化工学报 ›› 2024, Vol. 75 ›› Issue (8): 2949-2959.DOI: 10.11949/0438-1157.20240224

收稿日期:2024-03-01

修回日期:2024-04-22

出版日期:2024-08-25

发布日期:2024-08-21

通讯作者:

赵海波

作者简介:童永祺(1995—),男,博士研究生,511685436@qq.com

基金资助:

Yongqi TONG1( ), Jie CHENG1, Hai LIN2, Xi CHEN1, Haibo ZHAO1(

), Jie CHENG1, Hai LIN2, Xi CHEN1, Haibo ZHAO1( )

)

Received:2024-03-01

Revised:2024-04-22

Online:2024-08-25

Published:2024-08-21

Contact:

Haibo ZHAO

摘要:

对自主设计的10 MWth化学链燃烧装置进行了全流程全尺度的计算颗粒流体力学(CPFD)模拟,得到了系统内详细的气固两相流流体动力学信息。首先基于经典实验验证了各曳力模型的可靠性,利用优选的EMMS-Yang曳力模型对系统进行了全流程模拟,分析了系统内的压力平衡,之后分析了系统内的固体循环流量,反应器内固含率分布、压力分布等关键参数,补充了实际运行过程中难以测量的细节信息,同时可以指导操作条件优化及反应器调控策略。模拟结果显示,系统实现了良好的压力平衡,空气反应器出口固体循环流量达到103.80 kg/s,燃料反应器出口固体循环流量达到40.10 kg/s,底部返料阀返料顺畅,使得系统快速达到稳定运行状态。

中图分类号:

童永祺, 程杰, 林海, 陈曦, 赵海波. 10 MWth化学链燃烧反应装置的CPFD模拟[J]. 化工学报, 2024, 75(8): 2949-2959.

Yongqi TONG, Jie CHENG, Hai LIN, Xi CHEN, Haibo ZHAO. CPFD simulation of a 10 MWth chemical looping combustion reactor[J]. CIESC Journal, 2024, 75(8): 2949-2959.

