化工学报 ›› 2025, Vol. 76 ›› Issue (S1): 93-105.DOI: 10.11949/0438-1157.20240777

收稿日期:2024-07-10

修回日期:2024-09-06

出版日期:2025-06-25

发布日期:2025-06-26

通讯作者:

白博峰

作者简介:王俊鹏(1992—),男,博士研究生,tuso_k@stu.xjtu.edu.cn

基金资助:

Junpeng WANG( ), Jiaqi FENG, Enbo ZHANG, Bofeng BAI(

), Jiaqi FENG, Enbo ZHANG, Bofeng BAI( )

)

Received:2024-07-10

Revised:2024-09-06

Online:2025-06-25

Published:2025-06-26

Contact:

Bofeng BAI

摘要:

迷宫阀芯是控制高压液体流量的关键部件,其流道结构内的空化现象是限制流量调节的瓶颈之一。针对曲折式与阵列式两类典型的迷宫阀芯结构,采用SST k-ω湍流模型和Rayleigh-Plesset空化模型,数值研究了流体流动与空化特性,提出了满足低空化率、高质量流率要求的阀芯结构型式。研究发现,相同压差下曲折式流道的质量流量更低,由于发生强烈的边界层分离现象和出现大尺度涡旋区域导致空化率增加;阵列式流道末级圆柱尾迹区发生强烈的空化现象,通过改进末级圆柱为水滴型结构,可显著降低局部空化率,同时具备良好的流通能力;当尾部角度b=30°时,平均空化率达到最低值41.9%,这表明存在一个使下游出口截面空化率达到最小值的最佳角度。本研究可为迷宫调节阀阀芯流道结构优化、提升抗空化性能和流体质量流率提供理论依据。

中图分类号:

王俊鹏, 冯佳琪, 张恩搏, 白博峰. 曲折式与阵列式迷宫阀芯结构内流动与空化特性研究[J]. 化工学报, 2025, 76(S1): 93-105.

Junpeng WANG, Jiaqi FENG, Enbo ZHANG, Bofeng BAI. Study on flow and cavitation characteristic in zigzag and array labyrinth valve core structures[J]. CIESC Journal, 2025, 76(S1): 93-105.

