化工学报 ›› 2025, Vol. 76 ›› Issue (4): 1493-1503.DOI: 10.11949/0438-1157.20240828

收稿日期:2024-07-22

修回日期:2024-10-06

出版日期:2025-04-25

发布日期:2025-05-12

通讯作者:

张文彪

作者简介:张翼辰(2000—),男,硕士研究生,yczhang_em@163.com

基金资助:

Yichen ZHANG( ), Wenbiao ZHANG(

), Wenbiao ZHANG( ), Haoyang LI, Xiaoyang NING

), Haoyang LI, Xiaoyang NING

Received:2024-07-22

Revised:2024-10-06

Online:2025-04-25

Published:2025-05-12

Contact:

Wenbiao ZHANG

摘要:

为了实现碳捕集、利用与封存条件下CO2管道输送流量的准确测量,在液相为连续相的CO2气液两相流工况下,基于虚高模型提出了一种利用文丘里管收缩段和扩张段差压比值的气液两相CO2流量测量方法。通过理论分析与实验验证,揭示了差压比值与Lockhart-Martinelli(L-M)参数及液相虚高之间的对应规律。针对经典模型存在的问题,提出了一种使用迭代方法计算液气质量流量比的模型,实现了CO2气液两相流分相流量的准确测量。在管道压力为4.9~5.2 MPa,温度为14~17℃,液气质量流量比在8.78~28.85的条件下,总质量流量测量相对误差优于±2.3%,液相流量相对误差优于±2.2%,气相流量相对误差优于±6.3%。结果表明基于双差压模型的文丘里流量计为气液两相CO2流量测量提供了一种简单可靠、经济实用的解决方案。

中图分类号:

张翼辰, 张文彪, 李浩洋, 宁晓阳. 基于双差压模型的文丘里管气液两相CO2流量测量[J]. 化工学报, 2025, 76(4): 1493-1503.

Yichen ZHANG, Wenbiao ZHANG, Haoyang LI, Xiaoyang NING. Flow measurement of gas-liquid two-phase CO2 using Venturi tube based on dual differential pressure model[J]. CIESC Journal, 2025, 76(4): 1493-1503.