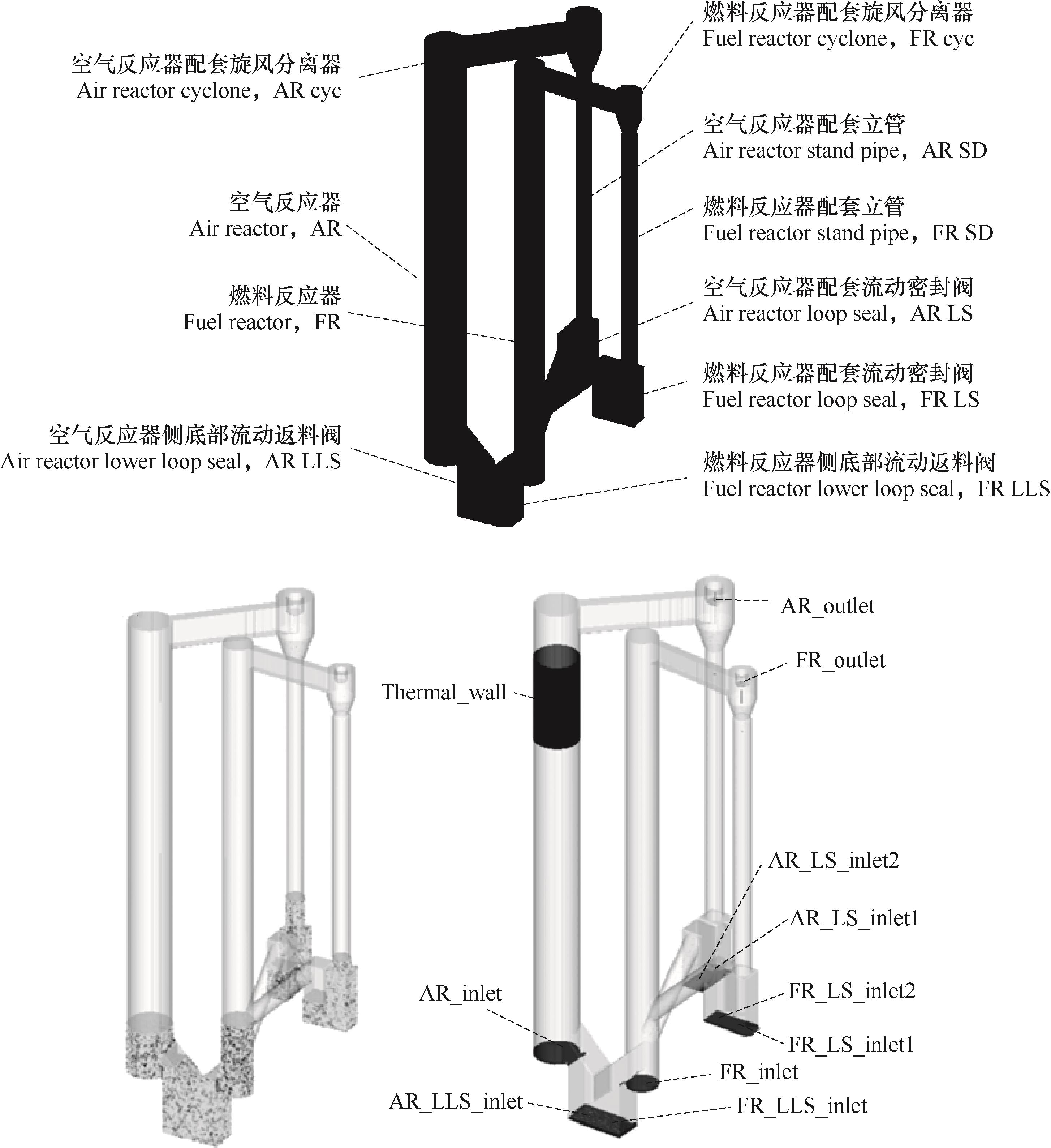

图1 10 MWth化学链燃烧装置计算模型、初始物料分布及进出口边界

Fig.1 10 MWth chemical looping combustion unit computational modeling, initial material distribution and boundary conditions

