化工学报 ›› 2024, Vol. 75 ›› Issue (5): 2072-2080.DOI: 10.11949/0438-1157.20231387

收稿日期:2023-12-28

修回日期:2024-03-06

出版日期:2024-05-25

发布日期:2024-06-25

通讯作者:

喻健良

作者简介:张帅(1998—),男,硕士研究生,zsdlut2017@163.com

基金资助:

Shuai ZHANG( ), Jianliang YU(

), Jianliang YU( ), Jianfei DING, Xingqing YAN

), Jianfei DING, Xingqing YAN

Received:2023-12-28

Revised:2024-03-06

Online:2024-05-25

Published:2024-06-25

Contact:

Jianliang YU

摘要:

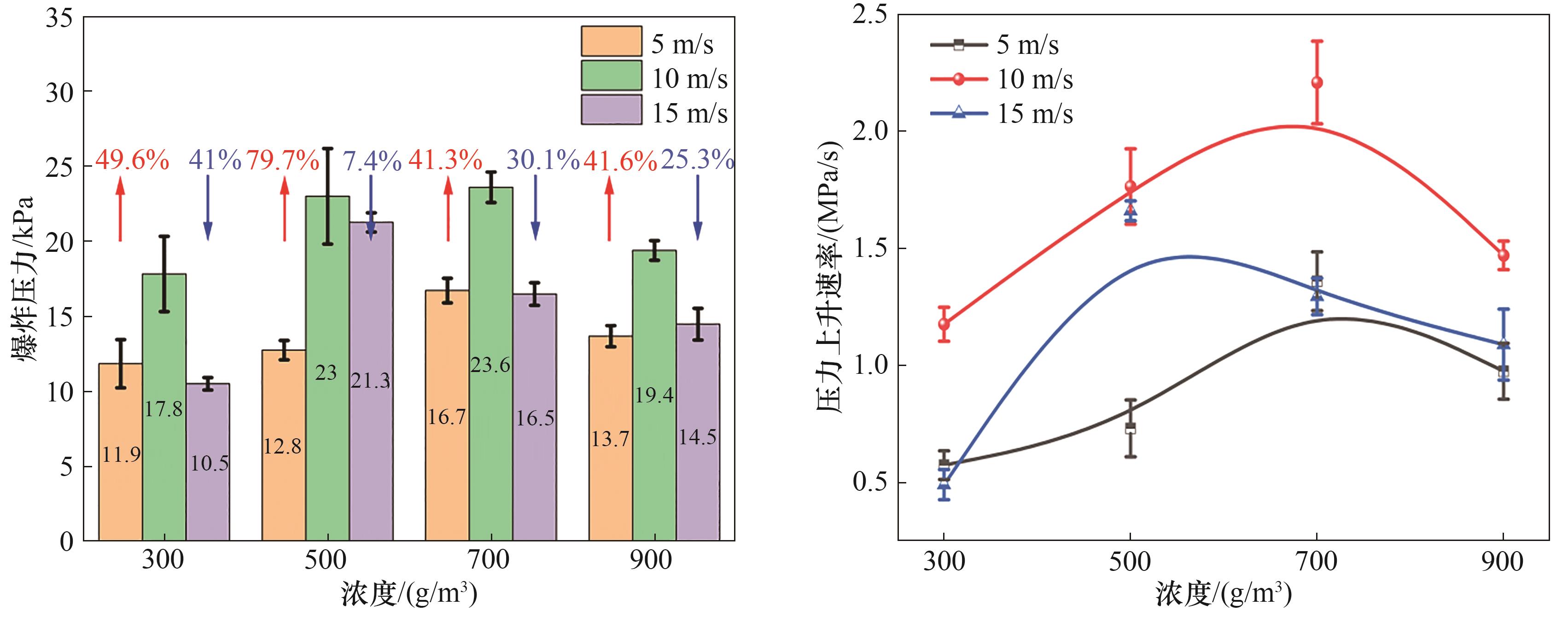

利用自主搭建的2 m长气流输运管道实验装置开展了不同气流速度下玉米淀粉爆炸实验,通过高速摄影和压力传感器获得火焰信息和压力参数。基于实验结果分析了气流输运工况气流速度对玉米淀粉爆炸火焰传播行为和爆炸特性的影响规律。结果表明:随着气流速度的增加,粉尘爆炸火焰亮度、火焰传播速度及最大爆炸压力呈先增大后减小的趋势,存在火焰呈螺旋状向管道末端传播的现象。气流速度从5 m/s升至10 m/s,火焰最大传播速度从74.07 m/s增加到89.51 m/s,最大爆炸压力由17.08 kPa增至23.42 kPa。气流速度提高到15 m/s时,火焰最大传播速度和爆炸压力均有所下降,质量浓度为300 g/m3时受影响最大,爆炸压力降低41%,500 g/m3时受影响最小,爆炸压力下降7.4%。

中图分类号:

张帅, 喻健良, 丁建飞, 闫兴清. 气流输运工况玉米淀粉爆炸火焰传播与压力特性实验研究[J]. 化工学报, 2024, 75(5): 2072-2080.

