化工学报 ›› 2025, Vol. 76 ›› Issue (10): 5522-5532.DOI: 10.11949/0438-1157.20250685

• 焦点问题·热点论坛 • 上一篇

王元哲( ), 刘振宇(

), 刘振宇( ), 闫玉新, 王丝语, 石磊, 刘清雅(

), 闫玉新, 王丝语, 石磊, 刘清雅( )

)

收稿日期:2025-06-25

修回日期:2025-07-27

出版日期:2025-10-25

发布日期:2025-11-25

通讯作者:

刘振宇,刘清雅

作者简介:王元哲(1997―),男,博士研究生,yzwang@mail.buct.edu.cn

基金资助:

Yuanzhe WANG( ), Zhenyu LIU(

), Zhenyu LIU( ), Yuxin YAN, Siyu WANG, Lei SHI, Qingya LIU(

), Yuxin YAN, Siyu WANG, Lei SHI, Qingya LIU( )

)

Received:2025-06-25

Revised:2025-07-27

Online:2025-10-25

Published:2025-11-25

Contact:

Zhenyu LIU, Qingya LIU

摘要:

煤直接液化反应器大型化是提高转化效率和经济性的必然选择,前人针对大型液化反应器涉及的工程化难题进行了诸多研究,支撑了神华百万吨级工业装置的稳定运行以及二代技术的发展,但仍面临提高油收率的挑战。深入认识煤直接液化技术换代伴随的煤反应环境的变化及其对自由基反应的影响是提高油收率的基础。本文着重分析了神华煤直接液化两代技术中煤浆的温度分布和化学反应特征,尤其是分配盘下部的自由基反应,研判了二代技术环境下煤的反应时间及液化效率,论证了煤浆温度、溶剂循环比以及梯级升温对上湾煤和哈密富油煤自由基碎片生成和加氢速率匹配的影响,探讨了高温溶剂外循环所导致的热高分温度提升促进缩聚反应的原因,提出降低外循环溶剂的量或温度进而提高油收率、降低缩聚反应、提高装置稳定性的思路。

中图分类号:

王元哲, 刘振宇, 闫玉新, 王丝语, 石磊, 刘清雅. 煤直接液化技术换代的化学反应问题[J]. 化工学报, 2025, 76(10): 5522-5532.

Yuanzhe WANG, Zhenyu LIU, Yuxin YAN, Siyu WANG, Lei SHI, Qingya LIU. Chemical reaction issues in the technological upgrading of direct coal liquefaction[J]. CIESC Journal, 2025, 76(10): 5522-5532.