| 参数 | 数值 |

|---|---|

| AR高度/m | 17 |

| FR高度/m | 17 |

| AR截面积/m2 | 1.8 |

| FR截面积/m2 | 0.93 |

| 总填料量/kg | 25000 |

| 初始颗粒堆积浓度 | 0.58 |

| 网格数/个 | 558568 |

| 时间步长/s | 0.0001 |

| 计算总时长/s | 60 |

| 空气反应器温度/K | 1223 |

| 燃料反应器温度/K | 1183 |

表1 模拟中采用的参数

Table 1 Parameters used in the simulation

| 参数 | 数值 |

|---|---|

| AR高度/m | 17 |

| FR高度/m | 17 |

| AR截面积/m2 | 1.8 |

| FR截面积/m2 | 0.93 |

| 总填料量/kg | 25000 |

| 初始颗粒堆积浓度 | 0.58 |

| 网格数/个 | 558568 |

| 时间步长/s | 0.0001 |

| 计算总时长/s | 60 |

| 空气反应器温度/K | 1223 |

| 燃料反应器温度/K | 1183 |

| 名称 | 类型 | 压力/Pa | 表观气速/(m/s) |

|---|---|---|---|

| AR_inlet | 速度入口 | — | 8.000 |

| AR_outlet | 压力出口 | 101325 | — |

| AR_LS_inlet1 | 速度入口 | — | 0.024 |

| AR_LS_inlet2 | 速度入口 | — | 0.121 |

| AR_LLS_inlet | 速度入口 | — | 0.150 |

| FR_inlet | 速度入口 | — | 4.000 |

| FR_outlet | 压力出口 | 101325 | — |

| FR_LS_inlet1 | 速度入口 | — | 0.024 |

| FR_LS_inlet2 | 速度入口 | — | 0.121 |

| FR_LLS_inlet | 速度入口 | — | 0.100 |

| Thermal_wall | 热流壁面 | — | — |

表2 模拟中的进出口参数

Table2 Import and export parameters in the simulation

| 名称 | 类型 | 压力/Pa | 表观气速/(m/s) |

|---|---|---|---|

| AR_inlet | 速度入口 | — | 8.000 |

| AR_outlet | 压力出口 | 101325 | — |

| AR_LS_inlet1 | 速度入口 | — | 0.024 |

| AR_LS_inlet2 | 速度入口 | — | 0.121 |

| AR_LLS_inlet | 速度入口 | — | 0.150 |

| FR_inlet | 速度入口 | — | 4.000 |

| FR_outlet | 压力出口 | 101325 | — |

| FR_LS_inlet1 | 速度入口 | — | 0.024 |

| FR_LS_inlet2 | 速度入口 | — | 0.121 |

| FR_LLS_inlet | 速度入口 | — | 0.100 |

| Thermal_wall | 热流壁面 | — | — |

| 参数 | 单位 | CH4 | O2 |

|---|---|---|---|

| ρm | mol/m3 | 32811 | 22472 |

| rg | m | 2.6×10-7 | 2.6×10-7 |

| b | — | 12 | 4 |

| k0 | mol1-n ·m3n-2/s | 8.0×10-4 | 3.1×10-4 |

| E | kJ/mol | 49 | 14 |

| n | — | 1.3 | 1.0 |

| Cg | %(体积分数) | 3 | 11 |

表3 氧载体颗粒反应动力学参数

Table 3 Kinetic parameters for the reaction of oxygen carrier particles

| 参数 | 单位 | CH4 | O2 |

|---|---|---|---|

| ρm | mol/m3 | 32811 | 22472 |

| rg | m | 2.6×10-7 | 2.6×10-7 |

| b | — | 12 | 4 |

| k0 | mol1-n ·m3n-2/s | 8.0×10-4 | 3.1×10-4 |

| E | kJ/mol | 49 | 14 |

| n | — | 1.3 | 1.0 |

| Cg | %(体积分数) | 3 | 11 |

| 粒径/μm | 平均粒径/μm | 密度/(kg/m3) | 最小流化速度/(m/s) | 终端速度/(m/s) | 颗粒分类 |

|---|---|---|---|---|---|

| 70~240 | 139 | 2400 | 0.091 | 1.2 | B |

表4 经典实验工况颗粒参数

Table 4 Particle parameters for classical experimental conditions

| 粒径/μm | 平均粒径/μm | 密度/(kg/m3) | 最小流化速度/(m/s) | 终端速度/(m/s) | 颗粒分类 |

|---|---|---|---|---|---|

| 70~240 | 139 | 2400 | 0.091 | 1.2 | B |

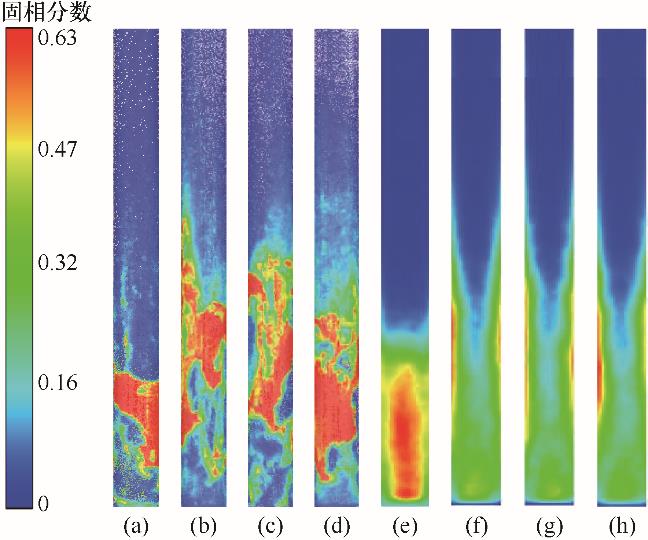

图3 不同曳力模型颗粒在反应器内的分布情况[(a)~(d)分别为EMMS-Yang、WenYu-Ergun、Turton-Levenspiel、Nonspherical-Ganser曳力模型t=60 s时刻的颗粒瞬时分布;(e)~(h)为四种曳力模型稳态时颗粒的平均固含率分布]

