化工学报 ›› 2022, Vol. 73 ›› Issue (12): 5449-5460.DOI: 10.11949/0438-1157.20221231

收稿日期:2022-09-09

修回日期:2022-10-17

出版日期:2022-12-05

发布日期:2023-01-17

通讯作者:

孙晓岩

作者简介:李怀旭(1997—),男,硕士研究生,2438906689@qq.com

基金资助:

Huaixu LI( ), Xiaoyan SUN(

), Xiaoyan SUN( ), Shaohui TAO, Li XIA, Shuguang XIANG

), Shaohui TAO, Li XIA, Shuguang XIANG

Received:2022-09-09

Revised:2022-10-17

Online:2022-12-05

Published:2023-01-17

Contact:

Xiaoyan SUN

摘要:

随着石油分子管理技术的进步,石油及其下游的汽油等产品逐渐以其真实分子组成进行表征。而油品的分子表征在带来更详实信息的同时,也导致炼油过程模拟与优化模型的规模和计算量急剧上升。针对这一问题,应用无须事先确定类别数的密度峰聚类技术,并基于真实组分的热力学性质对油品进行集总,从而以少量虚拟组分对产品油进行充分表征。针对某装置的脱硫汽油集总结果表明,所提出的密度峰聚类集总方法极大地降低了表征汽油产品的分子数目,并在保证模拟精度的同时,有效地提高了汽油分馏塔的模拟计算效率。

中图分类号:

李怀旭, 孙晓岩, 陶少辉, 夏力, 项曙光. 基于分子热力学性质和密度峰聚类的脱硫汽油集总[J]. 化工学报, 2022, 73(12): 5449-5460.

Huaixu LI, Xiaoyan SUN, Shaohui TAO, Li XIA, Shuguang XIANG. Lumping gasoline with molecular properties and density peak clustering[J]. CIESC Journal, 2022, 73(12): 5449-5460.

