化工学报 ›› 2021, Vol. 72 ›› Issue (11): 5800-5809.DOI: 10.11949/0438-1157.20210694

收稿日期:2021-05-21

修回日期:2021-06-21

出版日期:2021-11-05

发布日期:2021-11-12

通讯作者:

陆规

作者简介:陈程(1987—),女,博士,高级工程师,基金资助:

Cheng CHEN1( ),Xin CHEN2,Feng XU3,Bin WU1,Yuanyuan LI2,Gui LU2(

),Xin CHEN2,Feng XU3,Bin WU1,Yuanyuan LI2,Gui LU2( )

)

Received:2021-05-21

Revised:2021-06-21

Online:2021-11-05

Published:2021-11-12

Contact:

Gui LU

摘要:

湿法脱硫排出的废水是燃煤机组废水中最难处理的末端废水之一。热法固化是实现脱硫废水零排放的必然途径。通过构建整个燃煤机组厂级尺度热力系统虚拟仿真模型,从能量流、物料流、水平衡及其之间的相互影响机制的角度对比分析了目前三种主流不同脱硫工艺路线的优劣。在此基础上,提出了基于吸附式热泵和多效蒸馏浓缩,废热用于干燥的新型脱硫工艺,新工艺所需的高温烟气量最小,仅为旁路直喷式的1/5,为目前主流浓缩干燥方案的1/3,在回收水分的同时,极大降低高温烟气的消耗量,降低对主机安全性的影响。相关研究可以为燃煤机组脱硫废水零排放及深度节水提供新的解决思路。

中图分类号:

陈程, 陈鑫, 徐凤, 吴斌, 李元媛, 陆规. 燃煤机组脱硫废水零排放物料-能-水耦合机制及优化[J]. 化工学报, 2021, 72(11): 5800-5809.

Cheng CHEN, Xin CHEN, Feng XU, Bin WU, Yuanyuan LI, Gui LU. Matter-energy-water coupling mechanism and optimization for zero discharge of desulfurization wastewater from coal-fired units[J]. CIESC Journal, 2021, 72(11): 5800-5809.