| 参数 | SZC | CZC | CAC | SCC |

|---|---|---|---|---|

| 碟片外径L/mm | 238.34 | 238.34 | 238.34 | 238.34 |

| 碟片内径l/mm | 53.48 | 53.48 | 53.48 | 53.48 |

| 流道高度H/mm | 3.00 | 3.00 | 3.00 | 3.00 |

| 入口宽度d1/mm | 6.00 | 6.00 | 6.00 | 6.00 |

| 出口宽度d13/mm | 10.78 | 10.78 | 10.78 | 10.78 |

| 流道总级数n | 13 | 13 | 13 | 13 |

| 流道扩张率di+1/di | 1.05 | 1.05 | 1.05 | 1.05 |

| 外圆角半径R/mm | — | 3 | — | — |

| 内圆角半径r/mm | — | 1.25 | — | — |

表1 迷宫阀芯碟片及流道几何参数

Table 1 The geometry parameter of labyrinth valve disc and flow channel

| 参数 | SZC | CZC | CAC | SCC |

|---|---|---|---|---|

| 碟片外径L/mm | 238.34 | 238.34 | 238.34 | 238.34 |

| 碟片内径l/mm | 53.48 | 53.48 | 53.48 | 53.48 |

| 流道高度H/mm | 3.00 | 3.00 | 3.00 | 3.00 |

| 入口宽度d1/mm | 6.00 | 6.00 | 6.00 | 6.00 |

| 出口宽度d13/mm | 10.78 | 10.78 | 10.78 | 10.78 |

| 流道总级数n | 13 | 13 | 13 | 13 |

| 流道扩张率di+1/di | 1.05 | 1.05 | 1.05 | 1.05 |

| 外圆角半径R/mm | — | 3 | — | — |

| 内圆角半径r/mm | — | 1.25 | — | — |

| 构型 | 网格方案 | 总数量 | 最大单元尺寸/mm | 压差/Pa |

|---|---|---|---|---|

| SZC | 1# | 819168 | 1.02 | 3.01×106 |

| 2# | 1319328 | 0.85 | 3.29×106 | |

| 3# | 1840800 | 0.75 | 3.43×106 | |

| 4# | 2908800 | 0.59 | 3.42×106 | |

| CZC | 1# | 472192 | 0.98 | 3.25×106 |

| 2# | 982528 | 0.77 | 2.03×106 | |

| 3# | 2057088 | 0.65 | 1.93×106 | |

| 4# | 3001152 | 0.4 | 1.90×106 | |

| CAC | 1# | 1030400 | 0.78 | 1.08×106 |

| 2# | 2060800 | 0.61 | 1.10×106 | |

| 3# | 3392000 | 0.48 | 1.19×106 | |

| 4# | 4212160 | 0.22 | 1.18×106 | |

| SCC | 1# | 1052800 | 1.36 | 1.65×107 |

| 2# | 1911200 | 0.98 | 1.55×107 | |

| 3# | 3204000 | 0.85 | 1.59×107 | |

| 4# | 4234400 | 0.66 | 1.58×107 |

表2 网格无关性验证结果

Table 2 Results of grids independence verification

| 构型 | 网格方案 | 总数量 | 最大单元尺寸/mm | 压差/Pa |

|---|---|---|---|---|

| SZC | 1# | 819168 | 1.02 | 3.01×106 |

| 2# | 1319328 | 0.85 | 3.29×106 | |

| 3# | 1840800 | 0.75 | 3.43×106 | |

