化工学报 ›› 2023, Vol. 74 ›› Issue (8): 3149-3170.DOI: 10.11949/0438-1157.20230151

收稿日期:2023-02-23

修回日期:2023-08-08

出版日期:2023-08-25

发布日期:2023-10-18

通讯作者:

李文明

作者简介:陈天华(2001—),男,硕士研究生,220220638@seu.edu.cn

基金资助:

Tianhua CHEN( ), Zhaoxuan LIU, Qun HAN, Chengbin ZHANG, Wenming LI(

), Zhaoxuan LIU, Qun HAN, Chengbin ZHANG, Wenming LI( )

)

Received:2023-02-23

Revised:2023-08-08

Online:2023-08-25

Published:2023-10-18

Contact:

Wenming LI

摘要:

喷雾冷却是一种高效的散热手段,广泛应用于高热通量电子元器件的热管理。近年来,喷雾冷却引起了极大的关注,其换热能力得到了显著的提升。特别地,新型微纳米表面的开发极大地促进了喷雾冷却传热的发展,丰富了喷雾传热强化的机理研究。因此,本文全面系统地总结了喷雾冷却的最新研究成果,讨论了喷雾换热的强化机理,从传热表面特性,工作介质以及喷嘴参数等多个方面讨论了喷雾冷却换热的关键影响因素。最后,进一步探讨了喷雾冷却抑制Leidenfrost现象的机制,并对喷雾冷却未来研究方向进行了展望。

中图分类号:

陈天华, 刘兆轩, 韩群, 张程宾, 李文明. 喷雾冷却换热强化研究进展及影响因素[J]. 化工学报, 2023, 74(8): 3149-3170.

Tianhua CHEN, Zhaoxuan LIU, Qun HAN, Chengbin ZHANG, Wenming LI. Research progress and influencing factors of the heat transfer enhancement of spray cooling[J]. CIESC Journal, 2023, 74(8): 3149-3170.

| 文献 | 经验公式 | 工质 | 备注 |

|---|---|---|---|

| [ | 蒸馏水 | ||

| [ | 蒸馏水 | ||

| [ | FC-32 FC-87 蒸馏水 | ||

| [ | PF-5060 FC-72 FC-87 蒸馏水 | N+为液滴数密度 | |

| [ | PF-5060 | P为局部撞击压力 | |

| [ | 蒸馏水 | 流量:6.2~12.4 kg/(m2·s); ΔP=2~7 bar | |

| [ | 蒸馏水 |

表1 不同CHF经验关联式

Table 1 Various empirical correlations of CHF

| 文献 | 经验公式 | 工质 | 备注 |

|---|---|---|---|

| [ | 蒸馏水 | ||

| [ | 蒸馏水 | ||

| [ | FC-32 FC-87 蒸馏水 | ||

| [ | PF-5060 FC-72 FC-87 蒸馏水 | N+为液滴数密度 | |

| [ | PF-5060 | P为局部撞击压力 | |

| [ | 蒸馏水 | 流量:6.2~12.4 kg/(m2·s); ΔP=2~7 bar | |

| [ | 蒸馏水 |

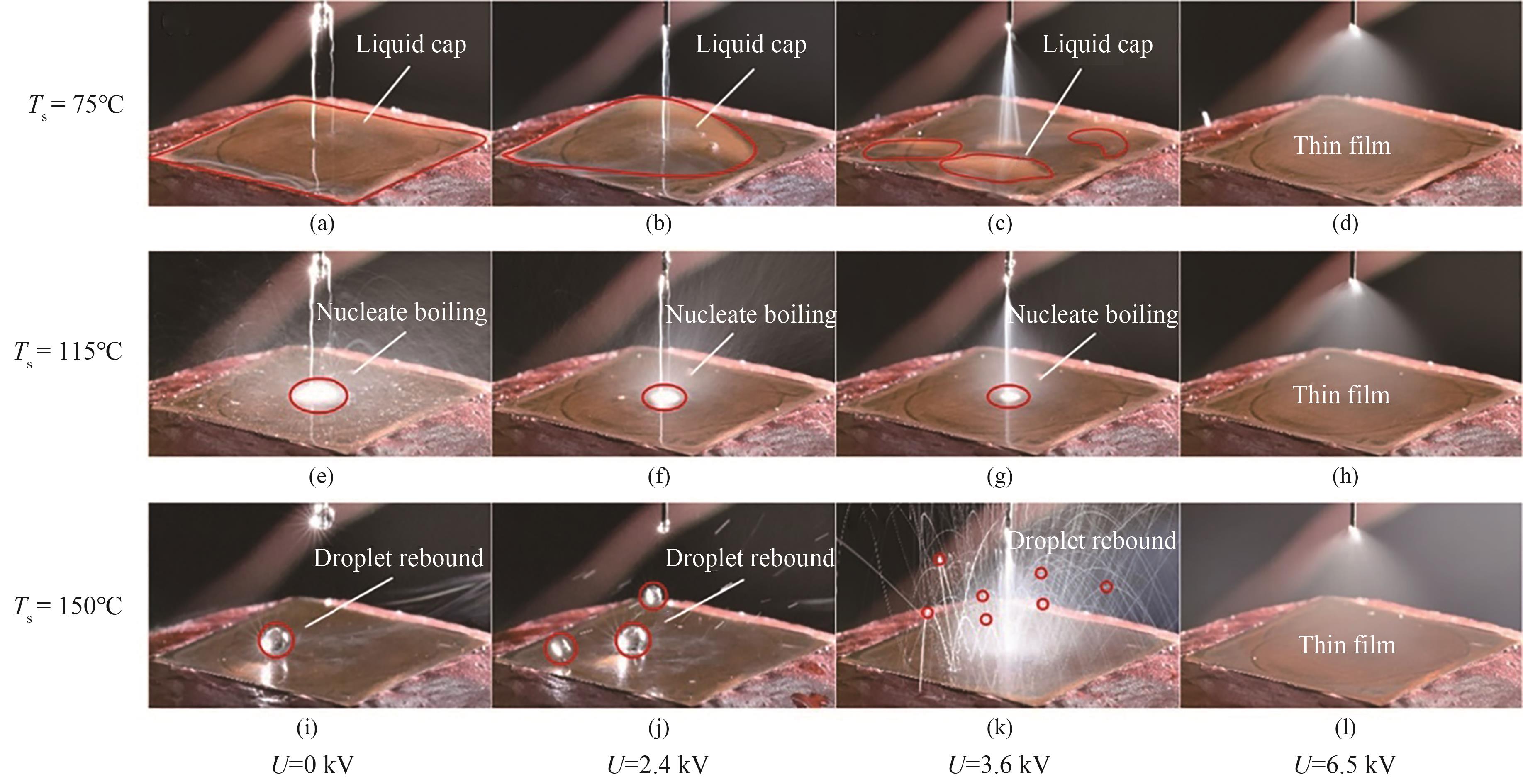

图5 不同表面温度下电喷雾四种模式液滴的动态行为和成膜特性[36]

Fig.5 Dynamic behaviors and film formation of four modes of electrospray droplets for various surface temperature[36]

| 文献 | 经验公式 | 适用条件 | 工质 | 公式误差/% |

|---|---|---|---|---|

| [ | 10<Re<1000 | 蒸馏水 | 12 | |

| [ | 0<Re<300 | 蒸馏水 | 7.73 | |

| [ | Re>440 | 蒸馏水 | 3.7 | |

| 240<Re<527 | 蒸馏水 | 15 | ||

| [ | — | 蒸馏水 | 2.5 | |

| [ | 2.1<Pr<6.8 | 蒸馏水 | 7 | |

| [ | Re>240 | 蒸馏水 | 4 | |

| [ | 13<Re<180 0.06< | 蒸馏水 | 25 | |

| [ | 10<Re<1000 0.15< | 蒸馏水 | 14 |

表2 各种不同的传热经验关联式

Table 2 Various empirical correlations of heat transfer

| 文献 | 经验公式 | 适用条件 | 工质 | 公式误差/% |

|---|---|---|---|---|

| [ | 10<Re<1000 | 蒸馏水 | 12 | |

| [ | 0<Re<300 | 蒸馏水 | 7.73 | |

| [ | Re>440 | 蒸馏水 | 3.7 | |

| 240<Re<527 | 蒸馏水 | 15 | ||

| [ | — | 蒸馏水 | 2.5 | |

| [ | 2.1<Pr<6.8 | 蒸馏水 | 7 | |

| [ | Re>240 | 蒸馏水 | 4 | |

| [ | 13<Re<180 0.06< | 蒸馏水 | 25 | |

| [ | 10<Re<1000 0.15< | 蒸馏水 | 14 |

| 文献 | 表面微结构设计 | 结论 |

|---|---|---|

| [ | 设计了三种微结构热沉表面。 立方肋:肋距2 mm,肋宽1 mm,肋高1 mm; 金字塔肋:肋距1 mm,肋宽1 mm,肋高1 mm; 直肋:肋距2 mm,肋宽1 mm,肋高1 mm