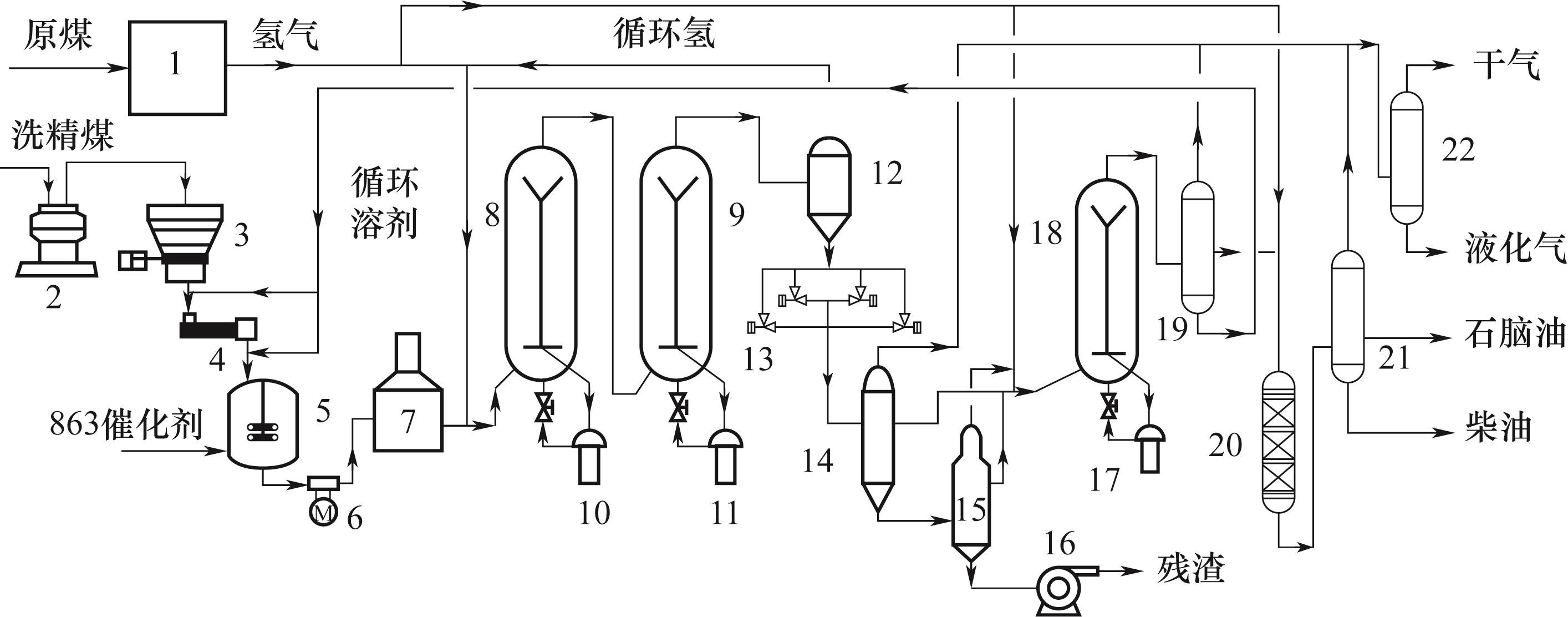

图2 中国神华煤直接液化第一代技术流程示意[13-14]1—煤制氢装置;2—磨煤机;3—煤粉仓;4—混捏机;5—煤浆罐;6—进料泵;7—预热炉;8—第一反应器;9—第二反应器;10,11,17—强制循环泵;12—分离器;13—五通式减压阀;14—常压塔;15—减压塔;16—减底泵;18—加氢稳定反应器;19,21,22—分馏塔;20—加氢改质反应器

Fig.2 Schematic diagram of Shenhua first-generation DCL technology[13-14]1—coal hydrogen device; 2—coal mill; 3—coal bunker; 4—mixing machine; 5—coal slurry tank; 6—feed pump; 7—preheating furnace; 8—first liquefaction reactor; 9—second liquefaction reactor; 10, 11, 17—recirculating pump; 12—splitter; 13—five-way decompression valve; 14—atmospheric distillation tower; 15—vacuum distillation tower; 16—bottom pump; 18—hydrogenation stabilization reactor; 19, 21, 22—separation tower; 20—hydrogenation and upgrading reactor

| 对比项目 | 一代技术 | 二代技术 |

|---|---|---|

| 反应器形式及内部构造 | 浆态床/回流杯+ 中心管+循环泵 | 浆态床/无内构件 |

| 串联反应器台数 | 2 | 3 |

| 液化名义温度/℃ | 455 | 455 |

| 溶剂循环方式 | 内(小)循环 | 外(大)循环 |

| 热高分温度/℃ | 约420 | 约460 |

表1 神华煤直接液化技术对比

Table 1 Comparison of Shenhua DCL technologies

| 对比项目 | 一代技术 | 二代技术 |

|---|---|---|

| 反应器形式及内部构造 | 浆态床/回流杯+ 中心管+循环泵 | 浆态床/无内构件 |

| 串联反应器台数 | 2 | 3 |

| 液化名义温度/℃ | 455 | 455 |

| 溶剂循环方式 | 内(小)循环 | 外(大)循环 |

| 热高分温度/℃ | 约420 | 约460 |

| 煤浆流量/(t/h) | 循环比R | Csolid,2-1/Csolid,1-1 | CHDS,2-1/CHDS,1-1 | rcoal,2-1/rcoal,1-1 | roil,2-1/roil,1-1 | τcoal,2-1/τcoal,1-1 | τcoal,2-T/τcoal,1-T |

|---|---|---|---|---|---|---|---|

| 1170 | 0 | 1.0 | 1.00 | 1.00 | 1.0 | 0.74 | 1.11 |

| 1170 | 1 | 0.50 | 0.50 | 0.25 | 0.25 | 0.37 | 0.56 |

| 1170 | 2 | 0.33 | 0.33 | 0.11 | 0.11 | 0.25 | 0.38 |

| 1170 | 3 | 0.25 | 0.25 | 0.06 | 0.06 | 0.18 | 0.27 |

表2 二代技术一反中反应物的平均浓度、平均反应速率及停留时间与一代技术的对比

Table 2 Comparison of the reactants’ mean concentration, mean reaction rates and residence time in the primary reactor of two generations DCL technologies

