• •

翟庆伟1( ), 韩东旭2(

), 韩东旭2( ), 田中辉3, 于阳4, 王鹏2, 陈宇杰2, 宇波5

), 田中辉3, 于阳4, 王鹏2, 陈宇杰2, 宇波5

收稿日期:2025-09-01

修回日期:2025-12-16

出版日期:2025-12-19

通讯作者:

韩东旭

作者简介:翟庆伟(1993-),男,博士研究生,zhaiqingwei6@163.com

基金资助:

Qingwei ZHAI1( ), Dongxu HAN2(

), Dongxu HAN2( ), Zhonghui TIAN3, Yang YU4, Peng WANG2, Yujie CHEN2, Bo YU5

), Zhonghui TIAN3, Yang YU4, Peng WANG2, Yujie CHEN2, Bo YU5

Received:2025-09-01

Revised:2025-12-16

Online:2025-12-19

Contact:

Dongxu HAN

摘要:

液氢储罐的热管理直接关系到运行安全与能效,而其复杂热过程的预测依赖于高效准确的仿真模型。现有的计算流体力学(CFD)模型虽能细致刻画气-液相变与温度场分布,但计算代价过高,难以支撑大型储罐的工程应用;传统热力学方法虽然具有较高计算效率,却难以同时揭示罐内介质的温度梯度分布以及介质与多层绝热结构之间的动态热耦合。为此,构建了一种适用于液氢柱罐和球罐的新型多节点非平衡热力学-热阻网络耦合模型,可同时描述气-液相动态相变、温度梯度以及绝热层热通量及温度分布。基于该模型,结合美国国家航空航天局(NASA)多用途氢实验平台(MHTB)与液氢球罐实验(K-Site)进行了对比验证。模型在压力、气液相温度及绝热结构热通量预测上的最大相对误差均处于合理范围(压力 <5.2%,气相温度 <6.3%,液相温度 <0.61%,绝热结构 1.4%~12.4%),表明该模型能够稳定再现多工况下液氢储罐的自增压行为。该研究为液氢储罐的长期储存设计、运行优化与安全评估提供了有效仿真工具。

中图分类号:

翟庆伟, 韩东旭, 田中辉, 于阳, 王鹏, 陈宇杰, 宇波. 液氢储罐新型多节点热力学-热阻网络耦合模型的构建与验证研究[J]. 化工学报, DOI: 10.11949/0438-1157.20250974.

Qingwei ZHAI, Dongxu HAN, Zhonghui TIAN, Yang YU, Peng WANG, Yujie CHEN, Bo YU. Construction and validation of a novel multi-node thermodynamic–thermal resistance network coupled model for liquid hydrogen storage tanks[J]. CIESC Journal, DOI: 10.11949/0438-1157.20250974.

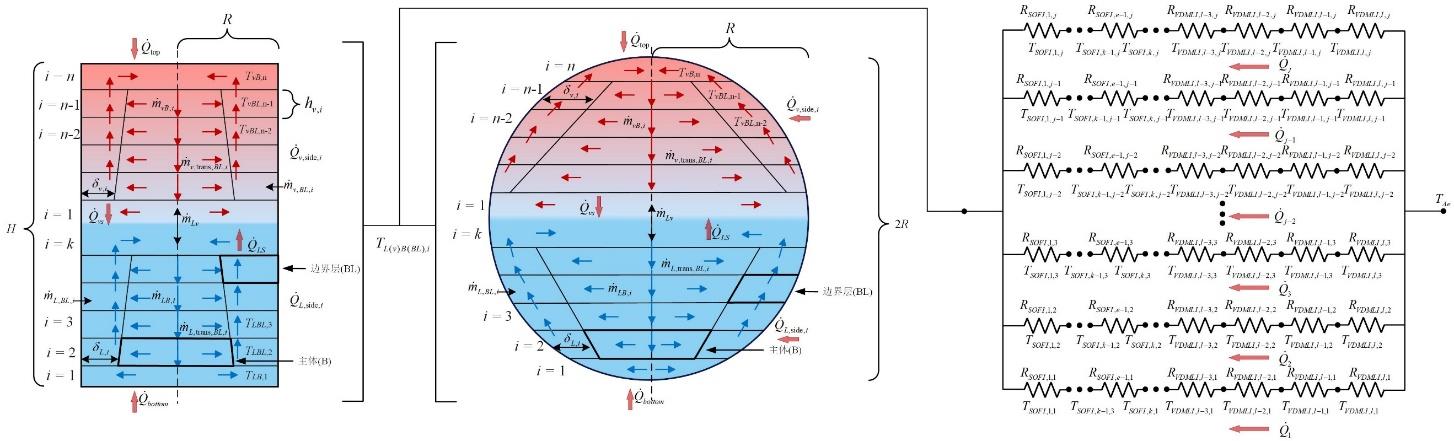

图2 多节点非平衡热力学模型与二维热阻网络法耦合示意图

Fig. 2 Schematic diagram of the coupled multi-node non-equilibrium thermodynamic model and two-dimensional thermal resistance network method

