化工学报 ›› 2024, Vol. 75 ›› Issue (1): 231-241.DOI: 10.11949/0438-1157.20231114

李晓阳1( ), 李东1(

), 李东1( ), 陶明磊1, 周致富1(

), 陶明磊1, 周致富1( ), 张灵怡1, 苏力争2, 张天宁2, 李智2, 陈斌1

), 张灵怡1, 苏力争2, 张天宁2, 李智2, 陈斌1

收稿日期:2023-10-30

修回日期:2023-12-20

出版日期:2024-01-25

发布日期:2024-03-11

通讯作者:

李东,周致富

作者简介:李晓阳(1999—),女,硕士研究生,joeng@stu.xjtu.edu.cn

基金资助:

Xiaoyang LI1( ), Dong LI1(

), Dong LI1( ), Minglei TAO1, Zhifu ZHOU1(

), Minglei TAO1, Zhifu ZHOU1( ), Lingyi ZHANG1, Lizheng SU2, Tianning ZHANG2, Zhi LI2, Bin CHEN1

), Lingyi ZHANG1, Lizheng SU2, Tianning ZHANG2, Zhi LI2, Bin CHEN1

Received:2023-10-30

Revised:2023-12-20

Online:2024-01-25

Published:2024-03-11

Contact:

Dong LI, Zhifu ZHOU

摘要:

低沸点制冷剂(R134a)喷雾冷却能快速降低表面温度,在高性能芯片等电子设备热管理、生物医学中均具有广泛应用,可实现喷雾表面的低温高效散热。多喷嘴喷雾冷却可实现较大冷却表面的均匀冷却及冷量的灵活调控。搭建了制冷剂喷雾冷却实验台,研究了多喷嘴喷雾冷却表面传热特性,并分析了喷嘴的孔径、间距、高度、喷雾时间和喷雾压力等因素对多喷嘴喷雾冷却表面传热特性的影响。结果表明:喷嘴孔径对冷却均匀性影响最大,其次是喷嘴间距,适当的喷嘴孔径(0.4 mm)和间距(11 mm)能使制冷剂喷雾在表面合理分布,最低温Tmin能达到最小值;10 mm喷嘴高度和1.2 MPa喷雾压力可以使液滴充分雾化并延长有效冷却时间。

中图分类号:

李晓阳, 李东, 陶明磊, 周致富, 张灵怡, 苏力争, 张天宁, 李智, 陈斌. 多喷嘴喷雾冷却表面传热特性实验研究[J]. 化工学报, 2024, 75(1): 231-241.

Xiaoyang LI, Dong LI, Minglei TAO, Zhifu ZHOU, Lingyi ZHANG, Lizheng SU, Tianning ZHANG, Zhi LI, Bin CHEN. Experimental study on heat transfer characteristics of multi nozzle spray cooling surface[J]. CIESC Journal, 2024, 75(1): 231-241.