| 煤浆流量/(t/h) | 循环比R | Csolid,2-1/Csolid,1-1 | CHDS,2-1/CHDS,1-1 | rcoal,2-1/rcoal,1-1 | roil,2-1/roil,1-1 | τcoal,2-1/τcoal,1-1 | τcoal,2-T/τcoal,1-T |

|---|---|---|---|---|---|---|---|

| 1170 | 0 | 1.0 | 1.00 | 1.00 | 1.0 | 0.74 | 1.11 |

| 1170 | 1 | 0.50 | 0.50 | 0.25 | 0.25 | 0.37 | 0.56 |

| 1170 | 2 | 0.33 | 0.33 | 0.11 | 0.11 | 0.25 | 0.38 |

| 1170 | 3 | 0.25 | 0.25 | 0.06 | 0.06 | 0.18 | 0.27 |

| 测温点 | 第一反应器径向温度/℃ | 第二反应器径向温度/℃ | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 平均 | 1 | 2 | 3 | 4 | 平均 | |

| A | 465.3 | 465.5 | 466.1 | 466.7 | 465.9 | 460.4 | 461.9 | 462.1 | 462.1 | 461.6 |

| B | 462.4 | 463.4 | 463.0 | 464.4 | 463.3 | 459.6 | 460.9 | 460.6 | 461.3 | 460.6 |

| C | 459.5 | 460.1 | 460.0 | 461.5 | 460.4 | 458.9 | 459.6 | 460.0 | 460.0 | 459.6 |

| D | 456.8 | 458.3 | 458.4 | 458.3 | 458.0 | 457.8 | 458.6 | 458.7 | 459.0 | 458.5 |

| E | 454.6 | 456.9 | 456.1 | 456.0 | 455.9 | 457.2 | 458.2 | 457.9 | 457.6 | 457.7 |

| F | 453.6 | 456.2 | 453.4 | 452.8 | 454.0 | 455.8 | 456.5 | 457.0 | 456.7 | 456.5 |

| G | 452.4 | 453.1 | 449.5 | 451.1 | 451.5 | 454.7 | 455.9 | 456.3 | 455.4 | 455.6 |

| H | 447.7 | 448.4 | 447.3 | 447.5 | 447.7 | 453.4 | 455.1 | 455.1 | 454.7 | 454.6 |

表3 神华煤直接液化一代技术反应器内煤浆在内循环比R=3下的温度分布[14]

Table 3 Temperature distribution of coal slurry in the Shenhua’s first-generation DCL reactor under internal circulation ratio R=3[14]

| 测温点 | 第一反应器径向温度/℃ | 第二反应器径向温度/℃ | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 平均 | 1 | 2 | 3 | 4 | 平均 | |

| A | 465.3 | 465.5 | 466.1 | 466.7 | 465.9 | 460.4 | 461.9 | 462.1 | 462.1 | 461.6 |

| B | 462.4 | 463.4 | 463.0 | 464.4 | 463.3 | 459.6 | 460.9 | 460.6 | 461.3 | 460.6 |

| C | 459.5 | 460.1 | 460.0 | 461.5 | 460.4 | 458.9 | 459.6 | 460.0 | 460.0 | 459.6 |

| D | 456.8 | 458.3 | 458.4 | 458.3 | 458.0 | 457.8 | 458.6 | 458.7 | 459.0 | 458.5 |

| E | 454.6 | 456.9 | 456.1 | 456.0 | 455.9 | 457.2 | 458.2 | 457.9 | 457.6 | 457.7 |

| F | 453.6 | 456.2 | 453.4 | 452.8 | 454.0 | 455.8 | 456.5 | 457.0 | 456.7 | 456.5 |

| G | 452.4 | 453.1 | 449.5 | 451.1 | 451.5 | 454.7 | 455.9 | 456.3 | 455.4 | 455.6 |

| H | 447.7 | 448.4 | 447.3 | 447.5 | 447.7 | 453.4 | 455.1 | 455.1 | 454.7 | 454.6 |

| 煤样 | 工业分析/%(mass) | 元素分析/%(mass,daf) | 摩尔比 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mad | Aad | Vdaf | C | H | Oa | N | S | H/C | O/C | |

| SW | 1.5 | 5.2 | 30.1 | 77.6 | 4.8 | 16.6 | 0.8 | 0.2 | 0.75 | 0.16 |

| NMH | 4.8 | 5.3 | 47.1 | 67.0 | 5.4 | 26.3 | 0.9 | 0.4 | 0.97 | 0.29 |

表4 原料煤的元素分析和工业分析结果[20]

