CIESC Journal ›› 2025, Vol. 76 ›› Issue (8): 4165-4176.DOI: 10.11949/0438-1157.20250039

• Surface and interface engineering • Previous Articles Next Articles

Mengjiao WANG( ), Kaixue HU, Xiangkai MENG, Jinbo JIANG, Xudong PENG(

), Kaixue HU, Xiangkai MENG, Jinbo JIANG, Xudong PENG( )

)

Received:2025-01-10

Revised:2025-02-12

Online:2025-09-17

Published:2025-08-25

Contact:

Xudong PENG

通讯作者:

彭旭东

作者简介:王梦娇(1992—),女,博士,讲师,mjwangzj@163.com

基金资助:CLC Number:

Mengjiao WANG, Kaixue HU, Xiangkai MENG, Jinbo JIANG, Xudong PENG. Influence of micro-texture size and areal density on surface of silicon carbide on tribological properties of sliding sealing surfaces[J]. CIESC Journal, 2025, 76(8): 4165-4176.

王梦娇, 胡凯学, 孟祥铠, 江锦波, 彭旭东. 碳化硅表面微织构尺寸和面密度对滑动密封面摩擦学性能的影响[J]. 化工学报, 2025, 76(8): 4165-4176.

Add to citation manager EndNote|Ris|BibTeX

| 技术参数 | 数值 |

|---|---|

| 密度/(g/cm3) | >3.10 |

| 热导率/(W/(m·K)) | 110 |

| 弹性模量/GPa | 400 |

| 弯曲强度/MPa | 400 |

| 硬度/HS | 115 |

| 粗糙度Ra/μm | 0.15 |

| 泊松比ν | 0.14 |

Table 1 Performance parameter of SiC substrate

| 技术参数 | 数值 |

|---|---|

| 密度/(g/cm3) | >3.10 |

| 热导率/(W/(m·K)) | 110 |

| 弹性模量/GPa | 400 |

| 弯曲强度/MPa | 400 |

| 硬度/HS | 115 |

| 粗糙度Ra/μm | 0.15 |

| 泊松比ν | 0.14 |

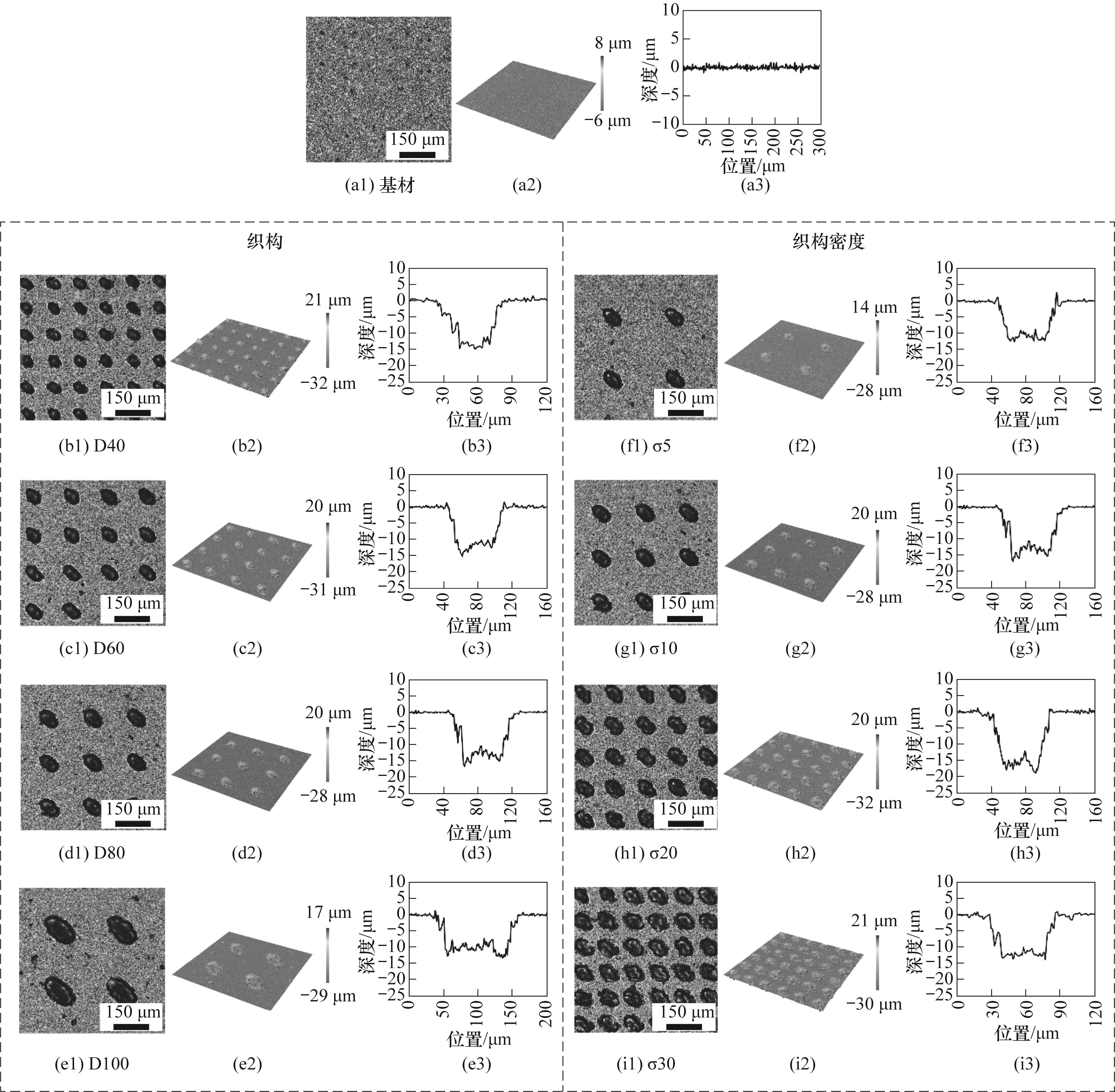

Fig.4 Optical microscopy images, 3D photographs and 2D contour maps of SiC substrates and 45° elliptical-textured SiC with different sizes and areal densities

Fig.6 Friction coefficient (a), average friction coefficient (b) and wear rate (c) of SiC substrates and 45° elliptical-textured SiC with different sizes