| 喷雾时间/ms | 制冷剂喷射质量/g | ||

|---|---|---|---|

| 0.6 MPa | 1.2 MPa | 1.9 MPa | |

| 30 | 0.242 | 0.410 | 0.537 |

| 50 | 0.403 | 0.684 | 0.895 |

| 70 | 0.564 | 0.957 | 1.253 |

表1 不同驱动压力和不同喷雾时间的制冷剂喷射量

Table 1 Refrigerant injection at different drive pressures and spray time

| 喷雾时间/ms | 制冷剂喷射质量/g | ||

|---|---|---|---|

| 0.6 MPa | 1.2 MPa | 1.9 MPa | |

| 30 | 0.242 | 0.410 | 0.537 |

| 50 | 0.403 | 0.684 | 0.895 |

| 70 | 0.564 | 0.957 | 1.253 |

| 项目 | 厚度z/mm | 热导率 | 密度 | 比热容 cp /(J/(kg·K)) |

|---|---|---|---|---|

| 紫铜 | 1 | 398 | 8930 | 386 |

| 人体皮肤 | 0.05 | 0.209 | 1000 | 3530 |

| 环氧树脂 | 5.0 | 0.841 | 1936.96 | 564.80 |

表2 紫铜、人体皮肤和环氧树脂热物理性质

Table 2 Thermophysical properties of copper, human skin, and epoxy resin

| 项目 | 厚度z/mm | 热导率 | 密度 | 比热容 cp /(J/(kg·K)) |

|---|---|---|---|---|

| 紫铜 | 1 | 398 | 8930 | 386 |

| 人体皮肤 | 0.05 | 0.209 | 1000 | 3530 |

| 环氧树脂 | 5.0 | 0.841 | 1936.96 | 564.80 |

图8 不同喷嘴直径下制冷剂喷瞬态雾冷却下喷雾表面不同测点温度变化曲线

Fig.8 Temperature variation of different measuring points on the surface during cryogen spray cooling with different nozzle diameters

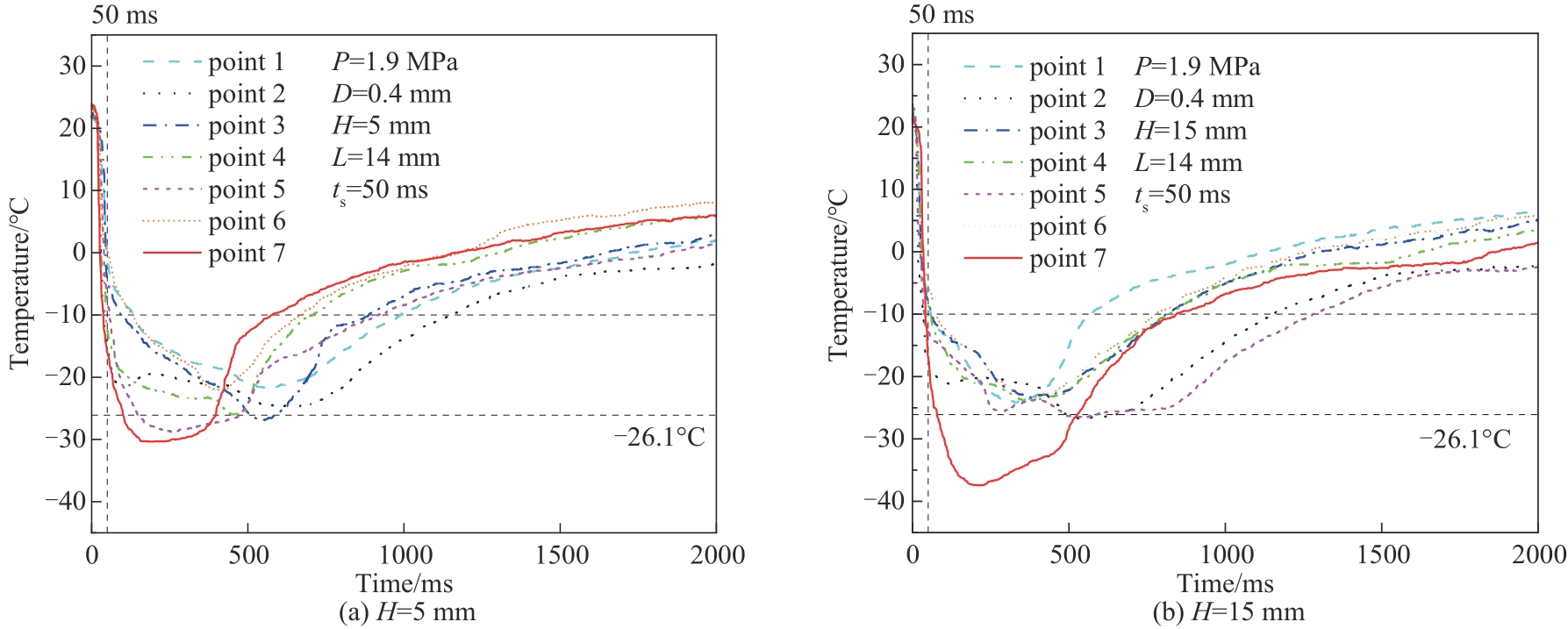

图9 不同喷嘴高度下制冷剂喷瞬态雾冷却下喷雾表面不同测点温度变化曲线

Fig.9 Temperature variation of different measuring points on the surface during cryogen spray cooling at different nozzle heights