Table 4 Proximate and ultimate analyses of raw coals[20]

| 煤样 | 工业分析/%(mass) | 元素分析/%(mass,daf) | 摩尔比 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mad | Aad | Vdaf | C | H | Oa | N | S | H/C | O/C | |

| SW | 1.5 | 5.2 | 30.1 | 77.6 | 4.8 | 16.6 | 0.8 | 0.2 | 0.75 | 0.16 |

| NMH | 4.8 | 5.3 | 47.1 | 67.0 | 5.4 | 26.3 | 0.9 | 0.4 | 0.97 | 0.29 |

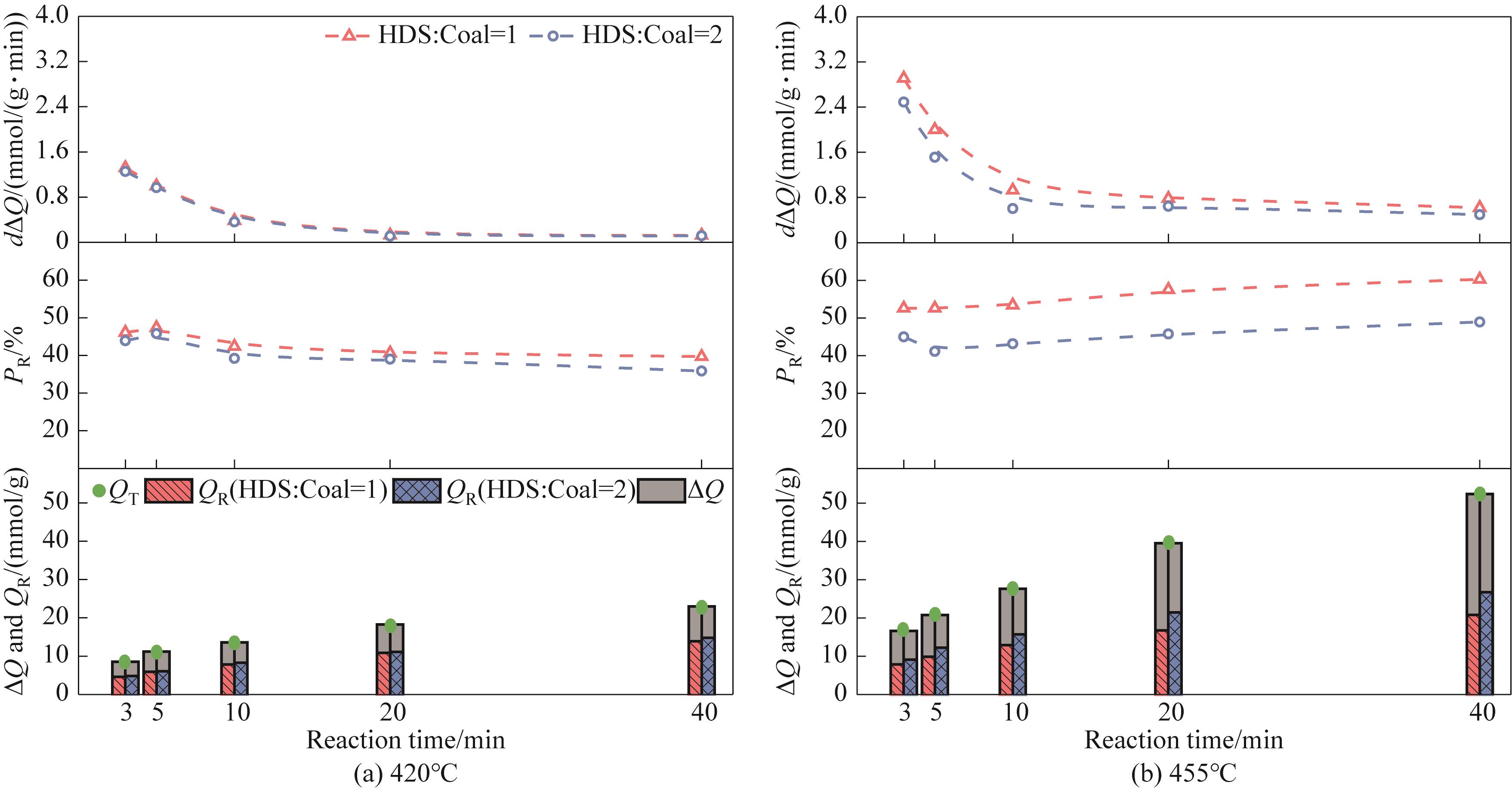

图7 SW煤的自由基碎片参数在不同温度和供氢溶剂用量下数值(基于文献[20-21]数据计算的新参数)