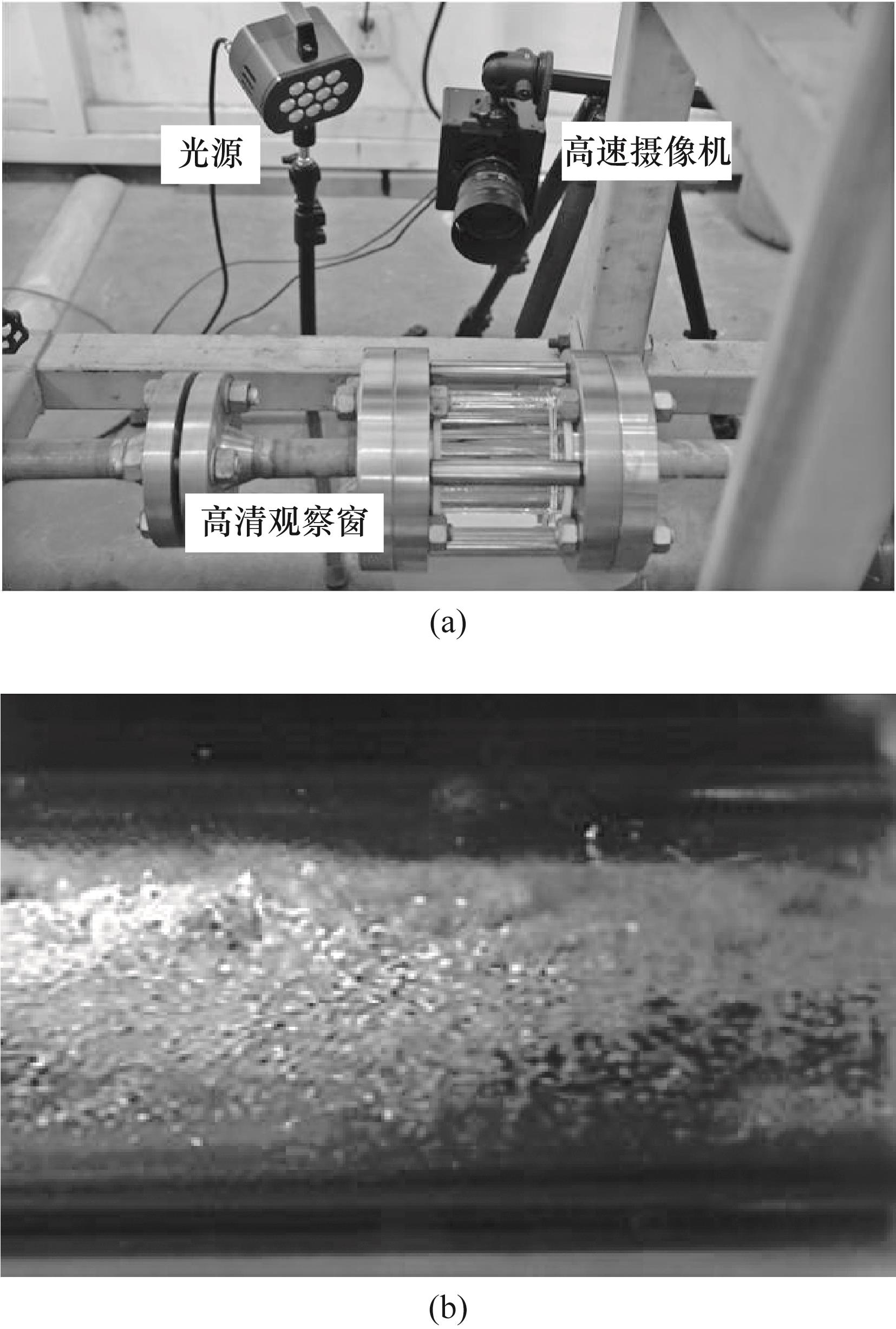

图7 (a)高速摄像系统;(b)水平管道气液两相CO2流型图像

Fig.7 (a) High-speed imaging system; (b) Image of flow pattern from gas-liquid two-phase CO₂ flow in the horizontal pipeline

| 模型 | 经验参数 | ||

|---|---|---|---|

| A | b | c | |

| Collins模型 | 0.331 | 0.852 | 0.571 |

| De Leeuw模型 | 0.123 | — | — |

| 张宏建模型 | 0.824 | 0.869 | 0.021 |

| Steven模型 | ASte=2454.465(1/r)2-389.709(1/r)+17.873 | ||

| BSte=61.479(1/r)2-8.810(1/r)+1.222 | |||

| CSte=1722.977(1/r)2-272.71(1/r)+12.328 | |||

| DSte=57.718(1/r)2-6.692(1/r)+1.571 | |||

表1 不同流量测量模型中使用的参数

Table 1 Parameters used in different flow measurement models

| 模型 | 经验参数 | ||

|---|---|---|---|

| A | b | c | |

| Collins模型 | 0.331 | 0.852 | 0.571 |

| De Leeuw模型 | 0.123 | — | — |

| 张宏建模型 | 0.824 | 0.869 | 0.021 |

| Steven模型 | ASte=2454.465(1/r)2-389.709(1/r)+17.873 | ||

| BSte=61.479(1/r)2-8.810(1/r)+1.222 | |||

| CSte=1722.977(1/r)2-272.71(1/r)+12.328 | |||

| DSte=57.718(1/r)2-6.692(1/r)+1.571 | |||

液相质量流量/ (kg/s) | 气相质量流量/ (kg/s) | 温度/℃ | 压力/MPa | K | 1/X | 气相质量流量的 相对误差/% | 液相质量流量的 相对误差/% | 总质量流量的相对误差/% |

|---|---|---|---|---|---|---|---|---|

| 1.00 | 0.03~0.11 | 14.1~15.1 | 4.9~5.0 | 1.11~1.19 | 0.08~0.25 | -2.2~3.9 | -1.3~2.0 | -1.1~2.0 |

| 1.07 | 0.04~0.12 | 15.9~16.9 | 5.1~5.2 | 1.11~1.19 | 0.09~0.25 | -3.7~3.6 | -0.6~2.1 | -0.6~2.2 |

| 1.18 | 0.07~0.12 | 16.3~17.0 | 5.1~5.2 | 1.12~1.17 | 0.14~0.22 | -6.3~4.9 | -1.0~1.1 | -0.5~1.2 |

表2 不同工况下双差压模型的相对误差

Table 2 Relative error of dual differential pressure model under different conditions