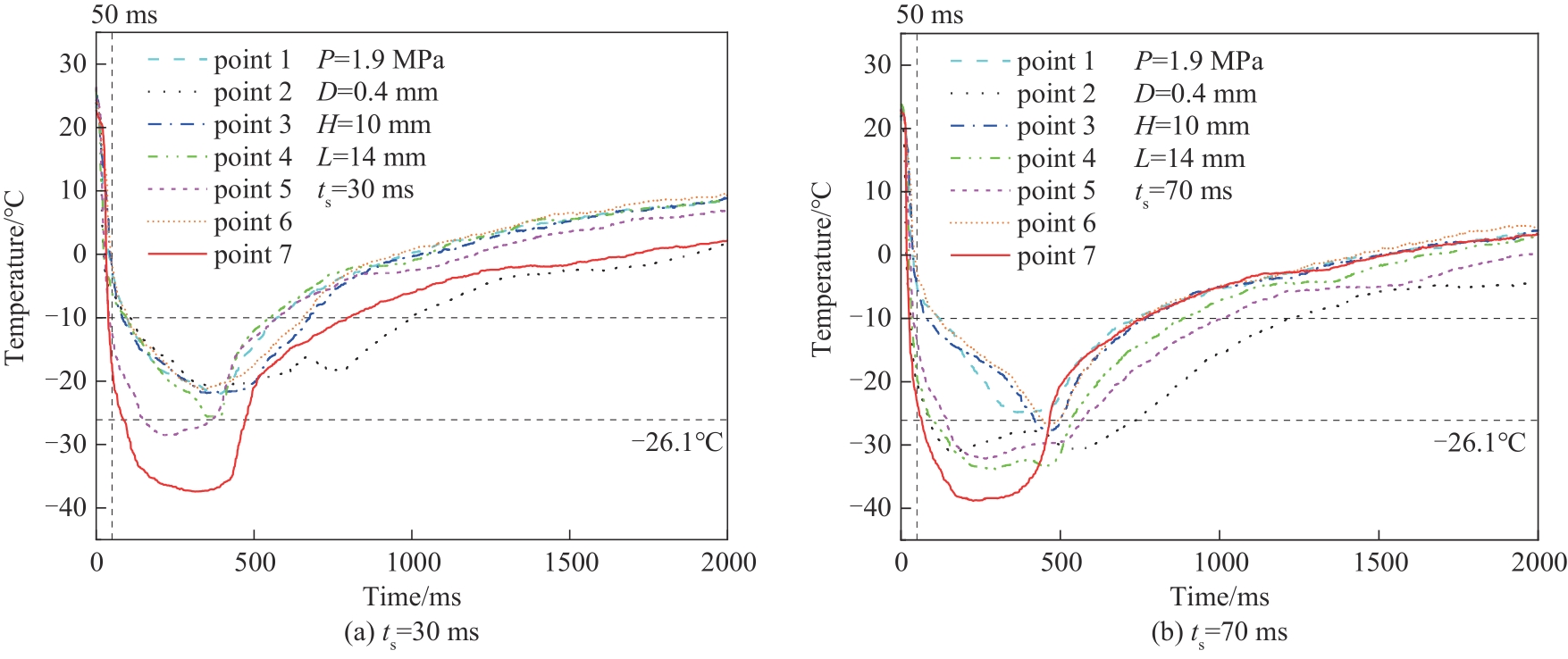

图10 不同喷雾时间下制冷剂喷瞬态雾冷却下喷雾表面不同测点温度变化曲线

Fig.10 Temperature variation of different measuring points on the surface during cryogen spray cooling with different spray time