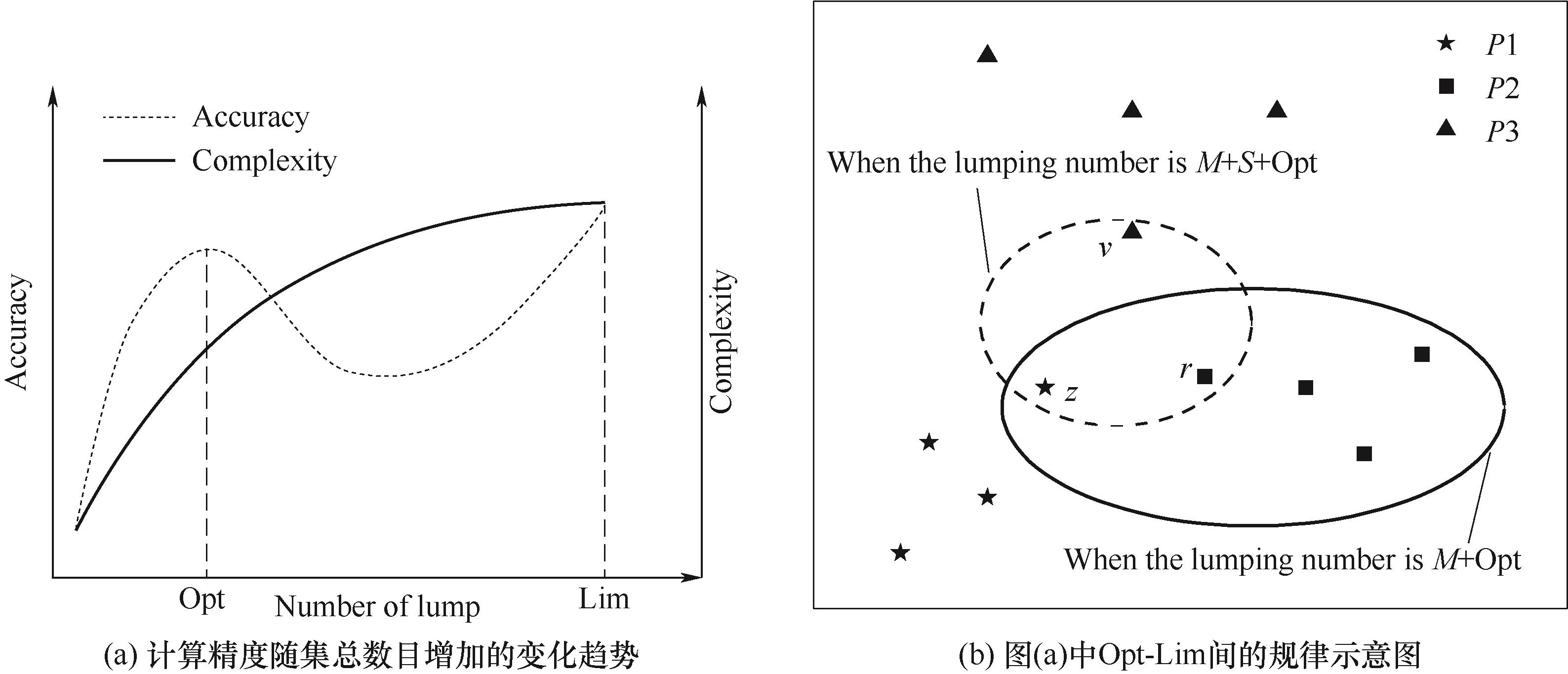

图4 计算精度与组分分配情况随集总数目变化的示意图M, S—增加的集总数目; v, r, z—真实子组分

Fig.4 Schematic diagram of the variation of calculation accuracy and component distribution with the number of lumps

| Molecular formula | Component | MW (28—162) | Tb /K (169—517) | Pc /MPa (2.11—5.69) | Tc/K (282—772) | (0.08—0.5) |

|---|---|---|---|---|---|---|

| C12H26 | dodecane | 170.34 | 489.47 | 1.82 | 658.00 | 0.57 |

| C12H8S | dibenzothiophene | 184.26 | 604.61 | 3.86 | 897.00 | 0.40 |

| C12H18 | 1,4-diisopropylbenzene | 162.27 | 483.65 | 2.45 | 689.00 | 0.39 |

表1 离群组分的部分性质

Table 1 Partial properties of outlier components

| Molecular formula | Component | MW (28—162) | Tb /K (169—517) | Pc /MPa (2.11—5.69) | Tc/K (282—772) | (0.08—0.5) |

|---|---|---|---|---|---|---|

| C12H26 | dodecane | 170.34 | 489.47 | 1.82 | 658.00 | 0.57 |

| C12H8S | dibenzothiophene | 184.26 | 604.61 | 3.86 | 897.00 | 0.40 |

| C12H18 | 1,4-diisopropylbenzene | 162.27 | 483.65 | 2.45 | 689.00 | 0.39 |

| Center component/pseudo-components | MW | Tb/K | Pc/MPa | Tc/K | |

|---|---|---|---|---|---|

| cis-2-butene / PC1 | 56.11 / 57.90 | 276.87 / 275.98 | 4.21 / 4.24 | 435.50 / 440.22 | 0.20 / 0.16 |

| cis-2-pentene / PC2 | 70.13 / 71.24 | 310.08 / 305.00 | 3.64 / 3.19 | 475.00 / 463.04 | 0.24 / 0.23 |

| cis-3-hexene / PC3 | 84.16 / 87.78 | 339.60 / 347.87 | 3.17 / 3.27 | 509.00 / 526.40 | 0.28 / 0.25 |

| 3-methylheptane / PC4 | 114.23 / 114.17 | 392.08 / 391.78 | 2.55 / 2.68 | 563.60 / 571.37 | 0.37 / 0.33 |

| 2,2-dimethyloctane / PC5 | 142.28 /142.26 | 430.05 / 438.46 | 2.16 / 2.23 | 602.00 / 617.68 | 0.43 / 0.41 |

| (1S,3S)-1,2,3-trimethylcyclopentane / PC6 | 112.22 / 117.14 | 390.35 / 418.68 | 2.90 / 3.16 | 579.82 / 630.26 | 0.28 / 0.30 |

| 1,4-dimethyl-2-ethylbenzene / PC7 | 134.22 / 134.15 | 459.98 / 467.90 | 2.88 / 3.38 | 663.00 / 700.67 | 0.41 / 0.31 |