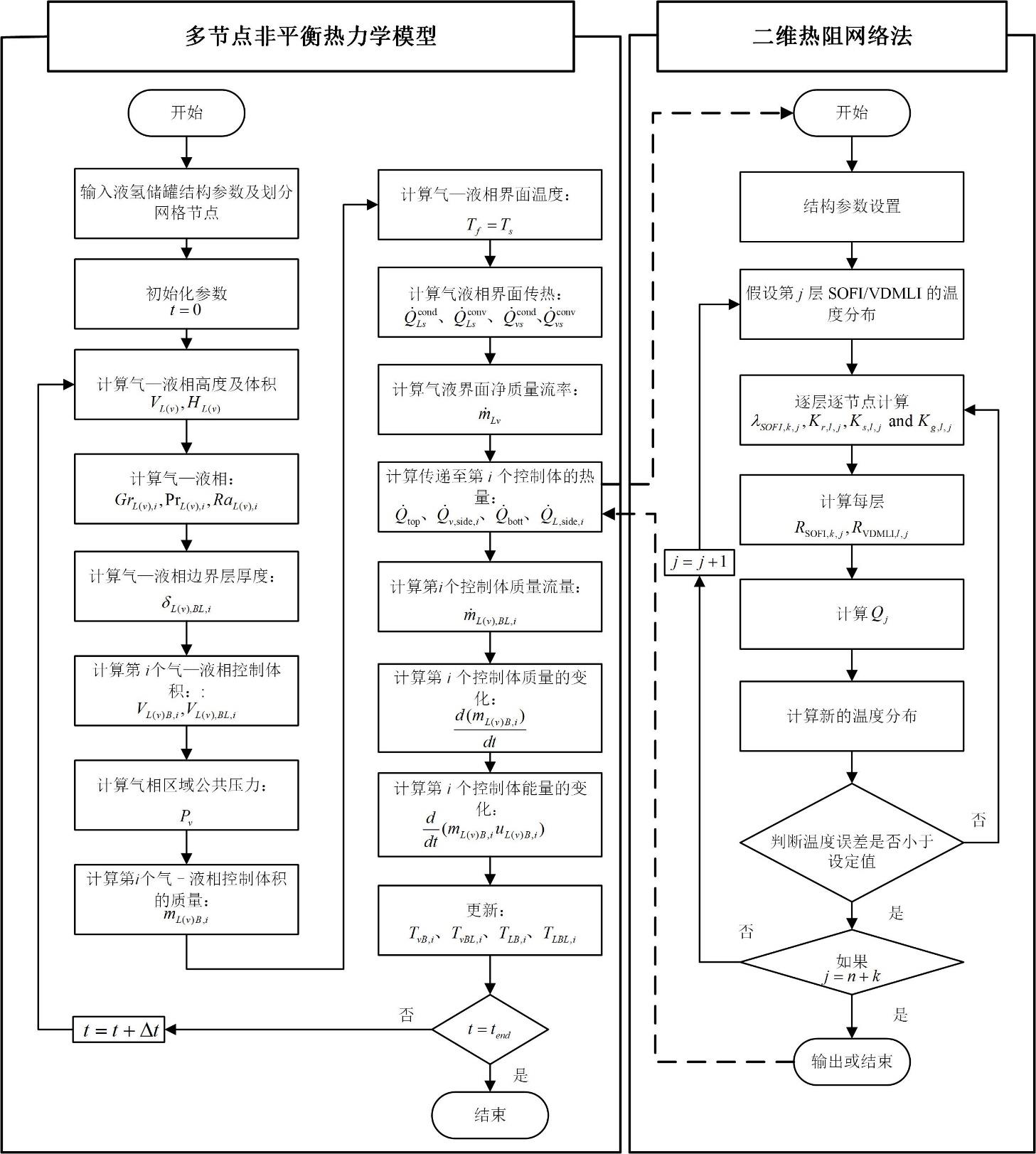

图3 多节点非平衡热力学模型耦合二维热阻网络法计算程序逻辑框图

Fig. 3 Flowchart of the computational program for the coupled multi-node non-equilibrium thermodynamic model and two-dimensional thermal resistance network method

| 绝热层 | 参数 | 值 |

|---|---|---|

| SOFI | 厚度 | 0.0353 m |

| VDMLI | 辐射屏蔽层数 | 45 |

| VDMLI 总厚度 | 0.0375 m | |

低密度 中密度 高密度 | 8 层/cm (10层) 12 层/cm (15层) 16 层/cm (20 层) |

表1 绝热结构参数[33]

Table 1 Insulation structure parameters[33]

| 绝热层 | 参数 | 值 |

|---|---|---|

| SOFI | 厚度 | 0.0353 m |

| VDMLI | 辐射屏蔽层数 | 45 |

| VDMLI 总厚度 | 0.0375 m | |

低密度 中密度 高密度 | 8 层/cm (10层) 12 层/cm (15层) 16 层/cm (20 层) |

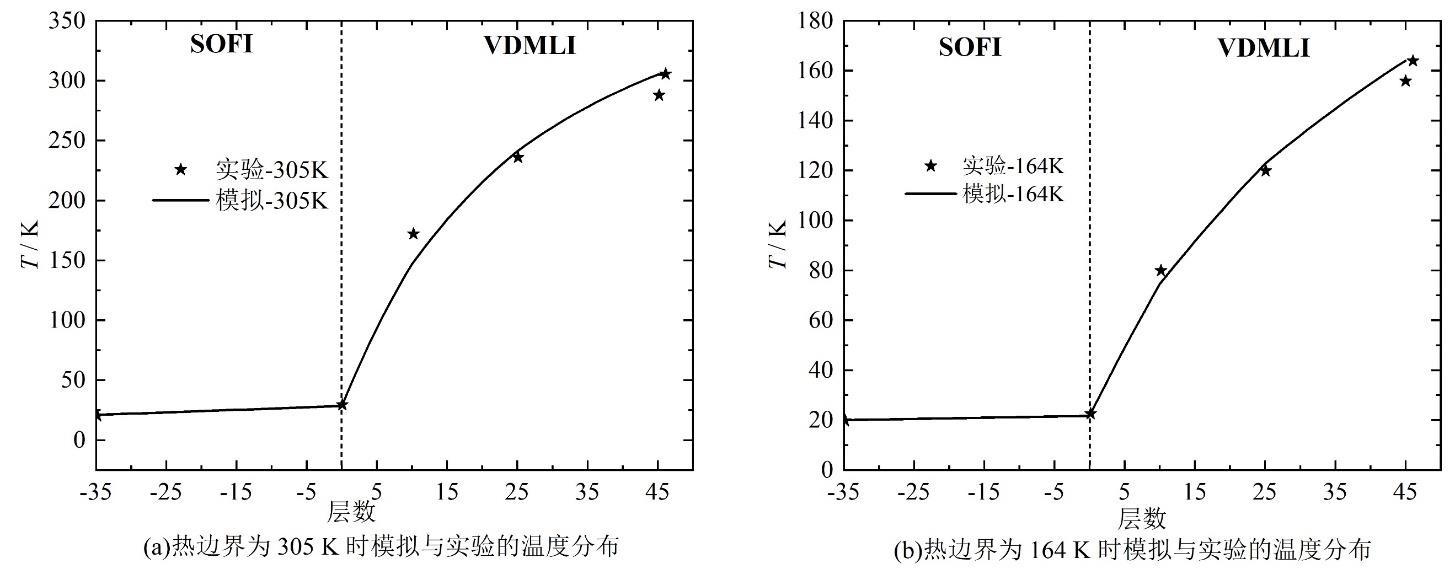

图5 不同热边界温度条件下模型计算结果与MHTB实验数据的对比[33]