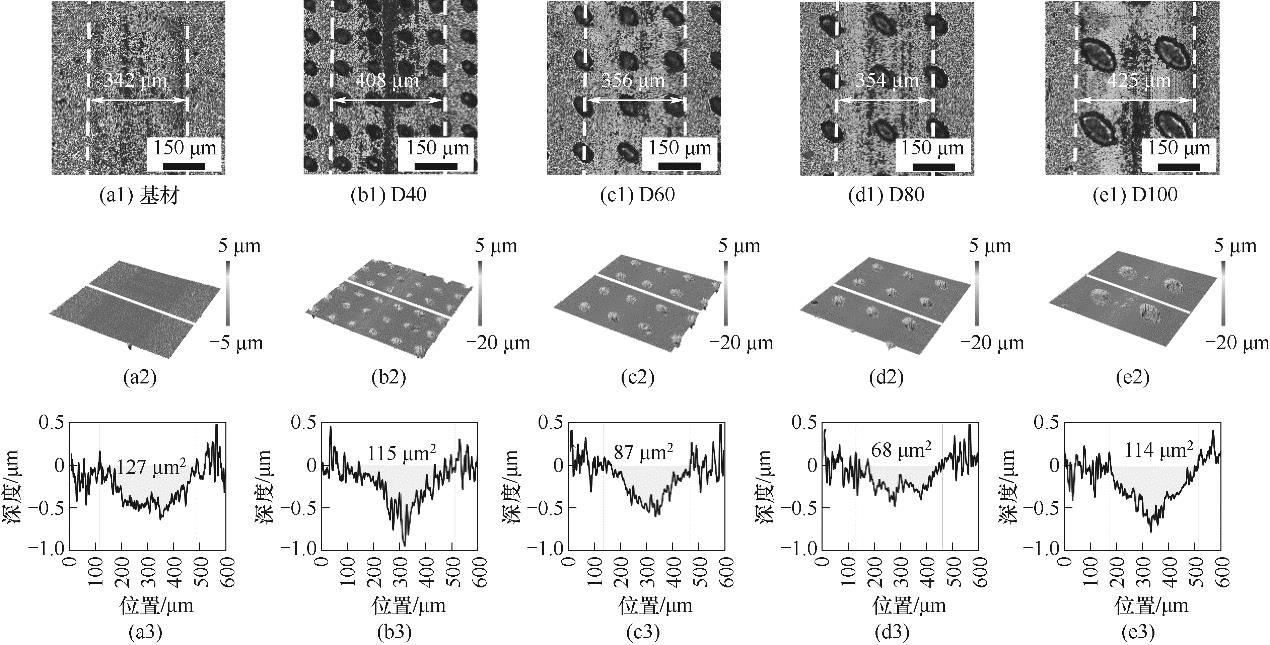

Fig.7 Optical microscopy images, 3D photographs, and 2D contour maps of the surface wear morphologies of SiC substrates and 45° elliptical-textured SiC with different sizes

Fig.9 Friction coefficient (a), average friction coefficient (b) and wear rate (c) of SiC substrates and 45° elliptical-textured SiC with different areal densities

Fig.10 Optical microscope images, 3D and 2D contour maps of surface wear morphologies of SiC substrates and 45° elliptical-textured SiC with different areal densities

| [1] | Zhang L X, Ding X X, Wang S P, et al. Research progress on the dynamic stability of dry gas seals[J]. Processes, 2024, 12(3): 575. |

| [2] | 江鹏, 江锦波, 彭旭东, 等. 传热模型对近临界工况CO2干气密封温压分布和稳态性能影响[J]. 化工学报, 2021, 72(8): 4239-4254. |

| Jiang P, Jiang J B, Peng X D, et al. Influence of heat transfer model on temperature and pressure distribution and steady state performance of CO2 dry gas seal under near critical condition[J]. CIESC Journal, 2021, 72(8): 4239-4254. | |

| [3] | 柴杨洋, 彭旭东, 江锦波, 等. 浸锑石墨与无压烧结SiC和3D打印SiC密封材料配对副的摩擦磨损特性研究[J]. 化工学报, 2024, 75(5): 1966-1976. |

| Chai Y Y, Peng X D, Jiang J B, et al. Study on friction and wear behaviors of antimony impregnated graphite with pressureless sintered SiC and 3D-printed SiC sealing materials pairs[J]. CIESC Journal, 2024, 75(5): 1966-1976. | |