| 2-hexene, 4-methyl-,(2Z)- / PC8 | 98.19 / 103.08 | 359.22 / 391.82 | 2.99 / 3.52 | 527.40 / 595.92 | 0.34 / 0.26 |

| 2,5-dimethylheptane / PC9 | 128.26 / 127.79 | 407.10 / 414.78 | 2.36 / 2.53 | 580.70 / 632.40 | 0.38 / 0.37 |

| 1-ethyl-2-propylbenzene / PC10 | 148.25 / 156.89 | 473.94 / 479.27 | 2.57 / 2.35 | 672.00 / 677.56 | 0.44 / 0.42 |

表2 中心组分与对应的虚拟组分的部分性质

Table 2 Partial properties of center components and corresponding pseudo-components

| Center component/pseudo-components | MW | Tb/K | Pc/MPa | Tc/K | |

|---|---|---|---|---|---|

| cis-2-butene / PC1 | 56.11 / 57.90 | 276.87 / 275.98 | 4.21 / 4.24 | 435.50 / 440.22 | 0.20 / 0.16 |

| cis-2-pentene / PC2 | 70.13 / 71.24 | 310.08 / 305.00 | 3.64 / 3.19 | 475.00 / 463.04 | 0.24 / 0.23 |

| cis-3-hexene / PC3 | 84.16 / 87.78 | 339.60 / 347.87 | 3.17 / 3.27 | 509.00 / 526.40 | 0.28 / 0.25 |

| 3-methylheptane / PC4 | 114.23 / 114.17 | 392.08 / 391.78 | 2.55 / 2.68 | 563.60 / 571.37 | 0.37 / 0.33 |

| 2,2-dimethyloctane / PC5 | 142.28 /142.26 | 430.05 / 438.46 | 2.16 / 2.23 | 602.00 / 617.68 | 0.43 / 0.41 |

| (1S,3S)-1,2,3-trimethylcyclopentane / PC6 | 112.22 / 117.14 | 390.35 / 418.68 | 2.90 / 3.16 | 579.82 / 630.26 | 0.28 / 0.30 |

| 1,4-dimethyl-2-ethylbenzene / PC7 | 134.22 / 134.15 | 459.98 / 467.90 | 2.88 / 3.38 | 663.00 / 700.67 | 0.41 / 0.31 |

| 2-hexene, 4-methyl-,(2Z)- / PC8 | 98.19 / 103.08 | 359.22 / 391.82 | 2.99 / 3.52 | 527.40 / 595.92 | 0.34 / 0.26 |

| 2,5-dimethylheptane / PC9 | 128.26 / 127.79 | 407.10 / 414.78 | 2.36 / 2.53 | 580.70 / 632.40 | 0.38 / 0.37 |

| 1-ethyl-2-propylbenzene / PC10 | 148.25 / 156.89 | 473.94 / 479.27 | 2.57 / 2.35 | 672.00 / 677.56 | 0.44 / 0.42 |

图10 不同集总方法下闪蒸热负荷的绝对误差(与真实组分下的热负荷相比)比较

Fig.10 Comparison of the absolute error of the flash heat duty (compared to the heat load of the real component) of different lumped methods