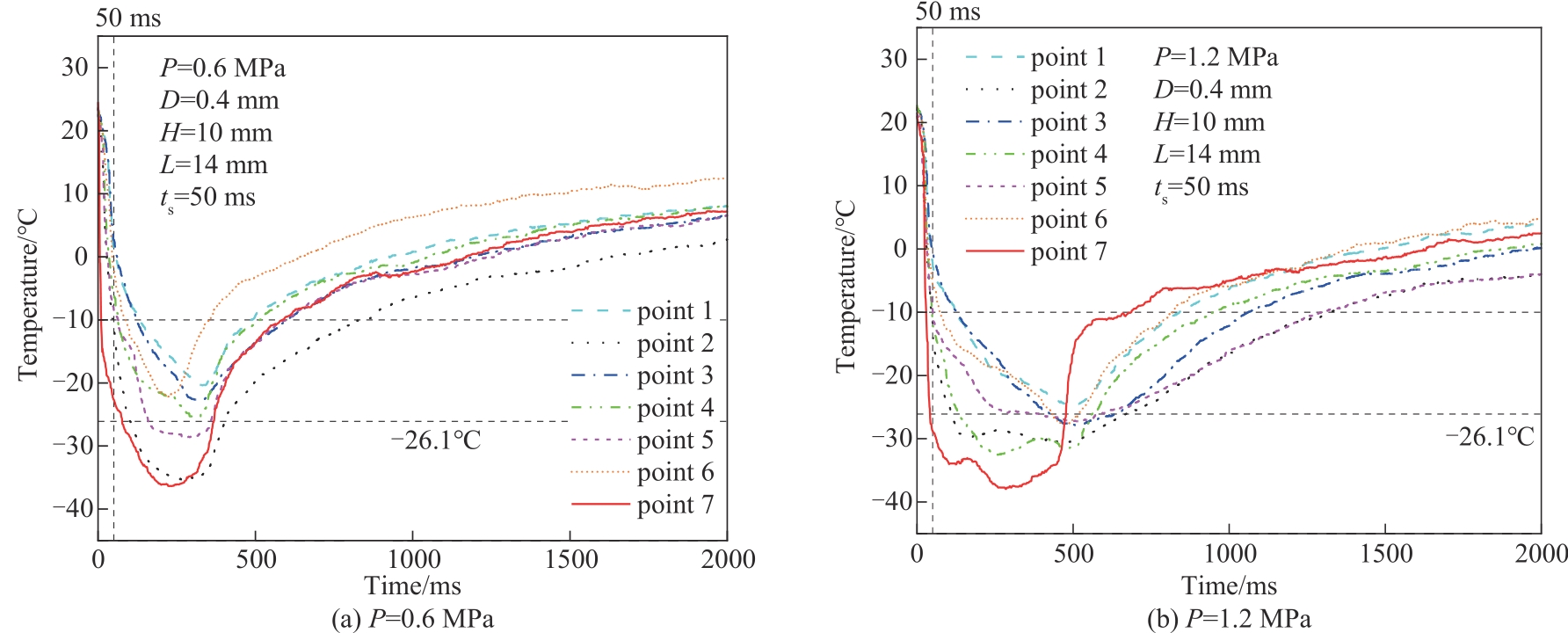

图11 不同喷雾压力下制冷剂喷瞬态雾冷却下喷雾表面不同测点温度变化曲线

Fig.11 Temperature variation of different measuring points on the surface during cryogen spray cooling under different drive pressure