| [4] | Fan W J, Huang W F, Liu Y, et al. State evolution of dry gas seal during repeated start-stop operation using acoustic emission method[J]. Tribology Transactions, 2020, 63(1): 173-181. |

| [5] | 马宏军. 长输管线压缩机Burgmann干气密封国内维修技术探讨[J]. 油气田地面工程, 2019, 38(7): 60-66. |

| Ma H J. Domestic repair technology discussion on Burgmann dry gas seal used for the long distance transportation pipeline compressor[J]. Oil-Gas Field Surface Engineering, 2019, 38(7): 60-66. | |

| [6] | 李敦钫. 碳化硅和氧化铝基陶瓷材料的摩擦磨损特性研究[D]. 昆明: 昆明理工大学, 2003. |

| Li D F. Study on friction and wear characteristics of silicon carbide and alumina-based ceramic materials[D]. Kunming: Kunming University of Science and Technology, 2003. | |

| [7] | Dorkar N V, Kim Y W, Venkata Manoj Kumar B. Role of hBN content, humidity, and temperature on the sliding wear behaviour of SiC ceramics[J]. Journal of the European Ceramic Society, 2023, 43(16): 7282-7295. |

| [8] | 赵文静, 屠治荣, 孟祥铠, 等. 非规则V形表面织构化机械端面密封性能研究[J]. 化工学报, 2022, 73(10): 4585-4593. |

| Zhao W J, Tu Z R, Meng X K, et al. Effect of irregular V-shaped surface texture on the performance of mechanical face seal[J]. CIESC Journal, 2022, 73(10): 4585-4593. | |

| [9] | 马文林, 未亮亮. 微织构对铜基自润滑复合材料摩擦磨损性能的影响[J]. 表面技术, 2023, 52(1): 93-102. |

| Ma W L, Wei L L. Effect of micro-texture on the friction and wear performance of copper-based self-lubricating composites[J]. Surface Technology, 2023, 52(1): 93-102. | |