Shuai ZHANG, Jianliang YU, Jianfei DING, Xingqing YAN. Experimental study on flame propagation and pressure characteristics of corn starch explosion under airflow transport conditions[J]. CIESC Journal, 2024, 75(5): 2072-2080.

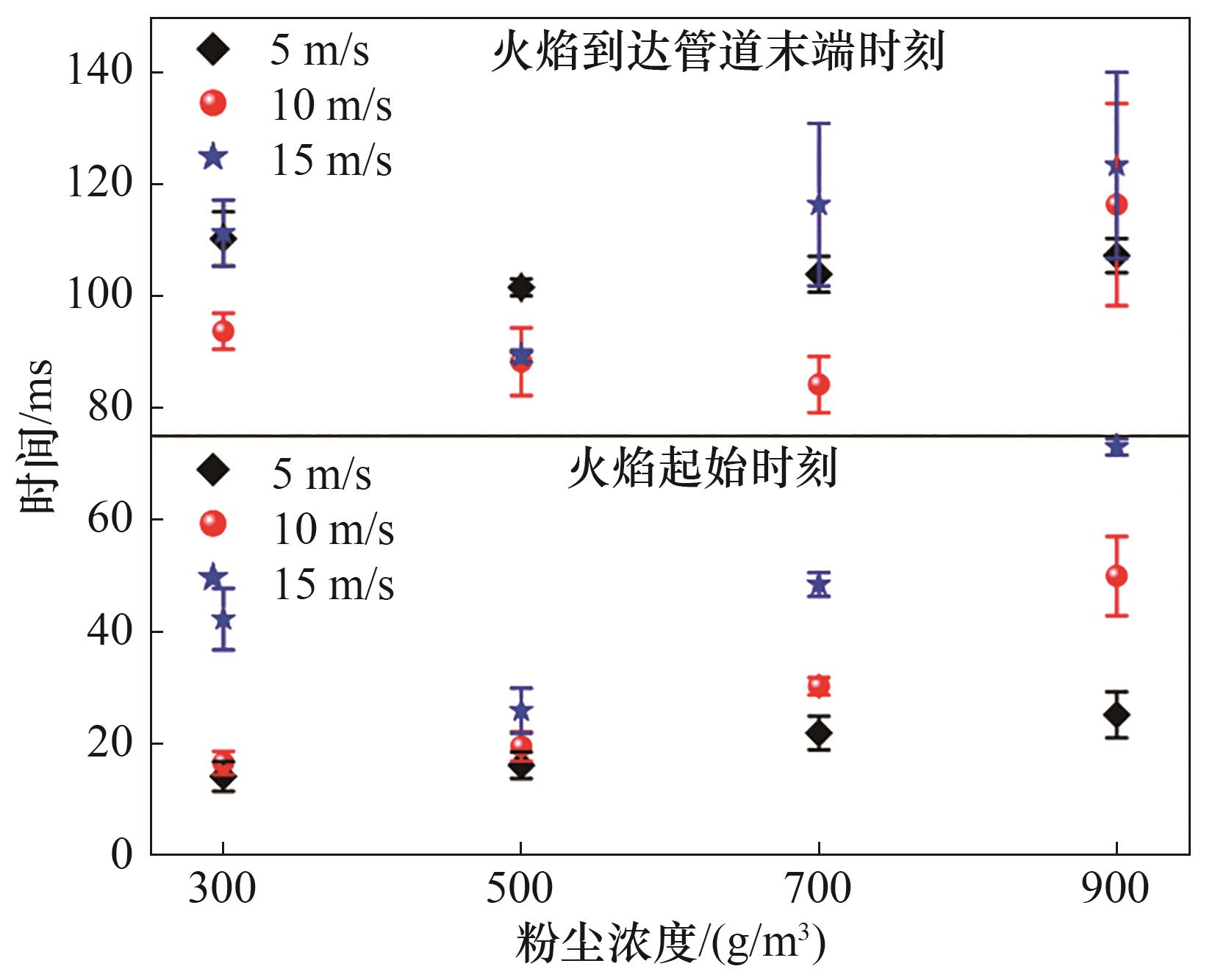

图7 不同气流速度条件下不同浓度火焰起始时刻和火焰到达管道末端时刻

Fig.7 The moment of flame onset and the moment of flame arrival at the end of the pipe with various concentrations under different airflow velocities