Fig. 5 Comparison between model predictions and MHTB experimental data under different thermal boundary temperature conditions[33]

| 热边界温度/ K | 实验热通量/( W/m2) | 模型计算结果/( W/m2) | 偏差/% |

|---|---|---|---|

| 164 | 0.085 | 0.0799 | 6.0 |

| 305 | 0.25 | 0.2536 | 1.44 |

表2 不同热边界温度热通量对比结果[34]

Table 2 Comparison of heat flux results under different thermal boundary temperatures[34]

| 热边界温度/ K | 实验热通量/( W/m2) | 模型计算结果/( W/m2) | 偏差/% |

|---|---|---|---|

| 164 | 0.085 | 0.0799 | 6.0 |

| 305 | 0.25 | 0.2536 | 1.44 |

| 填充率/% | 压力/ kPa | 液氢温度/K | 气氢温度/K | 漏热量/W |

|---|---|---|---|---|

| 25 | 122.3 | 20.9 | 20.99~28.7 | 18.8 |

| 50 | 122.37 | 20.96 | 20.99~28.54 | 18.7 |

| 50 | 112.6 | 20.7 | 20.7~28.1 | 51 |

| 90 | 112.3 | 20.6 | 20.66~24.09 | 20.2 |

| 90 | 113.4 | 20.6 | 20.66~21.02 | 71.3 |

表3 MHTB不同液氢填充率下初始参数[35-37]

Table 3 Initial parameters of MHTB under different liquid hydrogen fill levels[35-37]

| 填充率/% | 压力/ kPa | 液氢温度/K | 气氢温度/K | 漏热量/W |

|---|---|---|---|---|

| 25 | 122.3 | 20.9 | 20.99~28.7 | 18.8 |

| 50 | 122.37 | 20.96 | 20.99~28.54 | 18.7 |

| 50 | 112.6 | 20.7 | 20.7~28.1 | 51 |

| 90 | 112.3 | 20.6 | 20.66~24.09 | 20.2 |

| 90 | 113.4 | 20.6 | 20.66~21.02 | 71.3 |

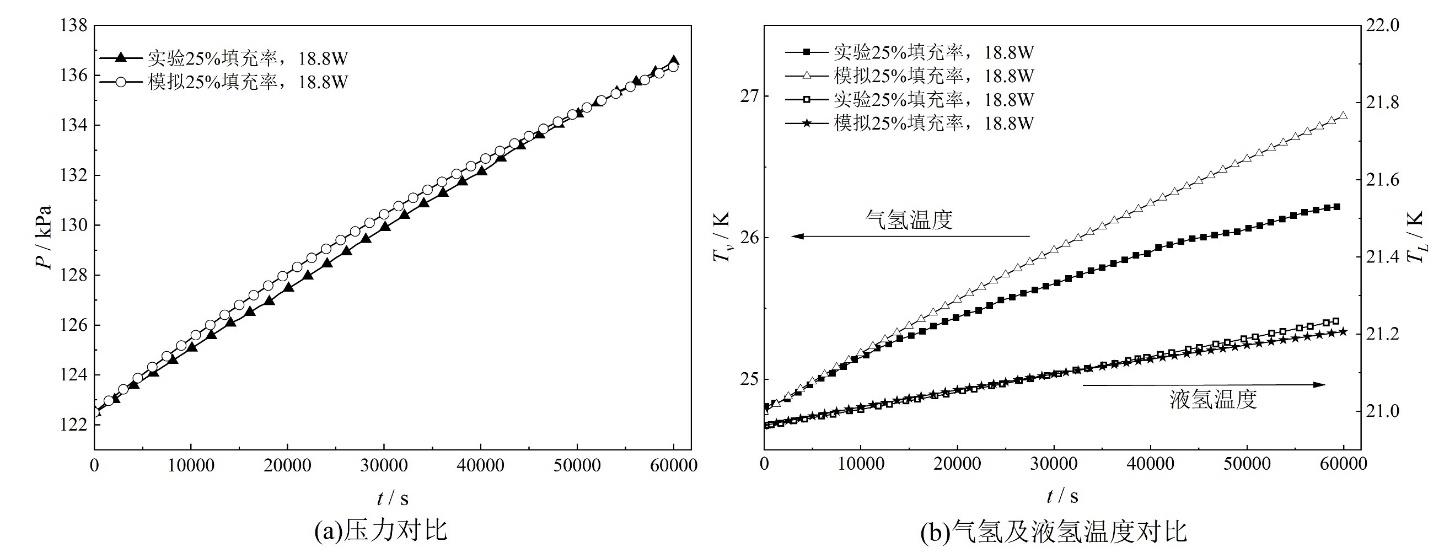

图6 液氢柱罐填充率为25%时模拟与实验结果对比

Fig. 6 Comparison between simulation and experimental results for the liquid hydrogen cylindrical tank at a fill level of 25%