| 工质种类:蒸馏水。 定量强化效果:三种微结构都起到了增强换热的作用,其中直肋结构增强效果最优,测得平壁面的CHF为80 W/ cm2,立方肋、金字塔肋和直肋的CHF分别为114、105、126 W/cm2。 强化换热特性机理:(1)增加润湿面积,降低单相对流热阻;(2)润湿面积增加,潜在成核位点数量增加,液体流动接触时间延长 |

| [ | 设计了两种微结构热沉表面。 立方肋:肋距0.6 mm,肋宽0.3 mm,肋高0.7 mm; 直肋:肋距0.6 mm,肋宽0.3 mm,肋高0.7 mm

| 工质种类:蒸馏水。 |

定量强化效果:表面温度较低时,直肋面换热效果最好;表面温度较高时,立方肋换热效果最好。平壁面、立方肋、直肋的CHF分别为109.8、159.1、120.2 W/ cm2。 强化换热特性机理:(1)表面槽道大大增加了容纳液体的空间,致使加热面上形成更薄液膜,液膜越薄,传热越强;(2)槽深过大会增大槽道间液体流动阻力,可能会致使大量冷却液淤积在槽道中,减弱对流换热效果 | ||

| [ | 设计了三种微结构热沉表面。 立方肋:肋距0.4 mm,肋宽0.8 mm,肋高0.2 mm; 扇形肋:肋高0.2 mm; 直肋:肋距0.4 mm,肋宽0.4 mm,肋高0.2 mm

| 工质种类:蒸馏水。 |

| 定量强化效果:表面平均温度为80℃时,光滑表面热通量为 42. 2 W/cm2,立方肋、直肋、扇形肋表面热通量分别为 61.8、56.3、51.3 W/cm2,热通量增幅依次为 46.4%、33.4%和 21.6%,但三种微结构的表面温度不均匀性都大于光滑表面。 | ||

| 强化换热特性机理:(1)微结构提高了表面的润湿性,同时对液体有滞留作用,起到一定的抑制干涸区扩张的作用;(2)微结构的存在提高了喷雾冷却热通量,使之提前进入两相区,避免了沸腾的滞后性 | ||

| [ | 设计了一种直肋微结构热沉表面。 直肋:肋距0.5 mm,肋宽0.5 mm,肋高0.5 mm

| 工质种类:蒸馏水。 定量强化效果:与平壁相比,直肋微结构表面的平均温度降低16.36℃,HTC提高了33.04%,但其表面温度均匀性较平壁更差。 强化换热特性机理:(1)微槽的存在令三相接触线长度增加,有助于液膜蒸发和液体流动;(2)沟槽增加了换热面积;(3)沟槽和微结构增加了成核位点 |

| [ | 设计了五种立方肋微结构热沉表面。 1号肋:肋距0.05 mm,肋宽0.05 mm,肋高0.0 5mm; 2号肋:肋距0.1 mm,肋宽0.1 mm,肋高0.05 mm; 3号肋:肋距0.2 mm,肋宽0.2 mm,肋高0.2 mm; 4号肋:肋距0.3 mm,肋宽0.3 mm,肋高0.2 mm; 5号肋:肋距0.4 mm,肋宽0.4 mm,肋高0.2 mm

| 工质种类:蒸馏水。 定量强化效果:五种立方肋都起到了增强换热的作用,而其中3号立方肋取得了最优增强效果,其CHF和HTC可达161 W/cm2和27.2 kW/(m2·K),比平壁面分别提高了42%和28%。 强化换热特性机理:(1)微结构的存在增加了换热面积和有效成核位点;(2)3号立方肋的肋间距与液滴尺寸有更好的一致性,液滴的平均直径为163 μm,这使得液滴完全进入3号立方肋表面结构的间距 |

| [ | 设计了四种微结构热沉表面:。 1号立方肋:肋宽0.5 mm,肋高1.0 mm; 2号立方肋:肋宽0.5 mm,肋高0.5 mm; 1号直肋:肋宽0.5 mm,肋高1.0 mm; 2号直肋:肋宽0.5 mm,肋高3.0 mm

| 工质种类:蒸馏水。 |

| 定量强化效果:与平面相比,两个直肋表面的喷雾热性能提高了约100%,翅片高度为1.0 mm和3.0 mm的直翅片表面表现出相似的热性能。对于0.5 mm立方肋表面,传热增强仅为60%左右。然而,对于1.0 mm立方肋表面,传热增强可达到最大280%左右。 | ||

| 强化换热特性机理:(1)微结构增加了表面换热面积、成核位点;(2)随着肋高度增加,更多的液滴撞击在肋侧,而更少的液滴直接撞击在凹槽内的液膜上,降低了对液膜驱动流动的影响,会在一定程度上抑制对流换热 |

表3 不同的微结构表面研究

Table 3 Studies of different microstructure surfaces

| 文献 | 表面微结构设计 | 结论 |

|---|---|---|

| [ | 设计了三种微结构热沉表面。 立方肋:肋距2 mm,肋宽1 mm,肋高1 mm; 金字塔肋:肋距1 mm,肋宽1 mm,肋高1 mm; 直肋:肋距2 mm,肋宽1 mm,肋高1 mm

| 工质种类:蒸馏水。 定量强化效果:三种微结构都起到了增强换热的作用,其中直肋结构增强效果最优,测得平壁面的CHF为80 W/ cm2,立方肋、金字塔肋和直肋的CHF分别为114、105、126 W/cm2。 强化换热特性机理:(1)增加润湿面积,降低单相对流热阻;(2)润湿面积增加,潜在成核位点数量增加,液体流动接触时间延长 |

| [ | 设计了两种微结构热沉表面。 立方肋:肋距0.6 mm,肋宽0.3 mm,肋高0.7 mm; 直肋:肋距0.6 mm,肋宽0.3 mm,肋高0.7 mm

| 工质种类:蒸馏水。 |

定量强化效果:表面温度较低时,直肋面换热效果最好;表面温度较高时,立方肋换热效果最好。平壁面、立方肋、直肋的CHF分别为109.8、159.1、120.2 W/ cm2。 强化换热特性机理:(1)表面槽道大大增加了容纳液体的空间,致使加热面上形成更薄液膜,液膜越薄,传热越强;(2)槽深过大会增大槽道间液体流动阻力,可能会致使大量冷却液淤积在槽道中,减弱对流换热效果 | ||

| [ | 设计了三种微结构热沉表面。 立方肋:肋距0.4 mm,肋宽0.8 mm,肋高0.2 mm; 扇形肋:肋高0.2 mm; 直肋:肋距0.4 mm,肋宽0.4 mm,肋高0.2 mm

| 工质种类:蒸馏水。 |

| 定量强化效果:表面平均温度为80℃时,光滑表面热通量为 42. 2 W/cm2,立方肋、直肋、扇形肋表面热通量分别为 61.8、56.3、51.3 W/cm2,热通量增幅依次为 46.4%、33.4%和 21.6%,但三种微结构的表面温度不均匀性都大于光滑表面。 | ||

| 强化换热特性机理:(1)微结构提高了表面的润湿性,同时对液体有滞留作用,起到一定的抑制干涸区扩张的作用;(2)微结构的存在提高了喷雾冷却热通量,使之提前进入两相区,避免了沸腾的滞后性 | ||

| [ | 设计了一种直肋微结构热沉表面。 直肋:肋距0.5 mm,肋宽0.5 mm,肋高0.5 mm

| 工质种类:蒸馏水。 定量强化效果:与平壁相比,直肋微结构表面的平均温度降低16.36℃,HTC提高了33.04%,但其表面温度均匀性较平壁更差。 强化换热特性机理:(1)微槽的存在令三相接触线长度增加,有助于液膜蒸发和液体流动;(2)沟槽增加了换热面积;(3)沟槽和微结构增加了成核位点 |