| [10] | Zhang K D, Deng J X, Ding Z L, et al. Improving dry machining performance of TiAlN hard-coated tools through combined technology of femtosecond laser-textures and WS2 soft—coatings[J]. Journal of Manufacturing Processes, 2017, 30: 492-501. |

| [11] | Rosenkranz A, Costa H L, Baykara M Z, et al. Synergetic effects of surface texturing and solid lubricants to tailor friction and wear — a review[J]. Tribology International, 2021, 155: 106792. |

| [12] | Arslan A, Masjuki H H, Varman M, et al. Effects of texture diameter and depth on the tribological performance of DLC coating under lubricated sliding condition[J]. Applied Surface Science, 2015, 356: 1135-1149. |

| [13] | 黄云磊, 钟林, 王国荣, 等. 表面织构润滑减摩的国内外研究现状及进展[J]. 表面技术, 2021, 50(12): 217-232. |

| Huang Y L, Zhong L, Wang G R, et al. Research status and progress of surface texture lubrication and friction reduction[J]. Surface Technology, 2021, 50(12): 217-232. | |

| [14] | Segu D Z, Choi S G, Choi J H, et al. The effect of multi-scale laser textured surface on lubrication regime[J]. Applied Surface Science, 2013, 270: 58-63. |

| [15] | 赵立新, 章宝玲, 刘洋, 等. 基于表面织构技术改善摩擦学性能的研究进展[J]. 摩擦学学报, 2022, 42(1): 202-224. |

| Zhao L X, Zhang B L, Liu Y, et al. State of the art for improving tribological performance based on of surface texturing technology[J]. Tribology, 2022, 42(1): 202-224. | |

| [16] | Zhu C X, Wang X Y, Ma W B. Experimental study on the wear characteristics of textured joint surfaces under bionic lubrication[J]. Key Engineering Materials, 2023, 945: 19-25. |

| [17] | 于海武, 袁思欢, 孙造, 等. 微凹坑形状对试件表面摩擦特性的影响[J]. 华南理工大学学报(自然科学版), 2011, 39(1): 106-110, 123. |

| Yu H W, Yuan S H, Sun Z, et al. Effect of micro-dimple shapes on tribological properties of specimen surfaces[J]. Journal of South China University of Technology (Natural Science Edition), 2011, 39(1): 106-110, 123. | |

| [18] | 彭旭东, 佘宝瑛, 孟祥铠, 等. 不同排布方向性椭圆孔液体润滑机械密封性能的研究[J]. 摩擦学学报, 2013, 33(5): 481-487. |

| Peng X D, She B Y, Meng X K, et al. Sealing performance of liquid-lubricated mechanical seals with different arrangements inclined elliptical dimples[J]. Tribology, 2013, 33(5): 481-487. | |

| [19] | 刘凯. 干气密封双端面织构的摩擦磨损与密封性能[D]. 济南: 山东大学, 2022. |

| Liu K. Friction, wear and sealing performance of double-end texture of dry gas seal[D]. Jinan: Shandong University, 2022. | |

| [20] | 王丽丽, 张伟, 赵兴堂, 等. 微织构尺寸对轴承摩擦磨损性能的影响[J]. 摩擦学学报, 2021, 41(5): 723-730. |

| Wang L L, Zhang W, Zhao X T, et al. Effect of micro-texture size on friction and wear performance of journal bearing[J]. Tribology, 2021, 41(5): 723-730. | |

| [21] | Panigrahi D K, Sarangi M. Tribological performance of positive deterministic textured surfaces in parallel sliding lubricated contacts: effect of texture size and height[J]. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, 2020, 234(12): 1908-1925. |

| [22] | Janssen A, Pinedo B, Igartua A, et al. Study on friction and wear reducing surface micro-structures for a positive displacement pump handling highly abrasive shale oil[J]. Tribology International, 2017, 107: 1-9. |

| [23] | 杨程, 彭迎娇, 刘思琪, 等. 表面圆形凹坑微织构对DC53模具钢的摩擦学性能影响[J]. 塑性工程学报, 2024, 31(2): 208-217. |

| Yang C, Peng Y J, Liu S Q, et al. Influence of surface circular pit micro-texture on tribological properties of DC53 die steel[J]. Journal of Plasticity Engineering, 2024, 31(2): 208-217. | |