液相质量流量/ (kg/s) | 气相质量流量/ (kg/s) | 温度/℃ | 压力/MPa | K | 1/X | 气相质量流量的 相对误差/% | 液相质量流量的 相对误差/% | 总质量流量的相对误差/% |

|---|---|---|---|---|---|---|---|---|

| 1.00 | 0.03~0.11 | 14.1~15.1 | 4.9~5.0 | 1.11~1.19 | 0.08~0.25 | -2.2~3.9 | -1.3~2.0 | -1.1~2.0 |

| 1.07 | 0.04~0.12 | 15.9~16.9 | 5.1~5.2 | 1.11~1.19 | 0.09~0.25 | -3.7~3.6 | -0.6~2.1 | -0.6~2.2 |

| 1.18 | 0.07~0.12 | 16.3~17.0 | 5.1~5.2 | 1.12~1.17 | 0.14~0.22 | -6.3~4.9 | -1.0~1.1 | -0.5~1.2 |

| 1 | 习近平. 在第七十五届联合国大会一般性辩论上的讲话[J]. 中华人民共和国国务院公报, 2020(28): 5-7. |

| Xi J P. Speech at the general debate of the 75th session of the United Nations General Assembly[J]. Gazette of the State Council of the People's Republic of China, 2020(28): 5-7. | |

| 2 | 云慧敏, 代建军, 李辉, 等. 生物质耦合燃煤发电经济环境效益评估[J]. 化工学报, 2021, 72(12): 6311-6327. |

| Yun H M, Dai J J, Li H, et al. Economic and environmental assessment of biomass coupled coal-fired power generation[J]. CIESC Journal, 2021, 72(12): 6311-6327. | |

| 3 | Dods M N, Kim E J, Long J R, et al. Deep CCS: moving beyond 90% carbon dioxide capture[J]. Environmental Science & Technology, 2021, 55(13): 8524-8534. |

| 4 | Mills C, Chinello G, Henry M. Flow measurement challenges for carbon capture, utilization and storage[J]. Flow Measurement and Instrumentation, 2022, 88: 102261. |

| 5 | Arellano Y, Tjugum S A, Pedersen O B, et al. Measurement technologies for pipeline transport of carbon dioxide-rich mixtures for CCS[J]. Flow Measurement and Instrumentation, 2024, 95: 102515. |

| 6 | Park J H, Cha J E. Measurements of the flow of supercritical pressure carbon dioxide through Venturi flow meter[J]. Flow Measurement and Instrumentation, 2023, 91: 102364. |

| 7 | Lockhart R W, Martinelli R C. Proposed correlation of data for isothermal two-phase, two-component flow in pipes[J]. Chemical Engineering Progress, 1949, 45(1): 39-48. |

| 8 | Murdock J W. Two-phase flow measurement with orifices[J]. Journal of Basic Engineering, 1962, 84(4): 419-432. |

| 9 | Bizon E. Two-phase flow measurement with sharp-edged orifices and Venturis[R]. Chalk River(Ontario): Atomic Energy of Canada Ltd., 1965. |

| 10 | James R. Metering of steam-water two-phase flow by sharp-edged orifices[J]. Proceedings of the Institution of Mechanical Engineers, 1965, 180(1): 549-572. |

| 11 | Chisholm D. Flow of incompressible two-phase mixtures through sharp-edged orifices[J]. Journal of Mechanical Engineering Science, 1967, 9(1): 72-78. |

| 12 | Collins D B, Gacesa M. Measurement of steam quality in two-phase upflow with Venturimeters and orifice plates[J]. Journal of Basic Engineering, 1971, 93(1): 11-20. |

| 13 | Lin Z H. Two-phase flow measurements with sharp-edged orifices[J]. International Journal of Multiphase Flow, 1982, 8(6): 683-693. |

| 14 | Liu X L, Lao L Y, Falcone G. A comprehensive assessment of correlations for two-phase flow through Venturi tubes[J]. Journal of Natural Gas Science and Engineering, 2020, 78: 103323. |

| 15 | De Leeuw R. Liquid correction of Venturi meter readings in wet gas flow[C]//Proceedings of the 1997 North Sea Flow Measurement Workshop. Kristiansand, 1997. |

| 16 | Steven R N. Wet gas metering with a horizontally mounted Venturi meter[J]. Flow Measurement and Instrumentation, 2002, 12(5/6): 361-372. |

| 17 | Zhang H J, Yue W T, Huang Z Y. Investigation of oil-air two-phase mass flow rate measurement using Venturi and void fraction sensor[J]. Journal of Zhejiang University: Science A, 2005, 6(6): 601-606. |

