化工学报 ›› 2023, Vol. 74 ›› Issue (8): 3485-3493.DOI: 10.11949/0438-1157.20230726

倪文翔1,2( ), 赵京2(

), 赵京2( ), 李博2, 魏小林2, 吴东垠1, 刘迪1, 王强3

), 李博2, 魏小林2, 吴东垠1, 刘迪1, 王强3

收稿日期:2023-07-13

修回日期:2023-08-06

出版日期:2023-08-25

发布日期:2023-10-18

通讯作者:

赵京

作者简介:倪文翔(1999—),男,硕士研究生,ni190725@163.com

基金资助:

Wenxiang NI1,2( ), Jing ZHAO2(

), Jing ZHAO2( ), Bo LI2, Xiaolin WEI2, Dongyin WU1, Di LIU1, Qiang WANG3

), Bo LI2, Xiaolin WEI2, Dongyin WU1, Di LIU1, Qiang WANG3

Received:2023-07-13

Revised:2023-08-06

Online:2023-08-25

Published:2023-10-18

Contact:

Jing ZHAO

摘要:

转炉煤气全干法工艺能够将转炉煤汽经气化冷却烟道后显热资源进一步深度回收,然而,转炉煤气的多尘性引起余热锅炉积灰的问题正严重影响系统的长期稳定运行。基于一台100 t转炉实际运行过程锅炉的积灰情况,首先采用分子筛和颗粒物采集器(DLPI)分析了灰颗粒的粒径分布,然后通过XRD、XRF和SEM-EDS等表征手段详细分析了不同粒径灰颗粒的主要成分及占比情况,最后通过实验开展了灰颗粒的黏结特性研究。结果表明:全干法工艺中锅炉积灰颗粒粒径主要分布在0.3~3 μm和70~100 μm,主要成分为不同价态的铁氧化物。黏结实验表明:灰颗粒的粒径越小经烧结后的黏附强度越大,黏附强度会随着烧结时间延长显著升高,而且热冲击会减小灰颗粒的黏附强度。

中图分类号:

倪文翔, 赵京, 李博, 魏小林, 吴东垠, 刘迪, 王强. 转炉煤气全干法显热回收工艺中余热锅炉积灰特性研究[J]. 化工学报, 2023, 74(8): 3485-3493.

Wenxiang NI, Jing ZHAO, Bo LI, Xiaolin WEI, Dongyin WU, Di LIU, Qiang WANG. Study on waste heat boiler ash deposition characteristics in sensible heat recovery process of converter gas[J]. CIESC Journal, 2023, 74(8): 3485-3493.