Fig.7 The radical quantities of SW coal at different temperatures and HDS∶Coal ratios (Data extracted from Refs.[20-21])

图8 NMH煤的自由基碎片参数在不同温度和供氢溶剂用量下数值(基于文献[20-21]数据计算的新参数)

Fig.8 The radical quantities of NMH coal at different temperatures and HDS∶Coal ratios (Data extracted from Refs.[20-21])

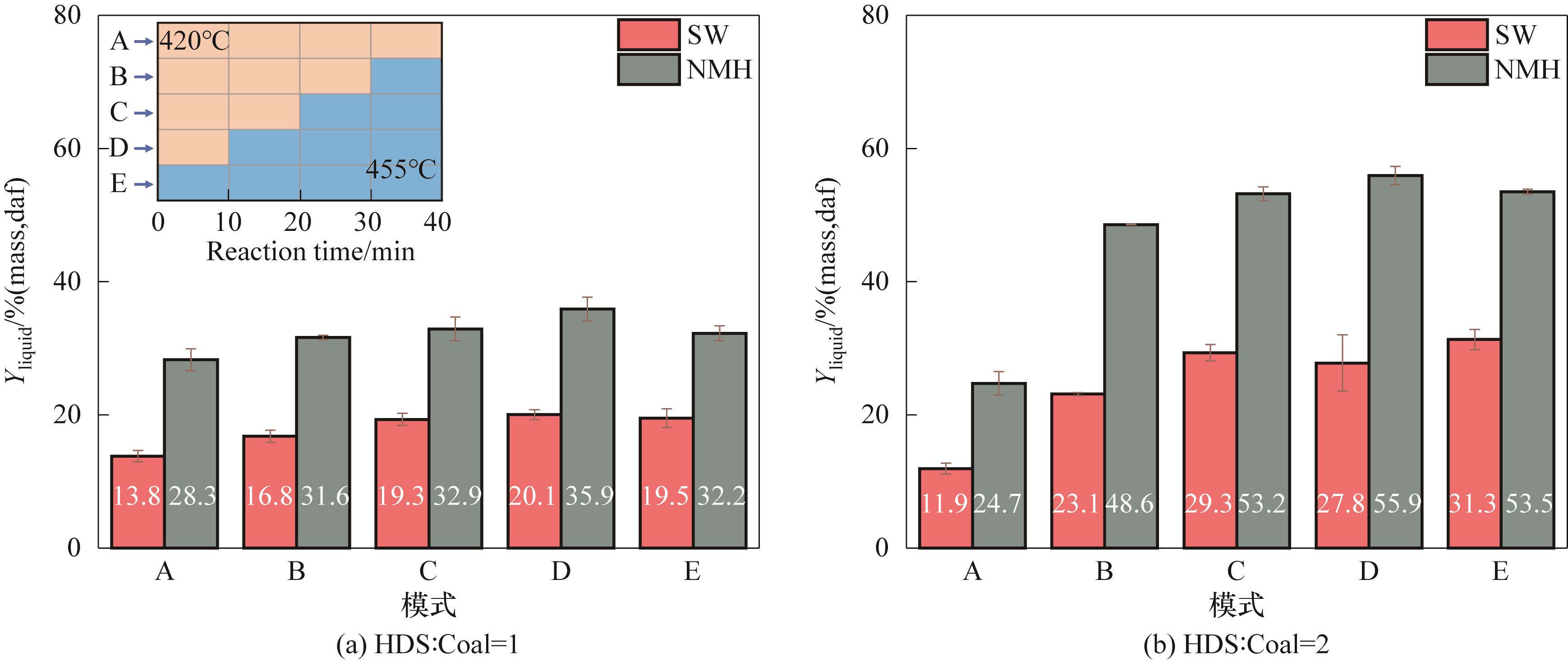

图9 两段升温液化模式下的液体收率对比(数据来自文献[20])(模式A表示420℃反应40 min;模式D表示420℃反应10 min后升温至455℃反应30 min;模式E表示455℃反应40 min)

