化工学报 ›› 2025, Vol. 76 ›› Issue (10): 5351-5361.DOI: 10.11949/0438-1157.20250444

收稿日期:2025-04-26

修回日期:2025-06-22

出版日期:2025-10-25

发布日期:2025-11-25

通讯作者:

张海

作者简介:李亮(1997—),男,博士研究生,ll20@mails.tsinghua.edu.cn

基金资助:

Liang LI1( ), Yang ZHANG1,2, Hai ZHANG1(

), Yang ZHANG1,2, Hai ZHANG1( )

)

Received:2025-04-26

Revised:2025-06-22

Online:2025-10-25

Published:2025-11-25

Contact:

Hai ZHANG

摘要:

为了研究多孔介质结构特征对燃烧强化作用的影响,在孔隙率和孔径基础上,引入新的结构参数弯曲度表征多孔介质的形貌结构特性,并对不同结构参数条件下多孔介质中低热值H2/CO混合气的燃烧稳定性开展实验研究。结果表明,多孔介质可提高稳燃上限,拓宽贫燃极限并降低污染物排放。与孔隙率和孔径对燃烧稳定性的非单调影响特性不同,实验中弯曲度对燃烧稳定性的影响呈单调变化趋势,高弯曲度结构具有更强的燃烧增强效果。通过优化结构参数,可以扩大多孔介质燃烧的稳燃范围。此外,三个结构参数针对不同的燃烧状态也表现出不同的影响,对于高功率密度燃烧,采用高孔隙率结构可以实现更低的CO排放,对于极贫燃燃烧则应采用高弯曲度、低孔隙率的结构。

中图分类号:

李亮, 张扬, 张海. 多孔介质形貌与结构对低热值H2/CO混合气燃烧特性影响的实验研究[J]. 化工学报, 2025, 76(10): 5351-5361.

Liang LI, Yang ZHANG, Hai ZHANG. Experiments on burning low calorific value H2/CO in the porous media: effect of porous morphology and structure[J]. CIESC Journal, 2025, 76(10): 5351-5361.