| 指标 | 烟气温度/℃ | 给水 温度/℃ | |||||

|---|---|---|---|---|---|---|---|

前屏 出口 | 后屏出口 | 高再出口 | 高过 出口 | 低再出口 | 省煤器出口 | ||

| 设计 | 1124.91 | 1020 | 900 | 785 | 515 | 296.04 | 280.4 |

| 模拟 | 1244 | 1137 | 964 | 683 | 512 | 296 | 260 |

| 误差 | 9.60% | 11.5% | 6.64% | 13.00% | 0.58% | 0 | 7.31% |

| 指标 | 温升/℃ | 总功率/ kW | |||||

| #7、#8 | #6 | #5 | #1 | #2 | #3 | ||

| 设计 | 47 | 20 | 40 | 20 | 30 | 30 | 600000 |

| 模拟 | 57 | 20 | 39 | 20 | 30 | 33 | 604890 |

| 误差 | 21.30% | 0 | 2.50% | 0 | 0 | 10% | 0.81% |

表1 600 MW电厂模型验证

Table 1 Validation of 600 MW power plant model

| 指标 | 烟气温度/℃ | 给水 温度/℃ | |||||

|---|---|---|---|---|---|---|---|

前屏 出口 | 后屏出口 | 高再出口 | 高过 出口 | 低再出口 | 省煤器出口 | ||

| 设计 | 1124.91 | 1020 | 900 | 785 | 515 | 296.04 | 280.4 |

| 模拟 | 1244 | 1137 | 964 | 683 | 512 | 296 | 260 |

| 误差 | 9.60% | 11.5% | 6.64% | 13.00% | 0.58% | 0 | 7.31% |

| 指标 | 温升/℃ | 总功率/ kW | |||||

| #7、#8 | #6 | #5 | #1 | #2 | #3 | ||

| 设计 | 47 | 20 | 40 | 20 | 30 | 30 | 600000 |

| 模拟 | 57 | 20 | 39 | 20 | 30 | 33 | 604890 |

| 误差 | 21.30% | 0 | 2.50% | 0 | 0 | 10% | 0.81% |

| 物质名称 | 单位 | 喷入前脱硫废水 | 喷入后脱硫废水 |

|---|---|---|---|

| water | kg·h-1 | 15953.9 | 1.1 |

| SO2 | kg·h-1 | 3.32×10-9 | 0.0014 |

| kg·h-1 | 0.037 | 0.034 | |

| kg·h-1 | 6288.8 | 6823.5 | |

| kg·h-1 | 53.9 | 58.4 | |

| kg·h-1 | 1073.5 | 1218.2 | |

| kg·h-1 | 950.0 | 919.1 | |

| CaSO4(s) | kg·h-1 | 32.0 | 31.1 |

| Cl- | kg·h-1 | 246.6 | 267.5 |

| 总流量 | kg·h-1 | 28452.5 | 13825.4 |

表2 干燥塔进出口物料

Table 2 Drying tower inlet and outlet parameters

| 物质名称 | 单位 | 喷入前脱硫废水 | 喷入后脱硫废水 |

|---|---|---|---|

| water | kg·h-1 | 15953.9 | 1.1 |

| SO2 | kg·h-1 | 3.32×10-9 | 0.0014 |

| kg·h-1 | 0.037 | 0.034 | |

| kg·h-1 | 6288.8 | 6823.5 | |

| kg·h-1 | 53.9 | 58.4 | |

| kg·h-1 | 1073.5 | 1218.2 | |

| kg·h-1 | 950.0 | 919.1 | |

| CaSO4(s) | kg·h-1 | 32.0 | 31.1 |

| Cl- | kg·h-1 | 246.6 | 267.5 |

| 总流量 | kg·h-1 | 28452.5 | 13825.4 |

| 物质名称 | 单位 | 浓缩塔入口废水含量 | 浓缩塔出口废水含量 | 干燥塔出口废水含量 |

|---|---|---|---|---|

| water | kg·h-1 | 16946.53 | 9704.90 | 1.85 |

| SO2 | kg·h-1 | 2.03×10-7 | 0.61 | 0.0015 |

| kg·h-1 | 10.20 | 1.11 | 1.11 | |

| kg·h-1 | 5626.34 | 4884.68 | 4884.68 | |

| kg·h-1 | 47.37 | 41.12 | 41.12 | |

| kg·h-1 | 647.08 | 488.31 | 488.31 | |

| kg·h-1 | 1488.19 | 1443.85 | 1443.85 | |

| CaSO4(s) | kg·h-1 | 33.62 | 35.42 | 35.42 |