| [ | 设计了五种立方肋微结构热沉表面。 1号肋:肋距0.05 mm,肋宽0.05 mm,肋高0.0 5mm; 2号肋:肋距0.1 mm,肋宽0.1 mm,肋高0.05 mm; 3号肋:肋距0.2 mm,肋宽0.2 mm,肋高0.2 mm; 4号肋:肋距0.3 mm,肋宽0.3 mm,肋高0.2 mm; 5号肋:肋距0.4 mm,肋宽0.4 mm,肋高0.2 mm

| 工质种类:蒸馏水。 定量强化效果:五种立方肋都起到了增强换热的作用,而其中3号立方肋取得了最优增强效果,其CHF和HTC可达161 W/cm2和27.2 kW/(m2·K),比平壁面分别提高了42%和28%。 强化换热特性机理:(1)微结构的存在增加了换热面积和有效成核位点;(2)3号立方肋的肋间距与液滴尺寸有更好的一致性,液滴的平均直径为163 μm,这使得液滴完全进入3号立方肋表面结构的间距 |

| [ | 设计了四种微结构热沉表面:。 1号立方肋:肋宽0.5 mm,肋高1.0 mm; 2号立方肋:肋宽0.5 mm,肋高0.5 mm; 1号直肋:肋宽0.5 mm,肋高1.0 mm; 2号直肋:肋宽0.5 mm,肋高3.0 mm

| 工质种类:蒸馏水。 |

| 定量强化效果:与平面相比,两个直肋表面的喷雾热性能提高了约100%,翅片高度为1.0 mm和3.0 mm的直翅片表面表现出相似的热性能。对于0.5 mm立方肋表面,传热增强仅为60%左右。然而,对于1.0 mm立方肋表面,传热增强可达到最大280%左右。 | ||

| 强化换热特性机理:(1)微结构增加了表面换热面积、成核位点;(2)随着肋高度增加,更多的液滴撞击在肋侧,而更少的液滴直接撞击在凹槽内的液膜上,降低了对液膜驱动流动的影响,会在一定程度上抑制对流换热 |

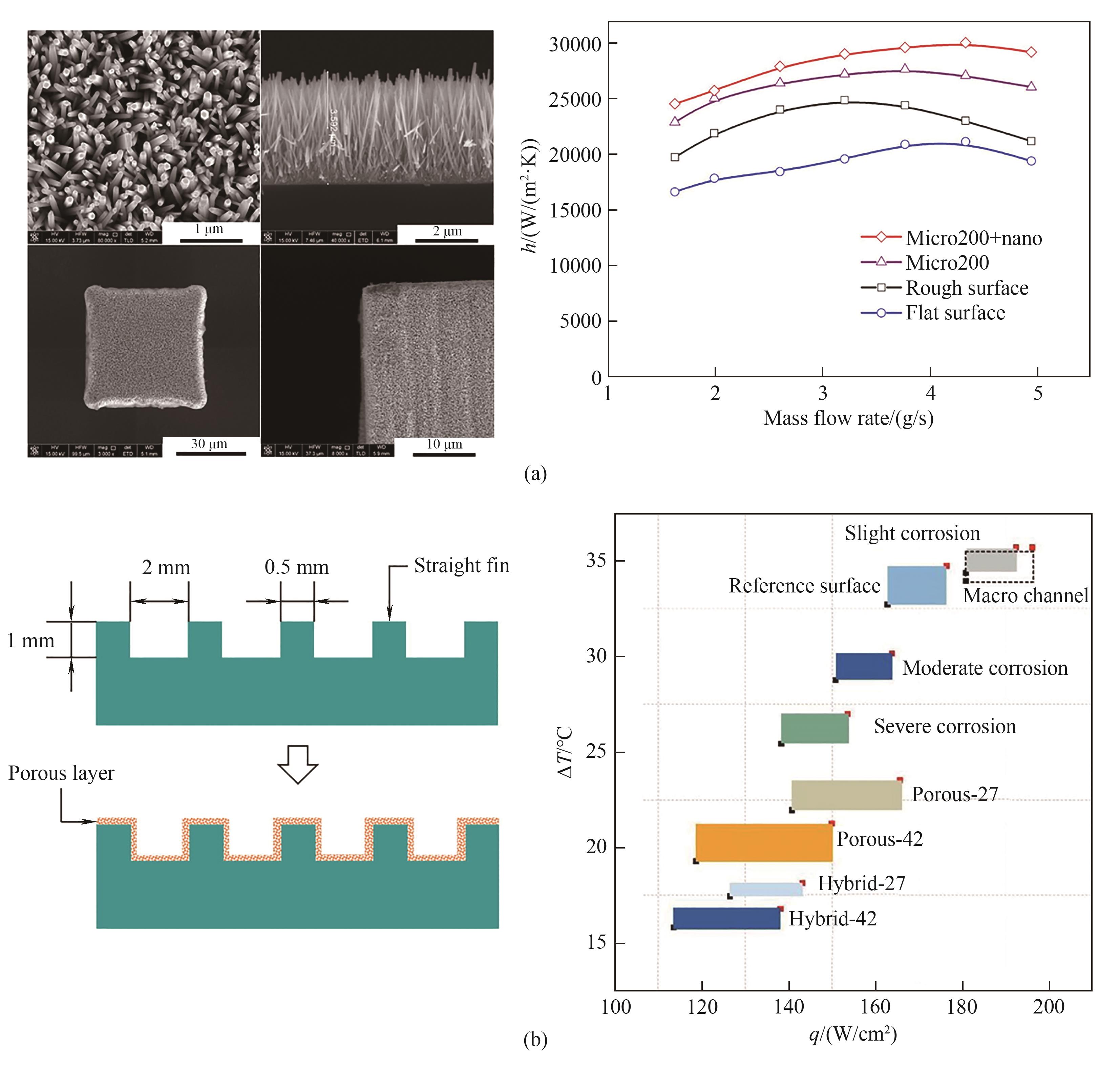

图10 微结构表面特性修饰增强换热:(a) 纳米线修饰微结构表面[92];(b) 多孔结构结合微结构表面[104]

Fig.10 Heat transfer enhanced by microstructure surface modification: (a) nanowires coated microstructure surface[92]; (b) porous structure combined with microstructure surface[104]

| 工质 | 文献 | 喷嘴 数量 | 喷嘴高度/mm | 流量 | 喷雾 方向 | 表面 结构 | CHF/ (W/cm2) | 最高HTC/ (W/(cm2·K)) | CHF时表面温度/℃ | 工作压力/MPa | 工作饱和温度/℃ |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 蒸馏水 | [ | 单 | 10 | 0.83×10-2 m3/(s·m2) | 水平 | 平面 | 596 | 4.435 | 145 | 0.1013 | 100 |

| 蒸馏水 | [ | 单 | 15 | 41.6 L/h | 向下 | 平面 | 675 | — | 41.5 | 0.1013 | 100 |

| 液氨 | [ | 双 | 11 | 1.6 ml/cm2 | 向下 | 平面 | 750 | — | 50 | 0.550 | 7 |

| R134a | [ | 单 | 13 | 0.211 L/min | 向下 | 平面 | 101.1 | 2.478 | 49.75 | 0.4 | 8.95 |

| R410a | [ | 单 | 25 | 6.1 g/s | 向下 | 平面 | 204 | 6.586 | 40 | 0.62 | -7.7 |

| R22 | [ | 单 | 22 | — | 向下 | 平面 | 276.1 | 7 | 26.8 | 0.34 | -11 |

| FC-77 | [ | 单 | — | 2.39×10-5 m3/s | 向下 | 平面 | 349 | 3.41 | 129.4 | 0.1013 | 97 |