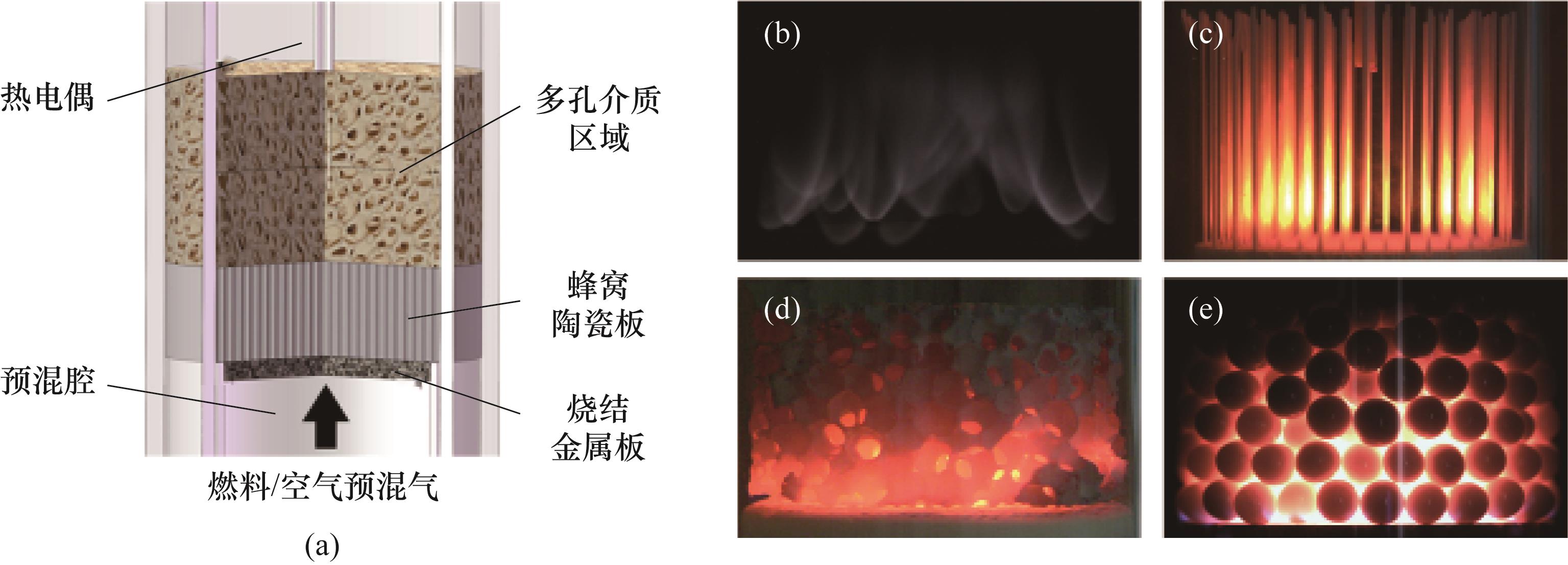

图2 多孔介质燃烧器与结构示意图(a)与不同形貌的多孔介质/无多孔介质燃烧状态照片[(b)~(e)]

Fig.2 Schematic of the porous media zone (a) and the flame pictures with and without porous media [(b)—(e)]

| 实验编号 | 孔隙率ε | 平均孔径dm/mm | 弯曲度τ | 单棒直径dr/mm | 阵列数量Nr |

|---|---|---|---|---|---|

| PM1 | 0.974 | 3.11 | 1.0 | 0.6 | 182 |

| PM2 | 0.953 | 2.93 | 1.0 | 0.8 | 182 |

| PM3 | 0.927 | 2.16 | 1.0 | 0.8 | 285 |

| PM4 | 0.927 | 2.71 | 1.0 | 1.0 | 182 |

| PM5 | 0.927 | 3.25 | 1.0 | 1.2 | 126 |

| PM6 | 0.927 | 6.78 | 1.0 | 2.5 | 29 |

| PM7 | 0.895 | 2.71 | 1.0 | 1.2 | 182 |

| PM8 (泡沫结构) | 0.830 | 3.45 | 1.19 | — | — |

| PM9 (直孔蜂窝) | 0.439 | 3.92 | 1.0 | — | — |

| PM10 (颗粒堆积) | 0.438 | 5.00 | 1.40 | — | — |

表1 多孔介质结构参数

Table 1 Structural parameters of the PM used

| 实验编号 | 孔隙率ε | 平均孔径dm/mm | 弯曲度τ | 单棒直径dr/mm | 阵列数量Nr |

|---|---|---|---|---|---|

| PM1 | 0.974 | 3.11 | 1.0 | 0.6 | 182 |

| PM2 | 0.953 | 2.93 | 1.0 | 0.8 | 182 |

| PM3 | 0.927 | 2.16 | 1.0 | 0.8 | 285 |

| PM4 | 0.927 | 2.71 | 1.0 | 1.0 | 182 |

| PM5 | 0.927 | 3.25 | 1.0 | 1.2 | 126 |

| PM6 | 0.927 | 6.78 | 1.0 | 2.5 | 29 |

| PM7 | 0.895 | 2.71 | 1.0 | 1.2 | 182 |

| PM8 (泡沫结构) | 0.830 | 3.45 | 1.19 | — | — |

| PM9 (直孔蜂窝) | 0.439 | 3.92 | 1.0 | — | — |

| PM10 (颗粒堆积) | 0.438 | 5.00 | 1.40 | — | — |

| 功率密度QB/(MW/m3) | 当量比ϕ | 表观气体流速UD/(cm/s) |

|---|---|---|

| 0.3 | 0.35 | 17.2 |

| 0.30 | 19.7 | |

| 0.25 | 23.2 | |

| 0.20 | 28.5 | |

| 0.6 | 0.35 | 34.4 |

| 0.30 | 39.4 | |

| 0.25 | 46.4 | |

| 0.20 | 56.9 | |

| 0.8 | 0.35 | 46.4 |

| 0.30 | 53.0 | |

| 0.25 | 62.5 | |

| 0.20 | 76.7 |

表2 实验工况

Table 2 Operating conditions

| 功率密度QB/(MW/m3) | 当量比ϕ | 表观气体流速UD/(cm/s) |

|---|---|---|

| 0.3 | 0.35 | 17.2 |

| 0.30 | 19.7 | |

| 0.25 | 23.2 | |

| 0.20 | 28.5 | |

| 0.6 | 0.35 | 34.4 |

| 0.30 | 39.4 | |

| 0.25 | 46.4 | |

| 0.20 | 56.9 | |

| 0.8 | 0.35 | 46.4 |

| 0.30 | 53.0 | |

| 0.25 | 62.5 | |

| 0.20 | 76.7 |

| [1] | Gür T M. Comprehensive review of methane conversion in solid oxide fuel cells: prospects for efficient electricity generation from natural gas[J]. Progress in Energy and Combustion Science, 2016, 54: 1-64. |

