化工学报 ›› 2025, Vol. 76 ›› Issue (7): 3212-3225.DOI: 10.11949/0438-1157.20241423

收稿日期:2024-12-09

修回日期:2025-04-22

出版日期:2025-07-25

发布日期:2025-08-13

通讯作者:

张霖宙

作者简介:高照(1995—),男,博士研究生,cup-gaozhao@outlook.com

基金资助:

Zhao GAO( ), Xi WU, Dan XIA, Linzhou ZHANG(

), Xi WU, Dan XIA, Linzhou ZHANG( )

)

Received:2024-12-09

Revised:2025-04-22

Online:2025-07-25

Published:2025-08-13

Contact:

Linzhou ZHANG

摘要:

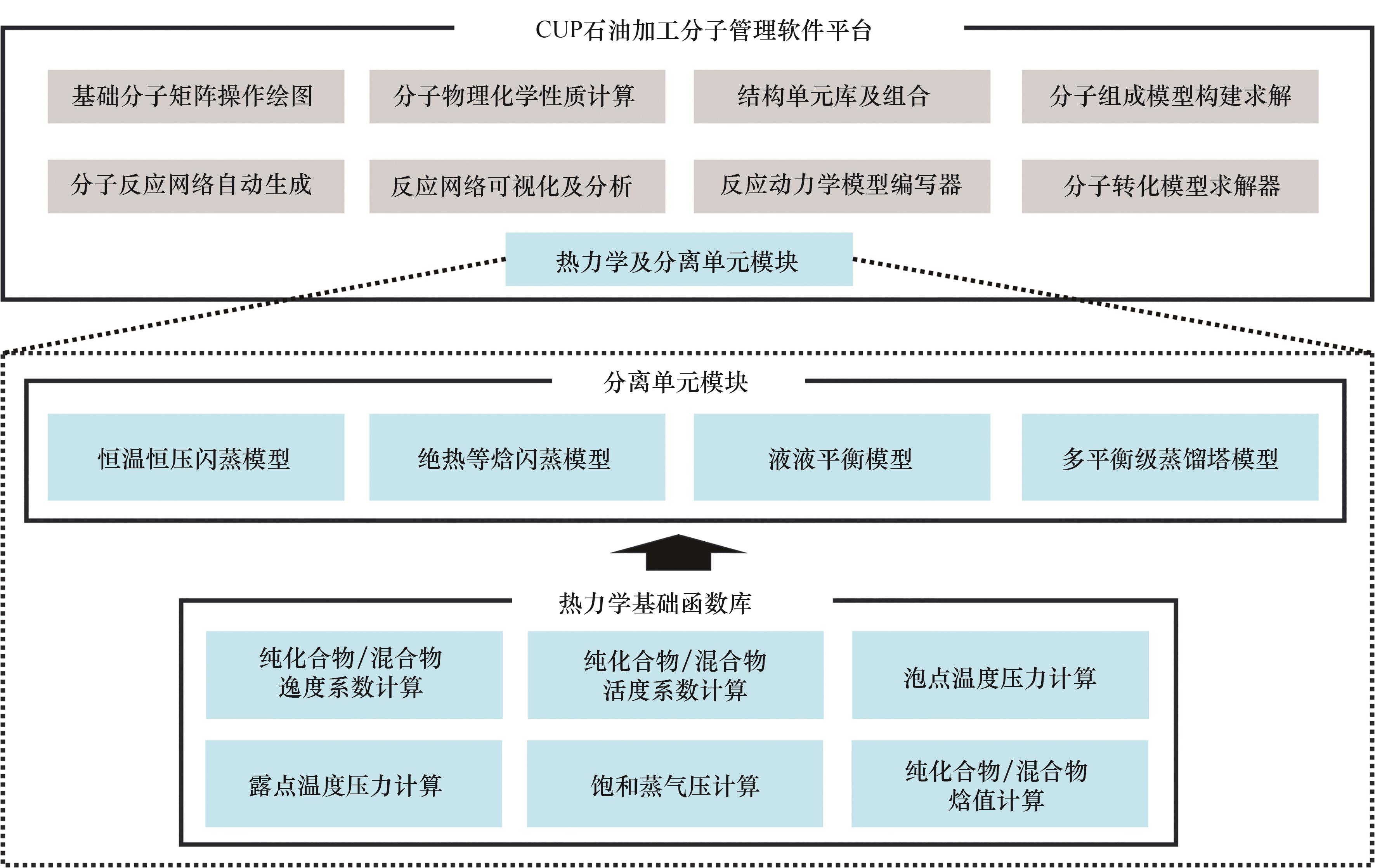

石油复杂分子体系的热力学及分离过程建模是实现炼化过程分子管理的关键步骤之一。基于平台化的建模思路,设计了热力学及分离单元模块的开发架构,建立了热力学基础函数库和分离单元模型库,实现了炼化过程复杂分子体系的热力学性质计算及典型分离过程建模。为了验证模型计算的正确性,首先基于实验数据和商用流程模拟软件计算结果进行测试和对比,确认了热力学基础函数、平衡计算和闪蒸/蒸馏塔分离单元计算结果的准确性。最后,通过对分子层次柴油分离过程的机理计算,证明了所开发的平台可实现复杂分子体系的模拟,所开发的模块为石油复杂分子体系的分离过程模拟与优化提供了有效的计算工具。

