化工学报 ›› 2023, Vol. 74 ›› Issue (6): 2555-2564.DOI: 10.11949/0438-1157.20230173

赵志萍( ), 陈晨, 汤琼(

), 陈晨, 汤琼( ), 徐红, 刘雷(

), 徐红, 刘雷( ), 董晋湘

), 董晋湘

收稿日期:2023-02-27

修回日期:2023-05-05

出版日期:2023-06-05

发布日期:2023-07-27

通讯作者:

汤琼,刘雷

作者简介:赵志萍(2000—),女,硕士研究生,zhaozhiping1005@163.com

基金资助:

Zhiping ZHAO( ), Chen CHEN, Qiong TANG(

), Chen CHEN, Qiong TANG( ), Hong XU, Lei LIU(

), Hong XU, Lei LIU( ), Jinxiang DONG

), Jinxiang DONG

Received:2023-02-27

Revised:2023-05-05

Online:2023-06-05

Published:2023-07-27

Contact:

Qiong TANG, Lei LIU

摘要:

离子液体(Et3NHCl-AlCl3)催化1-己烯和萘合成了多己基萘基础油,以聚α-烯烃(PAO8)基础油制备的锂基润滑脂作为参照,通过调节基础油中多己基萘与PAO8的复配比(10∶90、20∶80、30∶70和40∶60)制备了不同皂分含量的锂基润滑脂。对不同润滑脂样品的理化性能进行测试表征,利用流变仪和SRV-V摩擦磨损试验机系统地评价了加入的多己基萘对锂基润滑脂的流变学和摩擦学性能的影响,并借助3D白光干涉仪对钢盘磨损表面进行了分析。实验结果表明:基础油中多己基萘与PAO8复配质量比为20∶80时具有良好的协同效应,添加多己基萘可以显著提高PAO8基础油的稠化能力,节约稠化剂的用量,同时在较高温度(85℃)的工况下,多己基萘可以提高PAO8锂基润滑脂的流变和摩擦学性能。

中图分类号:

赵志萍, 陈晨, 汤琼, 徐红, 刘雷, 董晋湘. 多己基萘/聚α-烯烃锂基润滑脂的流变学和摩擦学性能[J]. 化工学报, 2023, 74(6): 2555-2564.

Zhiping ZHAO, Chen CHEN, Qiong TANG, Hong XU, Lei LIU, Jinxiang DONG. Rheological and tribological properties of poly-hexylnaphthalene/ poly-α-olefin lithium grease[J]. CIESC Journal, 2023, 74(6): 2555-2564.

| 润滑脂 | 氧化起始温度/℃ | |

|---|---|---|

| 8% | 10% | |

| PAO8 | 281.8 | 288.1 |

| PHN10 | 290.0 | 288.4 |

| PHN20 | 292.4 | 291.2 |

| PHN30 | 297.3 | 298.8 |

| PHN40 | 319.0 | 323.1 |

表1 不同皂分下(8%、10%)润滑脂样品的氧化起始温度

Table 1 The oxidation onset temperature of grease samples with different soap contents (8%,10%)

| 润滑脂 | 氧化起始温度/℃ | |

|---|---|---|

| 8% | 10% | |

| PAO8 | 281.8 | 288.1 |

| PHN10 | 290.0 | 288.4 |

| PHN20 | 292.4 | 291.2 |

| PHN30 | 297.3 | 298.8 |

| PHN40 | 319.0 | 323.1 |

图7 以PAO8、PHN20和PHN40为基础油制备的锂基脂在85、105℃下的摩擦曲线和平均摩擦因数

Fig.7 Friction curves and average friction coefficient of lithium grease prepared from PAO8, PHN20 and PHN40 as base oil at 85℃ and 105℃

图9 85℃下以PAO8、PHN20、PHN40为基础油制备的锂基脂润滑的钢盘的3D白光图和磨痕轮廓图

Fig.9 3D images and profiles of wear scar of steel disc lubricated by different lithium grease prepared with PAO8,PHN20 andPHN40 as base oil at 85℃