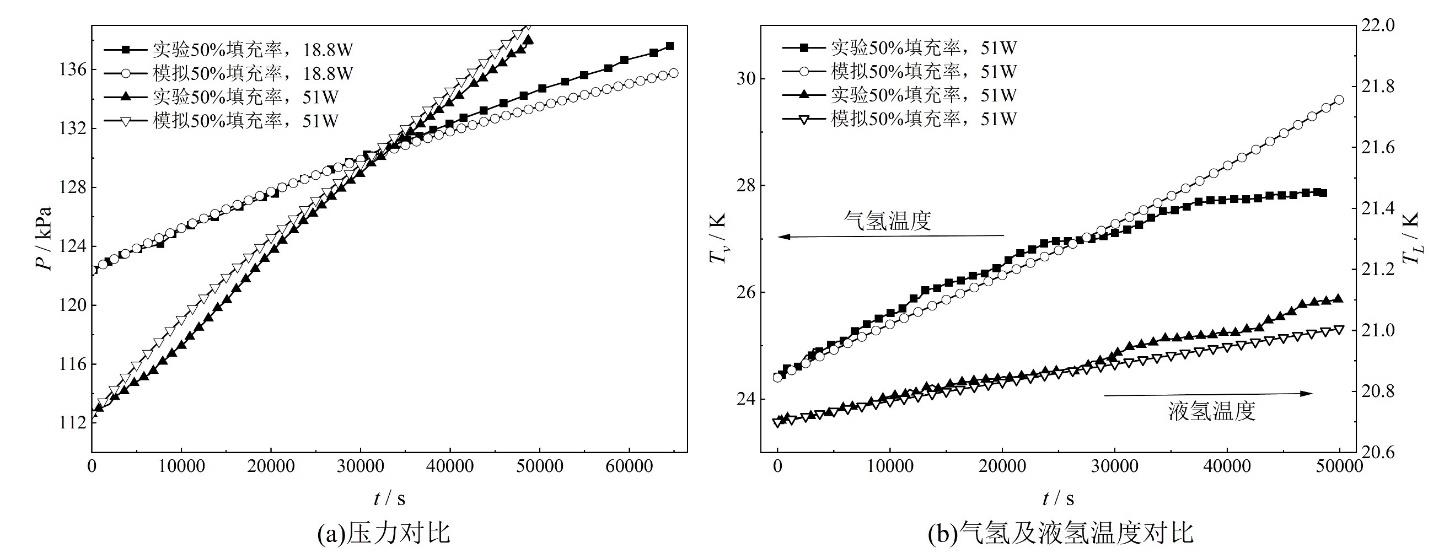

图7 液氢柱罐填充率为50%时不同漏热量下模拟与实验结果对比

Fig. 7 Comparison between simulation and experimental results for the liquid hydrogen cylindrical tank at a fill level of 50% under different heat leak conditions

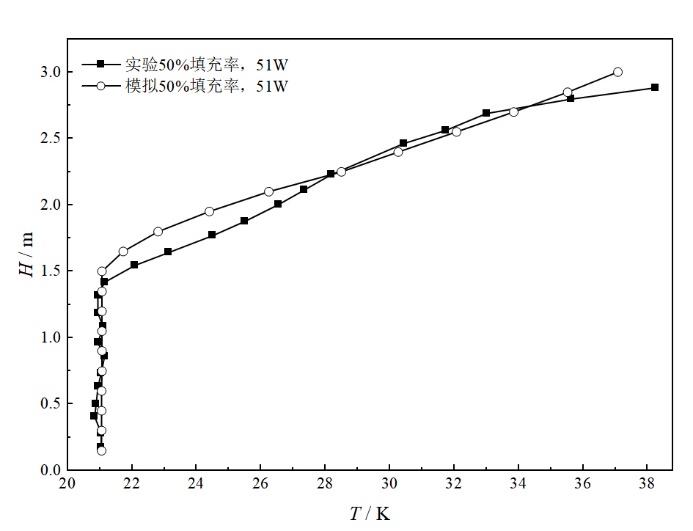

图8 液氢柱罐在填充率为 50%、漏热量为 51 W 时,自增压结束后罐内介质温度分布的模拟与实验对比

Fig. 8 Comparison of simulated and experimental temperature distributions inside the liquid hydrogen cylindrical tank at a fill level of 50% and a heat leak of 51 W after the completion of self-pressurization

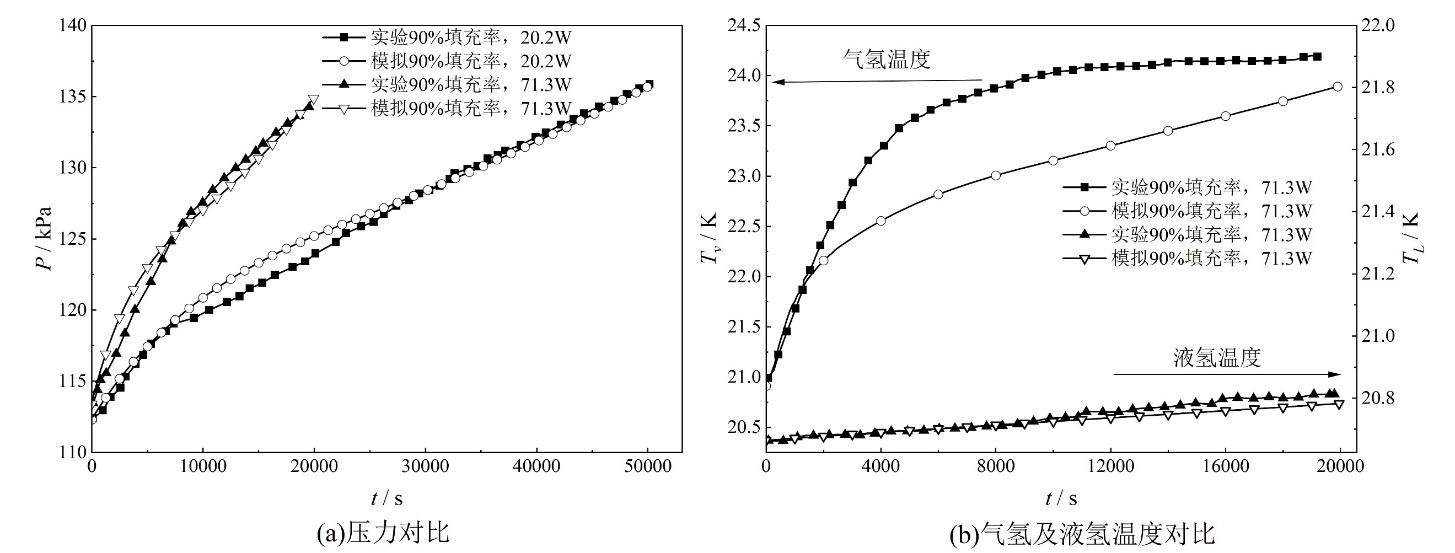

图9 液氢柱罐填充率为90%时不同漏热量下模拟与实验结果对比

Fig. 9 Comparison of simulated and experimental results for the liquid hydrogen cylindrical tank at a fill level of 90% under different heat leak conditions

| 填充率/% | 压力/ kPa | 液氢温度/K | 气氢温度/K | 热通量/(W/m2) |

|---|---|---|---|---|

| 29 | 103.7 | 20.04 | 20.49~29 | 2, 3.5 |

| 49 | 103.7 | 20.12 | 20.3~29 | 2, 3.5 |

| 83 | 103.7 | 20.1 | 20.2~26 | 2, 3.5 |

表4 K-Site不同液氢填充率下初始参数[38]