Fig. 9 Comparison of liquid yields under two-stage heating liquefaction process (Data from Ref.[20])(Model A represents react at 420℃ for 40 min; Model D represents react 420℃ for 10 min and heat up to 455℃ and react for 30 min; Model E represents react at 455℃ for 40 min)

| [1] | 中华人民共和国国家统计局. 2023年12月份能源生产情况[R]. 2023. |

| National Bureau of Statistics of China. Energy production in December 2023[R]. 2023. | |

| [2] | Vasireddy S, Morreale B, Cugini A, et al. Clean liquid fuels from direct coal liquefaction: chemistry, catalysis, technological status and challenges[J]. Energy & Environmental Science, 2011, 4(2): 311-345. |

| [3] | Shui H F, Cai Z Y, Xu C B. Recent advances in direct coal liquefaction[J]. Energies, 2010, 3(2): 155-170. |

| [4] | 刘振宇. 煤化学的前沿与挑战: 结构与反应[J]. 中国科学: 化学, 2014, 44(9): 1431-1439. |

| Liu Z Y. Advancement in coal chemistry: structure and reactivity[J]. Scientia Sinica Chimica, 2014, 44(9): 1431-1439. | |

| [5] | 刘振宇. 煤直接液化技术发展的化学脉络及化学工程挑战[J]. 化工进展, 2010, 29(2): 193-197. |

| Liu Z Y. Principal chemistry and chemical engineering challenges in direct coal liquefaction technology[J]. Chemical Industry and Engineering Progress, 2010, 29(2): 193-197. | |

| [6] | Liu Z Y, Shi S D, Li Y W. Coal liquefaction technologies—Development in China and challenges in chemical reaction engineering[J]. Chemical Engineering Science, 2010, 65(1): 12-17. |

| [7] | 李文博. 煤直接液化技术发展方向及建议[J]. 中国石化, 2024(8): 44-46. |

| Li W B. Development direction and suggestion of direct coal liquefaction technology[J]. Sinopec Monthly, 2024(8): 44-46. | |

| [8] | 刘振宇. 重质有机资源热解的自由基化学[M]. 北京: 化学工业出版社, 2024. |

| Liu Z Y. The Free Radical Chemistry in Pyrolysis of Heavy Organic Resources[M]. Beijing: Chemical Industry Press, 2024. | |

| [9] | 任相坤, 房鼎业, 金嘉璐, 等. 煤直接液化技术开发新进展[J].化工进展, 2010, 29(2): 198-204. |

| Ren X K, Fang D Y, Jin J L, et al. New proceed achieved in the direct coal liquefaction[J]. Chemical Industry and Engineering Progress, 2010, 29(2): 198-204. | |

| [10] | 舒歌平. 神华煤直接液化工艺开发历程及其意义[J]. 神华科技, 2009, 7(1): 78-82. |

| Shu G P. Development history and its significance of Shenhua coal direct liquefaction[J]. Shenhua Science and Technology, 2009, 7(1): 78-82. | |

| [11] | 国家能源集团煤直接液化二代技术工程化开发项目开工[EB/OL]. [2024-12-04]. . |

| CHN E n e r g y ' s second-generation technology engineering development project starts construction[EB/OL]. [2024-12-04]. . | |

| [12] | 我国首个应用二代技术的煤直接液化项目开工[EB/OL]. [2024-10-09]. . |

| C h i n a ' s first direct coal liquefaction project using second-generation technology starts construction[EB/OL]. [2024-10-09]. . | |

| [13] | Wang J L, Xie L Y, Peng Y F, et al. Molecular composition of direct coal liquefaction products obtained from the Shenhua industrial plant[J]. Fuel, 2024, 357: 129735. |

| [14] | 李小强, 刘永, 秦光书. 神华煤直接液化示范项目的进展及发展方向[J]. 煤化工, 2015, 43(4): 12-15, 37. |

| Li X Q, Liu Y, Qin G S. Progress and development direction of Shenhua coal direct liquefaction demonstration project[J]. Coal Chemical Industry, 2015, 43(4): 12-15, 37. | |

| [15] | 吴秀章, 舒歌平, 李克健, 等. 煤炭直接液化工艺与工程[M]. 北京: 科学出版社, 2015. |

| Wu X Z, Shu G P, Li K J, et al. Technology and Engineering of Direct Coal Liquefaction Process[M]. Beijing: Science Press, 2015. | |