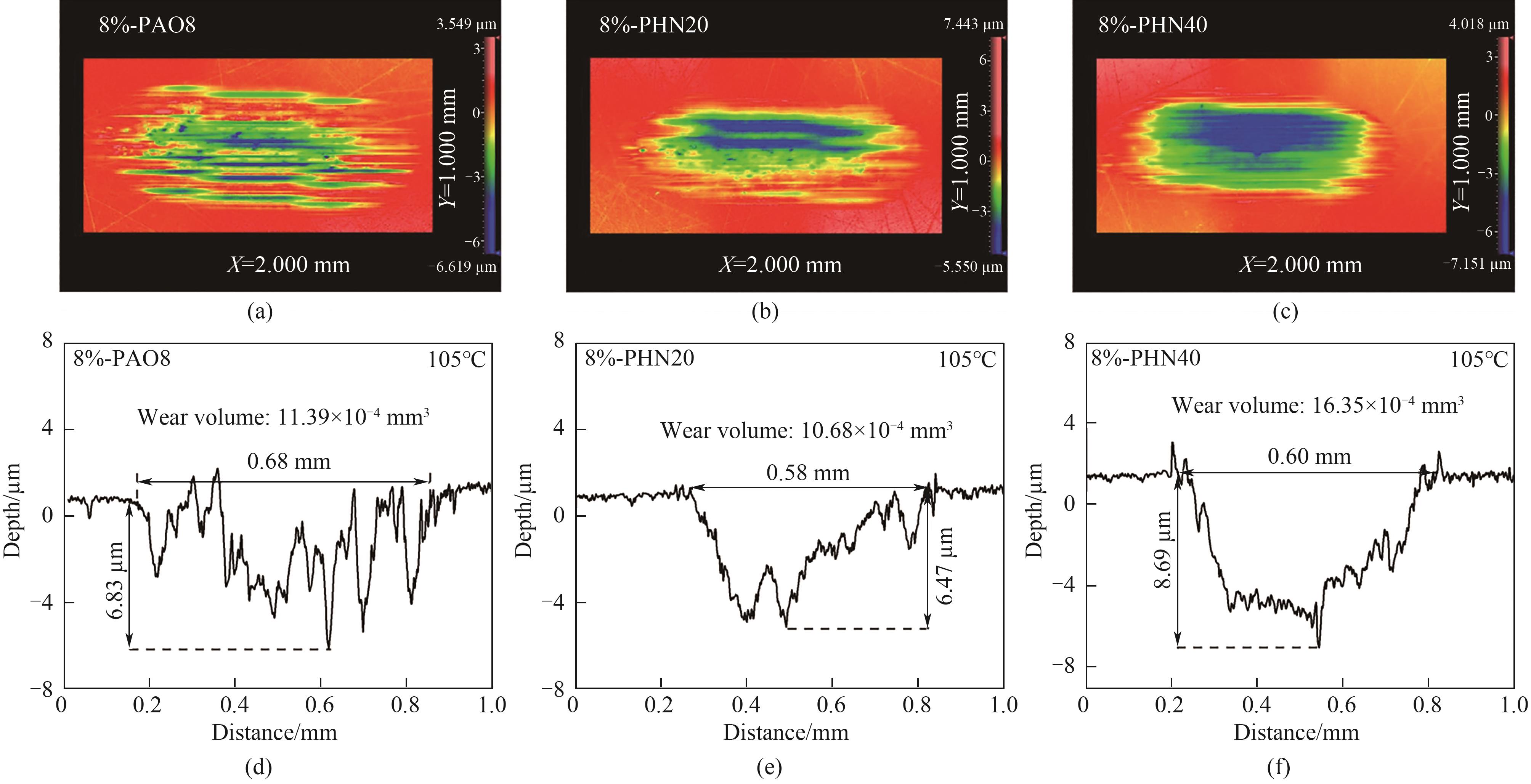

图10 105℃下以PAO8、PHN20、PHN40为基础油制备的锂基脂润滑的钢盘的3D白光图和磨痕轮廓图

Fig.10 3D images and profiles of wear scar of steel disc lubricated by different lithium grease prepared with PAO8,PHN20 andPHN40 as base oil at 105℃

