈健 2,吕永康 1. 应用催化氧化催化剂脱除烟气中NO的研究进展[J]. 化工进展, 2014, 33(06): 1453-1458. |

| [12] | 李祥珍,王晓钟,刘 瑜,陈 伟,黄 璐. 介孔材料Al-SBA-15的合成研究进展[J]. 化工进展, 2013, 32(07): 1555-1563. |

| [13] | 曹渊,张莉,王晓,徐彦芹. pH及温度双重敏感性MCM-41/P(AA-co-NIPAAm)的制备和释药性能 [J]. 化工学报, 2012, 63(3): 970-977. |

| [14] | 徐计元,邹勇,程林. 烧结镍毛细芯的孔参数控制及其对抽吸性能的影响[J]. 化工学报, 2012, 63(2): 463-469. |

| [15] | 亢 宇,张明森,王洪涛,谢伦嘉,姜健准,郭 顺,邱 波,刘长城. 不同形貌介孔材料催化剂的制备及在乙烯聚合中的应用[J]. 化工进展, 2012, 31(05): 1032-1038. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号