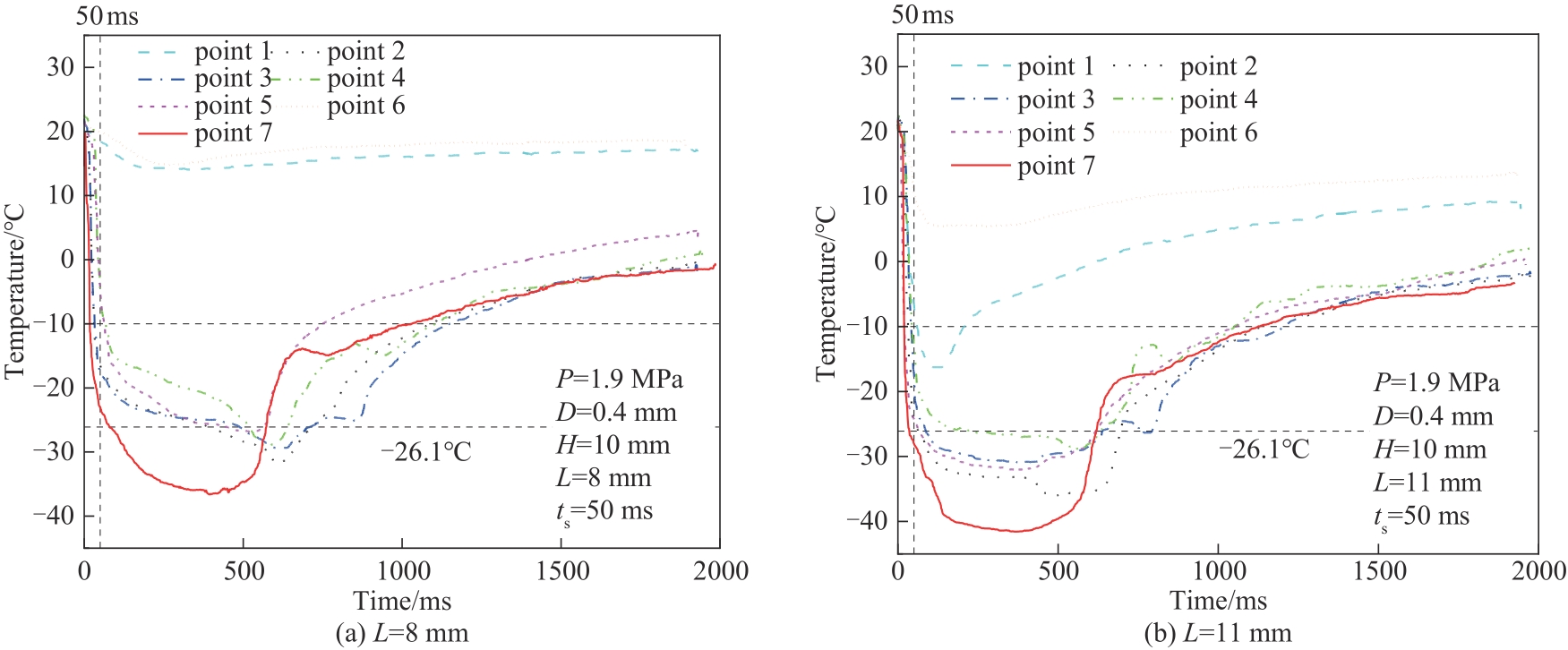

图12 不同喷嘴间距下制冷剂喷瞬态雾冷却下喷雾表面不同测点温度变化曲线

Fig.12 Temperature variation of different measuring points on the spray surface during cryogen spray cooling under different nozzle distances

图13 不同喷雾参数下基板表面各测点最低温度和有效冷却时间统计

Fig.13 Statistics of minimum temperature and effective cooling time of each measuring point on the cooling surface with different spray parameters