中图分类号:

高照, 吴熙, 夏丹, 张霖宙. 石油加工分子管理平台热力学及分离单元模块开发[J]. 化工学报, 2025, 76(7): 3212-3225.

Zhao GAO, Xi WU, Dan XIA, Linzhou ZHANG. Development of thermodynamics and separation unit modules of petroleum refining molecular management platform[J]. CIESC Journal, 2025, 76(7): 3212-3225.

图1 热力学及分离单元模块与石油加工分子管理平台的连接

Fig.1 Connection between thermodynamics and separation unit modules and petroleum processing molecular management platform

| 性质 | 实验值 | 计算值 |

|---|---|---|

| 密度(20℃)/(g/ml) | 0.8341 | 0.8354 |

| 碳元素含量/%(质量分数) | 86.97 | 86.97 |

| 氢元素含量/%(质量分数) | 12.97 | 12.97 |

| 硫元素含量/%(质量分数) | 5.50×10-2 | 5.51×10-2 |

| 氮元素含量/%(质量分数) | 2.80×10-3 | 2.79×10-3 |

表1 柴油宏观性质的实验值及计算值

Table 1 Experimental and calculated values of bulk properties of diesel

| 性质 | 实验值 | 计算值 |

|---|---|---|

| 密度(20℃)/(g/ml) | 0.8341 | 0.8354 |

| 碳元素含量/%(质量分数) | 86.97 | 86.97 |

| 氢元素含量/%(质量分数) | 12.97 | 12.97 |

| 硫元素含量/%(质量分数) | 5.50×10-2 | 5.51×10-2 |

| 氮元素含量/%(质量分数) | 2.80×10-3 | 2.79×10-3 |

| [1] | Seader J D, Henley E J, Roper D K. Separation Process Principles[M]. 2nd ed. New York: John Wiley & Sons, 2005. |

| [2] | 徐春明, 杨朝合. 石油炼制工程[M]. 4版. 北京: 石油工业出版社, 2009. |

| Xu C M, Yang C H. Petroleum Refining Engineering[M]. 4th ed. Beijing: Petroleum Industry Press, 2009. | |

| [3] | 曹湘洪. 石油化工流程模拟技术进展及应用[M]. 北京: 中国石化出版社, 2010. |

| Cao X H. Progress and Application of Petrochemical Process Simulation Technology[M]. Beijing: China Petrochemical Press, 2010. | |

| [4] | Gmehling J, Kleiber M, Kolbe B, et al. Chemical Thermodynamics for Process Simulation[M]. Wiley, 2019. |

| [5] | Smejkal Q, M Š. Comparison of computer simulation of reactive distillation using aspen plus and hysys software[J]. Chemical Engineering and Processing: Process Intensification, 2002, 41(5): 413-418. |

| [6] | August D, Chang J, Girbal S, et al. UNISIM: an open simulation environment and library for complex architecture design and collaborative development[J]. IEEE Computer Architecture Letters, 2007, 6(2): 45-48. |

| [7] | 蒋洪, 刘支强, 严启团, 等. 天然气低温分离工艺中汞的分布模拟[J]. 天然气工业, 2011, 31(3): 80-84, 115-116. |

| Jiang H, Liu Z Q, Yan Q T, et al. A simulation study of the mercury distribution in the low-temperature gas separation process[J]. Natural Gas Industry, 2011, 31(3): 80-84, 115-116. | |

| [8] | Luo Y Q, Wang L W, Wang H, et al. Simultaneous optimization of heat-integrated crude oil distillation systems[J]. Chinese Journal of Chemical Engineering, 2015, 23(9): 1518-1522. |

| [9] | Haydary J. Chemical Process Design and Simulation: Aspen Plus and Aspen Hysys Applications[M]. Hoboken, NJ: John Wiley & Sons, Inc., 2019. |

| [10] | 王健红, 陈晓春, 魏杰, 等. 化工装置动态模拟与优化工艺软件平台[J]. 化工进展, 1997, 16(4): 49-51. |

| Wang J H, Chen X C, Wei J, et al. Development and application of the chemical process dynamic simulation and optimization system[J]. Chemical Industry and Engineering Progress, 1997, 16(4): 49-51. | |