Table 4 Initial parameters of K-Site liquid hydrogen tank at different fill levels[38]

| 填充率/% | 压力/ kPa | 液氢温度/K | 气氢温度/K | 热通量/(W/m2) |

|---|---|---|---|---|

| 29 | 103.7 | 20.04 | 20.49~29 | 2, 3.5 |

| 49 | 103.7 | 20.12 | 20.3~29 | 2, 3.5 |

| 83 | 103.7 | 20.1 | 20.2~26 | 2, 3.5 |

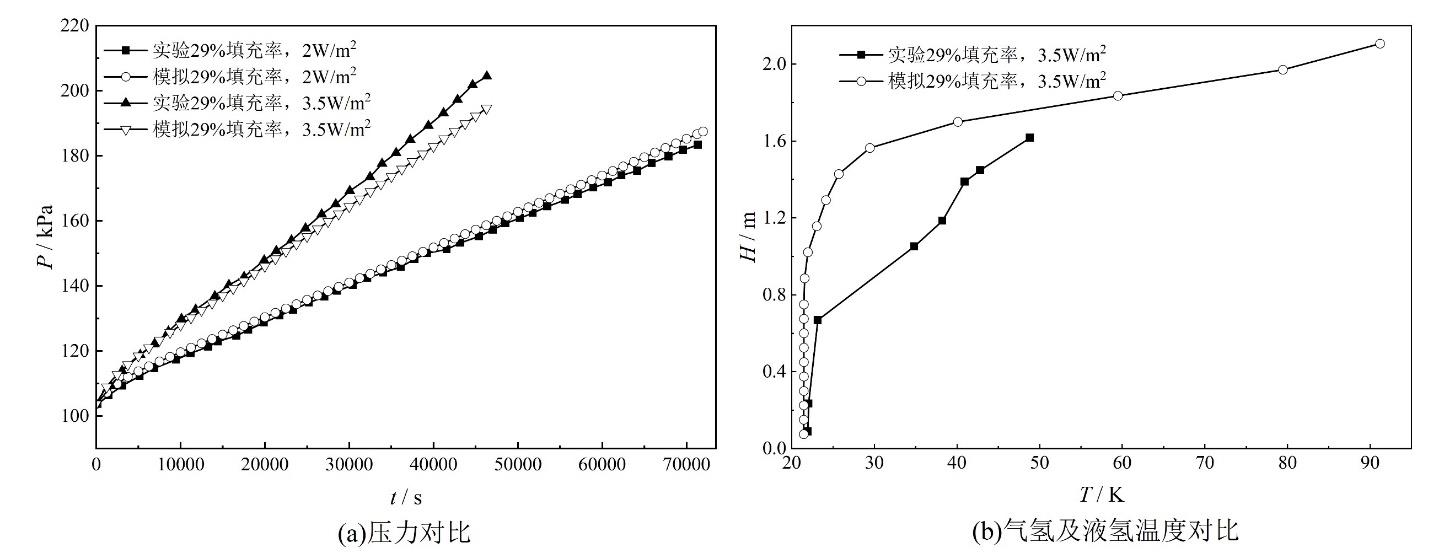

图10 液氢球罐填充率为29%时不同热通量下模拟与实验结果对比

Fig. 10 Comparison of simulation and experimental results for the spherical liquid hydrogen tank at 29% fill level under different heat flux conditions

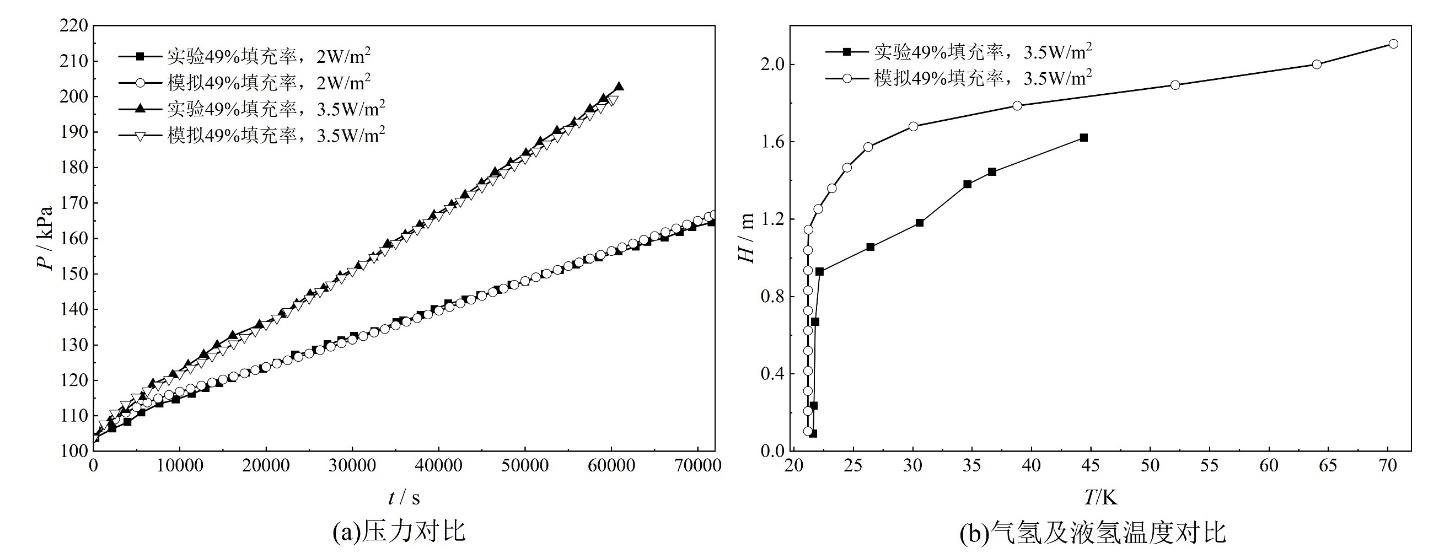

图11 液氢球罐填充率为49%时不同热通量下模拟与实验结果对比

Fig. 11 Comparison of simulation and experimental results for the spherical liquid hydrogen tank at 49% fill level under different heat flux conditions