| Cl- | kg·h-1 | 220.76 | 191.84 | 191.84 |

| 总流量 | kg·h-1 | 28452.5 | 19770.80 | 10247.29 |

表3 浓缩-干燥法进出口物料变化

Table 3 Concentration - drying method of import and export material changes

| 物质名称 | 单位 | 浓缩塔入口废水含量 | 浓缩塔出口废水含量 | 干燥塔出口废水含量 |

|---|---|---|---|---|

| water | kg·h-1 | 16946.53 | 9704.90 | 1.85 |

| SO2 | kg·h-1 | 2.03×10-7 | 0.61 | 0.0015 |

| kg·h-1 | 10.20 | 1.11 | 1.11 | |

| kg·h-1 | 5626.34 | 4884.68 | 4884.68 | |

| kg·h-1 | 47.37 | 41.12 | 41.12 | |

| kg·h-1 | 647.08 | 488.31 | 488.31 | |

| kg·h-1 | 1488.19 | 1443.85 | 1443.85 | |

| CaSO4(s) | kg·h-1 | 33.62 | 35.42 | 35.42 |

| Cl- | kg·h-1 | 220.76 | 191.84 | 191.84 |

| 总流量 | kg·h-1 | 28452.5 | 19770.80 | 10247.29 |

| 物质名称 | 单位 | 多效蒸馏入口脱硫废水 | 多效蒸馏出口脱硫废水 |

|---|---|---|---|

| water | kg·h-1 | 17196.00 | 9701.67 |

| SO2 | kg·h-1 | 2.92×10-9 | 0 |

| kg·h-1 | 0.031 | 0.030 | |

| kg·h-1 | 4585.17 | 4715.64 | |

| kg·h-1 | 39.78 | 40.89 | |

| kg·h-1 | 1459.35 | 1529.06 | |

| kg·h-1 | 1441.47 | 1424.68 | |

| CaSO4(s) | kg·h-1 | 18.53 | 18.73 |

| Cl- | kg·h-1 | 179.75 | 184.86 |

| 总流量 | kg·h-1 | 28452.5 | 21197.06 |

表4 多效蒸馏进出口物料变化

Table 4 Multi-effect distillation import and export material changes

| 物质名称 | 单位 | 多效蒸馏入口脱硫废水 | 多效蒸馏出口脱硫废水 |

|---|---|---|---|

| water | kg·h-1 | 17196.00 | 9701.67 |

| SO2 | kg·h-1 | 2.92×10-9 | 0 |

| kg·h-1 | 0.031 | 0.030 | |

| kg·h-1 | 4585.17 | 4715.64 | |

| kg·h-1 | 39.78 | 40.89 | |

| kg·h-1 | 1459.35 | 1529.06 | |

| kg·h-1 | 1441.47 | 1424.68 | |

| CaSO4(s) | kg·h-1 | 18.53 | 18.73 |

| Cl- | kg·h-1 | 179.75 | 184.86 |

| 总流量 | kg·h-1 | 28452.5 | 21197.06 |

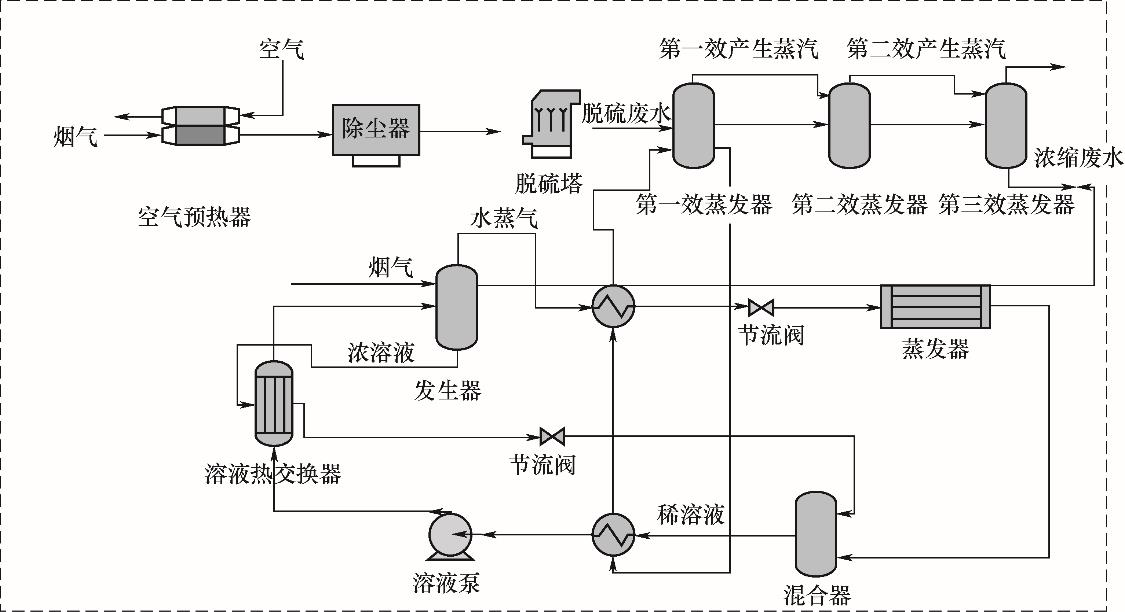

图8 新型吸收式热泵驱动多效蒸馏浓缩干燥脱硫废水处理工艺

Fig.8 Absorption heat pump driven multi-effect distillation concentration drying desulfurization wastewater treatment process

| 技术路线 | 消耗热量/kW | 入口废水流量/(kg·h-1) | 结晶固体/(kg·h-1) | 凝结水含量/(kg·h-1) | 高温烟气热量/kW |

|---|---|---|---|---|---|

| 旁路烟气+干燥 | 10323.75 | 28452.5 | 13825.39 | N/A | 10323.75 |

| 浓缩塔+干燥 | 12590.74 | 28452.54 | 10247.29 | N/A | 6695.37 |

| MED +干燥 | 9142.97 | 28452.54 | 12455.26 | 7208.68 | 6692.97 |

| MED+热泵+干燥 | 6213.89 | 28452.54 | 12710.46 | 13208.57 | 2358.65 |

表5 四种工艺路线定量对比

Table 5 Quantitative comparison of four process routes

| 技术路线 | 消耗热量/kW | 入口废水流量/(kg·h-1) | 结晶固体/(kg·h-1) | 凝结水含量/(kg·h-1) | 高温烟气热量/kW |