| 参数 | 最低温度/°C | 温差/°C | 冷却时间差/ms |

|---|---|---|---|

| 喷嘴孔径 | |||

| 0.2 mm | -32.5 | 16.6 | 1554 |

| 0.4 mm | -40.4 | 18.8 | 505 |

| 0.6 mm | -37.5 | 20.2 | 318 |

| 喷嘴高度 | |||

| 5 mm | -30.4 | 8.7 | 563 |

| 10 mm | -40.4 | 18.8 | 505 |

| 15 mm | -37.5 | 14.1 | 725 |

| 喷雾时间 | |||

| 30 ms | -37.4 | 17.0 | 437 |

| 50 ms | -40.4 | 18.8 | 505 |

| 70 ms | -38.8 | 14.0 | 567 |

| 喷雾压力 | |||

| 0.6 MPa | -36.4 | 16.1 | 513 |

| 1.2 MPa | -38.0 | 13.2 | 608 |

| 1.9 MPa | -40.4 | 18.8 | 505 |

| 喷嘴间距 | |||

| 8 mm | -36.6 | 7.7 | 437 |

| 11 mm | -40.6 | 25.3 | 1021 |

| 14 mm | -40.4 | 18.8 | 505 |

表3 不同喷雾参数下基板表面各测点最低温度、表面温差和有效冷却时间统计

Table 3 Statistics of minimum temperature, surface temperature difference and effective cooling time of each measuring point on the substrate surface with different spray parameters

| 参数 | 最低温度/°C | 温差/°C | 冷却时间差/ms |

|---|---|---|---|

| 喷嘴孔径 | |||

| 0.2 mm | -32.5 | 16.6 | 1554 |

| 0.4 mm | -40.4 | 18.8 | 505 |

| 0.6 mm | -37.5 | 20.2 | 318 |

| 喷嘴高度 | |||

| 5 mm | -30.4 | 8.7 | 563 |

| 10 mm | -40.4 | 18.8 | 505 |

| 15 mm | -37.5 | 14.1 | 725 |

| 喷雾时间 | |||

| 30 ms | -37.4 | 17.0 | 437 |

| 50 ms | -40.4 | 18.8 | 505 |

| 70 ms | -38.8 | 14.0 | 567 |

| 喷雾压力 | |||

| 0.6 MPa | -36.4 | 16.1 | 513 |

| 1.2 MPa | -38.0 | 13.2 | 608 |

| 1.9 MPa | -40.4 | 18.8 | 505 |

| 喷嘴间距 | |||

| 8 mm | -36.6 | 7.7 | 437 |

| 11 mm | -40.6 | 25.3 | 1021 |

| 14 mm | -40.4 | 18.8 | 505 |

| 1 | Hsieh S S, Luo S Y. Droplet impact dynamics and transient heat transfer of a micro spray system for power electronics devices[J]. International Journal of Heat and Mass Transfer, 2016, 92: 190-205. |

| 2 | Bar-Cohen A, Maurer J, Felbinger J. DARPA's intra/interchip enhanced cooling (ICECool) program[C]//CS MANTECH Conference. 2013: 171-174. |

| 3 | Mudawar I. Assessment of high-heat-flux thermal management schemes[J]. IEEE Transactions on Components and Packaging Technologies, 2001, 24(2): 122-141. |

| 4 | Chen R H, Chow L C, Navedo J E. Effects of spray characteristics on critical heat flux in subcooled water spray cooling[J]. International Journal of Heat and Mass Transfer, 2002, 45(19): 4033-4043. |

| 5 | Gao X, Li R. Effects of nozzle positioning on single-phase spray cooling[J]. International Journal of Heat and Mass Transfer, 2017, 115: 1247-1257. |

| 6 | Zhang W W, Li Y Y, Long W J, et al. Enhancement mechanism of high alcohol surfactant on spray cooling: experimental study[J]. International Journal of Heat and Mass Transfer, 2018, 126: 363-376. |

| 7 | Tilton D E, Pais M R, Chow L. High power density spray cooling[R]. Wright Laboratory: New Haven, OH, USA, 1989. |

| 8 | Rini D P, Chen R H, Chow L C. Bubble behavior and nucleate boiling heat transfer in saturated FC-72 spray cooling[J]. Journal of Heat Transfer, 2002, 124(1): 63-72. |

| 9 | Chen H, Cheng W L, Peng Y H, et al. Experimental study on optimal spray parameters of piezoelectric atomizer based spray cooling[J]. International Journal of Heat and Mass Transfer, 2016, 103: 57-65. |