表4 不同冷却工质对喷雾冷却换热性能的影响

Table 4 The effects of different working fluids on spray cooling performance

| 工质 | 文献 | 喷嘴 数量 | 喷嘴高度/mm | 流量 | 喷雾 方向 | 表面 结构 | CHF/ (W/cm2) | 最高HTC/ (W/(cm2·K)) | CHF时表面温度/℃ | 工作压力/MPa | 工作饱和温度/℃ |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 蒸馏水 | [ | 单 | 10 | 0.83×10-2 m3/(s·m2) | 水平 | 平面 | 596 | 4.435 | 145 | 0.1013 | 100 |

| 蒸馏水 | [ | 单 | 15 | 41.6 L/h | 向下 | 平面 | 675 | — | 41.5 | 0.1013 | 100 |

| 液氨 | [ | 双 | 11 | 1.6 ml/cm2 | 向下 | 平面 | 750 | — | 50 | 0.550 | 7 |

| R134a | [ | 单 | 13 | 0.211 L/min | 向下 | 平面 | 101.1 | 2.478 | 49.75 | 0.4 | 8.95 |

| R410a | [ | 单 | 25 | 6.1 g/s | 向下 | 平面 | 204 | 6.586 | 40 | 0.62 | -7.7 |

| R22 | [ | 单 | 22 | — | 向下 | 平面 | 276.1 | 7 | 26.8 | 0.34 | -11 |

| FC-77 | [ | 单 | — | 2.39×10-5 m3/s | 向下 | 平面 | 349 | 3.41 | 129.4 | 0.1013 | 97 |

| 文献 | 流量/(ml/min) | 喷嘴高度/mm | 最优倾斜角/(°) |

|---|---|---|---|

| [ | 69.33 | 15 | 0 |

| [ | 21.8 | 14 | 40 |

| [ | 200 | 17 | 30 |

| [ | 30.8 | 8 | 18 |

表5 最优倾斜角的研究

Table 5 The study of optimal tilt angle

| 文献 | 流量/(ml/min) | 喷嘴高度/mm | 最优倾斜角/(°) |

|---|---|---|---|

| [ | 69.33 | 15 | 0 |

| [ | 21.8 | 14 | 40 |

| [ | 200 | 17 | 30 |

| [ | 30.8 | 8 | 18 |

图12 受热表面液膜分布情况(微孔出口直径分别为5、7、9、20、25 μm)[134]

Fig.12 Distribution of liquid film on the heating surface (micropore outlet with different diameters of 5, 7, 9, 20, 25 μm)[134]

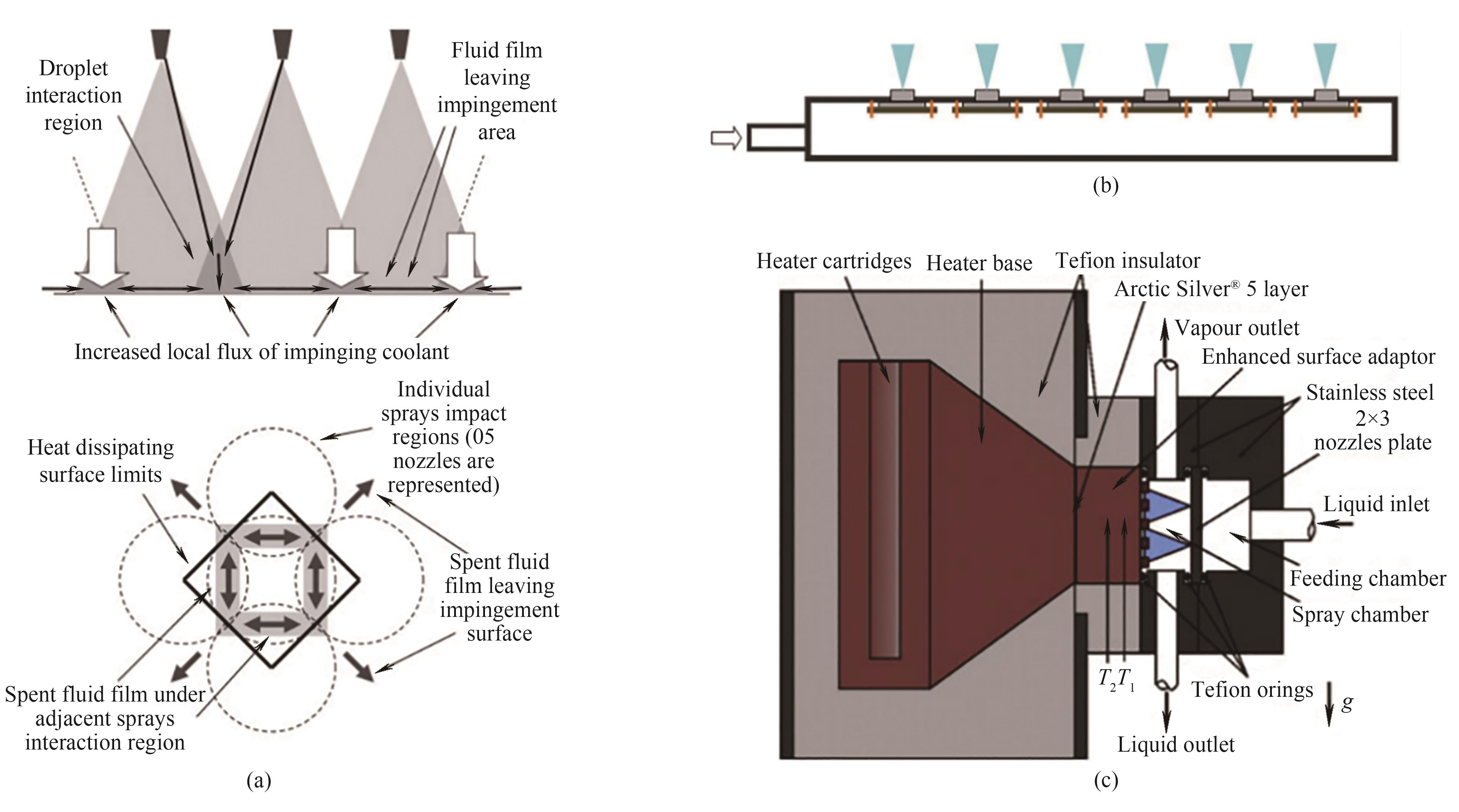

图13 阵列喷雾系统:(a)表面液膜流型[60];(b)向上喷雾[16];(c)侧向喷雾[138]

Fig.13 Array spray system: (a) flow patterns of liquid film[60]; (b) upward spray[16]; (c) side spray[138]

| 1 | Arbab N, Wang W, Lin C J, et al. Thermal modeling and analysis of a double-stator switched reluctance motor[J]. IEEE Transactions on Energy Conversion, 2015, 30(3): 1209-1217. |

| 2 | 王长宏, 朱冬生. 电子封装热管理的热电冷却技术研究进展[J]. 电子元件与材料, 2008, 27(11): 4-7. |

| Wang C H, Zhu D S. Research progress on thermoelectric cooling technology applied in electronic packaging thermal management[J]. Electronic Components and Materials, 2008, 27(11): 4-7. | |

| 3 | 朱冬生, 雷俊禧, 王长宏, 等. 电子元器件热电冷却技术研究进展[J]. 微电子学, 2009, 39(1): 94-100. |

| Zhu D S, Lei J X, Wang C H, et al. Research progress in electronic component heat dissipation using thermoelectric cooling technology[J]. Microelectronics, 2009, 39(1): 94-100. | |

| 4 | 谢宁宁. 喷雾冷却及其换热强化的实验与理论研究[D]. 北京:中国科学院研究生院(工程热物理研究所), 2012. |

| Xie N N. Experimental and theoretical study on spray cooling and its heat transfer enhancement[D]. Beijing: Institue of Engineering Thermophysics, Chinese Academy of Sciences, 2012. | |

| 5 | Xu R N, Wang G Y, Jiang P X. Spray cooling on enhanced surfaces: a review of the progress and mechanisms[J]. Journal of Electronic Packaging, 2022, 144(1): 010802. |

| 6 | Hu Y Y, Lei Y F, Liu X L, et al. Heat transfer enhancement of spray cooling by copper micromesh surface[J]. Materials Today Physics, 2022, 28: 100857. |

| 7 | Jones-Jackson S, Rodriguez R, Emadi A. Jet impingement cooling in power electronics for electrified automotive transportation: current status and future trends[J]. IEEE Transactions on Power Electronics, 2021, 36(9): 10420-10435. |

| 8 | Siddiqui F R, Tso C Y, Qiu H H, et al. Hybrid nanofluid spray cooling performance and its residue surface effects: toward thermal management of high heat flux devices[J]. Applied Thermal Engineering, 2022, 211: 118454. |

| 9 | Kandlikar S G, Bapat A V. Evaluation of jet impingement, spray and microchannel chip cooling options for high heat flux removal[J]. Heat Transfer Engineering, 2007, 28(11): 911-923. |

| 10 | Mudawar I, Bharathan D, Kelly K, et al. Two-phase spray cooling of hybrid vehicle electronics[C]//2008 11th Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems. Orlando, FL, USA: IEEE, 2008: 1210-1221. |

| 11 | 安庆龙, 傅玉灿, 徐九华, 等. 低温气动喷雾射流冲击冷却技术在钛合金磨削中的应用[J]. 中国机械工程, 2006, 17(11): 1117-1120. |