|---|---|---|---|---|---|

| 旁路烟气+干燥 | 10323.75 | 28452.5 | 13825.39 | N/A | 10323.75 |

| 浓缩塔+干燥 | 12590.74 | 28452.54 | 10247.29 | N/A | 6695.37 |

| MED +干燥 | 9142.97 | 28452.54 | 12455.26 | 7208.68 | 6692.97 |

| MED+热泵+干燥 | 6213.89 | 28452.54 | 12710.46 | 13208.57 | 2358.65 |

| 1 | 张静. 燃煤电厂脱硫废水零排放处理技术研究进展[J]. 煤质技术, 2021, 36(02): 7-13. |

| Zhang J. Research progress on zero-discharge treatment technology of desulfurization wastewater in coal-fired power plant[J]. Coal Quality Technology, 2021, 36(2): 7-13. | |

| 2 | 张家平, 孙碧玉, 何志炜. 脱硫废水“零排放”技术研究进展[J]. 中国环保产业, 2020(12): 52-58. |

| Zhang J P, Sun B Y, He Z W. Research progress of technologies for “zero discharge” of desulfurization wastewater[J]. China Environmental Protection Industry, 2020(12): 52-58. | |

| 3 | 蒋路漫, 周振, 田小测, 等. 电厂烟气脱硫废水零排放工艺中试研究[J]. 热力发电, 2019, 48(1): 103-109. |

| Jiang L M, Zhou Z, Tian X C, et al. Pilot-scale study on zero liquid discharge technology of flue gas desulfurization wastewater in coal-fired power plants[J]. Thermal Power Generation, 2019, 48(1): 103-109. | |

| 4 | Yan M W, Shi Y T. Thermal and economic analysis of multi-effect concentration system by utilizing waste heat of flue gas for magnesium desulfurization wastewater[J]. Energies, 2020, 13(20): 5384. |

| 5 | Han X Q, Zhang D, Yan J J, et al. Process development of flue gas desulphurization wastewater treatment in coal-fired power plants towards zero liquid discharge: Energetic, economic and environmental analyses[J]. Journal of Cleaner Production, 2020, 261: 121144. |

| 6 | 佘晓利, 潘卫国, 郭士义, 等. 燃煤电厂湿法烟气脱硫废水零排放技术进展[J]. 应用化工, 2018, 47(1): 160-164. |

| She X L, Pan W G, Guo S Y, et a1. Advances in zero-discharge technology for wet flue gas desulfurization wastewater from coal-fired power plants[J]. Applied Chemical Industry, 2018, 47(1): 160-164. | |

| 7 | 杨跃伞, 苑志华, 张净瑞, 等. 燃煤电厂脱硫废水零排放技术研究进展[J]. 水处理技术, 2017, 43(6): 29-33. |

| Yang Y S, Yuan Z H, Zhang J R, et a1. Research progress of technologies for zero-discharge of desulfurization wastewater from coal-fired power plants[J]. Technology of Water Treatment, 2017, 43(6): 29-33. | |

| 8 | 吴优福, 刘捷, 海玉琰, 等. 超超临界1000 MW机组脱硫废水零排放技术[J]. 热力发电, 2017, 46(5): 108-114. |

| Wu Y F, Liu J, Hai Y Y, et a1. Discussions on zero-discharge technology of desulfurization wastewater for ultra supercritical units[J]. Thermal Power Generation, 2017, 46(5): 108-114. | |

| 9 | 杜献亮. 煤化工行业高含盐废水处理及多效蒸发结晶技术的应用[J]. 煤炭与化工, 2014, 37(12): 129-131, 142. |

| Du X L. Treatment of high salt wastewater in coal chemical industry and application of multi-effect evaporation crystallization technology[J]. Coal and Chemical Industry, 2014, 37(12): 129-131, 142. | |

| 10 | 张净瑞, 梁海山, 郑煜铭, 等. 基于旁路烟道蒸发的脱硫废水零排放技术在火电厂的应用[J]. 环境工程, 2017, 35(10): 5-9. |

| Zhang J R, Liang H S, Zheng Y M, et al. Application of zero liquid discharge system of the desulfurization wastewater based on bypass flue evaporation system in thermal power plants[J]. Environmental Engineering, 2017, 35(10): 5-9. | |

| 11 | 程国辉. 燃煤电厂湿法脱硫废水零排放处理技术[J]. 化学工程与装备, 2021(4): 247-248. |

| Cheng G H. Zero discharge treatment technology of wet desulfurization wastewater in coal-fired power plant[J]. Chemical Engineering & Equipment, 2021(4): 247-248. | |