图12 不同气流速度下不同浓度玉米淀粉粉尘的最大爆炸压力和最大压力上升速率

Fig.12 Maximum pressures and maximum rates of pressure rise of corn starch dust with various concentrations under different airflow velocities

| 1 | Kuang S B, Zhou M M, Yu A B. CFD-DEM modelling and simulation of pneumatic conveying: a review[J]. Powder Technology, 2020, 365: 186-207. |

| 2 | Zhang F W, Olaleye A K, O’Mahony J A, et al. Dilute phase pneumatic conveying of whey protein isolate powders: particle breakage and its effects on bulk properties[J]. Advanced Powder Technology, 2020, 31(8): 3342-3350. |

| 3 | van Wingerden K. Prediction of pressure and flame effects in the direct surroundings of installations protected by dust explosion venting[J]. Journal of Loss Prevention in the Process Industries, 1993, 6(4): 241-249. |

| 4 | Proust C, Veyssiere B. Fundamental properties of flames propagating in starch dust-air mixtures[J]. Combustion Science and Technology, 1988, 62(4/5/6): 149-172. |

| 5 | 赵懿明, 刘毅飞, 杨振欣, 等. 点火能量对煤尘爆炸火焰传播规律的影响[J]. 中北大学学报(自然科学版), 2022, 43(1): 70-75. |

| Zhao Y M, Liu Y F, Yang Z X, et al. Influence of ignition energy on flame propagation law of coal dust explosion[J]. Journal of North University of China (Natural Science Edition), 2022, 43(1): 70-75. | |

| 6 | Bu Y J, Ma Z P, Li C, et al. Effect of admixed solid inertants on dispersibility of combustible dust clouds in a modified hartmann tube[J]. Process Safety and Environmental Protection, 2020, 135: 1-11. |

| 7 | 陈晓坤, 蔡灿凡, 肖旸, 等. 外部条件对玉米淀粉粉尘爆炸特性的影响[J]. 安全与环境学报, 2017, 17(4): 1327-1330. |

| Chen X K, Cai C F, Xiao Y, et al. Effect of the external conditions on the explosion characteristic features of the corn starch dust[J]. Journal of Safety and Environment, 2017, 17(4): 1327-1330. | |

| 8 | 裴蓓, 康亚祥, 余明高, 等. 点火延迟时间对CO2-超细水雾的抑爆特性影响[J]. 化工学报, 2022, 73(12): 5672-5684. |

| Pei B, Kang Y X, Yu M G, et al. Effect of ignition delay time on explosion suppression characteristics of CO2-ultra-fine water mist[J]. CIESC Journal, 2022, 73(12): 5672-5684. | |

| 9 | 浦以康, 贾复, 胡俊. 等容燃烧条件下粉尘等效燃烧速度的确定[J]. 燃烧科学与技术, 2002, 8(1): 1-5. |

| Pu Y K, Jia F, Hu J. Determination of the maximum effective burning velocity of dust-air mixtures in constant volume combustion[J]. Journal of Combustion Science and Technology, 2002, 8(1): 1-5. | |

| 10 | Eckhoff R K. Dust Explosions in the Process Industries[M]. Oxford, Boston: Butterworth-Heinemann, 1991. |

| 11 | Amyotte P R, Chippett S, Pegg M J. Effects of turbulence on dust explosions[J]. Progress in Energy and Combustion Science, 1988, 14(4): 293-310. |

| 12 | 沈世磊, 张奇, 马秋菊, 等. 湍流对铝粉爆炸特性的影响[J]. 兵工学报, 2016, 37(3): 455-461. |

| Shen S L, Zhang Q, Ma Q J, et al. Effect of turbulence on explosion characteristics of aluminum dust/air[J]. Acta Armamentarii, 2016, 37(3): 455-461. | |

| 13 | Cheng F M, Chang Z C, Luo Z M, et al. Numerical study on premixing characteristics and explosion process of starch in a vertical pipe under turbulent flow[J]. Journal of Loss Prevention in the Process Industries, 2020, 68: 104303. |

| 14 | Cuervo N, Murillo C, Dufaud O, et al. Combining CFD simulations and PIV measurements to optimize the conditions for dust explosion tests[J]. Chemical Engineering Transactions, 2014, 36: 259-264. |