| [2] | Ghang T G, Lee S M, Ahn K Y, et al. An experimental study on the reaction characteristics of a coupled reactor with a catalytic combustor and a steam reformer for SOFC systems[J]. International Journal of Hydrogen Energy, 2012, 37(4): 3234-3241. |

| [3] | Francisco R W, Rua F, Costa M, et al. On the combustion of hydrogen-rich gaseous fuels with low calorific value in a porous burner[J]. Energy & Fuels, 2010, 24(2): 880-887. |

| [4] | Howell J R, Hall M J, Ellzey J L. Combustion of hydrocarbon fuels within porous inert media[J]. Progress in Energy and Combustion Science, 1996, 22(2): 121-145. |

| [5] | Oliveira A A M, Kaviany M. Nonequilibrium in the transport of heat and reactants in combustion in porous media[J]. Progress in Energy and Combustion Science, 2001, 27(5): 523-545. |

| [6] | Weinberg F J. Combustion temperatures: the future?[J]. Nature, 1971, 233(5317): 239-241. |

| [7] | Banerjee A, Paul D. Developments and applications of porous medium combustion: a recent review[J]. Energy, 2021, 221: 119868. |

| [8] | Gharehghani A, Ghasemi K, Siavashi M, et al. Applications of porous materials in combustion systems: a comprehensive and state-of-the-art review[J]. Fuel, 2021, 304: 121411. |

| [9] | Kamal M M, Mohamad A A. Combustion in porous media[J]. Proceedings of the Institution of Mechanical Engineers, Part A: Journal of Power and Energy, 2006, 220(5): 487-508. |

| [10] | Mujeebu M A, Abdullah M Z, Abu Bakar M Z, et al. Combustion in porous media and its applications—a comprehensive survey[J]. Journal of Environmental Management, 2009, 90(8): 2287-2312. |

| [11] | Habib R, Yadollahi B, Saeed A, et al. Unsteady ultra-lean combustion of methane and biogas in a porous burner—an experimental study[J]. Applied Thermal Engineering, 2021, 182: 116099. |

| [12] | Kotani Y, Takeno T. An experimental study on stability and combustion characteristics of an excess enthalpy flame[J]. Symposium (International) on Combustion, 1982, 19(1): 1503-1509. |

| [13] | Wood S, Harris A T. Porous burners for lean-burn applications[J]. Progress in Energy and Combustion Science, 2008, 34(5): 667-684. |

| [14] | Mujeebu M A, Abdullah M Z, Mohamad A A, et al. Trends in modeling of porous media combustion[J]. Progress in Energy and Combustion Science, 2010, 36(6): 627-650. |

| [15] | 程乐鸣, 岑可法, 周昊, 等. 多孔介质燃烧理论与技术[M]. 北京: 化学工业出版社, 2013. |

| Cheng L M, Cen K F, Zhou H, et al. Theory and Technology of Porous Medium Combustion[M]. Beijing: Chemical Industry Press, 2013. | |

| [16] | Gao H B, Qu Z G, Feng X B, et al. Combustion of methane/air mixtures in a two-layer porous burner: a comparison of alumina foams, beads, and honeycombs[J]. Experimental Thermal and Fluid Science, 2014, 52: 215-220. |

| [17] | Liang X, Li Y W, He Z, et al. The effect of cellular structure on the strength and combustion properties of SiC porous ceramics[J]. Ceramics International, 2022, 48(2): 2538-2545. |

| [18] | Trimis D, Durst F. Combustion in a porous medium-advances and applications[J]. Combustion Science and Technology, 1996, 121(1/2/3/4/5/6): 153-168. |

| [19] | Gao H B, Qu Z G, He Y L, et al. Experimental study of combustion in a double-layer burner packed with alumina pellets of different diameters[J]. Applied Energy, 2012, 100: 295-302. |

| [20] | Samoilenko M, Seers P, Terriault P, et al. Design, manufacture and testing of porous materials with ordered and random porosity: application to porous medium burners[J]. Applied Thermal Engineering, 2019, 158: 113724. |