| An Q L, Fu Y C, Xu J H, et al. Application of cryogenic pneumatic mist jet impinging in grinding of Ti-6Al-4V[J]. China Mechanical Engineering, 2006, 17(11): 1117-1120. | |

| 12 | Wang J X, Guo W, Xiong K, et al. Review of aerospace-oriented spray cooling technology[J]. Progress in Aerospace Sciences, 2020, 116: 100635. |

| 13 | Chen H, Ruan X H, Peng Y H, et al. Application status and prospect of spray cooling in electronics and energy conversion industries[J]. Sustainable Energy Technologies and Assessments, 2022, 52: 102181. |

| 14 | 董彬, 孙权, 高春艳, 等. 动力电池喷雾冷却换热特性研究[J]. 工程热物理学报, 2022, 43(6): 1588-1595. |

| Dong B, Sun Q, Gao C Y, et al. Study on spray cooling heat transfer performance of power battery[J]. Journal of Engineering Thermophysics, 2022, 43(6): 1588-1595. | |

| 15 | Kandasamy R, Ho J Y, Liu P F, et al. Two-phase spray cooling for high ambient temperature data centers: evaluation of system performance[J]. Applied Energy, 2022, 305: 117816. |

| 16 | Zhang W W, Cheng W L, Shao S D, et al. Integrated thermal control and system assessment in plug-chip spray cooling enclosure[J]. Applied Thermal Engineering, 2016, 108: 104-114. |

| 17 | Liu P F, Kandasamy R, Ho J Y, et al. Dynamic performance analysis and thermal modelling of a novel two-phase spray cooled rack system for data center cooling[J]. Energy, 2023, 269: 126835. |

| 18 | Chen H, Cheng W L, Zhang W W, et al. Energy saving evaluation of a novel energy system based on spray cooling for supercomputer center[J]. Energy, 2017, 141: 304-315. |

| 19 | Wang J X, Li Y Z, Yu X K, et al. Investigation of heat transfer mechanism of low environmental pressure large-space spray cooling for near-space flight systems[J]. International Journal of Heat and Mass Transfer, 2018, 119: 496-507. |

| 20 | Huang Y Q, Wu Y H, Liu B H. Experimental investigation into the use of emergency spray on suppression of battery thermal runaway[J]. Journal of Energy Storage, 2021, 38: 102546. |

| 21 | Dong H H, Ruan L, Wang Y, et al. Performance of air/spray cooling system for large-capacity and high-power-density motors[J]. Applied Thermal Engineering, 2021, 192: 116925. |

| 22 | Nižetić S, Čoko D, Yadav A, et al. Water spray cooling technique applied on a photovoltaic panel: the performance response[J]. Energy Conversion and Management, 2016, 108: 287-296. |

| 23 | Sun Y B, Guan Z Q, Gurgenci H, et al. A study on multi-nozzle arrangement for spray cooling system in natural draft dry cooling tower[J]. Applied Thermal Engineering, 2017, 124: 795-814. |

| 24 | Pati A R, Panda A, Munshi B, et al. High mass flux spray quenching on an inclined surface: a novel methodology for the attainment of enhanced uniform cooling with unaltered surface morphology in transition boiling regime[J]. International Journal of Heat and Mass Transfer, 2019, 131: 11-30. |

| 25 | Yin J, Wang S M, Sang X H, et al. Spray cooling as a high-efficient thermal management solution: a review[J]. Energies, 2022, 15(22): 8547. |

| 26 | Hsieh S S, Hsu Y F, Wang M L. A microspray-based cooling system for high powered LEDs[J]. Energy Conversion and Management, 2014, 78: 338-346. |

| 27 | Xie J L, Gan Z W, Wong T N, et al. Thermal effects on a pressure swirl nozzle in spray cooling[J]. International Journal of Heat and Mass Transfer, 2014, 73: 130-140. |

| 28 | Li J X, Li Y Z, Li E H, et al. Numerical investigation on the thermodynamic characteristics of a liquid film upon spray cooling using an air-blast atomization nozzle[J]. Entropy, 2020, 22(3): 308. |

| 29 | Xue R, Ruan Y X, Liu X F, et al. Internal and external flow characteristics of multi-nozzle spray with liquid nitrogen[J]. Cryogenics, 2021, 114: 103255. |

| 30 | Liang G T, Mudawar I. Review of spray cooling (Part 1): Single-phase and nucleate boiling regimes, and critical heat flux[J]. International Journal of Heat and Mass Transfer, 2017, 115: 1174-1205. |

| 31 | Ravikumar S V, Jha J M, Sarkar I, et al. Mixed-surfactant additives for enhancement of air-atomized spray cooling of a hot steel plate[J]. Experimental Thermal and Fluid Science, 2014, 55: 210-220. |

| 32 | Herwig H. High heat flux cooling of electronics: the need for a paradigm shift[J]. Journal of Heat Transfer, 2013, 135(11): 111013. |

| 33 | Gomez A, Tang K Q. Charge and fission of droplets in electrostatic sprays[J]. Physics of Fluids, 1994, 6(1): 404-414. |

| 34 | Deng W W, Gomez A. Electrospray cooling for microelectronics[J]. International Journal of Heat and Mass Transfer, 2011, 54(11/12): 2270-2275. |

| 35 | Jin Y K, Wu C Y, Sun P C, et al. Electrification of water: from basics to applications[J]. Droplet, 2022, 1(2): 92-109. |

| 36 | Xu H J, Wang J F, Li B, et al. Effect of spray modes on electrospray cooling heat transfer of ethanol[J]. Applied Thermal Engineering, 2021, 189: 116757. |

| 37 | Strutt J W. On the equilibrium of liquid conducting masses charged with electricity[M]//Scientific Papers. Cambridge: Cambridge University Press, 2009: 130-131. |

| 38 | Friend J, Yeo L Y. Microscale acoustofluidics: microfluidics driven via acoustics and ultrasonics[J]. Reviews of Modern Physics, 2011, 83(2): 647-704. |

| 39 | Connacher W, Orosco J, Friend J. Droplet ejection at controlled angles via acoustofluidic jetting[J]. Physical Review Letters, 2020, 125(18): 184504. |

| 40 | Meacham J M, Varady M J, Degertekin F L, et al. Droplet formation and ejection from a micromachined ultrasonic droplet generator: visualization and scaling[J]. Physics of Fluids, 2005, 17(10): 100605. |

| 41 | Khandekar S, Sahu G, Muralidhar K, et al. Cooling of high-power LEDs by liquid sprays: challenges and prospects[J]. Applied Thermal Engineering, 2021, 184: 115640. |

| 42 | Jha J M, Ravikumar S V, Tiara A M, et al. Ultrafast cooling of a hot moving steel plate by using alumina nanofluid based air atomized spray impingement[J]. Applied Thermal Engineering, 2015, 75: 738-747. |

| 43 | Ravikumar S V, Jha J M, Mohapatra S S, et al. Influence of ultrafast cooling on microstructure and mechanical properties of steel[J]. Steel Research International, 2013, 84(11): 1157-1170. |

| 44 | Liu H, Cai C, Jia M, et al. Experimental investigation on spray cooling with low-alcohol additives[J]. Applied Thermal Engineering, 2019, 146: 921-930. |

| 45 | Liu P F, Kandasamy R, Ho J Y, et al. Experimental study on heat transfer enhancement using combined surface roughening and macro-structures in a confined double-nozzle spray cooling system[J]. Applied Thermal Engineering, 2022, 202: 117850. |

| 46 | Lipson N, Chandra S. Cooling of porous metal surfaces by droplet impact[J]. International Journal of Heat and Mass Transfer, 2020, 152: 119494. |

| 47 | Xiang L Y, Yu X J, Hong T, et al. Performance of spray cooling with vertical surface orientation: an experimental investigation[J]. Applied Thermal Engineering, 2023, 219: 119434. |

| 48 | Zhou Z F, Lin X W, Ji R J, et al. Enhancement of heat transfer on micro- and macro- structural surfaces in close-loop R410A flashing spray cooling system for heat dissipation of high-power electronics[J]. Applied Thermal Engineering, 2023, 223: 119978. |

| 49 | Zhou Z F, Lin Y K, Tang H L, et al. Heat transfer enhancement due to surface modification in the close-loop R410A flash evaporation spray cooling[J]. International Journal of Heat and Mass Transfer, 2019, 139: 1047-1055. |