| [24] | 杨洋, 龙伟民, 程战, 等. 仿生六边形织构对40Cr钢摩擦学性能的影响[J]. 金属热处理, 2023, 48(12): 250-254. |

| Yang Y, Long W M, Cheng Z, et al. Effect of bionic hexagonal texture on tribological properties of 40Cr steel[J]. Heat Treatment of Metals, 2023, 48(12): 250-254. | |

| [25] | Zou H B, Yan S, Shen T, et al. Efficiency of surface texturing in the reducing of wear for tests starting with initial point contact[J]. Wear, 2021, 482: 203957. |

| [26] | Xing Y Q, Deng J X, Feng X T, et al. Effect of laser surface texturing on Si3N4/TiC ceramic sliding against steel under dry friction[J]. Materials & Design, 2013, 52: 234-245. |

| [27] | 周跃杰, 彭旭东, 江锦波, 等. 端面宽度对机械密封极限pc v(pressure × velocity)值的影响[J]. 摩擦学学报, 2022, 42(1): 176-186. |

| Zhou Y J, Peng X D, Jiang J B, et al. Effects of end face width of mechanical seals on the limit pc v(pressure × velocity) value[J]. Tribology, 2022, 42(1): 176-186. | |

| [28] | 邓雯, 赵晓琴, 李双建, 等. Al2O3/MoS2复合涂层的制备及摩擦磨损性能[J]. 中国表面工程, 2017, 30(5): 110-118. |

| Deng W, Zhao X Q, Li S J, et al. Preparation and tribological properties of Al2O3/MoS2 composite coating[J]. China Surface Engineering, 2017, 30(5): 110-118. | |

| [29] | 张力, 朱传军, 吴剑钊, 等. 激光淬火化表面织构对盾构滚刀特种钢摩擦磨损性能影响的研究[J]. 热加工工艺, 2023, 52(22): 24-28. |

| Zhang L, Zhu C J, Wu J Z, et al. Effect of laser quenched surface texture on friction and wear properties of shield hob special steel[J]. Hot Working Technology, 2023, 52(22): 24-28. | |

| [30] | 孙建芳, 李傲松, 苏峰华, 等. 表面织构钛合金的干摩擦和全氟聚醚油润滑下的摩擦学性能研究[J]. 摩擦学学报, 2018, 38(6): 658-664. |

| Sun J F, Li A S, Su F H, et al. Tribological property of titanium alloy surface with different texture structure under dry friction and perfluoropolyether lubrication[J]. Tribology, 2018, 38(6): 658-664. | |

| [31] | 吴高灿. 复合涂层表面织构化刀具微量润滑切削钛合金试验研究[D]. 湘潭: 湘潭大学, 2021. |

| Wu G C. Experimental study on micro-lubrication cutting of titanium alloy with textured tool on composite coating surface[D]. Xiangtan: Xiangtan University, 2021. | |

| [32] | 何霞, 廖文玲, 王国荣, 等. 织构边缘凸起对压裂泵柱塞密封副摩擦性能的影响[J]. 润滑与密封, 2016, 41(7): 96-101. |

| He X, Liao W L, Wang G R, et al. Influence of edges bulgeof texture on tribological performances of plunger-seal pair in fracturing pump[J]. Lubrication Engineering, 2016, 41(7): 96-101. | |

| [33] | 黄志强, 熊辰, 钱韦吉, 等. 采油液力马达转子表面织构参数对其摩擦副摩擦学性能的影响[J]. 表面技术, 2022, 51(2): 176-184, 231. |

| Huang Z Q, Xiong C, Qian W J, et al. The effect of surface texture parameters of the rotor surface texture of oil production hydraulic motor on the tribological performance of the friction pair[J]. Surface Technology, 2022, 51(2): 176-184, 231. | |

| [34] | 解长鹏, 刘国东, 刘祁文, 等. 沟槽微织构硬质合金刀具的摩擦仿真分析[J]. 工具技术, 2022, 56(2): 43-47. |

| Xie C P, Liu G D, Liu Q W, et al. Attrition simulation analysis of carbide tool with groove microtexture[J]. Tool Engineering, 2022, 56(2): 43-47. |