| 12 | 刘应书, 孙宁起, 李子宜, 等. 冷凝法回收烟气吸附脱硫解吸气中SO2工艺参数的影响规律研究[J]. 化工学报, 2020, 71(12): 5620-5627. |

| Liu Y S, Sun N Q, Li Z Y, et al. Influence of process parameters of condensation on the recovery of SO2 in desorption gas from flue gas adsorption desulfurization[J]. CIESC Journal, 2020, 71(12): 5620-5627. | |

| 13 | 马双忱, 陈嘉宁, 刘宁, 等. 低温烟气余热浓缩脱硫废水实验研究与探讨[J]. 动力工程学报, 2020, 40(1): 51-57, 64. |

| Ma S C, Chen J N, Liu N, et al. Experimental study on the concentration of FGD wastewater using low-temperature flue gas[J]. Journal of Chinese Society of Power Engineering, 2020, 40(1): 51-57, 64. | |

| 14 | Guo H Q, Wang J, Wu J B, et al. Study on spray evaporation treatment of desulfurization wastewater[J]. Coatings, 2021, 11(4):418. |

| 15 | 马双忱, 周权, 曹建宗, 等. 湿法脱硫系统动态过程建模与仿真[J]. 化工学报, 2020, 71(8): 3741-3751. |

| Ma S C, Zhou Q, Cao J Z, et al. Modeling and simulation of wet desulfurization system dynamic process[J]. CIESC Journal, 2020, 71(8): 3741-3751. | |

| 16 | Chen H, Liu F J, Cai C J, et al. Release and migration characteristics of chlorine during the desulfurization wastewater evaporation process[J]. Fuel Processing Technology, 2021, 218: 106863. |

| 17 | Xu Y, Jin B, Zhou Z, et al. Experimental and numerical investigations of desulfurization wastewater evaporation in a lab-scale flue gas duct: evaporation and HCl release characteristics[J]. Environmental Technology, 2021, 42(9): 1411-1427. |

| 18 | 滕达, 李铁林, 李昂, 等. 单通道陶瓷膜管低压透水性能实验分析[J]. 化工学报, 2020, 71: 261-271. |

| Teng D, Li T L, Li A, et al. Experimental analysis of low pressure water permeability of single channel ceramic membrane tube[J]. CIESC Journal, 2020, 71: 261-271. | |

| 19 | 李飞. 旋转雾化蒸发技术对脱硫废水和烟气的适应性研究[J]. 中国电力, 2021, 54(4): 213-220. |

| Li F. Study on the adaptability of rotary atomization evaporation technology to desulfurization wastewater and flue gas[J]. Electric power[J]. Electric Power, 2021, 54(4): 213-220. | |

| 20 | Neveux T, Hagi H, Le Moullec Y. Performance simulation of full-scale wet flue gas desulfurization for oxy-coal combustion[J]. Energy Procedia, 2014, 63: 463-470. |

| 21 | Gutiérrez Ortiz F J. A simple realistic modeling of full-scale wet limestone FGD units[J]. Chemical Engineering Journal, 2010, 165(2): 426-439. |

| 22 | 展锦程, 冉景煜, 孙图星. 烟气脱硫吸收塔反应过程的数值模拟及试验研究[J]. 动力工程, 2008, 28(3): 433-437, 446. |

| Zhan J C, Ran J Y, Sun T X. Numerical simulation and experimental study on desulfurization process in FGD absorbers[J]. Journal of Power Engineering, 2008, 28(3): 433-437, 446. | |

| 23 | 张建华, 池毓菲, 邹宜金, 等. 燃煤电厂脱硫废水处理技术工程应用现状与展望[J]. 工业水处理, 2020, 40(10): 14-19. |

| Zhang J H, Chi Y F, Zou Y J, et al. Application progress and prospect of desulfurization wastewater treatment technologies in coal-fired power plants[J]. Industrial Water Treatment, 2020, 40(10): 14-19. | |

| 24 | 周正, 曹扬, 丁卫华, 等. 浓缩蒸发工艺在660 MW机组脱硫废水零排放中的应用[J]. 水处理技术, 2020, 46(11): 117-119, 124. |