Fig.3 Distribution of particles in the reactor for different drag models[(a)—(d) are the instantaneous distributions of particles at the moment of t=60 s for EMMS-Yang, WenYu-Ergun, Turton-Levenspiel, and Nonspherical-Ganser tracer models, respectively; (e)—(h) are the distributions of particles' average solids content in steady state for the four drag models]

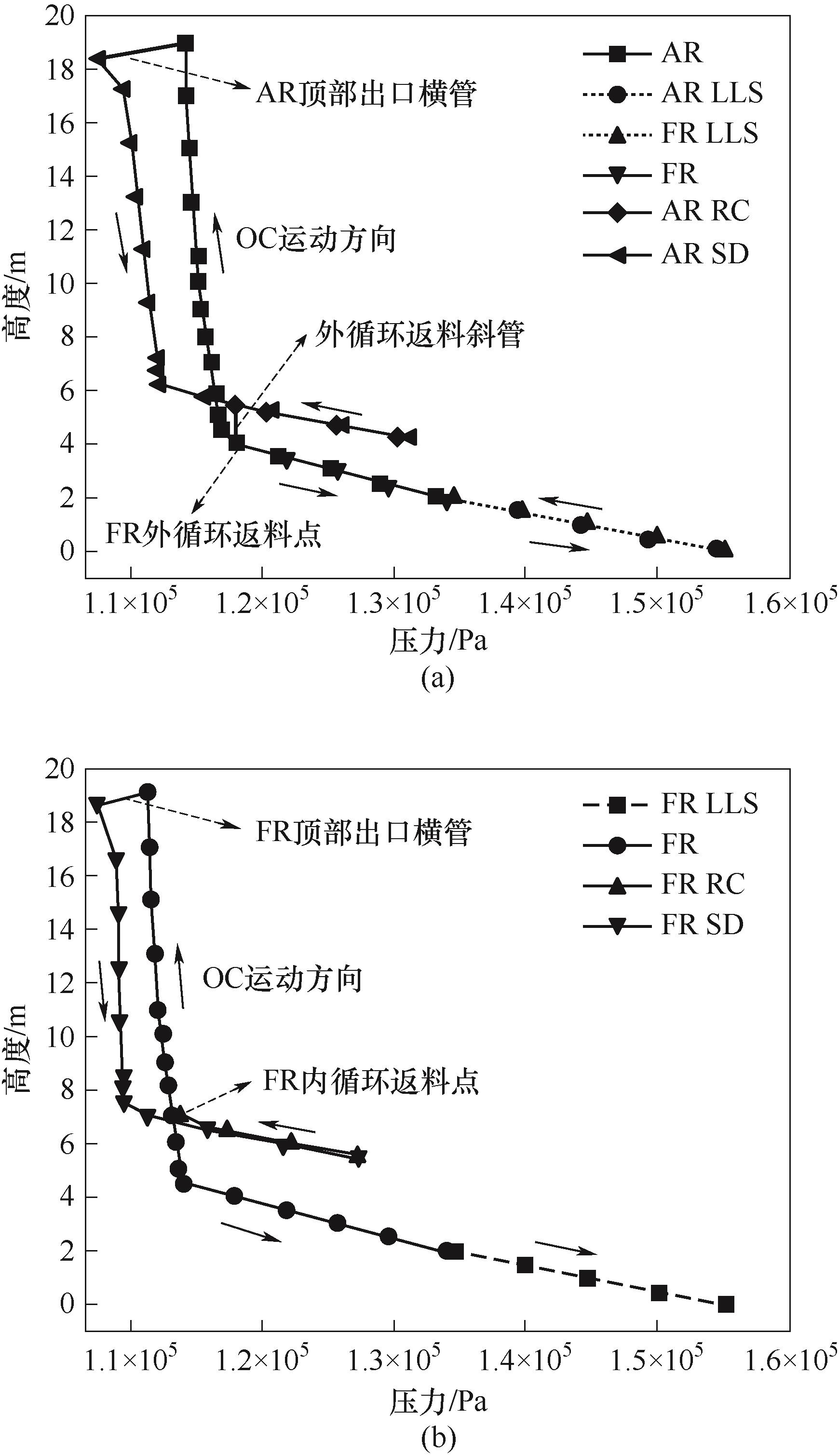

图8 氧载体外循环系统压力分布及氧载体FR内循环系统压力分布

Fig.8 Oxygen carrier external circulation system pressure distribution and oxygen carrier FR internal circulation system pressure distribution

| 1 | Leion H, Mattisson T, Lyngfelt A. Solid fuels in chemical-looping combustion[J]. International Journal of Greenhouse Gas Control, 2008, 2(2): 180-193. |

| 2 | Fan L S, Zeng L, Wang W, et al. Chemical looping processes for CO2 capture and carbonaceous fuel conversion—prospect and opportunity[J]. Energy & Environmental Science, 2012, 5(6): 7254-7280. |

| 3 | Abad A, Pérez-Vega R, de Diego L F, et al. Design and operation of a 50 kWth chemical looping combustion (CLC) unit for solid fuels[J]. Applied Energy, 2015, 157: 295-303. |

| 4 | Abad A, Mendiara T, Gayán P, et al. Comparative evaluation of the performance of coal combustion in 0.5 and 50 kWth chemical looping combustion units with ilmenite, redmud or iron ore as oxygen carrier[J]. Energy Procedia, 2017, 114: 285-301. |

| 5 | Siriwardane R, Riley J, Bayham S, et al. 50-kWth methane/air chemical looping combustion tests with commercially prepared CuO-Fe2O3-alumina oxygen carrier with two different techniques[J]. Applied Energy, 2018, 213: 92-99. |