| [16] | 吴秀章, 舒歌平. 强制内循环反应器在煤直接液化工艺中的应用[J]. 炼油技术与工程, 2009, 39(8): 31-35. |

| Wu X Z, Shu G P. Application of slurry bed reactors with forced internal circulation in direct coal liquefaction process[J]. Petroleum Refinery Engineering, 2009, 39(8): 31-35. | |

| [17] | 王升宝. 胜利煤液化油比热容的测定及关联[D]. 太原: 太原理工大学, 2008. |

| Wang S B. Research and correlation on specific heat capacity of Shengli coal liquefied fractions[D]. Taiyuan: Taiyuan University of Technology, 2008. | |

| [18] | 王建立, 康开通, 高山松, 等. 煤直接液化循环溶剂供氢性影响因素研究[J]. 中国煤炭, 2020, 46(5): 68-73. |

| Wang J L, Kang K T, Gao S S, et al. Study on influencing factors of hydrogen supply of circulating solvent in direct coal liquefaction[J]. China Coal, 2020, 46(5): 68-73. | |

| [19] | 赵鹏程, 王喜武. 煤直接液化工艺最佳转化率及收率[J]. 洁净煤技术, 2023, 29(S2): 69-73. |

| Zhao P C, Wang X W. Optimum conversion and yield of coal direct liquefaction process[J]. Clean Coal Technology, 2023, 29(S2): 69-73. | |

| [20] | Shen T, Liu Q Y, Liu Z Y. Comparison of two-stage and single-stage liquefaction schemes for their effect on conversion and liquid yield of two low rank coals[J]. Journal of Analytical and Applied Pyrolysis, 2023, 172: 106018. |

| [21] | Qin X Z, Yang T, Liu Z Y, et al. Molecular structure, bond cleavage and their relation of four low rank coals[J]. Fuel Processing Technology, 2022, 236: 107391. |

| [22] | Liu M X, Yang J L, Yang Y, et al. The radical and bond cleavage behaviors of 14 coals during pyrolysis with 9,10-dihydrophenanthrene[J]. Fuel, 2016, 182: 480-486. |

| [1] | 张圣美, 李明, 张莹, 易茜, 杨依婷, 刘雅莉. 乳化剂和温度对相变微胶囊性能的影响分析[J]. 化工学报, 2025, 76(S1): 444-452. |

| [2] | 谢晶, 舒歌平, 杨葛灵, 高山松, 王洪学, 卢晗锋, 陈银飞. Mo修饰的钼铁复合催化剂及其煤直接液化催化性能[J]. 化工学报, 2021, 72(9): 4675-4684. |

| [3] | 曲洋, 初茉, 朱书全, 张超, 郝成亮, 徐芳. 回转窑内利用液化残渣共热褐煤以抑制其粉化的影响因素分析[J]. 化工学报, 2018, 69(5): 2166-2174. |

| [4] | 张传江, 韩来喜, 蒋雪冬, 许明, 门卓武. 煤直接液化反应器循环杯的数值模拟及优化[J]. 化工学报, 2017, 68(7): 2703-2712. |

| [5] | 单贤根, 李克健, 章序文, 王洪学, 曹雪萍, 江洪波, 翁惠新. 神华上湾煤恒温阶段直接液化反应动力学[J]. 化工学报, 2017, 68(4): 1398-1406. |

| [6] | 谢晶, 卢晗锋, 陈银飞, 高山松, 王洪学. 助剂改性FeOOH及其煤直接液化催化活性[J]. 化工学报, 2016, 67(5): 1892-1899. |

| [7] | 乔建超,王建平,盛清涛,申 峻,凌开成. 由煤制取芳烃化合物的研究进展[J]. 化工进展, 2012, 31(08): 1717-1720. |

| [8] | 刘 振 宇. 煤直接液化技术发展的化学脉络及化学工程挑战 [J]. CIESC Journal, 2010, 29(2): 193-. |

| [9] | 熊楚安,王永刚,许德平. 中国直接液化油煤浆及液化残渣流变特性研究进展 [J]. CIESC Journal, 2009, 28(4): 597-. |

| [10] | 倪力军,张立国,倪进方,袁渭康. 链烷烃热裂解过程结构动力学模型与模拟 [J]. CIESC Journal, 1995, 46(5): 562-570. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号