| 氧化物 | 占比/% | 元素 | 占比/% | ||||

|---|---|---|---|---|---|---|---|

| 30~70 μm | 70~100 μm | 100 μm以上 | 30~70 μm | 70~100 μm | 100 μm以上 | ||

| Fe2O3 | 84.513 | 84.295 | 84.929 | Fe | 85.776 | 85.719 | 86.058 |

| CaO | 7.309 | 6.982 | 6.46 | Ca | 6.926 | 6.622 | 6.121 |

| MgO | 0.729 | 1.354 | 0.754 | K | 1.796 | 1.761 | 1.77 |

| SiO2 | 0.812 | 0.788 | 0.885 | Zn | 1.298 | 1.272 | 1.314 |

| MnO2 | 1.235 | 1.221 | 1.235 | Mn | 1.094 | 1.083 | 1.092 |

| K2O | 1.649 | 1.615 | 1.625 | Cl | 0.654 | 0.641 | 0.656 |

| ClO | 0.967 | 0.948 | 0.971 | Co | 0.551 | 0.534 | 0.587 |

| ZnO | 1.086 | 1.062 | 1.102 | Mg | 0.549 | 1.021 | 0.568 |

| P2O5 | 0.439 | 0.454 | 0.439 | Si | 0.479 | 0.465 | 0.521 |

| CoO | 0.472 | 0.456 | 0.504 | P | 0.243 | 0.252 | 0.243 |

| Al2O3 | 0.137 | 0.251 | 0.083 | Al | 0.091 | 0.166 | 0.055 |

| SO3 | 0.25 | 0.239 | 0.246 | S | 0.128 | 0.122 | 0.126 |

| 其他 | 0.402 | 0.335 | 0.767 | 其他 | 0.415 | 0.342 | 0.889 |

| 总计 | 100 | 100 | 100 | 总计 | 100 | 100 | 100 |

表1 样品的元素及氧化物分析

Table 1 Elemental and oxide analysis of samples

| 氧化物 | 占比/% | 元素 | 占比/% | ||||

|---|---|---|---|---|---|---|---|

| 30~70 μm | 70~100 μm | 100 μm以上 | 30~70 μm | 70~100 μm | 100 μm以上 | ||

| Fe2O3 | 84.513 | 84.295 | 84.929 | Fe | 85.776 | 85.719 | 86.058 |

| CaO | 7.309 | 6.982 | 6.46 | Ca | 6.926 | 6.622 | 6.121 |

| MgO | 0.729 | 1.354 | 0.754 | K | 1.796 | 1.761 | 1.77 |

| SiO2 | 0.812 | 0.788 | 0.885 | Zn | 1.298 | 1.272 | 1.314 |

| MnO2 | 1.235 | 1.221 | 1.235 | Mn | 1.094 | 1.083 | 1.092 |

| K2O | 1.649 | 1.615 | 1.625 | Cl | 0.654 | 0.641 | 0.656 |

| ClO | 0.967 | 0.948 | 0.971 | Co | 0.551 | 0.534 | 0.587 |

| ZnO | 1.086 | 1.062 | 1.102 | Mg | 0.549 | 1.021 | 0.568 |

| P2O5 | 0.439 | 0.454 | 0.439 | Si | 0.479 | 0.465 | 0.521 |

| CoO | 0.472 | 0.456 | 0.504 | P | 0.243 | 0.252 | 0.243 |

| Al2O3 | 0.137 | 0.251 | 0.083 | Al | 0.091 | 0.166 | 0.055 |

| SO3 | 0.25 | 0.239 | 0.246 | S | 0.128 | 0.122 | 0.126 |

| 其他 | 0.402 | 0.335 | 0.767 | 其他 | 0.415 | 0.342 | 0.889 |

| 总计 | 100 | 100 | 100 | 总计 | 100 | 100 | 100 |

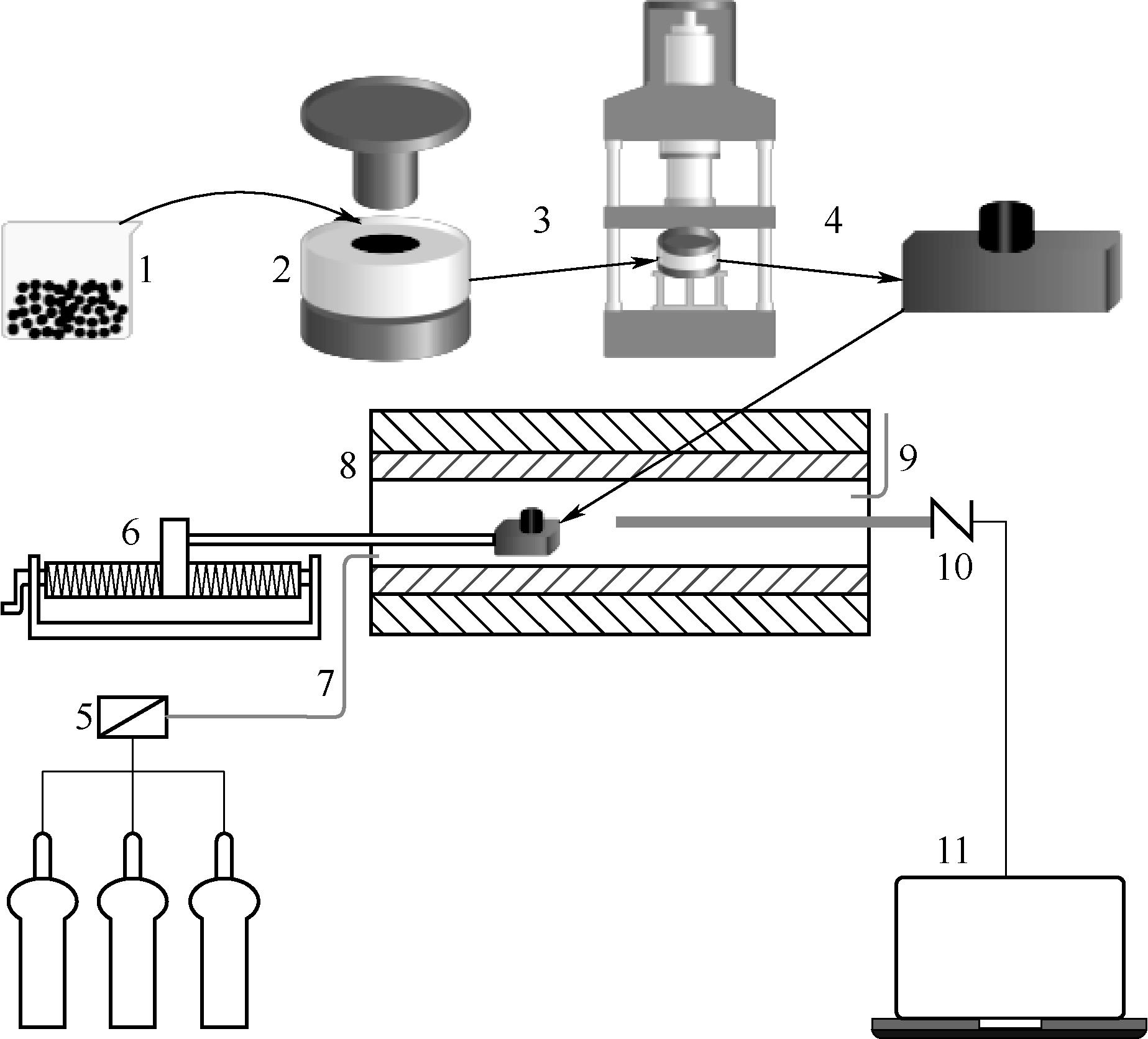