| 6 | Bayham S, Straub D, Weber J. Operation of the NETL chemical looping reactor with natural gas and a novel copper-iron material[R]. NETL Technical Report Series. Morgantown, WV, 2016. |

| 7 | Ströhle J, Orth M, Epple B. Design and operation of a 1 MWth chemical looping plant[J]. Applied Energy, 2014, 113: 1490-1495. |

| 8 | Adanez J, Abad A, Garcia-Labiano F, et al. Progress in chemical-looping combustion and reforming technologies[J]. Progress in Energy and Combustion Science, 2012, 38(2): 215-282. |

| 9 | Shah S, Ritvanen J, Hyppänen T, et al. Wall effects on space averaged two-fluid model equations for simulations of gas-solid flows in risers[J]. Chemical Engineering Science, 2013, 89: 206-215. |

| 10 | Banerjee S, Agarwal R. Transient reacting flow simulation of spouted fluidized bed for coal-direct chemical looping combustion with different Fe-based oxygen carriers[J]. Applied Energy, 2015, 160: 552-560. |

| 11 | Zhang Z M, Zhou L J, Agarwal R. Transient simulations of spouted fluidized bed for coal-direct chemical looping combustion[J]. Energy & Fuels, 2014, 28: 1548-1560. |

| 12 | Zhu X, Shen T X, Bollas G, et al. Design and operation of a multi-stage reactor system for chemical looping combustion process[J]. Fuel Processing Technology, 2021, 215: 106748. |

| 13 | Reinking Z, Shim H S, Whitty K J, et al. Computational simulation of a 100 kW dual circulating fluidized bed reactor processing coal by chemical looping with oxygen uncoupling[J]. International Journal of Greenhouse Gas Control, 2019, 90: 102795. |