| 50 | Salman A S, Abdulrazzaq N M, Oudah S K, et al. Experimental investigation of the impact of geometrical surface modification on spray cooling heat transfer performance in the non-boiling regime[J]. International Journal of Heat and Mass Transfer, 2019, 133: 330-340. |

| 51 | Xie J L, Tan Y B, Wong T N, et al. Multi-nozzle array spray cooling for large area high power devices in a closed loop system[J]. International Journal of Heat and Mass Transfer, 2014, 78: 1177-1186. |

| 52 | Wang Y, Zhou N Y, Yang Z, et al. Experimental investigation of aircraft spray cooling system with different heating surfaces and different additives[J]. Applied Thermal Engineering, 2016, 103: 510-521. |

| 53 | Liu P F, Kandasamy R, Ho J Y, et al. Comparative study on the enhancement of spray cooling heat transfer using conventional and bio-surfactants[J]. Applied Thermal Engineering, 2021, 194: 117047. |

| 54 | Wang J X, Li Y Z, Li J X, et al. A gas-atomized spray cooling system integrated with an ejector loop: ejector modeling and thermal performance analysis[J]. Energy Conversion and Management, 2019, 180: 106-118. |

| 55 | Wang J X, Li Y Z, Mao Y F, et al. Comparative study of the heating surface impact on porous-material-involved spray system for electronic cooling—an experimental approach[J]. Applied Thermal Engineering, 2018, 135: 537-548. |

| 56 | Wang J X, Li Y Z, Zhang H S, et al. Investigation of a spray cooling system with two nozzles for space application[J]. Applied Thermal Engineering, 2015, 89: 115-124. |

| 57 | Bostanci H, Rini D P, Kizito J P, et al. High heat flux spray cooling with ammonia: investigation of enhanced surfaces for CHF[J]. International Journal of Heat and Mass Transfer, 2012, 55(13/14): 3849-3856. |

| 58 | Li Q, Tie P, Xuan Y M. Investigation on heat transfer characteristics of R134a spray cooling[J]. Experimental Thermal and Fluid Science, 2015, 60: 182-187. |

| 59 | Bostanci H, He B, Chow L C. Spray cooling with ammonium hydroxide[J]. International Journal of Heat and Mass Transfer, 2017, 107: 45-52. |

| 60 | Pereira R H, Braga S L, Parise J A R. Single phase cooling of large surfaces with square arrays of impinging water sprays[J]. Applied Thermal Engineering, 2012, 36: 161-170. |

| 61 | Cheng W L, Zhang W W, Jiang L J, et al. Experimental investigation of large area spray cooling with compact chamber in the non-boiling regime[J]. Applied Thermal Engineering, 2015, 80: 160-167. |

| 62 | Chang T B, Syu S C, Yang Y K. Effects of particle volume fraction on spray heat transfer performance of Al2O3-water nanofluid[J]. International Journal of Heat and Mass Transfer, 2012, 55(4): 1014-1021. |

| 63 | Hou Y, Liu X F, Liu J H, et al. Experimental study on phase change spray cooling[J]. Experimental Thermal and Fluid Science, 2013, 46: 84-88. |

| 64 | Chen S T, Liu J H, Liu X F, et al. An experimental comparison of heat transfer characteristic between R134-a and R22 in spray cooling[J]. Experimental Thermal and Fluid Science, 2015, 66: 206-212. |

| 65 | Hou Y, Liu J H, Su X M, et al. Experimental study on the characteristics of a closed loop R134-a spray cooling[J]. Experimental Thermal and Fluid Science, 2015, 61: 194-200. |

| 66 | Martínez-Galván E, Antón R, Ramos J C, et al. Influence of surface roughness on a spray cooling system with R134a (Part Ⅰ): Heat transfer measurements[J]. Experimental Thermal and Fluid Science, 2013, 46: 183-190. |

| 67 | Estes K A, Mudawar I. Correlation of sauter mean diameter and critical heat flux for spray cooling of small surfaces[J]. International Journal of Heat and Mass Transfer, 1995, 38(16): 2985-2996. |

| 68 | Sawyer M L, Jeter S M, Abdel-Khalik S I. A critical heat flux correlation for droplet impact cooling[J]. International Journal of Heat and Mass Transfer, 1997, 40(9): 2123-2131. |

| 69 | Jiang S J, Dhir V K. Spray cooling in a closed system with different fractions of non-condensibles in the environment[J]. International Journal of Heat and Mass Transfer, 2004, 47(25): 5391-5406. |

| 70 | Silk E A, Kim J, Kiger K. Energy conservation based spray cooling CHF correlation for flat surface small area heaters[C]//ASME/JSME 2007 Thermal Engineering Heat Transfer Summer Conference. Vancouver, British Columbia, Canada: ASMEDC, 2007: 805-813. |

| 71 | Abbasi B, Kim J. Prediction of PF-5060 spray cooling heat transfer and critical heat flux[J]. Journal of Heat Transfer, 2011, 133(10): 101504. |

| 72 | Dou R F, Wen Z, Zhou G. Heat transfer characteristics of water spray impinging on high temperature stainless steel plate with finite thickness[J]. International Journal of Heat and Mass Transfer, 2015, 90: 376-387. |

| 73 | Zhao X, Zhang B, Xi X Z, et al. Analysis and prediction of single-phase and two-phase cooling characteristics of intermittent sprays[J]. International Journal of Heat and Mass Transfer, 2019, 133: 619-630. |

| 74 | Benther J D, Pelaez Restrepo J D, Stanley C, et al. Successive droplet impingement onto heated surfaces of different wettabilities[J]. International Journal of Heat and Mass Transfer, 2022, 185: 122169. |

| 75 | Zhao Z P, Li H Z, Liu Q, et al. Regulating droplet impact symmetry by surface engineering[J]. Droplet, 2023, 2(2): e52. |

| 76 | Grissom W M, Wierum F A. Liquid spray cooling of a heated surface [J]. International Journal of Heat and Mass Transfer, 1981, 24(2): 261-271 |

| 77 | Pautsch A G, Shedd T A, Nellis G F. Thickness measurements of the thin film in spray evaporative cooling[C]//The Ninth Intersociety Conference on Thermal and Thermomechanical Phenomena In Electronic Systems. Las Vegas, NV, USA: IEEE, 2004: 70-76. |

| 78 | Yan Z B, Zhao R, Duan F, et al. Spray cooling[M]//Two Phase Flow, Phase Change and Numerical Modeling. London: InTech, 2011. |

| 79 | Pais M R, Chow L C, Mahefkey E T. Surface roughness and its effects on the heat transfer mechanism in spray cooling[J]. Journal of Heat Transfer, 1992, 114(1): 211-219. |

| 80 | Wang Y, Jiang Y L, Chen W W, et al. Heat transfer characteristics of spray cooling beyond critical heat flux under severe heat dissipation condition[J]. Applied Thermal Engineering, 2017, 123: 1356-1364. |

| 81 | Oliphant K, Webb B W, McQuay M Q. An experimental comparison of liquid jet array and spray impingement cooling in the non-boiling regime[J]. Experimental Thermal and Fluid Science, 1998, 18(1): 1-10. |

| 82 | Karwa N, Kale S R, Subbarao P M V. Experimental study of non-boiling heat transfer from a horizontal surface by water sprays[J]. Experimental Thermal and Fluid Science, 2007, 32(2): 571-579. |

| 83 | 王亚青, 刘明侯, 刘东, 等. 喷雾冷却中散热面温度对无沸腾区换热特性的影响[J]. 中国激光, 2010, 37(1): 115-120. |

| Wang Y Q, Liu M H, Liu D, et al. Effect of test surface temperature on the non-boiling heat transfer performance in spray cooling[J]. Chinese Journal of Lasers, 2010, 37(1): 115-120. | |

| 84 | Wang Y Q, Liu M H, Liu D, et al. Experimental study on the effects of spray inclination on water spray cooling performance in non-boiling regime[J]. Experimental Thermal and Fluid Science, 2010, 34(7): 933-942. |

| 85 | Cheng W L, Han F Y, Liu Q N, et al. Spray characteristics and spray cooling heat transfer in the non-boiling regime[J]. Energy, 2011, 36(5): 3399-3405. |

| 86 | Wang Y Q, Liu M H, Liu D, et al. Heat flux correlation for spray cooling in the nonboiling regime[J]. Heat Transfer Engineering, 2011, 32(11/12): 1075-1081. |