图2 黏附强度实验1—沉积灰样;2—模具;3—压力机;4—置物台;5—供气系统;6—手动摇杆;7—进气口;8—管式炉;9—出气口;10—测力计;11—计算机

Fig.2 Adhesion strength test1—deposited ash sample; 2—mould; 3—press machine; 4—floating shelf; 5—gas supply system; 6—rocker; 7—gas in; 8—tube furnace; 9—gas out; 10—forcemeter; 11—laptop

| 元素 | 质量/% | 原子/% |

|---|---|---|

| Mg | 1.46 | 3.19 |

| Si | 1.49 | 2.82 |

| P | 0.15 | 0.25 |

| S | 0.21 | 0.34 |

| Cl | 0.47 | 0.71 |

| K | 2.41 | 3.28 |

| Ca | 2.28 | 3.03 |

| Mn | 2.76 | 2.67 |

| Fe | 81.6 | 77.7 |

| Co | 1.75 | 1.58 |

| Zn | 5.42 | 4.41 |

| 总计 | 100 | 100 |

表2 PM1灰样主要元素占比SEM-EDS结果

Table 2 SEM-EDS results of the proportion of main elements in PM1 ash deposition

| 元素 | 质量/% | 原子/% |

|---|---|---|

| Mg | 1.46 | 3.19 |

| Si | 1.49 | 2.82 |

| P | 0.15 | 0.25 |

| S | 0.21 | 0.34 |

| Cl | 0.47 | 0.71 |

| K | 2.41 | 3.28 |

| Ca | 2.28 | 3.03 |

| Mn | 2.76 | 2.67 |

| Fe | 81.6 | 77.7 |

| Co | 1.75 | 1.58 |

| Zn | 5.42 | 4.41 |

| 总计 | 100 | 100 |

| 1 | 王海风, 平晓东, 周继程, 等. 中国钢铁工业绿色发展回顾及展望[J]. 钢铁, 2023, 58(2): 8-18. |

| Wang H F, Ping X D, Zhou J C, et al. Review and prospect of green development of iron and steel industry in China[J]. Iron & Steel, 2023, 58(2): 8-18. | |

| 2 | Zhou J N, Jiang X K, Xie J B, et al. Thermodynamic analysis of improvement of converter gas by injecting pulverized coal into vaporization cooling flue[J]. Journal of Iron and Steel Research International, 2018, 25(1): 65-71. |

| 3 | 张福明, 张德国, 张凌义, 等. 大型转炉煤气干法除尘技术研究与应用[J]. 钢铁, 2013, 48(2): 1-9, 43. |

| Zhang F M, Zhang D G, Zhang L Y, et al. Research and application on large BOF gas dry dedusting technology[J]. Iron & Steel, 2013, 48(2): 1-9, 43. | |

| 4 | 魏小林, 余立新, 陈恩鉴, 等. 炼钢转炉煤气干法回收及其显热发电系统: 101245400B[P]. 2010-07-21. |

| Wei X L, Yu L X, Chen E J, et al. Dry recovery of gas from steel converter and its sensible heat power generation system: 101245400B[P]. 2010-07-21. | |

| 5 | 黄成永, 汤先岗, 魏传岱, 等. 转炉炼钢一次除尘蒸发冷却器严重积灰问题及解决方案[J]. 环境工程, 2019, 37(5): 146-149. |

| Huang C Y, Tang X G, Wei C D, et al. Serious dust accumulation problem and its solution of primary dust removal evaporation cooler for converter steelmaking[J]. Environmental Engineering, 2019, 37(5): 146-149. | |