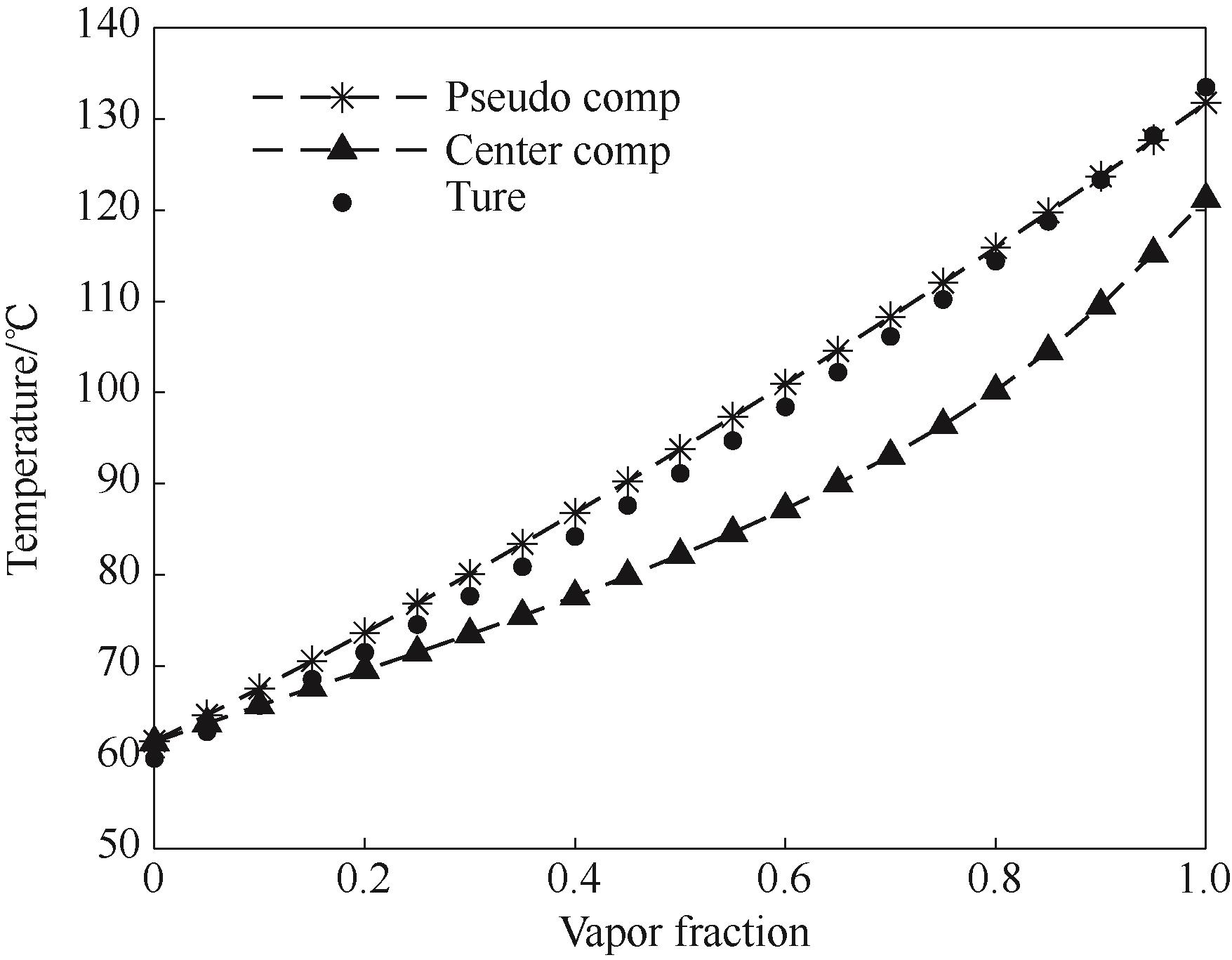

图11 中心组分与虚拟组分在不同汽化分率下的闪蒸温度对比(0.1 MPa)

Fig.11 Comparison of the flash temperature of the center component and the pseudo-component at different vaporization fractions at 0.1 MPa

| Pseudo-component | Tb (Pseudo-component)/K | Tb (Center component)/K | Absolute error/K |

|---|---|---|---|

| PC1 | 275.98 | 276.87 | 0.89 |

| PC2 | 305.00 | 310.10 | 5.10 |

| PC3 | 347.87 | 339.60 | 8.27 |

| PC4 | 391.78 | 392.08 | 0.30 |

| PC5 | 438.46 | 430.05 | 8.41 |

| PC6 | 418.68 | 390.35 | 28.33 |

| PC7 | 467.90 | 459.98 | 7.92 |

| PC8 | 391.82 | 359.22 | 32.60 |

| PC9 | 414.78 | 408.00 | 6.78 |

| PC10 | 479.27 | 473.94 | 5.33 |

表3 各虚拟组分与其中心组分的沸点差距

Table 3 Boiling point gap between each pseudo-component and its center component

| Pseudo-component | Tb (Pseudo-component)/K | Tb (Center component)/K | Absolute error/K |