| 87 | 张伟. 微槽表面喷雾冷却换热特性研究[D]. 青岛: 中国石油大学(华东), 2013. |

| Zhang W. Study on heat transfer characteristics of micro-groove surface spray cooling[D]. Qingdao: China University of Petroleum, 2013. | |

| 88 | 周年勇, 王瑜, 蒋彦龙, 等. 无沸腾区机载喷雾冷却实验关联式研究[J]. 航空动力学报, 2016, 31(5): 1113-1120. |

| Zhou N Y, Wang Y, Jiang Y L, et al. Investigation on experimental correlations for aircraft spray cooling system in non-boiling area[J]. Journal of Aerospace Power, 2016, 31(5): 1113-1120. | |

| 89 | Cheng W L, Zhang W W, Chen H, et al. Spray cooling and flash evaporation cooling: the current development and application[J]. Renewable and Sustainable Energy Reviews, 2016, 55: 614-628. |

| 90 | Yang J, Chow L C, Pais M R. Nucleate boiling heat transfer in spray cooling[J]. Journal of Heat Transfer, 1996, 118(3): 668-671. |

| 91 | Ali K, Amna R, Usman Rashid M, et al. An investigation of the influence of surface roughness, water quality and nozzle on spray cooling of aluminum alloy 6082[J]. Thermal Science and Engineering Progress, 2019, 10: 280-286. |

| 92 | Xu R N, Cao L, Wang G Y, et al. Experimental investigation of closed loop spray cooling with micro- and hybrid micro-/nano-engineered surfaces[J]. Applied Thermal Engineering, 2020, 180: 115697. |

| 93 | Silk E A, Kim J, Kiger K. Spray cooling of enhanced surfaces: impact of structured surface geometry and spray axis inclination[J]. International Journal of Heat and Mass Transfer, 2006, 49(25/26): 4910-4920. |

| 94 | 张伟, 王照亮, 徐明海. 微结构表面封闭式喷雾冷却传热特性[J]. 强激光与粒子束, 2012, 24(9): 2053-2058. |

| Zhang W, Wang Z L, Xu M H. Heat transfer characteristics in closed-loop spray cooling of micro-structured surfaces[J]. High Power Laser and Particle Beams, 2012, 24(9): 2053-2058. | |

| 95 | 刘妮, 李丽荣, 钟泽民. 微结构表面喷雾冷却性能试验研究[J]. 机械工程学报, 2017, 53(6): 158-165. |

| Liu N, Li L R, Zhong Z M. Heat transfer characteristics of spray cooling on micro-structured surface[J]. Journal of Mechanical Engineering, 2017, 53(6): 158-165. | |

| 96 | Liu N, Yu Z X, Zhu T H, et al. Effects of microstructured surface and mixed surfactants on the heat transfer performance of pulsed spray cooling[J]. International Journal of Thermal Sciences, 2020, 158: 106530. |

| 97 | Burton J C, Sharpe A L, van der Veen R C A, et al. Geometry of the vapor layer under a leidenfrost drop[J]. Physical Review Letters, 2012, 109(7): 074301. |

| 98 | Biance A L, Clanet C, Quéré D. Leidenfrost drops[J]. Physics of Fluids, 2003, 15(6): 1632-1637. |

| 99 | Zhang Z, Jiang P X, Christopher D M, et al. Experimental investigation of spray cooling on micro-, nano- and hybrid-structured surfaces[J]. International Journal of Heat and Mass Transfer, 2015, 80: 26-37. |

| 100 | Takata Y, Hidaka S, Widyaparaga A, et al. Effect of static contact angle on the droplet dynamics during the evaporation of a water droplet on the hot walls[J]. International Journal of Heat and Mass Transfer, 2014, 71: 691-705. |

| 101 | Lin P C, Cheng H C, Chen P H. Effects of wide-range copper surface wettability on spray cooling heat transfer[J]. Experimental Thermal and Fluid Science, 2023, 143: 110834. |

| 102 | Thiagarajan S J, Narumanchi S, King C, et al. Enhancement of heat transfer with pool and spray impingement boiling on microporous and nanowire surface coatings[C]//Proceedings of 2010 14th International Heat Transfer Conference. Washington, DC, USA, 2011: 819-828. |

| 103 | Chen J N, Xu R N, Zhang Z, et al. Phenomenon and mechanism of spray cooling on nanowire arrayed and hybrid micro/nanostructured surfaces[J]. Journal of Heat Transfer, 2018, 140(11): 112401. |

| 104 | Wang H, Wu J J, Yang Q, et al. Heat transfer enhancement of ammonia spray cooling by surface modification[J]. International Journal of Heat and Mass Transfer, 2016, 101: 60-68. |

| 105 | Thiagarajan S J, Narumanchi S, Yang R G. Effect of flow rate and subcooling on spray heat transfer on microporous copper surfaces[J]. International Journal of Heat and Mass Transfer, 2014, 69: 493-505. |

| 106 | Zhang Z, Li J, Jiang P X. Experimental investigation of spray cooling on flat and enhanced surfaces[J]. Applied Thermal Engineering, 2013, 51(1/2): 102-111. |

| 107 | Liu J H, Xue R, Chen L, et al. Influence of chamber pressure on heat transfer characteristics of a closed loop R134-a spray cooling[J]. Experimental Thermal and Fluid Science, 2016, 75: 89-95. |

| 108 | Visaria M, Mudawar I. Effects of high subcooling on two-phase spray cooling and critical heat flux[J]. International Journal of Heat and Mass Transfer, 2008, 51(21/22): 5269-5278. |

| 109 | Liu N, Yu Z X, Liang Y, et al. Effects of mixed surfactants on heat transfer performance of pulsed spray cooling[J]. International Journal of Heat and Mass Transfer, 2019, 144: 118593. |

| 110 | Liu N, Zhan T J, Zhang Y W, et al. Experimental investigation of comprehensive effects of surfactant and inclined mode on spray cooling heat transfer[J]. International Journal of Thermal Sciences, 2019, 136: 457-466. |

| 111 | Aksoy Y T, Liu L Y, Abboud M, et al. Role of nanoparticles in nanofluid droplet impact on solid surfaces[J]. Langmuir, 2023, 39(1): 12-19. |

| 112 | Bellerová H, Tseng A A, Pohanka M, et al. Spray cooling by solid jet nozzles using alumina/water nanofluids[J]. International Journal of Thermal Sciences, 2012, 62: 127-137. |

| 113 | Chakraborty S, Sarkar I, Ashok A, et al. Synthesis of Cu-Al LDH nanofluid and its application in spray cooling heat transfer of a hot steel plate[J]. Powder Technology, 2018, 335: 285-300. |

| 114 | Chakraborty S, Sarkar I, Ashok A, et al. Thermo-physical properties of Cu-Zn-Al LDH nanofluid and its application in spray cooling[J]. Applied Thermal Engineering, 2018, 141: 339-351. |

| 115 | Hao C L, Zhou Y, Zhou X F, et al. Dynamic control of droplet jumping by tailoring nanoparticle concentrations[J]. Applied Physics Letters, 2016, 109(2): 021601. |

| 116 | Li Y, Zhou J D, Hu M B, et al. Whole contact line pinning for droplets impacting on a hydrophobic surface due to hydrophilic TiO2 nanoparticle addition[J]. Langmuir, 2021, 37(22): 6673-6680. |

| 117 | Marseglia G, Sanches M, Ribeiro A P C, et al. Thermofluid characterization of nanofluids in spray cooling[J]. Applied Thermal Engineering, 2022, 210: 118411. |

| 118 | Tseng A A, Bellerová H, Pohanka M, et al. Effects of titania nanoparticles on heat transfer performance of spray cooling with full cone nozzle[J]. Applied Thermal Engineering, 2014, 62(1): 20-27. |

| 119 | Horacek B, Kiger K T, Kim J. Single nozzle spray cooling heat transfer mechanisms[J]. International Journal of Heat and Mass Transfer, 2005, 48(8): 1425-1438. |

| 120 | Cui Q A, Chandra S, McCahan S. The effect of dissolving gases or solids in water droplets boiling on a hot surface[J]. Journal of Heat Transfer, 2001, 123(4): 719-728. |

| 121 | Cheng W L, Xie B, Han F Y, et al. An experimental investigation of heat transfer enhancement by addition of high-alcohol surfactant (HAS) and dissolving salt additive (DSA) in spray cooling[J]. Experimental Thermal and Fluid Science, 2013, 45: 198-202. |