| 6 | 李森. 冶金炉炉气和烟气的发生、流动和反应过程研究[D]. 北京: 中国科学院力学所研究所, 2010. |

| Li S. Study on the generation, flow and reaction process of furnace gas and flue gas in metallurgical furnace[D]. Beijing: Institute of Mechanics, Chinese Academy of Sciences, 2010. | |

| 7 | 于恒, 黄细聪, 李科, 等. 钢铁企业除尘灰综合利用现状与展望[J]. 矿产保护与利用, 2021, 41(4): 164-171. |

| Yu H, Huang X C, Li K, et al. Present situation and prospect of comprehensive utilization of precipitator dust in iron and steel enterprises[J]. Conservation and Utilization of Mineral Resources, 2021, 41(4): 164-171. | |

| 8 | Nedar L. Dust formation in a BOF converter[J]. Steel Research, 1996, 67(8): 320-327. |

| 9 | Lv M, Li H, Lin T C, et al. Behavior of gas-slag-metal emulsion with nozzle-twisted lance in converter steelmaking process[J]. Steel Research International, 2021, 92(10): 2100103. |

| 10 | Babat S, Spörl R, Maier J, et al. Investigation of deposit formation and its characterization for a pulverized bituminous coal power plant[J]. Fuel Processing Technology, 2016, 141: 225-234. |

| 11 | Laxminarayan Y, Jensen P A, Wu H, et al. Deposit shedding in biomass-fired boilers: shear adhesion strength measurements[J]. Energy & Fuels, 2017, 31(8): 8733-8741. |

| 12 | Salmenoja K, Makela K. Prevention of superheater corrosion in the combustion of biofuels[C]// Proceedings of the NACE International, 2000. |

| 13 | 谷国富. 锅炉蒸汽吹灰、声波吹灰和燃气高能脉冲吹灰的技术经济比较[J]. 应用能源技术, 2004(1): 18-21. |

| Gu G F. Technical and economic comparison of boiler steam soot blowing, acoustic soot blowing and gas high-energy pulse soot blowing[J]. Applied Energy Technology, 2004(1): 18-21. | |

| 14 | 姚纪恒, 冯景源, 罗红新. 锅炉蒸汽吹灰、声波吹灰和高能燃气脉冲吹灰的技术经济比较[J]. 锅炉技术, 2001, 32(12): 26-30. |

| Yao J H, Feng J Y, Luo H X. Technical economy comparison for boiler steam soot-blowing, acoustic soot-blowing and high gas pulse soot-blowing[J]. Boiler Technology, 2001, 32(12): 26-30. | |

| 15 | Zhou Y, Zhu R, Wei G S. Recent advancements in source reduction and recycling technologies for converter dust[J]. Energy Reports, 2022, 8: 7274-7285. |

| 16 | 赵京, 张玉锋, 魏小林, 等. 高碱煤燃烧过程中亚微米颗粒物PM1的生成特性[J]. 化工学报, 2019, 70(8): 3113-3120. |

| Zhao J, Zhang Y F, Wei X L, et al. PM1 formation characteristics during high-alkali coal combustion[J]. CIESC Journal, 2019, 70(8): 3113-3120. | |

| 17 | Zhan Z H, Fry A, Zhang Y W, et al. Ash aerosol formation from oxy-coal combustion and its relation to ash deposit chemistry[J]. Proceedings of the Combustion Institute, 2015, 35(2): 2373-2380. |

| 18 | 阮仁晖, 谭厚章, 王学斌, 等. 高碱煤燃烧过程细颗粒物排放特性[J]. 煤炭学报, 2017, 42(4): 1056-1062. |

| Ruan R H, Tan H Z, Wang X B, et al. Characteristics of fine particulate matter released from burning coal with high content of alkali and alkaline earth metal[J]. Journal of China Coal Society, 2017, 42(4): 1056-1062. | |

| 19 | Seames W S. An initial study of the fine fragmentation fly ash particle mode generated during pulverized coal combustion[J]. Fuel Processing Technology, 2003, 81(2): 109-125. |

| 20 | Linak W P, Miller C A, Seames W S, et al. On trimodal particle size distributions in fly ash from pulverized-coal combustion[J]. Proceedings of the Combustion Institute, 2002, 29(1): 441-447. |

| 21 | Marner W J. Progress in gas-side fouling of heat-transfer surfaces: 1989—1995[J]. Applied Mechanics Reviews, 1996, 49(10S): S161-S166. |

| 22 | Shimogori M, Mine T, Ohyatsu N, et al. Effects of fine ash particles and alkali metals on ash deposition characteristics at the initial stage of ash deposition determined in 1.5 MWth pilot plant tests[J]. Fuel, 2012, 97: 233-240. |