| 4# | 2908800 | 0.59 | 3.42×106 | |

| CZC | 1# | 472192 | 0.98 | 3.25×106 |

| 2# | 982528 | 0.77 | 2.03×106 | |

| 3# | 2057088 | 0.65 | 1.93×106 | |

| 4# | 3001152 | 0.4 | 1.90×106 | |

| CAC | 1# | 1030400 | 0.78 | 1.08×106 |

| 2# | 2060800 | 0.61 | 1.10×106 | |

| 3# | 3392000 | 0.48 | 1.19×106 | |

| 4# | 4212160 | 0.22 | 1.18×106 | |

| SCC | 1# | 1052800 | 1.36 | 1.65×107 |

| 2# | 1911200 | 0.98 | 1.55×107 | |

| 3# | 3204000 | 0.85 | 1.59×107 | |

| 4# | 4234400 | 0.66 | 1.58×107 |

| 边界条件 | 取值 |

|---|---|

| 入口压力/MPa | 1,4,7,10 |

| 入口温度/℃ | 25 |

| 出口压力/MPa | 0 |

| 参考压力/MPa | 0.101325 |

| 饱和蒸气压力/Pa | 3169.9 |

表3 边界条件设置参数

Table 3 Parameters of boundary condition

| 边界条件 | 取值 |

|---|---|

| 入口压力/MPa | 1,4,7,10 |

| 入口温度/℃ | 25 |

| 出口压力/MPa | 0 |

| 参考压力/MPa | 0.101325 |

| 饱和蒸气压力/Pa | 3169.9 |

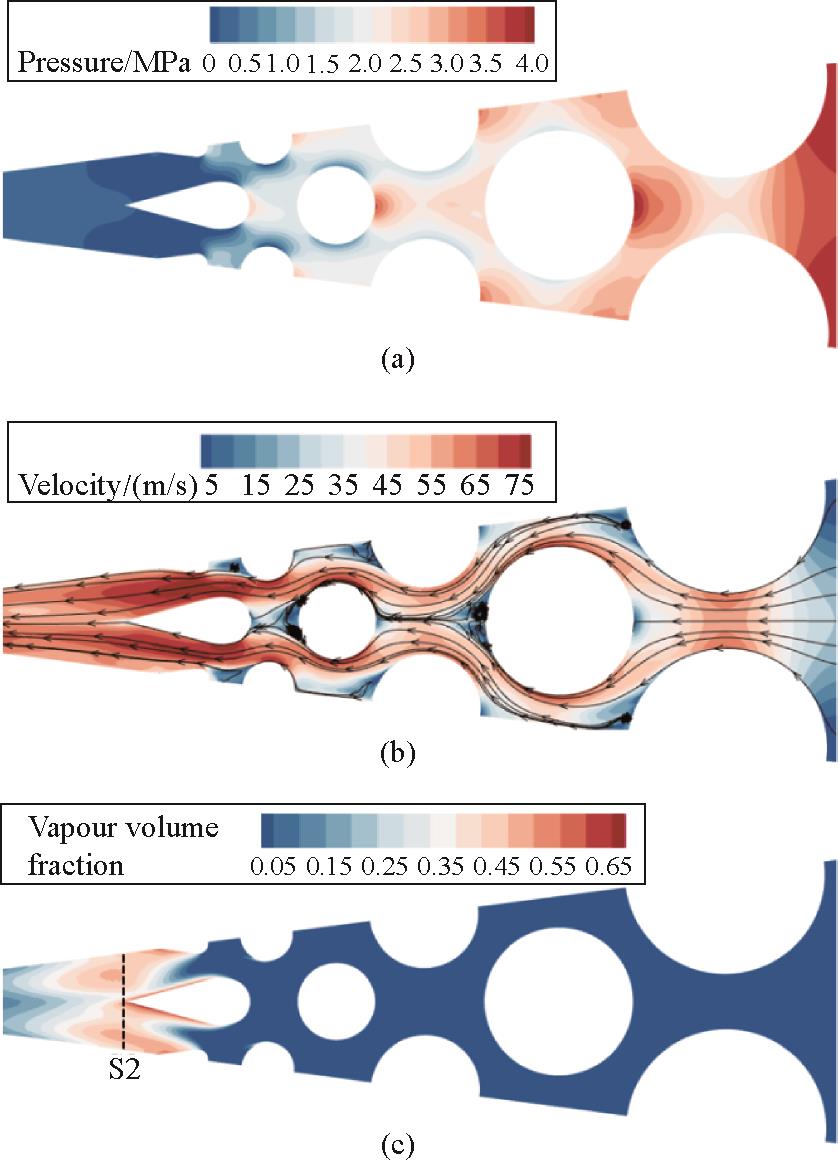

图13 优化流道结构中间截面仿真云图:压力(a)、流速(b)、气相体积分数(c)

Fig.13 Simulation cloud image of the middle section of optimized flow channel structure: pressure(a), flow rate(b), vapour volume fraction(c)

| 1 | Chen F Q, Qian J Y, Chen M R, et al. Turbulent compressible flow analysis on multi-stage high pressure reducing valve[J]. Flow Measurement and Instrumentation, 2018, 61: 26-37. |

| 2 | Gan R L, Li B R, Liu S, et al. Multi structural parameter analysis based on the labyrinth valve design with high pressure drop and low noise[J]. Flow Measurement and Instrumentation, 2023, 89: 102301. |

| 3 | Gao Z X, Yue Y, Wu J Y, et al. The flow and cavitation characteristics of cage-type control valves[J]. Engineering Applications of Computational Fluid Mechanics, 2021, 15(1): 951-963. |

| 4 | 王为术, 赵鹏飞, 陈刚, 等. 超超临界锅炉垂直水冷壁水动力特性[J]. 化工学报, 2013, 64(9): 3213-3219. |

| Wang W S, Zhao P F, Chen G, et al. Hydrodynamic characteristics of vertical water-wall in ultra-supercritical pressure boiler[J]. CIESC Journal, 2013, 64(9): 3213-3219. | |