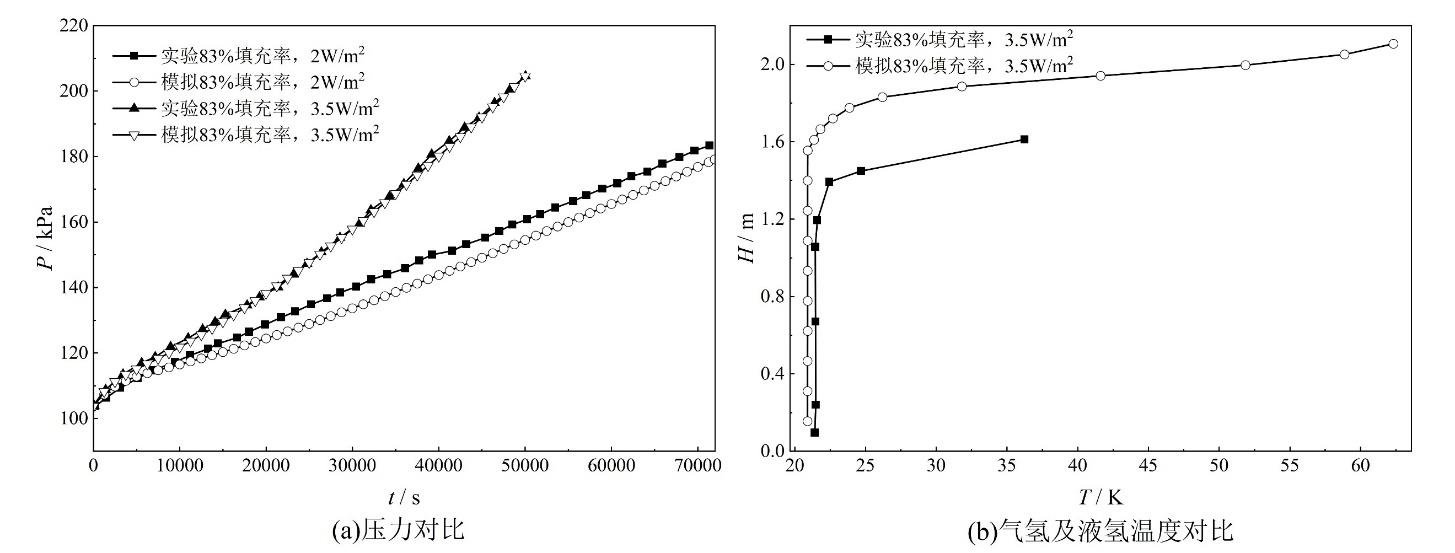

图12 液氢球罐填充率为29%时不同热通量下模拟与实验结果对比

Fig. 12 Comparison of simulation and experimental results for the spherical liquid hydrogen tank at 83% fill level under different heat flux conditions

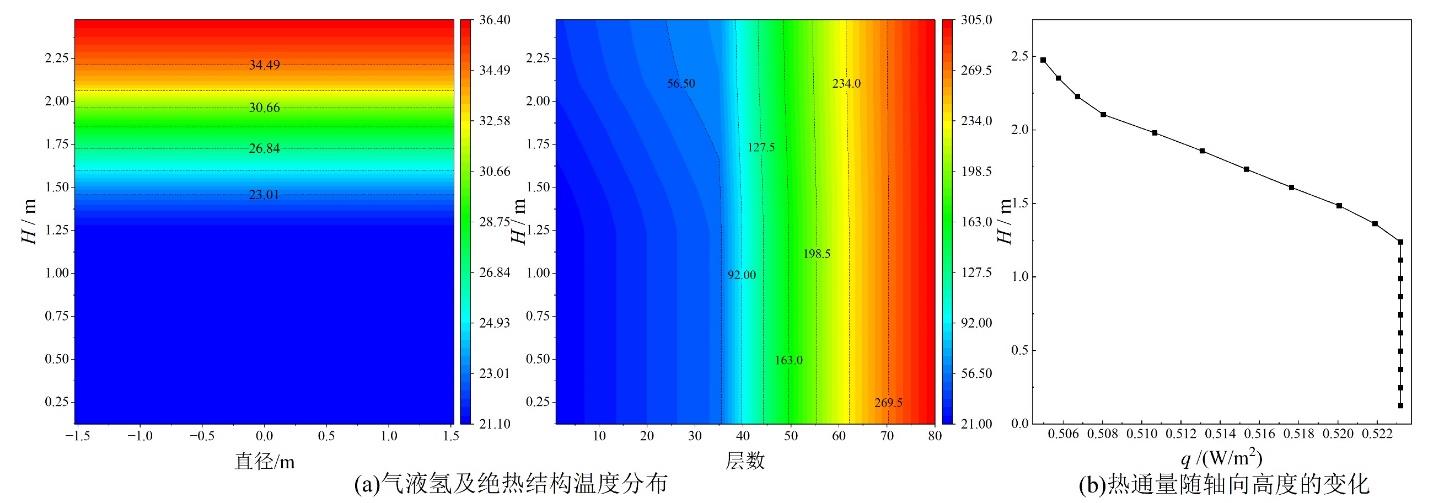

图13 液氢柱罐填充率为50%时自增压结束时温度及热通量分布

Fig. 13 Temperature and heat flux distribution at the end of self-pressurization for the cylindrical liquid hydrogen tank at 50% fill level