| 23 | Barroso J, Ballester J, Ferrer L M, et al. Study of coal ash deposition in an entrained flow reactor: influence of coal type, blend composition and operating conditions[J]. Fuel Processing Technology, 2006, 87(8): 737-752. |

| 24 | Dehbi A. A stochastic Langevin model of turbulent particle dispersion in the presence of thermophoresis[J]. International Journal of Multiphase Flow, 2009, 35(3): 219-226. |

| 25 | Mueller C, Selenius M, Theis M, et al. Deposition behaviour of molten alkali-rich fly ashes—development of a submodel for CFD applications[J]. Proceedings of the Combustion Institute, 2005, 30(2): 2991-2998. |

| 26 | Han H, He Y L, Tao W Q, et al. A parameter study of tube bundle heat exchangers for fouling rate reduction[J]. International Journal of Heat and Mass Transfer, 2014, 72: 210-221. |

| 27 | 马永明, 连国旺. 闪速炉炼铜中渣四氧化三铁的来源与控制[J]. 有色金属科学与工程, 2019, 10(2): 25-30. |

| Ma Y M, Lian G W. The source and control strategy of the magnetite in copper flash smelting[J]. Nonferrous Metals Science and Engineering, 2019, 10(2): 25-30. | |

| 28 | Naruse I, Kamihashira D, Miyauchi Y, et al. Fundamental ash deposition characteristics in pulverized coal reaction under high temperature conditions[J]. Fuel, 2005, 84(4): 405-410. |

| 29 | Venturini P, Borello D, Hanjalić K, et al. Modelling of particles deposition in an environment relevant to solid fuel boilers[J]. Applied Thermal Engineering, 2012, 49: 131-138. |

| 30 | Abd-Elhady M S, Malayeri M R, Müller-Steinhagen H. Fouling problems in exhaust gas recirculation coolers in the automotive industry[J]. Heat Transfer Engineering, 2011, 32(3/4): 248-257. |

| 31 | Skrifvars B J, Hupa M, Backman R, et al. Sintering mechanisms of FBC ashes[J]. Fuel, 1994, 73(2): 171-176. |

| 32 | Bar-Ziv E, Berman Y, Saveliev R, et al. Fouling formation in 575 MW tangential-fired pulverized-coal boiler[C]//Proceedings of ASME 2009 Power Conference. Albuquerque, New Mexico, USA, 2010: 19-25. |

| 33 | Conn R, Jones M L. Comparison of low-rank coal ash sintering characteristics with pilot plant ash fouling tendencies[C]// Conference on Slagging and Fouling Due to Impurities in Combustion Gases. Copper Mountain, CO, USA, 1984. |

| 34 | 刘鹏宇, 李德波, 刘彦丰, 等. 燃煤电厂锅炉机组受热面积灰结渣研究现状与展望[J]. 洁净煤技术, 2022, 28(5): 87-96. |

| Liu P Y, Li D B, Liu Y F, et al. Current status and prospects of research on ash slagging in heated area of coal-fired power plant boiler unit[J]. Clean Coal Technology, 2022, 28(5): 87-96. |

| [1] | 张东旺, 杨海瑞, 周托, 黄中, 李诗媛, 张缦. 生物质锅炉对流受热面积灰冷态模拟实验研究[J]. 化工学报, 2022, 73(8): 3731-3738. |

| [2] | 孙恒清, 盛昌栋. 含K成分形成初始沉积层的数学模型及烟气条件影响分析[J]. 化工学报, 2019, 70(9): 3495-3502. |

| [3] | 彭岩, 赵钦新, 王为术. 烟气横掠管束外表面的积灰特性[J]. 化工学报, 2018, 69(12): 5034-5041. |

| [4] | 邵怀爽, 马海东, 陈杰, 时明伟, 胡涛, 赵钦新. 分体管壳式余热锅炉内摩擦及局部压降[J]. 化工学报, 2016, 67(10): 4118-4125. |

| [5] | 李飞, 孙奉仲, 史月涛. 积灰与酸耦合作用下套管换热器传热特性热态实验[J]. 化工学报, 2014, 65(8): 2876-2881. |

| [6] | 穆林, 赵亮, 尹洪超. 化工废液焚烧炉内积灰结渣特性[J]. 化工学报, 2012, 63(11): 3645-3651. |

| [7] | 马有福,袁益超,陈昱,刘海磊,康明. 翅片螺距对锯齿螺旋翅片换热管特性的影响 [J]. CIESC Journal, 2011, 62(9): 2484-2489. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号