|---|---|---|---|

| PC1 | 275.98 | 276.87 | 0.89 |

| PC2 | 305.00 | 310.10 | 5.10 |

| PC3 | 347.87 | 339.60 | 8.27 |

| PC4 | 391.78 | 392.08 | 0.30 |

| PC5 | 438.46 | 430.05 | 8.41 |

| PC6 | 418.68 | 390.35 | 28.33 |

| PC7 | 467.90 | 459.98 | 7.92 |

| PC8 | 391.82 | 359.22 | 32.60 |

| PC9 | 414.78 | 408.00 | 6.78 |

| PC10 | 479.27 | 473.94 | 5.33 |

| 1 | Oliveira D F, Silva A C, Figueiredo W P, et al. Crude oil analysis by X-ray scattering technique[J]. X-Ray Spectrometry, 2019, 48(3): 195-201. |

| 2 | Abdulkadir I, Uba S, Salihu A A, et al. A rapid method of crude oil analysis using FT-IR spectroscopy[J]. Nigerian Journal of Basic and Applied Sciences, 2016, 24(1): 47. |

| 3 | 田松柏, 龙军, 李长秀, 等. 石油轻馏分的分子水平表征技术研究进展[J]. 石油学报(石油加工), 2017, 33(4): 595-604. |

| Tian S B, Long J, Li C X, et al. Research advance on analytical techniques of the petroleum light fractions at the molecular level[J]. Acta Petrolei Sinica (Petroleum Processing Section), 2017, 33(4): 595-604. | |

| 4 | Shi Q, Zhang L Z, Xu C M, et al. Molecular characterization and modeling of petroleum refining process: frontiers and challenges[J]. Scientia Sinica Chimica, 2020, 50(2): 192-203. |

| 5 | Feng S, Cui C, Li K Y, et al. Molecular composition modelling of petroleum fractions based on a hybrid structural unit and bond-electron matrix (SU-BEM) framework[J]. Chemical Engineering Science, 2019, 201: 145-156. |

| 6 | Ren Y, Liao Z W, Sun J Y, et al. Molecular reconstruction: recent progress toward composition modeling of petroleum fractions[J]. Chemical Engineering Journal, 2019, 357: 761-775. |

| 7 | Ren Y, Liao Z W, Sun J Y, et al. Molecular reconstruction of naphtha via limited bulk properties: methods and comparisons[J]. Industrial & Engineering Chemistry Research, 2019, 58(40): 18742-18755. |

| 8 | 于博, 周祥, 郭锦标. 石油组分分子水平划分方法研究进展[J]. 计算机与应用化学, 2014, 31(5): 583-586. |

| Yu B, Zhou X, Guo J B. Research progress of classification of crude oil components on molecular level[J]. Computers and Applied Chemistry, 2014, 31(5): 583-586. | |

| 9 | Weekman V W Jr. Model of catalytic cracking conversion in fixed, moving, and fluid-bed reactors[J]. Industrial & Engineering Chemistry Process Design and Development, 1968, 7(1): 90-95. |

| 10 | Montel F, Gouel P L. A new lumping scheme of analytical data for compositional studies[C]//SPE Annual Technical Conference and Exhibition. Houston, Texas: Society of Petroleum Engineers, 1984. |

| 11 | Leibovici C, Stenby E H, Knudsen K. A consistent procedure for pseudo-component delumping[J]. Fluid Phase Equilibria, 1996, 117(1/2): 225-232. |

| 12 | 封松. 石油分子层次组成及分离过程的模型构建[D]. 北京: 中国石油大学(北京), 2019. |

| Feng S. Molecular modeling of composition and separation process of petroleum fractions[D]. Beijing: China University of Petroleum, 2019. | |

| 13 | 张霖宙, 李凯宇, 史权, 等. 一种石油分子层次分离过程模拟的方法及其装置: 108279251A[P]. 2018-07-13. |

| Zhang L Z, Li K Y, Shi Q, et al. Method and device for simulating petroleum molecular level separation process: 108279251A[P]. 2018-07-13. | |

| 14 | Zheng L G. Improved K-means clustering algorithm based on dynamic clustering[J]. International Journal of Advanced Research in Big Data Management System, 2020, 4(1): 17-26. |