| [11] | 胡克林, 罗金生. 化工过程模拟技术进展与趋势[J]. 新疆工学院学报, 1997(4): 254-257, 261. |

| Hu K L, Luo J S. Progress and trends of chemical process simulation technique[J]. Journal of Xinjiang Institute of Technology, 1997(4): 254-257, 261. | |

| [12] | 李进龙, 何昌春, 彭昌军, 等. 热力学模型和相平衡网络平台开发及应用[J]. 辽宁石油化工大学学报, 2020, 40(4): 28-34. |

| Li J L, He C C, Peng C J, et al. Development and application of molecular thermodynamic model and online platform for fluid phase equilibria[J]. Journal of Liaoning Shihua University, 2020, 40(4): 28-34. | |

| [13] | 高雷, 楚纪正, 程远. 序贯模块法的面向对象程序设计[J]. 计算机仿真, 2001, 18(3): 56-59. |

| Gao L, Chu J Z, Cheng Y. The realizing of serial-modular approach with object-oriented programming[J]. Computer Simulation, 2001, 18(3): 56-59. | |

| [14] | 项曙光, 郑世清, 荣本光, 等. Vax ECSS 工程化学模拟系统[J]. 计算机与应用化学, 1992, 9(4): 282-288. |

| Xiang S G, Zheng S Q, Rong B G, et al. Vax ECSS engineering chemistry simulation system[J]. Computers and Applied Chemistry, 1992, 9(4): 282-288. | |

| [15] | 王晓红, 吕洪杰, 李玉刚, 等. 新一代化工系统软件结构与功能设计[J]. 青岛化工学院学报: 自然科学版, 2002, 23(1): 28-31. |

| Wang X H, Lyu H J, Li Y G, et al. Function design for a new chemical process system[J]. Journal of Qingdao Institute of Chemical Technology, 2002, 23(1): 28-31. | |

| [16] | 李玉刚, 胡仰栋, 韩方煜. 基于类库的化工过程模拟软件的系统设计[J]. 计算机与应用化学, 2000, 17(5): 416-420. |

| Li Y G, Hu Y D, Han F Y. Chemical process simulation system design based on class library[J]. Computers and Applied Chemistry, 2000, 17(5): 416-420. | |

| [17] | 谢六磊, 张华云, 李浩扬, 等. 基于APEX的连续重整装置实时优化系统[J]. 自动化博览, 2024, 41(5): 18-22. |

| Xie L L, Zhang H Y, Li H Y, et al. APEX-based real-time optimization system for continuous reforming unit[J]. Automation Panorama, 2024, 41(5): 18-22. | |

| [18] | Jacob S M, Gross B, Voltz S E, et al. A lumping and reaction scheme for catalytic cracking[J]. AIChE Journal, 1976, 22(4): 701-713. |

| [19] | Shankar N, Sivasubramanian V, Arunachalam K. Steady state optimization and characterization of crude oil using Aspen HYSYS[J]. Petroleum Science and Technology, 2016, 34(13): 1187-1194. |

| [20] | Gao Z, Xu Z M, Zhao S Q, et al. Heavy petroleum supercritical fluid deasphalting process simulation based on the saturate, aromatic, resin, and asphaltene composition[J]. Energy & Fuels, 2022, 36(16): 8818-8827. |

| [21] | Till Z, Chován T, Varga T. Uncertainties of lumped reaction networks in reactor design[J]. Industrial & Engineering Chemistry Research, 2020, 59(22): 10531-10541. |

| [22] | Marshall A G, Rodgers R P. Petroleomics: the next grand challenge for chemical analysis[J]. Accounts of Chemical Research, 2004, 37(1): 53-59. |

| [23] | 史权, 张亚和, 徐春明, 等. 石油组分高分辨质谱分析进展与展望[J]. 中国科学: 化学, 2014, 44(5): 694-700. |

| Shi Q, Zhang Y H, Xu C M, et al. Progress and prospect on petroleum analysis by fourier transform ion cyclotron resonance mass spectrometry[J]. Scientia Sinica: Chimica, 2014, 44(5): 694-700. | |

| [24] | 史权, 张霖宙, 赵锁奇, 等. 炼化分子管理技术:概念与理论基础[J]. 石油科学通报, 2016, 1(2): 270-278. |

| Shi Q, Zhang L Z, Zhao S Q, et al. Molecular management for petroleum refining: concepts and fundamentals[J]. Petroleum Science Bulletin, 2016, 1(2): 270-278. | |

| [25] | 张霖宙, 赵锁奇, 史权, 等. 石油分子表征与分子层次模型构建:前沿及挑战[J]. 中国科学: 化学, 2020, 50(2): 192-203. |