| 15 | 李新光, 王健, 钟圣俊, 等. 初始湍流对粉尘爆炸影响的实验研究[J]. 中国粉体技术, 2010, 16(5): 37-41. |

| Li X G, Wang J, Zhong S J, et al. Experimental investigation on influence of pre-ignition turbulence on dust explosion[J]. China Powder Science and Technology, 2010, 16(5): 37-41. | |

| 16 | 任纯力, 李新光, 王福利, 等. 湍流对粉尘云电火花点火过程的影响[J]. 中国安全生产科学技术, 2009, 5(6): 26-29. |

| Ren C L, Li X G, Wang F L, et al. Effect of turbulence on spark ignition process of dust cloud[J]. Journal of Safety Science and Technology, 2009, 5(6): 26-29. | |

| 17 | Scheid M, Geißler A, Krause U. Experiments on the influence of pre-ignition turbulence on vented gas and dust explosions[J]. Journal of Loss Prevention in the Process Industries, 2006, 19(2/3): 194-199. |

| 18 | 张博, 张奇, 谭汝媚. 喷粉压力及点火延迟时间对粉尘爆炸参数的影响[J]. 高压物理学报, 2014, 28(2): 183-190. |

| Zhang B, Zhang Q, Tan R M. Influence of dispersion pressure and ignition delay time on the dust explosion parameters[J]. Chinese Journal of High Pressure Physics, 2014, 28(2): 183-190. | |

| 19 | Gan B, Yang M R, Zhang S L, et al. Flame propagation and pressure characteristics of polymethyl methacrylate dust explosions in a horizontal pipe[J]. Journal of Loss Prevention in the Process Industries, 2019, 62: 103982. |

| 20 | Nifuku M, Enomoto H. Evaluation of the explosibility of malt grain dust based on static electrification during pneumatic transportation[J]. Journal of Loss Prevention in the Process Industries, 2001, 14(6): 509-514. |

| 21 | Nifuku M, Katoh H. A study on the static electrification of powders during pneumatic transportation and the ignition of dust cloud[J]. Powder Technology, 2003, 135/136: 234-242. |

| 22 | Pang L, Cao J J, Xiao Q P, et al. Explosion propagation in a dust removal pipeline under dust collector explosion[J]. Journal of Loss Prevention in the Process Industries, 2022, 74: 104662. |

| 23 | Kosinski P, Hoffmann A C. An investigation of the consequences of primary dust explosions in interconnected vessels[J]. Journal of Hazardous Materials, 2006, 137(2): 752-761. |

| 24 | 高伟, 阿部俊太郎, 荣建忠, 等. 气流特征对水平长管内石松子粉尘爆炸火焰结构的影响[J]. 爆炸与冲击, 2015, 35(3): 372-379. |

| Gao W, Shuntaro A, Rong J Z, et al. Effect of airflow characteristics on flame structure for following lycopodium dust-air mixtures in a long horizontal tube[J]. Explosion and Shock Waves, 2015, 35(3): 372-379. | |

| 25 | Zhang S L, Bi M S, Yang M R, et al. Flame propagation characteristics and explosion behaviors of aluminum dust explosions in a horizontal pipeline[J]. Powder Technology, 2020, 359: 172-180. |

| 26 | Li C, Ma Z P, Bu Y J, et al. Experimental study on the minimum ignition energy of cornstarch particle-air flows in a horizontal pipeline[J]. Journal of Loss Prevention in the Process Industries, 2022, 79: 104842. |

| 27 | 交通运输部. 港口连续装卸设备安全规程 第1部分:散粮筒仓系统: [S]. 北京: 中国标准出版社, 2010. |

| Ministry of Transport. Safety rules on ports continuous handling facilities(part 1): Grain silos system: [S]. Beijing: Standards Press of China, 2010. | |

| 28 | Byram G M, Martin R E. The modeling of fire whirlwinds[J]. Forest Science, 1970, 16(4): 386-399. |

| 29 | 卜亚杰, 苑春苗, 郝剑涛, 等. 电火花作用下粉尘云着火的延迟时间[J]. 东北大学学报(自然科学版), 2018, 39(11): 1658-1661, 1672. |

| Bu Y J, Yuan C M, Hao J T, et al. Electric spark ignition delay time of dust clouds[J]. Journal of Northeastern University (Natural Science), 2018, 39(11): 1658-1661, 1672. | |