| 122 | Cui Q A, Chandra S, McCahan S. The effect of dissolving salts in water sprays used for quenching a hot surface (part 2): Spray cooling[J]. Journal of Heat Transfer, 2003, 125(2): 333-338. |

| 123 | 吕瑞超, 刘红, 高久良, 等. 醇水混合冷却剂表面张力和接触角的测定[J]. 工程热物理学报, 2020, 41(3): 709-714. |

| Lyu R C, Liu H, Gao J L, et al. Measurement of surface tension and contact angle of alcohol-water mixed coolant[J]. Journal of Engineering Thermophysics, 2020, 41(3): 709-714. | |

| 124 | Ravikumar S V, Jha J M, Sarkar I, et al. Enhancement of heat transfer rate in air-atomized spray cooling of a hot steel plate by using an aqueous solution of non-ionic surfactant and ethanol[J]. Applied Thermal Engineering, 2014, 64(1/2): 64-75. |

| 125 | Bhatt N H, Raj R, Varshney P, et al. Enhancement of heat transfer rate of high mass flux spray cooling by ethanol-water and ethanol-Tween20-water solution at very high initial surface temperature[J]. International Journal of Heat and Mass Transfer, 2017, 110: 330-347. |

| 126 | Hsieh S S, Leu H Y, Liu H H. Spray cooling characteristics of nanofluids for electronic power devices[J]. Nanoscale Research Letters, 2015, 10(1): 139. |

| 127 | Liu H, Cai C, Yin H C, et al. Experimental investigation on heat transfer of spray cooling with the mixture of ethanol and water[J]. International Journal of Thermal Sciences, 2018, 133: 62-68. |

| 128 | Zhou N Y, Feng H, Guo Y X, et al. Experimental study on the spray cooling heat transfer performance and dimensionless correlations for ethylene glycol water solution[J]. Applied Thermal Engineering, 2022, 214: 118824. |

| 129 | Mudawar I, Estes K A. Optimizing and predicting CHF in spray cooling of a square surface[J]. Journal of Heat Transfer, 1996, 118(3): 672-679. |

| 130 | Xia Y K, Gao X, Li R. Management of surface cooling non-uniformity in spray cooling[J]. Applied Thermal Engineering, 2020, 180: 115819. |

| 131 | Lin Y K, Zhou Z F, Fang Y, et al. Heat transfer performance and optimization of a close-loop R410A flash evaporation spray cooling[J]. Applied Thermal Engineering, 2019, 159: 113966. |

| 132 | Li B Q, Cader T, Schwarzkopf J, et al. Spray angle effect during spray cooling of microelectronics: experimental measurements and comparison with inverse calculations[J]. Applied Thermal Engineering, 2006, 26(16): 1788-1795. |

| 133 | Liu N, Li L R, Kang Y T. Experimental study on heat transfer performance enhancement by micro-structured surfaces for inclination spray application[J]. International Journal of Heat and Mass Transfer, 2019, 133: 631-640. |

| 134 | Chen H, Cheng W L, Peng Y H, et al. Experimental study on optimal spray parameters of piezoelectric atomizer based spray cooling[J]. International Journal of Heat and Mass Transfer, 2016, 103: 57-65. |

| 135 | Panão M R O, Correia A M, Moreira A L N. High-power electronics thermal management with intermittent multijet sprays[J]. Applied Thermal Engineering, 2012, 37: 293-301. |

| 136 | Lin L C, Ponnappan R. Heat transfer characteristics of spray cooling in a closed loop[J]. International Journal of Heat and Mass Transfer, 2003, 46(20): 3737-3746. |

| 137 | Pautsch A G, Shedd T A. Spray impingement cooling with single- and multiple-nozzle arrays (Part Ⅰ): Heat transfer data using FC-72[J]. International Journal of Heat and Mass Transfer, 2005, 48(15): 3167-3175. |

| 138 | Xie J L, Tan Y B, Duan F, et al. Study of heat transfer enhancement for structured surfaces in spray cooling[J]. Applied Thermal Engineering, 2013, 59(1/2): 464-472. |

| 139 | Wei M Y, Song Y, Zhu Y Y, et al. Heat transfer suppression by suspended droplets on microstructured surfaces[J]. Applied Physics Letters, 2020, 116(23): 233703. |

| 140 | Park J, Kim D E. Dynamic Leidenfrost behaviors of different fluid drops on superheated surface: scaling for vapor film thickness[J]. Physics of Fluids, 2019, 31(10): 101702. |

| 141 | Farokhnia N, Sajadi S M, Irajizad P, et al. Decoupled hierarchical structures for suppression of leidenfrost phenomenon[J]. Langmuir, 2017, 33(10): 2541-2550. |

| 142 | Talari V, Behar P, Lu Y, et al. Leidenfrost drops on micro/nanostructured surfaces[J]. Frontiers in Energy, 2018, 12(1): 22-42. |

| 143 | Bernardin J D, Stebbins C J, Mudawar I. Effects of surface roughness on water droplet impact history and heat transfer regimes[J]. International Journal of Heat and Mass Transfer, 1996, 40(1): 73-88. |

| 144 | Bernardin J D, Mudawar I. A Leidenfrost point model for impinging droplets and sprays[J]. Journal of Heat Transfer, 2004, 126(2): 272-278. |

| 145 | Elbahri M, Paretkar D, Hirmas K, et al. Anti-lotus effect for nanostructuring at the leidenfrost temperature[J]. Advanced Materials, 2007, 19(9): 1262-1266. |

| 146 | Jiang M N, Wang Y, Liu F Y, et al. Inhibiting the Leidenfrost effect above 1000℃ for sustained thermal cooling[J]. Nature, 2022, 601(7894): 568-572. |

| 147 | Kim H, Truong B, Buongiorno J, et al. On the effect of surface roughness height, wettability, and nanoporosity on Leidenfrost phenomena[J]. Applied Physics Letters, 2011, 98(8): 083121. |

| 148 | Weickgenannt C M, Zhang Y Y, Sinha-Ray S, et al. Inverse-Leidenfrost phenomenon on nanofiber mats on hot surfaces[J]. Physical Review E, 2011, 84(3): 036310. |

| [1] | 张双星, 刘舫辰, 张义飞, 杜文静. R-134a脉动热管相变蓄放热实验研究[J]. 化工学报, 2023, 74(S1): 165-171. |

| [2] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [3] | 陈爱强, 代艳奇, 刘悦, 刘斌, 吴翰铭. 基板温度对HFE7100液滴蒸发过程的影响研究[J]. 化工学报, 2023, 74(S1): 191-197. |

| [4] | 刘明栖, 吴延鹏. 导光管直径和长度对传热影响的模拟分析[J]. 化工学报, 2023, 74(S1): 206-212. |

| [5] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [6] | 晁京伟, 许嘉兴, 李廷贤. 基于无管束蒸发换热强化策略的吸附热池的供热性能研究[J]. 化工学报, 2023, 74(S1): 302-310. |

| [7] | 程成, 段钟弟, 孙浩然, 胡海涛, 薛鸿祥. 表面微结构对析晶沉积特性影响的格子Boltzmann模拟[J]. 化工学报, 2023, 74(S1): 74-86. |

| [8] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [9] | 王玉兵, 李杰, 詹宏波, 朱光亚, 张大林. R134a在菱形离散肋微小通道内的流动沸腾换热实验研究[J]. 化工学报, 2023, 74(9): 3797-3806. |

| [10] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [11] | 李科, 文键, 忻碧平. 耦合蒸气冷却屏的真空多层绝热结构对液氢储罐自增压过程的影响机制研究[J]. 化工学报, 2023, 74(9): 3786-3796. |

| [12] | 洪瑞, 袁宝强, 杜文静. 垂直上升管内超临界二氧化碳传热恶化机理分析[J]. 化工学报, 2023, 74(8): 3309-3319. |

| [13] | 杨越, 张丹, 郑巨淦, 涂茂萍, 杨庆忠. NaCl水溶液喷射闪蒸-掺混蒸发的实验研究[J]. 化工学报, 2023, 74(8): 3279-3291. |

| [14] | 张贲, 王松柏, 魏子亚, 郝婷婷, 马学虎, 温荣福. 超亲水多孔金属结构驱动的毛细液膜冷凝及传热强化[J]. 化工学报, 2023, 74(7): 2824-2835. |

| [15] | 王海, 林宏, 王晨, 许浩洁, 左磊, 王军锋. 高压静电场强化多孔介质表面沸腾传热特性研究[J]. 化工学报, 2023, 74(7): 2869-2879. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号