| Zhang L Z, Zhao S Q, Shi Q, et al. Molecular characterization and modeling of petroleum refining process: frontiers and challenges[J]. Scientia Sinica (Chimica), 2020, 50(2): 192-203. | |

| [26] | 邱彤, 陈金财, 方舟. 基于结构导向集总的石油馏分分子重构模型[J]. 清华大学学报: 自然科学版, 2016, 56(4): 424-429. |

| Qiu T, Chen J C, Fang Z. Molecular reconstruction model for petroleum fractions based on structure oriented lumping[J]. Journal of Tsinghua University: Science and Technology, 2016, 56(4): 424-429. | |

| [27] | Fang Z, Qiu T, Zhou W G. Coupled simulation of recirculation zonal firebox model and detailed kinetic reactor model in an industrial ethylene cracking furnace[J]. Chinese Journal of Chemical Engineering, 2017, 25(8): 1091-1100. |

| [28] | Zhao Q M, Bi K X, Qiu T. Data-driven intelligent modeling framework for the steam cracking process[J]. Chinese Journal of Chemical Engineering, 2023, 61: 237-247. |

| [29] | 倪腾亚, 刘纪昌, 沈本贤, 等. 基于结构导向集总的渣油分子组成矩阵构建模型[J]. 石油炼制与化工, 2015, 46(7): 15-22. |

| Ni T Y, Liu J C, Shen B X, et al. Molecular composition model of residue based on structure oriented lumping[J]. Petroleum Processing and Petrochemicals, 2015, 46(7): 15-22. | |

| [30] | Liu J C, Chen H, Pi Z P, et al. Molecular-level-process model with feedback of the heat effects on a complex reaction network in a fluidized catalytic cracking process[J]. Industrial & Engineering Chemistry Research, 2017, 56(13): 3568-3577. |

| [31] | 王睿通, 刘纪昌, 仲从伟, 等. 基于结构导向集总的催化重整分子水平反应动力学模型[J]. 石油学报(石油加工), 2020, 36(1): 95-105. |

| Wang R T, Liu J C, Zhong C W, et al. Reaction kinetic model for catalytic reforming based on structure oriented lumping[J]. Acta Petrolei Sinica (Petroleum Processing Section), 2020, 36(1): 95-105. | |

| [32] | 张霖宙, 陈政宇, 吕文进, 等. 石油加工分子管理平台构建[J]. 中国科学: 化学, 2018, 48(4): 411-426. |

| Zhang L Z, Chen Z Y, Lyv W J, et al. Development of petroleum refining molecular management modeling platform[J]. Scientia Sinica: Chimica, 2018, 48(4): 411-426. | |

| [33] | Feng S, Cui C, Li K Y, et al. Molecular composition modelling of petroleum fractions based on a hybrid structural unit and bond-electron matrix (SU-BEM) framework[J]. Chemical Engineering Science, 2019, 201: 145-156. |

| [34] | Guan D, Cai G Q, Zhang L Z. Dual-objective optimization for petroleum molecular reconstruction based on property and composition similarities[J]. AIChE Journal, 2023, 69(8): e18108. |

| [35] | Chen Z Y, Feng S, Zhang L Z, et al. Molecular-level kinetic modeling of heavy oil fluid catalytic cracking process based on hybrid structural unit and bond-electron matrix[J]. AIChE Journal, 2021, 67(1): e17027. |

| [36] | 郭天民. 多元气-液平衡和精馏[M]. 北京: 石油工业出版社, 2002. |

| Guo T M. Multi-gas-liquid Equilibrium and Distillation[M]. Beijing: Petroleum Industry Press, 2002. | |

| [37] | Wichterle I, Kobayashi R. Vapor-liquid equilibrium of methane-ethane-propane system at low temperatures and high pressures[J]. Journal of Chemical & Engineering Data, 1972, 17(1): 13-18. |

| [38] | Dingrani J G, Thodos G. Vapor-liquid equilibrium behavior of the ethane: n-butane: n-hexane system[J]. The Canadian Journal of Chemical Engineering, 1978, 56(5): 616-623. |

| [39] | Goni M U, Burgass R, Chapoy A, et al. Isochoric bubble point data for binary systems of 1 (ethane) in 2 (decane, undecane, dodecane and tridecane)[J]. Fluid Phase Equilibria, 2024, 577: 113968. |

| [40] | Lenoir J M, Hipkin H G. Measured enthalpies for mixtures of benzene with n-pentane[J]. Journal of Chemical & Engineering Data, 1972, 17(3): 319-323. |

| [1] | 李怀旭, 孙晓岩, 陶少辉, 夏力, 项曙光. 基于分子热力学性质和密度峰聚类的脱硫汽油集总[J]. 化工学报, 2022, 73(12): 5449-5460. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号