| Zhou Z, Cao Y, Ding W H, et al. Application of concentrated evaporation technology in zero smission of desulfurization wastewater of a 660 MW unit[J]. Technology of Water Treatment, 2020, 46(11): 117-119, 124. | |

| 25 | 刘春红, 秦刚华, 邹正伟, 等. 燃煤发电厂的深度节水与废水零排放[J]. 水处理技术, 2020, 46(10): 128-132. |

| Liu C H, Qin G H, Zou Z W, et al. Deep water saving and zero liquid dischargeincoal-fired power plant[J]. Technology of Water Treatment, 2020, 46(10): 128-132. | |

| 26 | 林炜. 烟道蒸发脱硫废水零排放的优化应用研究[J]. 安全与环境工程, 2020, 27(5): 55-61. |

| Lin W. Study on the optimal application of zero discharge of flue evaporation desulfurization wastewater[J]. Safety and Environmental Engineering, 2020, 27(5): 55-61. | |

| 27 | Zhang X M, Zhang C L, Meng F N, et al. Near-zero liquid discharge of desulfurization wastewater by electrodialysis-reverse osmosis hybrid system[J]. Journal of Water Process Engineering, 2021, 40: 101962. |

| 28 | 许甲清, 叶春松, 李清, 等. 脱硫废水低温烟气蒸发零排放系统平衡计算[J]. 热力发电, 2021, 50(2): 97-103. |

| Xu J Q, Ye C S, Li Q, et al. Balance calculation for zero discharge system of desulfurization wastewater using low temperature flue gas evaporation method[J]. Thermal Power Generation, 2021, 50(2): 97-103. | |

| 29 | Ma S C, Chai J, Chen G D, et al. Research on desulfurization wastewater evaporation: Present and future perspectives[J]. Renewable and Sustainable Energy Reviews, 2016, 58: 1143-1151. |

| 30 | Ma S C, Chai J, Wu K, et al. Experimental research on bypass evaporation tower technology for zero liquid discharge of desulfurization wastewater[J]. Environmental Technology, 2019, 40(20): 2715-2725. |

| [1] | 黄琮琪, 吴一梅, 陈建业, 邵双全. 碱性电解水制氢装置热管理系统仿真研究[J]. 化工学报, 2023, 74(S1): 320-328. |

| [2] | 仪桐辛, 张磊, 都健. 吸收式热泵循环的新型有机工质对计算机辅助分子设计[J]. 化工学报, 2021, 72(3): 1457-1464. |

| [3] | 马双忱, 范紫瑄, 万忠诚, 陈嘉宁, 张净瑞, 马采妮. 高盐水条件下亚硫酸盐氧化特性实验研究[J]. 化工学报, 2019, 70(5): 1964-1972. |

| [4] | 刘勇, 赵汶, 刘瑞, 杨林军. 化学团聚促进电除尘脱除PM2.5的实验研究[J]. 化工学报, 2014, 65(9): 3609-3616. |

| [5] | 李卜义,王建友. 浓海水处理及综合利用技术的新进展[J]. 化工进展, 2014, 33(11): 3067-3074. |

| [6] | 齐春华, 邢玉雷, 康权, 徐克, 冯厚军. 30t·d-1低温多效海水淡化装置中试试验[J]. 化工学报, 2013, 64(8): 3023-3030. |

| [7] | 吴伟, 石文星, 王宝龙, 李先庭. 不同增压方式对空气源吸收式热泵性能影响的模拟分析[J]. 化工学报, 2013, 64(7): 2360-2368. |

| [8] | 贾红书1,付 林1,张世钢2. 开式吸收式热泵及在烟气余热回收中的应用[J]. 化工进展, 2013, 32(12): 2805-2812. |

| [9] | 王愉晨1,池勇志1,苏润西1,孙 涛2,杨和义2,苑宏英1,姜远光1,费学宁1. 浓盐水零排放技术的研究进展[J]. 化工进展, 2013, 32(06): 1423-1428. |

| [10] | 马学虎,兰 忠,王四芳,李 璐. 海水淡化浓盐水排放对环境的影响与零排放技术研究进展 [J]. CIESC Journal, 2011, 30(1): 233-. |

| [11] | 吕向红. 液化天然气分离的节能蒸馏工艺 [J]. CIESC Journal, 2008, 27(6): 954-. |

| [12] | 钟理,谭盈科. 水/二甘醇Ⅱ型吸收式热泵性能的模拟 [J]. CIESC Journal, 1992, 43(3): 353-359. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号