| 5 | Li F Q, Quay B, Wang P, et al. Transient thermal behaviors of a scaled turbine valve: conjugate heat transfer simulation and experimental measurement[J]. International Journal of Heat and Mass Transfer, 2019, 141: 116-128. |

| 6 | Hou C W, Qian J Y, Chen F Q, et al. Parametric analysis on throttling components of multi-stage high pressure reducing valve[J]. Applied Thermal Engineering, 2018, 128: 1238-1248. |

| 7 | Jin H Z, Zhang J M, Liu X F, et al. Study on flow-induced noise characteristics of multistage depressurization valve in the nuclear power plant[J]. Nuclear Engineering and Design, 2023, 407: 112282. |

| 8 | Jin Z J, Gao Z X, Zhang M, et al. Computational fluid dynamics analysis on orifice structure inside valve core of pilot-control angle globe valve[J]. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 2018, 232(13): 2419-2429. |

| 9 | Li W M, Yang S Y, Chen Y P, et al. Tesla valves and capillary structures-activated thermal regulator[J]. Nature Communications, 2023, 14(1): 3996. |

| 10 | Lisowski E, Filo G. CFD analysis of the characteristics of a proportional flow control valve with an innovative opening shape[J]. Energy Conversion and Management, 2016, 123: 15-28. |

| 11 | Jin Z J, Qiu C, Jiang C H, et al. Effect of valve core shapes on cavitation flow through a sleeve regulating valve[J]. Journal of Zhejiang University: Science A, 2020, 21(1): 1-14. |

| 12 | Wu D Z, Li S Y, Wu P. CFD simulation of flow-pressure characteristics of a pressure control valve for automotive fuel supply system[J]. Energy Conversion and Management, 2015, 101: 658-665. |

| 13 | Song X G, Cui L, Cao M S, et al. A CFD analysis of the dynamics of a direct-operated safety relief valve mounted on a pressure vessel[J]. Energy Conversion and Management, 2014, 81: 407-419. |

| 14 | 彭杰伟, 马有福, 吴恒亮, 等. 水平管内多孔板后的气液两相流型可视化实验[J]. 化工学报, 2017, 68(6): 2266-2274. |

| Peng J W, Ma Y F, Wu H L, et al. Visualization study on flow pattern of gas-liquid two-phase flowing through multi-orifice plate in horizontal pipe[J]. CIESC Journal, 2017, 68(6): 2266-2274. | |

| 15 | 金多文. 迷宫式调节阀及其在电厂中的应用[J]. 水利电力机械, 2001, 23(1): 9-13. |

| Jin D W. The concept and applications of labyrinth regulating valves in power station[J]. Water Conservancy & Electric Power Machinery, 2001, 23(1): 9-13. | |

| 16 | Singh D, Charlton M, Asim T, et al. Quantification of additive manufacturing induced variations in the global and local performance characteristics of a complex multi-stage control valve trim[J]. Journal of Petroleum Science and Engineering, 2020, 190: 107053. |

| 17 | Singh D, Aliyu A M, Charlton M, et al. Local multiphase flow characteristics of a severe-service control valve[J]. Journal of Petroleum Science and Engineering, 2020, 195: 107557. |

| 18 | Singh D, Charlton M, Aliyu A M, et al. Development of novel predictive equations for local flow asymmetry within control valves using a distribution parameter-based method under multiphase conditions[J]. Journal of Petroleum Science and Engineering, 2022, 213: 110367. |

| 19 | Zhang E B, Xu H C, Li J, et al. Turbulence dissipation of leakage flow in supercritical CO2 labyrinth seals[J]. Progress in Nuclear Energy, 2022, 151: 104336. |

| 20 | Zhang J, Zhao W H, Tang Y P, et al. Structural optimization of labyrinth-channel emitters based on hydraulic and anti-clogging performances[J]. Irrigation Science, 2011, 29(5): 351-357. |