| 15 | 张明微, 吴海涛. 一种优化初始聚类中心的k-means算法[J]. 上海师范大学学报(自然科学版), 2016, 45(5): 599-603. |

| Zhang M W, Wu H T. A k-means algorithm to optimize the initial cluster centers[J]. Journal of Shanghai Normal University (Natural Sciences), 2016, 45(5): 599-603. | |

| 16 | 秦美华, 朱红求, 李勇刚, 等. 基于STA-K均值聚类的电化学废水处理过程离子浓度软测量[J]. 化工学报, 2019, 70(9): 3458-3464. |

| Qin M H, Zhu H Q, Li Y G, et al. Soft-sensor method for ion concentration of electrochemical wastewater treatment based on STA-K-means clustering[J]. CIESC Journal, 2019, 70(9): 3458-3464. | |

| 17 | Rodriguez A, Laio A. Clustering by fast search and find of density peaks[J]. Science, 2014, 344(6191): 1492-1496. |

| 18 | Cheng Y Z. Mean shift, mode seeking, and clustering[J]. IEEE Transactions on Pattern Analysis and Machine Intelligence, 1995, 17(8): 790-799. |

| 19 | Fukunaga K, Hostetler L. The estimation of the gradient of a density function, with applications in pattern recognition[J]. IEEE Transactions on Information Theory, 1975, 21(1): 32-40. |

| 20 | Mehmood R, Zhang G Z, Bie R F, et al. Clustering by fast search and find of density peaks via heat diffusion[J]. Neurocomputing, 2016, 208: 210-217. |

| 21 | Lyu B C, Wu W H, Hu Z Q. A novel bidirectional clustering algorithm based on local density[J]. Scientific Reports, 2021, 11: 14214. |

| 22 | 陈叶旺, 申莲莲, 钟才明, 等. 密度峰值聚类算法综述[J]. 计算机研究与发展, 2020, 57(2): 378-394. |

| Chen Y W, Shen L L, Zhong C M, et al. Survey on density peak clustering algorithm[J]. Journal of Computer Research and Development, 2020, 57(2): 378-394. | |

| 23 | Flores K G, Garza S E. Density peaks clustering with gap-based automatic center detection[J]. Knowledge-Based Systems, 2020, 206: 106350. |

| 24 | Ding J J, He X X, Yuan J Q, et al. Automatic clustering based on density peak detection using generalized extreme value distribution[J]. Soft Computing, 2018, 22(9): 2777-2796. |

| 25 | 毕荣山, 韩智慧, 陶少辉, 等. 基于热扩散核密度确定密度峰值法的历史工况识别[J]. 化工学报, 2022, 73(4): 1615-1622. |

| Bi R S, Han Z H, Tao S H, et al. Recognizing historical operating conditions by determining the density peaks at kernel density estimation of heat diffusion[J]. CIESC Journal, 2022, 73(4): 1615-1622. | |

| 26 | Rodriguez M Z, Comin C H, Casanova D, et al. Clustering algorithms: a comparative approach[J]. PLoS One, 2019, 14(1): e0210236. |

| 27 | Sun L, Liu R N, Xu J C, et al. An adaptive density peaks clustering method with fisher linear discriminant[J]. IEEE Access, 2019, 7: 72936-72955. |

| 28 | Sehgal G, Garg K. Comparison of various clustering algorithms[J]. International Journal of Computer Science and Information Technologies, 2014, 5(3): 3074-3076. |

| 29 | Leibovici C F. A consistent procedure for the estimation of properties associated to lumped systems[J]. Fluid Phase Equilibria, 1993, 87(2): 189-197. |

| 30 | 张建忠, 张彪, 王仁安. 用改进的Riazi-Daubert法预测烃类临界性质[J]. 石油炼制与化工, 1998, 29(3): 55-56. |

| Zhang J Z, Zhang B, Wang R A. Prediction of critical properties of hydrocarbons with modified riazi daubert method[J]. Petroleum Processing and Petrochemicals, 1998, 29(3): 55-56. | |

| 31 | 齐丽, 孙晓岩, 王建平, 等. 石油馏分偏心因子估算方法及评价[J]. 计算机与应用化学, 2017, 34(10): 774-779. |

| Qi L, Sun X Y, Wang J P, et al. Evaluation of estimation method for acentric factor of petroleum fractions[J]. Computers and Applied Chemistry, 2017, 34(10): 774-779. | |