| 1 | Holmberg K, Erdemir A. Global impact of friction on energy consumption, economy and environment[J]. FME Transactions, 2015, 43(3): 181-185. |

| 2 | Cai M R, Guo R S, Zhou F, et al. Lubricating a bright future: lubrication contribution to energy saving and low carbon emission[J]. Science China Technological Sciences, 2013, 56(12): 2888-2913. |

| 3 | Farré-Lladós J, Westerberg L G, Casals-Terré J, et al. On the flow dynamics of polymer greases[J]. Lubricants, 2022, 10(4): 66. |

| 4 | 曾晖, 李少飞, 刘涛, 等. 功能性润滑脂的开发进展[J]. 化工学报, 2015, 66(8): 2878-2887. |

| Zeng H, Li S F, Liu T, et al. Functional lubricating materials-engineering research and development progress of lubricating grease[J]. CIESC Journal, 2015, 66(8): 2878-2887. | |

| 5 | Pan J B, Cheng Y H, Yang J Y. Effect of heat treatment on the lubricating properties of lithium lubricating grease[J]. RSC Advances, 2015, 5(72): 58686-58693. |

| 6 | Ren G L, Li W, Li H, et al. Regulating performance characteristics of lithium complex greases via dibasic acids[J]. Lubrication Science, 2020, 32(6): 261-272. |

| 7 | Wu C, Yang K, Chen Y, et al. Investigation of friction and vibration performance of lithium complex grease containing nano-particles on rolling bearing[J]. Tribology International, 2021, 155: 106761. |

| 8 | He Q, Wang Z G, Li A, et al. Tribological properties of nanometer Al2O3 and nanometer ZnO as additives in lithium-based grease[J]. Industrial Lubrication and Tribology, 2018, 70(6): 953-960. |

| 9 | Zhang J, Li J T, Wang A L, et al. Improvement of the tribological properties of a lithium-based grease by addition of graphene[J]. Journal of Nanoscience and Nanotechnology, 2018, 18(10): 7163-7169. |

| 10 | Wang Z Y, Chang J, Cai C. Tribological performance of phosphonium ionic liquids as additives in lithium lubricating grease[J]. Lubricants, 2018, 6(1): 23. |

| 11 | Fan X Q, Li W, Li H, et al. Probing the effect of thickener on tribological properties of lubricating greases[J]. Tribology International, 2018, 118: 128-139. |

| 12 | Hao H, Liu Z W, Zhao F Q, et al. Material flow analysis of lithium in China[J]. Resources Policy, 2017, 51: 100-106. |

| 13 | Jiang H B, Xu X L, Hong X Z, et al. Preparation of high viscosity PAO from mixed alpha-olefins over metallocene catalyst[J]. China Petroleum Processing & Petrochemical Technology, 2018, 20(2): 90-96. |

| 14 | Hanifpour A, Bahri-Laleh N, Mohebbi A, et al. Oligomerization of higher α-olefins to poly(α-olefins)[J]. Iranian Polymer Journal, 2022, 31(1): 107-126. |

| 15 | Gajewski J B, Głogowski M J. Anti-wear additive content in fully synthetic PAO and PAG base oils and its effect on electrostatic and tribological phenomena in a rotating shaft-oil-lip seal system[J]. Journal of Physics: Conference Series, 2013, 418: 012045. |

| 16 | Porfiryev Y, Shuvalov S, Popov P, et al. Effect of base oil nature on the operational properties of low-temperature greases[J]. ACS Omega, 2020, 5(21): 11946-11954. |

| 17 | de Laurentis N, Cann P, Lugt P M, et al. The influence of base oil properties on the friction behaviour of lithium greases in rolling/sliding concentrated contacts[J]. Tribology Letters, 2017, 65(4): 128. |