| 21 | Geng K H, Hu C X, Yang C, et al. Numerical investigation on transient aero-thermal characteristics of a labyrinth regulating valve for nuclear power plant[J]. Nuclear Engineering and Design, 2021, 382: 111369. |

| 22 | Rahmeyer W J, Miller H L, Sherikar S V. Cavitation testing results for a tortuous path control valve[C]//Kata J, Matsumoto Y. The 1995 ASME/JSME Fluid Engineering and Laser Anemometry Conference and Exhibition. Cavitation and Multiphase-Flow. Hilton Head, South Carolina, USA: ASME, 1995, 210: 63-68. |

| 23 | 范利霞, 王奎升, 孔令真. 迷宫式蒸汽调节阀的级数计算方法研究[J]. 北京化工大学学报(自然科学版), 2019, 46(3): 75-82. |

| Fan L X, Wang K S, Kong L Z. A method for calculating the stage number of a labyrinth steam conditioning valve[J]. Journal of Beijing University of Chemical Technology (Natural Science Edition), 2019, 46(3): 75-82. | |

| 24 | 吕家皓, 吴欣, 何磊. 基于多目标遗传算法和反向传播神经网络的调节阀流道结构优化[J]. 机电工程, 2023, 40(12): 1880-1888. |

| Lyu J H, Wu X, He L. Optimization of control valve flow channel structure based on MOGA and BPNN[J]. Journal of Mechanical & Electrical Engineering, 2023, 40(12): 1880-1888. | |

| 25 | Wang H M, Zhao Y, Wang J X, et al. Numerical simulation of flow characteristics for a labyrinth passage in a pressure valve[J]. Journal of Hydrodynamics, Ser. B, 2016, 28(4): 629-636. |

| 26 | Braun M J, Kudriavtsev V V. Fluid flow structures in staggered banks of cylinders located in a channel[J]. Journal of Fluids Engineering, 1995, 117(1): 36-44. |

| 27 | Asim T, Charlton M, Mishra R. CFD based investigations for the design of severe service control valves used in energy systems[J]. Energy Conversion and Management, 2017, 153: 288-303. |

| 28 | Asim T, Oliveira A, Charlton M, et al. Improved design of a multi-stage continuous-resistance trim for minimum energy loss in control valves[J]. Energy, 2019, 174: 954-971. |

| 29 | Asim T, Mishra R, Oliveira A, et al. Effects of the geometrical features of flow paths on the flow capacity of a control valve trim[J]. Journal of Petroleum Science and Engineering, 2019, 172: 124-138. |

| 30 | Menter F R. Influence of freestream values on k-omega turbulence model predictions[J]. AIAA Journal, 1992, 30(6): 1657-1659. |

| 31 | Menter F R. Two-equation eddy-viscosity turbulence models for engineering applications[J]. AIAA Journal, 1994, 32(8): 1598-1605. |

| 32 | 姜俊泽, 张伟明. 水平管道气液两相段塞流参数计算的精确模型[J]. 化工学报, 2012, 63(12): 3826-3831. |

| Jiang J Z, Zhang W M. Accurate model for computing parameters of gas-liquid slug flow in horizontal pipe[J]. CIESC Journal, 2012, 63(12): 3826-3831. | |

| 33 | Singhal A K, Athavale M M, Li H Y, et al. Mathematical basis and validation of the full cavitation model[J]. Journal of Fluids Engineering, 2002, 124(3): 617-624. |

| 34 | Bakir F, Rey R, Gerber A G, et al. Numerical and experimental investigations of the cavitating behavior of an inducer[J]. International Journal of Rotating Machinery, 2004, 10(1): 15-25. |

| 35 | Go T S, Kim K. The effect of divergence angle on the control valve trim characteristics[J]. Journal of Fluid Machinery, 2013, 16(1): 32-39. |