| 10 | Kandasamy R, Ho J Y, Liu P F, et al. Two-phase spray cooling for high ambient temperature data centers: evaluation of system performance[J]. Applied Energy, 2022, 305: 117816. |

| 11 | Xue R, Lin X Y, Ruan Y, et al. Cooling performance of multi-nozzle spray with liquid nitrogen[J]. Cryogenics, 2022, 121: 103389. |

| 12 | Bandaru S V R, Villanueva W, Konovalenko A, et al. Upward-facing multi-nozzle spray cooling experiments for external cooling of reactor pressure vessels[J]. International Journal of Heat and Mass Transfer, 2020, 163: 120516. |

| 13 | Aguilar G, Choi B, Broekgaarden M, et al. An overview of three promising mechanical, optical, and biochemical engineering approaches to improve selective photothermolysis of refractory port wine stains[J]. Annals of Biomedical Engineering, 2012, 40(2): 486-506. |

| 14 | Nelson J S, Milner T E, Anvari B, et al. Dynamic epidermal cooling during pulsed laser treatment of port-wine stain. A new methodology with preliminary clinical evaluation[J]. Archives of Dermatology, 1995, 131(6): 695-700. |

| 15 | Nelson J S, Milner T E, Anvari B, et al. Dynamic epidermal cooling in conjunction with laser‐induced photothermolysis of port wine stain blood vessels[J]. Lasers in Surgery and Medicine, 1996, 19(2): 224-229. |

| 16 | Aguilar G, Wang G X, Nelson J S. Dynamic behavior of cryogen spray cooling: effects of spurt duration and spray distance[J]. Lasers in Surgery and Medicine: The Official Journal of the American Society for Laser Medicine and Surgery, 2003, 32(2): 152-159. |

| 17 | Aguilar G, Wang G X, Nelson J S. Effect of spurt duration on the heat transfer dynamics during cryogen spray cooling[J]. Physics in Medicine and Biology, 2003, 48(14): 2169-2181. |

| 18 | Zhou Z F, Wang R, Chen B, et al. Heat transfer characteristics during pulsed spray cooling with R404A at different spray distances and back pressures[J]. Applied Thermal Engineering, 2016, 102: 813-821. |

| 19 | Zhou Z F, Chen B, Wang R, et al. Coupling effect of hypobaric pressure and spray distance on heat transfer dynamics of R134a pulsed flashing spray cooling[J]. Experimental Thermal and Fluid Science, 2016, 70: 96-104. |

| 20 | Sarmadian A, Dunne J F, Jose J T, et al. Correlation models of critical heat flux and associated temperature for spray evaporative cooling of vibrating surfaces[J]. International Journal of Heat and Mass Transfer, 2021, 179: 121735. |

| 21 | Sarmadian A, Thalackottore Jose J, Dunne J F, et al. The effect of key parameter changes on the critical heat flux of spray evaporatively-cooled vibrating surfaces using a single misting nozzle[J]. Applied Thermal Engineering, 2022, 213: 118815. |

| 22 | Tian J M, Chen B, Zhou Z F. Parametric effect investigation on surface heat transfer performances during cryogen spray cooling[J]. Applied Thermal Engineering, 2018, 143: 767-776. |

| 23 | Tian J M, Chen B, Li D. Light transmittance dynamics and spectral absorption characteristics during auxiliary cryogen spray cooling in laser dermatology[J]. Lasers in Medical Science, 2022, 37(3): 2079-2086. |

| 24 | Li B F, Wang J F, Tian J M, et al. Transient cooling performance of R134a flash-evaporation spray enhanced by cold air jet: a novel heat transfer enhancement method in laser dermatology[J]. International Journal of Heat and Mass Transfer, 2022, 199: 123468. |

| 25 | Franco W, Liu J E, Wang G X, et al. Radial and temporal variations in surface heat transfer during cryogen spray cooling[J]. Physics in Medicine and Biology, 2005, 50(2): 387-397. |