| 14 | Chen X, Ma J C, Tian X, et al. CPFD simulation and optimization of a 50 kWth dual circulating fluidized bed reactor for chemical looping combustion of coal[J]. International Journal of Greenhouse Gas Control, 2019, 90: 102800. |

| 15 | Abad A, Adánez J, García-Labiano F, et al. Mapping of the range of operational conditions for Cu-, Fe-, and Ni-based oxygen carriers in chemical-looping combustion[J]. Chemical Engineering Science, 2007, 62(1/2): 533-549. |

| 16 | Su M Z, Zhao H B, Ma J C. Computational fluid dynamics simulation for chemical looping combustion of coal in a dual circulation fluidized bed[J]. Energy Conversion and Management, 2015, 105: 1-12. |

| 17 | Mahalatkar K, Kuhlman J, Huckaby E D, et al. Computational fluid dynamic simulations of chemical looping fuel reactors utilizing gaseous fuels[J]. Chemical Engineering Science, 2011, 66(3): 469-479. |

| 18 | Snider D M, Clark S M, O'Rourke P J. Eulerian-Lagrangian method for three-dimensional thermal reacting flow with application to coal gasifiers[J]. Chemical Engineering Science, 2011, 66(6): 1285-1295. |

| 19 | Wang Q G, Yang H R, Wang P N, et al. Application of CPFD method in the simulation of a circulating fluidized bed with a loop seal(part Ⅰ): Determination of modeling parameters[J]. Powder Technology, 2014, 253: 814-821. |

| 20 | Everson R, Neomagus H, Kaitano R. The modeling of the combustion of high-ash coal-char particles suitable for pressurised fluidized bed combustion: shrinking reacted core model[J]. Fuel, 2005, 84(9): 1136-1143. |

| 21 | Castilla G M, Montañés R M, Pallarès D, et al. Dynamic modeling of the reactive side in large-scale fluidized bed boilers[J]. Industrial & Engineering Chemistry Research, 2021, 60(10): 3936-3956. |

| 22 | Monazam E R, Breault R W, Siriwardane R, et al. Kinetics of the reduction of hematite (Fe2O3) by methane (CH4) during chemical looping combustion: a global mechanism[J]. Chemical Engineering Journal, 2013, 232: 478-487. |

| 23 | Guío-Pérez D C, Pröll T, Hofbauer H. Solids residence time distribution in the secondary reactor of a dual circulating fluidized bed system[J]. Chemical Engineering Science, 2013, 104: 269-284. |

| 24 | Harichandan A B, Shamim T. CFD analysis of bubble hydrodynamics in a fuel reactor for a hydrogen-fueled chemical looping combustion system[J]. Energy Conversion and Management, 2014, 86: 1010-1022. |

| 25 | Wang S, Gao J M, Lu H L, et al. Simulation of flow behavior of particles by cluster structure-dependent drag coefficient model for chemical looping combustion process: air reactor modeling[J]. Fuel Processing Technology, 2012, 104: 219-233. |

| 26 | Kraft S, Kirnbauer F, Hofbauer H. Influence of drag laws on pressure and bed material recirculation rate in a cold flow model of an 8 MW dual fluidized bed system by means of CPFD[J]. Particuology, 2018, 36: 70-81. |

| 27 | Breault R W, Weber J, Straub D, et al. Computational fluid dynamics modeling of the fuel reactor in NETL's 50 kWth chemical looping facility[J]. Journal of Energy Resources Technology, 2017, 139(4): 042211. |

| 28 | Gidaspow D. Multiphase Flow and Fluidization: Continuum and Kinetic Theory Description[M]. New York: Academic Press, 1994. |

| 29 | Turton R, Levenspiel O. A short note on the drag correlation for spheres[J]. Powder Technology, 1986, 47(1): 83-86. |

| 30 | Li J H, Kwauk M. Particle-Fluid Two-Phase Flow: The Engergy-Minimization Multi-Scale Method[M]. Beijing: Metallurgical Industry Press, 1994. |