| 18 | Zhang E H, Li W M, Zhao G Q, et al. A study on microstructure, friction and rheology of four lithium greases formulated with four different base oils[J]. Tribology Letters, 2021, 69(3): 1-9. |

| 19 | Chen C, Liu Y J, Tang Q, et al. Tribological and rheological performance of lithium grease with poly-α-olefin and alkyl-tetralin as base oils[J]. Chinese Journal of Chemical Engineering, 2023, 56: 180-192. |

| 20 | Hourani M J, Hessell T, Abramshe R A, et al. Alkylated naphthalenes as high-performance synthetic lubricating fluids[J]. Tribology Transactions, 2007, 50(1): 82-87. |

| 21 | Xu N, Wang X B, Ma R, et al. Insights into the rheological behaviors and tribological performances of lubricating grease: entangled structure of a fiber thickener and functional groups of a base oil[J]. New Journal of Chemistry, 2018, 42(2): 1484-1491. |

| 22 | Mazzo-Skalski S. Alkylated naphthalene basestocks advance high-performance lubricants[J]. Tribology & Lubrication Technology, 2009, 65(11): 38-40. |

| 23 | 刘谋, 罗勇, 刘勇, 等. 一种由烷基萘基础油制备的高温锂基润滑脂及其制备方法: 110283638A[P]. 2019-09-27. |

| Liu M, Luo Y, Liu Y, et al. High-temperature lithium base grease prepared from alkylnaphthalene base oil and preparation method of lithium base grease: 110283638A[P]. 2019-09-27. | |

| 24 | Belov P S, Grigor’eva E N, Nikonorov E M, et al. Alkylnaphthalenes as components of high-temperature lubricants[J]. Chemistry and Technology of Fuels and Oils, 1984, 20(4): 208-210. |

| 25 | Yang T, Wang F J, Huang J P, et al. Efficient continuous-flow synthesis of long-chain alkylated naphthalene catalyzed by ionic liquids in a microreaction system[J]. Reaction Chemistry & Engineering, 2021, 6(10): 1950-1960. |

| 26 | Li L, Zhao X R, Chen C, et al. Highly selective synthesis of polyalkylated naphthalenes catalyzed by ionic liquids and their tribological properties as lubricant base oil[J]. ChemistrySelect, 2019, 4(18): 5284-5290. |

| 27 | 韩路坤, 牛文星, 徐红, 等. 有机柱撑型层状硅铝酸钠的合成及摩擦学性能研究[J]. 润滑与密封, 2022, 47(2): 109-115. |

| Han L K, Niu W X, Xu H, et al. Synthesis and tribological properties of lamellar aluminosilicates-C18N+Me3 [J]. Lubrication Engineering, 2022, 47(2): 109-115. | |

| 28 | Paszkowski M. Assessment of the effect of temperature, shear rate and thickener content on the thixotropy of lithium lubricating greases[J]. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, 2013, 227(3): 209-219. |

| 29 | Wang Y S, Wu B J. Friction characteristics and mechanisms of two lithium greases in elastohydrodynamic lubrication[J]. Journal of Failure Analysis and Prevention, 2020, 20(4): 1266-1273. |

| 30 | Zhou W G, Huang L, Wang C F, et al. A study on the effects of temperature changes on the rheological properties of lithium lubricating grease and data processing[C]//Liang Q, Wang W, Liu X, et al. International Conference in Communications, Signal Processing, and Systems. Singapore: Springer, 2022: 514-522. |

| 31 | Delgado M A, Sánchez M C, Valencia C, et al. Relationship among microstructure, rheology and processing of a lithium lubricating grease[J]. Chemical Engineering Research and Design, 2005, 83(9): 1085-1092. |

| 32 | Delgado M A, Valencia C, Sánchez M C, et al. Influence of soap concentration and oil viscosity on the rheology and microstructure of lubricating greases[J]. Industrial & Engineering Chemistry Research, 2006, 45(6): 1902-1910. |