| [21] | Hsu P F, Evans W D, Howell J R. Experimental and numerical study of premixed combustion within nonhomogeneous porous ceramics[J]. Combustion Science and Technology, 1993, 90(1/2/3/4): 149-172. |

| [22] | Masset P A, Duchaine F, Pestre A, et al. Modelling challenges of volume-averaged combustion in inert porous media[J]. Combustion and Flame, 2023, 251: 112678. |

| [23] | Devi S, Sahoo N, Muthukumar P. Combustion of biogas in porous radiant burner: low emission combustion[J]. Energy Procedia, 2019, 158: 1116-1121. |

| [24] | 张俊春. 多孔介质燃烧处理低热值气体及燃烧不稳定性研究[D]. 杭州: 浙江大学, 2014. |

| Zhang J C. Study on treatment of low calorific value gas and combustion instability by porous medium combustion[D]. Hangzhou: Zhejiang University, 2014. | |

| [25] | 姜海. 多孔介质内预混气体燃烧的实验和数值研究[D]. 合肥: 中国科学技术大学, 2008. |

| Jiang H. Experimental and numerical study on premixed gas combustion in porous media[D]. Hefei: University of Science and Technology of China, 2008. | |

| [26] | Gentillon P, Singh S, Lakshman S, et al. A comprehensive experimental characterisation of a novel porous media combustion-based thermophotovoltaic system with controlled emission[J]. Applied Energy, 2019, 254: 113721. |

| [27] | Li Q Q, Li J, Shi J R, et al. Effects of heat transfer on flame stability limits in a planar micro-combustor partially filled with porous medium[J]. Proceedings of the Combustion Institute, 2019, 37(4): 5645-5654. |

| [28] | Pan J F, Wu D, Liu Y X, et al. Hydrogen/oxygen premixed combustion characteristics in micro porous media combustor[J]. Energy Procedia, 2014, 61: 1279-1285. |

| [29] | Tolouei A, Gharehghani A. Numerical investigation of premixed methane-ammonia combustion in a mesoscale porous combustor[J]. Fuel, 2024, 366: 131427. |

| [30] | Chen X J, Li J W, Zhao D, et al. Effects of porous media on partially premixed combustion and heat transfer in meso-scale burners fuelled with ethanol[J]. Energy, 2021, 224: 120191. |

| [31] | Bedoya C, Dinkov I, Habisreuther P, et al. Experimental study, 1D volume-averaged calculations and 3D direct pore level simulations of the flame stabilization in porous inert media at elevated pressure[J]. Combustion and Flame, 2015, 162(10): 3740-3754. |

| [32] | Flores-Montoya E, Masset P A, Schuller T, et al. Flame-front tracking in porous media burners[J]. Combustion and Flame, 2024, 267: 113597. |

| [33] | Li L, Zhang R F, Zhang Y, et al. Burning ammonia with methane blending in an air-staged porous media burner[J]. Fuel, 2025, 387: 134385. |

| [34] | Berg C F. Permeability description by characteristic length, tortuosity, constriction and porosity[J]. Transport in Porous Media, 2014, 103(3): 381-400. |

| [35] | Graczyk K M, Matyka M. Predicting porosity, permeability, and tortuosity of porous media from images by deep learning[J]. Scientific Reports, 2020, 10(1): 21488. |

| [36] | Cooper S J, Bertei A, Shearing P R, et al. TauFactor: an open-source application for calculating tortuosity factors from tomographic data[J]. SoftwareX, 2016, 5: 203-210. |

| [37] | Rabbani A, Jamshidi S, Salehi S. An automated simple algorithm for realistic pore network extraction from micro-tomography images[J]. Journal of Petroleum Science and Engineering, 2014, 123: 164-171. |

| [1] | 王关晴,罗丹,丁宁,黄雪峰,徐江荣. 稀薄燃气多孔介质燃烧二维火焰数值模拟[J]. 化工学报, 2012, 63(6): 1893-1901. |

| [2] | 王关晴, 程乐鸣, 郑成航, 骆仲泱, 岑可法. 往复热循环多孔介质“超焓燃烧”特性 [J]. 化工学报, 2009, 60(2): 435-443. |

| [3] | 史俊瑞, 解茂昭, 周磊. 往复式惰性多孔介质燃烧器的可燃极限及最大半周期 [J]. 化工学报, 2007, 58(8): 1983-1988. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号