| 30 | Eckhoff R K. Influence of initial and explosion-induced turbulence on dust explosions in closed and vented vessels research at CMI[J]. Powder Technology, 1992, 71(2): 181-187. |

| 31 | Chen Z H, Fan B C. Flame propagation through aluminum particle cloud in a combustion tube[J]. Journal of Loss Prevention in the Process Industries, 2005, 18(1): 13-19. |

| 32 | Aslanov S K, Shevchuk V G, Kostyshin Y N, et al. Oscillatory combustion of air suspensions[J]. Combustion, Explosion and Shock Waves, 1993, 29(2): 163-169. |

| 33 | Huang C Y, Chen X F, Yuan B H, et al. Insight into suppression performance and mechanisms of ultrafine powders on wood dust deflagration under equivalent concentration[J]. Journal of Hazardous Materials, 2020, 394: 122584. |

| 34 | Huang C Y, Wang S S, Chu Y Y, et al. Comprehensive investigations on the explosion suppression of biomass fuels: starch as a representative[J]. Fuel, 2022, 315: 123276. |

| [1] | 杨克, 贾岳, 纪虹, 邢志祥, 蒋军成. 垃圾焚烧飞灰对瓦斯爆炸压力及火焰传播的抑制作用及机理研究[J]. 化工学报, 2023, 74(8): 3597-3607. |

| [2] | 江丙友, 丁大伟, 苏明清, 鲁昆仑. 聚磷酸铵对聚乙烯粉尘爆炸特性及热解动力学影响研究[J]. 化工学报, 2023, 74(10): 4352-4366. |

| [3] | 李国庆, 杜扬, 白洁, 武军, 李孟源, 吴晓澍, 朱亮. 平板障碍物通道形状对油气爆炸传播特性影响[J]. 化工学报, 2020, 71(4): 1912-1921. |

| [4] | 靳红旺, 郑立刚, 朱小超, 于水军, 潘荣锟, 杜德朋, 窦增果. 竖直管道中氧化铝抑制铝粉爆炸特性研究[J]. 化工学报, 2020, 71(4): 1929-1939. |

| [5] | 喻健良, 侯玉洁, 闫兴清, 纪文涛, 于小哲, 王祎博. 密闭空间内聚乙烯粉尘爆炸火焰传播特性的实验研究[J]. 化工学报, 2019, 70(3): 1227-1235. |

| [6] | 张增亮, 王昕, 王昊平. 带孔障碍物对管道中可燃气体爆炸特性的影响[J]. 化工学报, 2019, 70(11): 4497-4503. |

| [7] | 侯俊才, 李超, 贾伟东, 魏旭星, 李一鸣, 孟浩, 张庆昂, 吴筱敏. 负直流电场对不同初始压力预混甲烷/空气火焰的影响[J]. 化工学报, 2018, 69(4): 1602-1610. |

| [8] | 孟祥文, 李震, 唐元政, 何燕, 吴筱敏. 不同CO2浓度下负直流电场对C3H8/O2/Ar/CO2预混火焰的影响规律[J]. 化工学报, 2018, 69(12): 5229-5236. |

| [9] | 张尊华, 曾璇, 梁俊杰, 王昭军, 李格升. 天然气成分波动对其预混火焰传播特性的影响[J]. 化工学报, 2018, 69(12): 5209-5219. |

| [10] | 房建峰, 赵海军, 周辉, 葛述卿, 吴筱敏. 电场对甲烷-空气混合气燃烧特性的影响[J]. 化工学报, 2018, 69(10): 4409-4417. |

| [11] | 孙少辰, 毕明树, 刘刚, 邓进军. 爆轰火焰在管道阻火器内的传播与淬熄特性[J]. 化工学报, 2016, 67(5): 2176-2184. |

| [12] | 苏航, 蒋利桥, 曹海亮, 刘秦飞, 李言钦, 赵黛青. 微型定容燃烧腔内C2~C4烷烃/空气火焰传播[J]. 化工学报, 2016, 67(11): 4574-4579. |

| [13] | 崔雨辰, 段浩, 吴筱敏, 相楠. 交流和直流电场对天然气贫燃火焰的影响[J]. 化工学报, 2015, 66(6): 2235-2241. |

| [14] | 张庆武, 蒋军成, 喻源, 崔益虎. 初始压力对容器通过导管泄爆过程的影响[J]. 化工学报, 2014, 65(4): 1544-1550. |

| [15] | 高利苹1,于源2,刘家祥1. 涡流空气分级机转笼转速对其分级精度的影响[J]. 化工学报, 2012, 63(4): 1056-1062. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号