| 32 | 孙兰义. 化工过程模拟实训: Aspen Plus教程[M]. 2版. 北京: 化学工业出版社, 2017: 477. |

| Sun L Y. Chemical Process Simulation Training: Aspen Plus Tutorial[M]. 2nd ed. Beijing: Chemical Industry Press, 2017: 477. | |

| 33 | Lv Y, Liu M D, Xiang Y. Fast searching density peak clustering algorithm based on shared nearest neighbor and adaptive clustering center[J]. Symmetry, 2020, 12(12): 2014. |

| [1] | 曹跃, 余冲, 李智, 杨明磊. 工业数据驱动的加氢裂化装置多工况切换过渡状态检测[J]. 化工学报, 2023, 74(9): 3841-3854. |

| [2] | 林典, 江国梅, 徐秀彬, 赵波, 刘冬梅, 吴旭. 硅基类液防原油黏附涂层的研制及其减阻性能研究[J]. 化工学报, 2023, 74(8): 3438-3445. |

| [3] | 刘爽, 张霖宙, 许志明, 赵锁奇. 渣油及其组分黏度的分子层次组成关联研究[J]. 化工学报, 2023, 74(8): 3226-3241. |

| [4] | 诸程瑛, 王振雷. 基于改进深度强化学习的乙烯裂解炉操作优化[J]. 化工学报, 2023, 74(8): 3429-3437. |

| [5] | 尹刚, 李伊惠, 何飞, 曹文琦, 王民, 颜非亚, 向禹, 卢剑, 罗斌, 卢润廷. 基于KPCA和SVM的铝电解槽漏槽事故预警方法[J]. 化工学报, 2023, 74(8): 3419-3428. |

| [6] | 周继鹏, 何文军, 李涛. 异形催化剂上乙烯催化氧化失活动力学反应工程计算[J]. 化工学报, 2023, 74(6): 2416-2426. |

| [7] | 高学金, 姚玉卓, 韩华云, 齐咏生. 基于注意力动态卷积自编码器的发酵过程故障监测[J]. 化工学报, 2023, 74(6): 2503-2521. |

| [8] | 姚晓宇, 沈俊, 李健, 李振兴, 康慧芳, 唐博, 董学强, 公茂琼. 流体气液临界参数测量方法研究进展[J]. 化工学报, 2023, 74(5): 1847-1861. |

| [9] | 陈科, 杜理, 曾英, 任思颖, 于旭东. 四元体系LiCl+MgCl2+CaCl2+H2O 323.2 K相平衡研究及计算[J]. 化工学报, 2023, 74(5): 1896-1903. |

| [10] | 郑书闽, 郭鹏程, 颜建国, 王帅, 李文博, 周淇. 微小通道内过冷流动沸腾阻力特性实验及预测研究[J]. 化工学报, 2023, 74(4): 1549-1560. |

| [11] | 顾学荣, 刘硕士, 杨思宇. 基于并行EGO和代理模型辅助的多参数优化方法研究[J]. 化工学报, 2023, 74(3): 1205-1215. |

| [12] | 毛元敬, 杨智, 莫松平, 郭浩, 陈颖, 罗向龙, 陈健勇, 梁颖宗. C6~C10烷醇的SAFT-VR Mie状态方程参数回归及其热物性研究[J]. 化工学报, 2023, 74(3): 1033-1041. |

| [13] | 张生安, 刘桂莲. 高效太阳能电解水制氢系统及其性能的多目标优化[J]. 化工学报, 2023, 74(3): 1260-1274. |

| [14] | 张家庆, 蒋榕培, 史伟康, 武博翔, 杨超, 刘朝晖. 煤基/石油基火箭煤油高参数黏温特性与组分特性研究[J]. 化工学报, 2023, 74(2): 653-665. |

| [15] | 程文婷, 李杰, 徐丽, 程芳琴, 刘国际. AlCl3·6H2O在FeCl3、CaCl2、KCl及KCl–FeCl3溶液中溶解度的实验及预测[J]. 化工学报, 2023, 74(2): 642-652. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号