| 36 | Slama V, Simurda D, Lenhard R. Pressure losses downstream of a compact valve in the inlet chamber of an intermediate-pressure steam turbine[J]. Energies, 2022, 15(22): 8753. |

| 37 | Qian J Y, Gao Z X, Hou C W, et al. A comprehensive review of cavitation in valves: mechanical heart valves and control valves[J]. Bio-Design and Manufacturing, 2019, 2(2): 119-136. |

| [1] | 孙云龙, 徐肖肖, 黄永方, 郭纪超, 陈卫卫. 水平光滑管内CO2流动沸腾的非绝热可视化研究[J]. 化工学报, 2025, 76(S1): 230-236. |

| [2] | 孙九春, 桑运龙, 王海涛, 贾浩, 朱艳. 泥水盾构仓体内射流对泥浆输送特性影响研究[J]. 化工学报, 2025, 76(S1): 246-257. |

| [3] | 何婷, 黄舒阳, 黄坤, 陈利琼. 基于余热利用的天然气化学吸收脱碳-高温热泵耦合流程研究[J]. 化工学报, 2025, 76(S1): 297-308. |

| [4] | 段浩磊, 陈浩远, 梁坤峰, 王林, 陈彬, 曹勇, 张晨光, 李硕鹏, 朱登宇, 何亚茹, 杨大鹏. 纯电动车热管理系统低GWP工质替代方案性能分析与综合评价[J]. 化工学报, 2025, 76(S1): 54-61. |

| [5] | 于宏鑫, 王宁波, 郭焱华, 邵双全. 动态蓄冰系统的板式换热器流动换热模拟研究[J]. 化工学报, 2025, 76(S1): 106-113. |

| [6] | 吴馨, 龚建英, 李祥宇, 王宇涛, 杨小龙, 蒋震. 超声波激励疏水表面液滴运动的实验研究[J]. 化工学报, 2025, 76(S1): 133-139. |

| [7] | 燕子腾, 詹飞龙, 丁国良. 空调用套管式分流器结构设计及分流效果验证[J]. 化工学报, 2025, 76(S1): 152-159. |

| [8] | 袁琳慧, 王瑜. 单服务器浸没射流式液冷系统散热性能[J]. 化工学报, 2025, 76(S1): 160-169. |

| [9] | 赵子祥, 段钟弟, 孙浩然, 薛鸿祥. 大温差两相流动诱导水锤冲击的数值模型[J]. 化工学报, 2025, 76(S1): 170-180. |

| [10] | 黄灏, 王文, 贺隆坤. LNG船薄膜型液货舱预冷过程模拟与分析[J]. 化工学报, 2025, 76(S1): 187-194. |

| [11] | 汪思远, 刘国强, 熊通, 晏刚. 窗式空调器轴流风机的风速非均匀分布特性及其对冷凝器流路优化设计的影响规律[J]. 化工学报, 2025, 76(S1): 205-216. |

| [12] | 曹庆泰, 郭松源, 李建强, 蒋赞, 汪彬, 耑锐, 吴静怡, 杨光. 负过载下多孔隔板对液氧贮箱蓄液性能的影响研究[J]. 化工学报, 2025, 76(S1): 217-229. |

| [13] | 刘璐, 万开, 王文玥, 王太, 汤建成, 王少恒. 基于氦膨胀制冷的正仲氢转化耦合流动换热研究[J]. 化工学报, 2025, 76(4): 1513-1522. |

| [14] | 张翼辰, 张文彪, 李浩洋, 宁晓阳. 基于双差压模型的文丘里管气液两相CO2流量测量[J]. 化工学报, 2025, 76(4): 1493-1503. |

| [15] | 许成城, 邵索拉, 魏文建, 郑旭. 多工况下直凝式蓄热型铝制辐射板换热器供暖性能研究[J]. 化工学报, 2025, 76(4): 1545-1558. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号