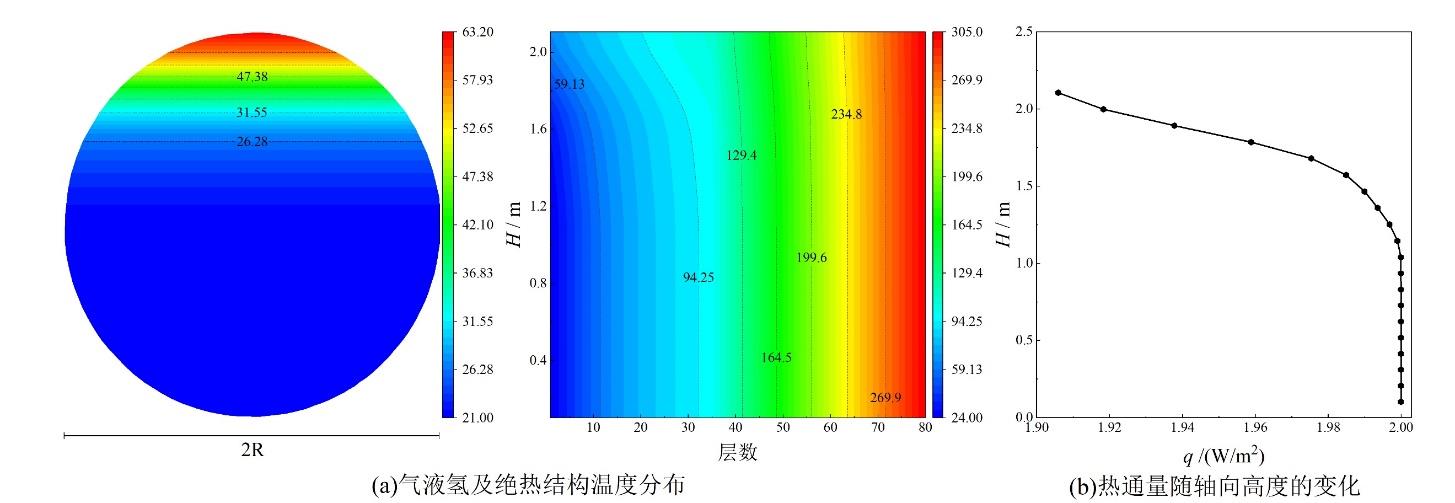

图14 液氢球罐填充率为49%时自增压结束时温度及热通量分布

Fig. 14 Temperature and heat flux distribution at the end of self-pressurization for the spherical liquid hydrogen tank at 49% fill level

| [1] | Shu K Y, Guan B, Zhuang Z Q, et al. Reshaping the energy landscape: Explorations and strategic perspectives on hydrogen energy preparation, efficient storage, safe transportation and wide applications[J]. International Journal of Hydrogen Energy, 2025, 97: 160-213. |

| [2] | Tarhan C, Ali Çil M. A study on hydrogen, the clean energy of the future: Hydrogen storage methods[J]. Journal of Energy Storage, 2021, 40: 102676. |

| [3] | Lu M, Wei W, Hui L, et al. Optimizing hydrogen storage: A comparative economic and financial analysis for sustainable energy markets[J]. International Journal of Hydrogen Energy, 2025, 133: 63-77. |

| [4] | 翟庆伟, 林锦辉, 李彦锋, 等. 新型泵-热协同增压液氢加氢站系统(火用)分析[J]. 化工学报, 2025, 76(10): 5390-5401. |

| Zhai Q W, Lin J H, Li Y F, et al. Exergy analysis of novel pump-thermal synergistic pressurization liquid hydrogen refueling station system[J]. CIESC Journal, 2025, 76(10): 5390-5401. | |

| [5] | Morales-Ospino R, Celzard A, Fierro V. Strategies to recover and minimize boil-off losses during liquid hydrogen storage[J]. Renewable and Sustainable Energy Reviews, 2023, 182: 113360. |

| [6] | 李科, 文键, 忻碧平. 耦合蒸气冷却屏的真空多层绝热结构对液氢储罐自增压过程的影响机制研究[J]. 化工学报, 2023, 74(9): 3786-3796. |

| Li K, Wen J, Xin B P, et al. Study on influence mechanism of vacuum multi-layer insulation coupled with vapor-cooled shield on self-pressurization process of liquid hydrogen storage tank[J]. CIESC Journal, 2023, 74(9): 3786-3796. | |

| [7] | 杨浩楠, 殷靓, 巨永林. 大型液氢储罐绝热结构发展现状及面临挑战[J]. 制冷学报, 2025, 46(3): 57-66. |

| Yang H N, Yin L, Ju Y L. Development status and challenges of thermal insulation in large liquid hydrogen storage tanks[J]. Journal of Refrigeration, 2025, 46(3): 57-66. | |

| [8] | Zuo Z Q, Jiang W B, Qin X J, et al. A numerical model for liquid–vapor transition in self-pressurized cryogenic containers [J]. Applied Thermal Engineering, 2021, 193: 117005. |

| [9] | Wang H R, Wang B, Xu T C, et al. Thermal models for self-pressurization prediction of liquid hydrogen tanks: Formulation, validation, assessment, and prospects[J]. Fuel, 2024, 365: 131247. |

| [10] | Aydelott J C. Normal gravity self-pressurization of 9-inch- /23 cm/ diameter spherical liquid hydrogen tankage, F, 1967 [C]. |

| [11] | Al Ghafri S Z S, Swanger A, Jusko V, et al. Modelling of Liquid Hydrogen Boil-Off[J]. Energies, 2022, 15(3): 1149. |

| [12] | Vishnu S B, Kuzhiveli B T. Mathematical modeling of thermal stratification in a double wall cryogenic propellant tank with different insulations using one-dimensional flow over vertical plate approximation[J]. Cryogenics, 2022, 121: 103393. |

| [13] | Daigle M J, Smelyanskiy V N, Boschee J, et al. Temperature Stratification in a Cryogenic Fuel Tank[J]. Journal of Thermophysics and Heat Transfer, 2013, 27(1): 116-126. |

| [14] | Qu Z Y, Cai Z C, Ma Z X, et al. Co-simulation of thermal behavior in liquid hydrogen tanks under vacuum degradation[J]. Energy, 2025, 329: 136841. |