| 26 | 王锐, 陈斌, 王嘉丰, 等. R1234yf瞬态喷雾冷却及过热度影响的实验研究[J]. 化工学报, 2018, 69(2): 595-601. |

| Wang R, Chen B, Wang J F, et al. Experimental research of R1234yf transient spray cooling and influence of cryogen superheat degree[J]. CIESC Journal, 2018, 69(2): 595-601. | |

| 27 | Aguilar G, Majaron B, Karapetian E, et al. Experimental study of cryogen spray properties for application in dermatologic laser surgery[J]. IEEE Transactions on Biomedical Engineering, 2003, 50(7): 863-869. |

| [1] | 陈天华, 刘兆轩, 韩群, 张程宾, 李文明. 喷雾冷却换热强化研究进展及影响因素[J]. 化工学报, 2023, 74(8): 3149-3170. |

| [2] | 李俊, 黎仕华, 孙志高, 宋士博. 超声对无沸腾区浸液式喷雾冷却的影响研究[J]. 化工学报, 2022, 73(4): 1566-1574. |

| [3] | 詹宏波, 郑文远, 文涛, 张大林. 微尺度通道内R134a的冷凝传热实验研究[J]. 化工学报, 2020, 71(S1): 83-89. |

| [4] | 周年勇, 徐慕豪, 冯浩, 段锋, 王庆荣, 陈海飞, 郭强. 闭式喷雾冷却的瞬态传热过程研究[J]. 化工学报, 2020, 71(3): 1018-1025. |

| [5] | 刘红, 何阳, 蔡畅, 高久良, 尹洪超. 乙醇和正丁醇添加剂对喷雾冷却的影响[J]. 化工学报, 2019, 70(1): 65-71. |

| [6] | 王勤, 刘轶伦, 卢炜, 王世宽, 何巍, 郝楠, 张绍志. R134a/R23-DMF溶液气泡泵输送性能实验[J]. 化工学报, 2018, 69(S2): 116-122. |

| [7] | 孟照峰, 张华, 秦延斌, 杨梦, 梁浩. R1234yf/R134a混合物在汽车空调中替代R134a的实验研究[J]. 化工学报, 2018, 69(6): 2396-2403. |

| [8] | 亓航, 张伟, 巩亮. 喷雾冲击条件下液膜流动与传热模型[J]. 化工学报, 2018, 69(5): 2014-2022. |

| [9] | 金旭, 于跃, 陈作舟, 党超镔, 刘忠彦. 超音速和亚音速喷嘴对可调式喷射器性能的影响[J]. 化工学报, 2018, 69(4): 1405-1411. |

| [10] | 辛慧, 陈斌, 周致富, 田加猛. 激光溶脂手术脉冲式制冷剂喷雾冷却数值研究[J]. 化工学报, 2018, 69(12): 4966-4971. |

| [11] | 陈斌, 周致富, 辛慧. 制冷剂瞬态闪蒸喷雾冷却研究进展[J]. 化工学报, 2018, 69(1): 57-68. |

| [12] | 谈莹莹, 王林, 白得坡, 闫晓娜. R23/R134a一级分凝和二级分凝自复叠喷射制冷循环性能理论分析[J]. 化工学报, 2016, 67(S2): 107-112. |

| [13] | 邱金友, 张华, 余晓明, 王袭, 吴银龙. 新型制冷剂R1234ze(E)水平圆管内流动沸腾换热特性[J]. 化工学报, 2016, 67(6): 2255-2262. |

| [14] | 杨涛, 周致富, 陈斌, 赵曦, 王国祥. 表面温度测量方式对喷雾冷却表面传热特性的影响[J]. 化工学报, 2016, 67(11): 4558-4565. |

| [15] | 田加猛, 陈斌, 李东, 周致富. 制冷剂瞬态喷雾冷却表面传热特性[J]. 化工学报, 2016, 67(10): 4064-4071. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号