| 31 | Chhabra R P, Agarwal L, Sinha N K. Drag on non-spherical particles: an evaluation of available methods[J]. Powder Technology, 1999, 101(3): 288-295. |

| 32 | Zhu L T, Liu Y X, Luo Z H. An effective three-marker drag model via sub-grid modeling for turbulent fluidization[J]. Chemical Engineering Science, 2018, 192: 759-773. |

| 33 | Gao X, Wu C, Cheng Y W, et al. Experimental and numerical investigation of solid behavior in a gas-solid turbulent fluidized bed[J]. Powder Technology, 2012, 228: 1-13. |

| [1] | 袁子涵, 王淑彦, 邵宝力, 谢磊, 陈曦, 马一玫. 基于幂律液固曳力模型流化床内湿颗粒流动特性的研究[J]. 化工学报, 2023, 74(5): 2000-2012. |

| [2] | 张金鹏, 王强, 王艳美, 严舒, 吴建波, 张慧, 白红存. 镍基载氧体化学链燃烧过程中宁夏QH和YCW煤分子结构演化特征及对比分析[J]. 化工学报, 2023, 74(10): 4252-4266. |

| [3] | 袁妮妮, 郭拓, 白红存, 何育荣, 袁永宁, 马晶晶, 郭庆杰. 化学链燃烧过程Fe2O3/Al2O3载氧体表面CH4反应:ReaxFF-MD模拟[J]. 化工学报, 2022, 73(9): 4054-4061. |

| [4] | 胡善伟, 刘新华. 气固流化系统多尺度跨流域EMMS建模[J]. 化工学报, 2022, 73(6): 2514-2528. |

| [5] | 周毓佳, 赵陈儒, 薄涵亮. 气泡曳力系数模型分区研究[J]. 化工学报, 2019, 70(S2): 108-116. |

| [6] | 梁咏诗, 赵香龙, 秦强, 郭屹, 程易. 气流床气化炉的CPFD数值模拟[J]. 化工学报, 2019, 70(9): 3291-3299. |

| [7] | 闫景春, 沈来宏, 蒋守席, 葛晖骏. 高钠煤化学链燃烧特性及煤焦气化反应动力学研究[J]. 化工学报, 2019, 70(5): 1913-1922. |

| [8] | 武永健, 罗春欢, 魏琳, 朱探金, 苏庆泉. 基于化学链燃烧的转炉放散煤气利用研究[J]. 化工学报, 2019, 70(5): 1923-1931. |

| [9] | 张仪, 白玉龙, 骆丁玲, 路建洲, 关彦军, 张锴. 液固散式流态化CFD模拟中曳力模型的影响[J]. 化工学报, 2019, 70(11): 4207-4215. |

| [10] | 殷上轶, 宋涛. CO2气氛下准东煤化学链燃烧特性研究[J]. 化工学报, 2018, 69(9): 3954-3964. |

| [11] | 冯乐乐, 王景玉, 吴玉新, 张海, 张缦, 吕俊复, 岳光溪. 颗粒特性对撞击分离器性能影响的实验与数值研究[J]. 化工学报, 2018, 69(8): 3348-3355. |

| [12] | 张志丰, 王亦飞, 朱龙雏, 李季林, 王辅臣, 于广锁. 基于铁基载氧体的无烟煤化学链燃烧过程中硫分布特性[J]. 化工学报, 2018, 69(4): 1578-1585. |

| [13] | 彭松, 曾德望, 陈超, 邱宇, 肖睿. 具有自载体功能的CoFeAlO4载氧体化学链燃烧反应特性[J]. 化工学报, 2018, 69(1): 515-522. |

| [14] | 张佳宝, 崔丽杰, 杨宁. 曳力模型和湍流模型对内环流反应器数值模拟的影响[J]. 化工学报, 2018, 69(1): 389-395. |

| [15] | 戴金鑫, 刘晶, 刘丰. 化学链燃烧中H2S对NiFe2O4氧载体活性的影响机理[J]. 化工学报, 2017, 68(3): 1163-1169. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号