| 33 | Lin B, Rustamov I, Zhang L, et al. Graphene-reinforced lithium grease for antifriction and antiwear[J]. ACS Applied Nano Materials, 2020, 3(10): 10508-10521. |

| 34 | Fan M J, Ai J, Hu C H, et al. Naphthoate based lubricating oil with high oxidation stability and lubricity[J]. Tribology International, 2019, 138: 204-210. |

| 35 | Wang Y S, Zhang P, Lin J H, et al. Rheological and tribological properties of lithium grease and polyurea grease with different consistencies[J]. Coatings, 2022, 12(4): 527. |

| [1] | 崔敬泽, 汤琼, 陈晨, 刘宇婕, 徐红, 刘雷, 董晋湘. 高黏度烷基苊基础油的合成及润滑性能研究[J]. 化工学报, 2022, 73(8): 3659-3668. |

| [2] | 余磊, 戴康徐, 鲁浩, 方岩雄, 曹华, 韩利芬, 赵鸿斌, 李诗娟. 含氮杂环的酯或酰胺类衍生物的制备及其摩擦学性能[J]. 化工学报, 2018, 69(9): 4083-4089. |

| [3] | 黄莉. 石蜡/水相变乳液的制备与性能[J]. 化工学报, 2018, 69(4): 1749-1757. |

| [4] | 张姗姗, 赵建国, 张进, 邢宝岩, 钱瑞, 曹宇, 杨晓峰, 王宝俊. 褶皱石墨烯球对润滑油摩擦性能的影响[J]. 化工学报, 2018, 69(10): 4479-4485. |

| [5] | 公丕建, 王海彦, 唐海燕, 徐红彬, 张懿. 无硫磷三嗪杂环衍生物润滑油添加剂的制备及摩擦性能[J]. 化工学报, 2017, 68(4): 1702-1711. |

| [6] | 蒋果, 徐景活, 冯健, 黄汉雄, 张水洞. 聚碳酸亚丙酯/热塑性氧化淀粉的流变、形态和性能[J]. 化工学报, 2015, 66(7): 2718-2724. |

| [7] | 龙文宇1,李晓鸥1,李东胜1,刘宝柱2,石岩3. 大连石化润滑油基础油酸值不合格解决方案[J]. 化工进展, 2014, 33(08): 2219-2223. |

| [8] | 徐梓钧, 赵亮, 和望利, 李志浩, 钱锋. 基于收益共享契约的基础油供应链建模方法[J]. 化工学报, 2013, 64(12): 4454-4460. |

| [9] | 邓成业, 黄汉雄. 聚丙烯基高含量埃洛石纳米管复合材料的制备和性能[J]. 化工学报, 2013, 64(10): 3824-3830. |

| [10] | 武春林,张效胜,徐 红,董晋湘. N,N-双十二烷基乙二胺的合成及摩擦学性能[J]. 化工进展, 2013, 32(08): 1893-1897. |

| [11] | 苏磊静,丁雪佳,雷晓慧,何金迎,王林生,李熙然. 聚烯烃包覆石蜡相变材料的结构和初步热性能[J]. 化工进展, 2013, 32(04): 853-856. |

| [12] | 钱建华,阴翔宇,张月,许家胜. 二氧化钛微球合成、表面修饰及摩擦学性能[J]. 化工学报, 2012, 63(6): 1986-1991. |

| [13] | 文瑾, 李洁, 刘士军, 陈启元. 表面修饰纳米铜颗粒添加剂的摩擦学性能 [J]. 化工学报, 2011, 62(4): 1157-1161. |

| [14] | 晋 刚,赵新亮,雷玉才. 转矩流变仪表征熔融聚合物的流变性能 [J]. CIESC Journal, 2011, 30(2): 371-. |

| [15] | 张 雨,丁雪佳,郭甜甜,周克斌,韩海军,张丽娟. PC/PETG共混物熔体的流变性能[J]. CIESC Journal, 2011, 30(12): 2685-. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号