| [1] | Jinbo JIANG, Zhuxin CHEN, Yangyi XIAO, Xin PENG, Yuan CHEN, Chen YU, Xiangkai MENG, Xudong PENG. Study on influence of operating conditions on thermodynamic process and steady state performance of supercritical CO2 dry gas seal [J]. CIESC Journal, 2025, 76(6): 2913-2928. |

| [2] | Yangyang CHAI, Xudong PENG, Jinbo JIANG, Xiangkai MENG, Yi MA. Study on friction and wear behaviors of antimony impregnated graphite with pressureless sintered SiC and 3D-printed SiC sealing materials pairs [J]. CIESC Journal, 2024, 75(5): 1966-1976. |

| [3] | Zhi ZHU, Hengjie XU, Wei CHEN, Wenyuan MAO, Qiangguo DENG, Xuejian SUN. Study on critical chocked characteristics of supercritical carbon dioxide spiral groove dry gas seal under thermal-fluid coupling lubrication [J]. CIESC Journal, 2024, 75(2): 604-615. |

| [4] | Junhua DING, Shurong YU, Shipeng WANG, Xianzhi HONG, Xin BAO, Xuexing DING. Flow simulation and sealing performance test of ultra-high speed dry gas seal under multiple effects [J]. CIESC Journal, 2023, 74(5): 2088-2099. |

| [5] | Ruqi YAN, Xuexing DING, Jie XU, Xianzhi HONG, Xin BAO. Flow field and steady performance of supercritical carbon dioxide dry gas seal based on turbulence model [J]. CIESC Journal, 2021, 72(8): 4292-4303. |

| [6] | Peng JIANG, Jinbo JIANG, Xudong PENG, Xiangkai MENG, Yi MA. Influence of heat transfer model on temperature and pressure distribution and steady state performance of CO2 dry gas seal under near critical condition [J]. CIESC Journal, 2021, 72(8): 4239-4254. |

| [7] | Xuejian SUN, Pengyun SONG, Wenyuan MAO, Qiangguo DENG, Hengjie XU, Wei CHEN. Dynamic contact analysis of dry gas seal during start-stop process considering material properties and surface topography of seal rings [J]. CIESC Journal, 2021, 72(8): 4279-4291. |

| [8] | JIANG Jinbo, TENG Liming, MENG Xiangkai, LI Jiyun, PENG Xudong. Dynamic characteristics of supercritical CO2 dry gas seal based on multi variables perturbation [J]. CIESC Journal, 2021, 72(4): 2190-2202. |

| [9] | SHANG Hao, CHEN Yuan, LI Xiaolu, WANG Bingqing, LI Yuntang, PENG Xudong. Study on the influence of nonlinear effect on performance of dry gas seal under film thickness disturbance [J]. CIESC Journal, 2021, 72(4): 2213-2222. |

| [10] | ZHOU Jian, JIANG Qian, YANG Yi, FENG Shasha, ZHONG Zhaoxiang, XING Weihong. Effect of sintering additives on properties of silicon carbide porous ceramics prepared at low temperature [J]. CIESC Journal, 2021, 72(4): 2293-2299. |

| [11] | Chen YU,Jinbo JIANG,Wenjing ZHAO,Jiyun LI,Xudong PENG,Yuming WANG. Geometrical model of surface groove based on micro-segment combination for dry gas seal and its parameter influence [J]. CIESC Journal, 2021, 72(10): 5294-5309. |

| [12] | Ruqi YAN, Xianzhi HONG, Xin BAO, Jie XU, Xuexing DING. Phase-distribution regularity and sealing performance of supercritical carbon dioxide dry gas seal [J]. CIESC Journal, 2020, 71(8): 3681-3690. |

| [13] | Yu FAN, Pengyun SONG, Hengjie XU. Study on startup operation of dry gas seal with steam lubrication [J]. CIESC Journal, 2020, 71(8): 3671-3680. |

| [14] | Wei CHEN, Pengyun SONG, Hengjie XU, Xuejian SUN. Effects of the real-gas characteristics of carbon dioxide with impurities on the dry gas seal performance [J]. CIESC Journal, 2020, 71(5): 2215-2229. |

| [15] | Zhenzhen MENG, Zhihong WU, Xinwei LIU, Yao WANG, Haikang ZHENG, Yubin WANG. Study on absorbing properties of bamboo-like silicon carbide whiskers [J]. CIESC Journal, 2020, 71(4): 1889-1897. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||