| [15] | Zhu X Y, Lee J H, Kim K-H, et al. Coupled CFD modeling and thermal analysis of multi-layered insulation structures in liquid hydrogen storage tanks for various vapor-cooled shields[J]. Case Studies in Thermal Engineering, 2024, 63: 105317. |

| [16] | Li D M, Liu H Y, Zhang C B, et al. Insulation optimization of liquid hydrogen storage tank using dynamic analysis[J]. International Journal of Hydrogen Energy, 2024, 110: 588-597. |

| [17] | Kang B, Choi J, Seop L, et al. Integrated thermal modeling and parametric study of liquid hydrogen storage tanks: Effects of insulation design and operating conditions[J]. Energy, 2025, 319: 134869. |

| [18] | Wang J, Webley P A, Hughes T J. Thermodynamic modelling of low fill levels in cryogenic storage tanks for application to liquid hydrogen maritime transport[J]. Applied Thermal Engineering, 2024, 256: 124054. |

| [19] | Wang Z, Mérida W. Thermal performance of cylindrical and spherical liquid hydrogen tanks [J]. International Journal of Hydrogen Energy, 2024, 53: 667-683. |

| [20] | Nisanga Nuwantha H D, Jung D, Huh C. Improvement in predicting the thermal behavior of liquid hydrogen storage through novel thermal modeling[J]. International Journal of Hydrogen Energy, 2024, 72: 1143-1158. |

| [21] | Lan E, Shi S B, Ji W, et al. Modeling and simulation of cryogenic propellant tank pressurization in normal gravity[J]. Applied Thermal Engineering, 2024, 236: 121628. |

| [22] | Duan Z D, Sun H R, Cheng C, et al. A moving-boundary based dynamic model for predicting the transient free convection and thermal stratification in liquefied gas storage tank[J]. International Journal of Thermal Sciences, 2021, 160: 106690. |

| [23] | Kirk D, Oliveira J, Schallhorn P. Modeling of Upper Stage Cryogenic Propellants in a Rotating, Reduced Gravity Environment [M]. 42nd AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit. American Institute of Aeronautics and Astronautics. 2006. |

| [24] | Osipov V V, Daigle M J, Muratov C B, et al. Dynamical model of rocket propellant loading with liquid hydrogen[J]. Journal of Spacecraft and Rockets, 2011, 48(6): 987-998. |

| [25] | Clark J. Universal Equations for Saturation Vapor Pressure [M]. 40th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit. American Institute of Aeronautics and Astronautics. 2004. |

| [26] | Liu Z, Li Y Z. Thermal physical performance in liquid hydrogen tank under constant wall temperature[J]. Renewable Energy, 2019, 130: 601-612. |

| [27] | McIntosh G E. Layer by layer MLI calculation using a separated mode equation[M]//Advances in Cryogenic Engineering. Boston, MA: Springer US, 1994: 1683-1690. |

| [28] | Sun Z R, Li M J, Qu Z G, et al. A quasi-2D thermodynamic model for performance analysis and optimization of liquid hydrogen storage system with multilayer insulation and vapor-cooled shield[J]. Journal of Energy Storage, 2023, 73: 109128. |

| [29] | Yu Y, Xie F S, Li Y Z. Study on characteristics of transient discharge and heat transfer of rarefied gas in multilayer insulation during ascent[J]. Applied Thermal Engineering, 2025, 261: 125191. |

| [30] | Leng Y K, Zhang S Q, Wang X Y, et al. Comparative study on thermodynamic performance of liquid hydrogen storage insulation system incorporating vapor-cooled shield with para–ortho hydrogen conversion by one-dimensional and quasi-two-dimensional model[J]. Energy Conversion and Management, 2024, 321: 119068. |

| [31] | Wang B, Wang H R, Gao Y F, et al. Theoretical analysis of entropy generation in multilayer insulations: a case study of performance optimization of variable density multilayer insulations for liquid hydrogen storage systems[J]. International Journal of Hydrogen Energy, 2024, 85: 175-190. |

| [32] | Bell I H, Wronski J, Quoilin S, et al. Pure and pseudo-pure fluid thermophysical property evaluation and the open-source thermophysical property library CoolProp[J]. Industrial & Engineering Chemistry Research, 2014, 53(6): 2498-2508. |

| [33] | Hastings L J, Hedayat A, Brown T M. Analytical modeling and test correlation of variable density multilayer insulation for cryogenic storage[R]. NASA/TM–2004–213175, 2004. |

| [34] | Hastings L J, Martin J J. Experimental testing of a foam/multilayer insulation (FMLI) thermal control system (TCS) for use on a cryogenic upper stage[J]. AIP Conference Proceedings, 1998, 420(1): 331-341. |

| [35] | Bolshinskiy L, Hedayat A, Hastings L J, et al. Tank system integrated model: a cryogenic tank performance prediction program[R]. NASA/TM–2017–218239, 2017. |

| [36] | Hastings L J, Flachbart R H, MartíN J J, et al. Spray Bar Zero-Gravity Vent System for On-Orbit Liquid Hydrogen Storage[R]. NASA/TM-2003-212926, 2003. |

| [37] | Wang H R, Wang B, Pan Q W, et al. Modeling and thermodynamic analysis of thermal performance in self-pressurized liquid hydrogen tanks[J]. International Journal of Hydrogen Energy, 2022, 47(71): 30530-30545. |

| [38] | Van Dresar N, Lin C, Hasan M. Self-pressurization of a flightweight liquid hydrogen tank - Effectsof fill level at low wall heat flux [M]. 30th Aerospace Sciences Meeting and Exhibit. American Institute of Aeronautics and Astronautics. 1992. |

| [1] | 李科, 谢昊琳, 文键. 耦合多重蒸气冷却屏的液氢储罐绝热性能的多目标遗传算法优化[J]. 化工学报, 2025, 76(8): 4217-4227. |

| [2] | 郭梁, 陈烨, 贾启明, 谢秀娟. 液氦贮罐的自增压理论模拟及实验研究[J]. 化工学报, 2025, 76(7): 3561-3571. |

| [3] | 王舜浩, 朱文俐, 胡正根, 周芮, 余柳, 王彬, 张小斌. 液氢缩比贮箱蒸发特性数值模拟及实验验证[J]. 化工学报, 2019, 70(3): 840-849. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号