| 18 | 张宏建, 岳伟挺, 马龙博, 等. 文丘里管中气液两相流差压波动信号与空隙率关系[J]. 化工学报, 2005, 56(11): 2102-2107. |

| Zhang H J, Yue W T, Ma L B, et al. Relationship between fluctuating differential pressure and void fraction of gas-liquid two-phase flow in Venturi tube[J]. Journal of Chemical Industry and Engineering(China), 2005, 56(11): 2102-2107. | |

| 19 | Silva A M, Teixeira J C F, Teixeira S F C F. Experiments in a large-scale venturi scrubber (part Ⅰ): Pressure drop[J]. Chemical Engineering and Processing: Process Intensification, 2009, 48(1): 59-67. |

| 20 | Yu P N, Xu Y, Zhang T, et al. A study on the modeling of static pressure distribution of wet gas in Venturi[J]. AIChE Journal, 2015, 61(2): 699-708. |

| 21 | Salehi S M, Lao L Y, Xing L C, et al. Devices and methods for wet gas flow metering: a comprehensive review[J]. Flow Measurement and Instrumentation, 2024, 96: 102518. |

| 22 | Xu L J, Zhou W L, Li X M. Wet gas flow modeling for a vertically mounted Venturi meter[J]. Measurement Science and Technology, 2012, 23(4): 045301. |

| 23 | Yuan C, Xu Y, Zhang T, et al. Dual-iterative model for gas condensate measurement based on void fraction[J]. Journal of Natural Gas Science and Engineering, 2015, 24: 330-336. |

| 24 | 牛守梓, 吴海涛, 徐英, 等. 基于文丘里管的页岩气试采期段塞流测量补偿方法[J]. 化工学报, 2018, 69(8): 3364-3372. |

| Niu S Z, Wu H T, Xu Y, et al. Compensation method for slug flow measurement in shale gas well using Venturi tube[J]. CIESC Journal, 2018, 69(8): 3364-3372. | |

| 25 | 张强, 徐英, 张涛. 长槽道内文丘里湿气流量测量虚高特性[J]. 化工学报, 2011, 62(3): 636-642. |

| Zhang Q, Xu Y, Zhang T. Wet gas performance of long slot internal Venturi meter[J]. CIESC Journal, 2011, 62(3): 636-642. | |

| 26 | Yuan C, Xu Y, Zhang T, et al. Experimental investigation of wet gas over reading in Venturi[J]. Experimental Thermal and Fluid Science, 2015, 66: 63-71. |

| 27 | Aursand P, Hammer M, Munkejord S T, et al. Pipeline transport of CO2 mixtures: models for transient simulation[J]. International Journal of Greenhouse Gas Control, 2013, 15: 174-185. |

| 28 | Armand A A. The resistance during the movement of a two-phase system in horizontal pipes[J]. Izv Vses. Teplotekh. Inst., 1946, 828(1): 16-23. |

| 29 | 国家质量监督检验检疫总局, 中国国家标准化管理委员会. 用安装在圆形截面管道中的差压装置测量满管流体流量 第4部分: 文丘里管: [S]. 北京: 中国标准出版社, 2007. |

| General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China. Measurement of fluid flow by means of pressure differential devices inserted in circular cross-section conduits running full(part 4): Venturi tubes: [S]. Beijing: Standards Press of China, 2007. | |

| 30 | 丁宁, 邵丁, 闫勇, 等. 基于门控循环单元的动态过程下两相CO2质量流量测量[J]. 仪器仪表学报, 2021, 42(10): 112-120. |

| Ding N, Shao D, Yan Y. Mass flowrate measurement of two-phase CO2 in a transient process using a gated recurrent unit neural network model[J]. Chinese Journal of Scientific Instrument, 2021, 42(10): 112-120. |

| [1] | 赵俊德, 周爱国, 陈彦霖, 郑家乐, 葛天舒. 吸附法CO2直接空气捕集技术能耗现状[J]. 化工学报, 2025, 76(4): 1375-1390. |

| [2] | 产文, 余万, 王岗, 苏华山, 黄芬霞, 胡涛. 改进回热布局的Allam循环热力、经济性能分析和双目标优化[J]. 化工学报, 2025, 76(4): 1680-1692. |

| [3] | 霍军良, 唐治国, 邱宗君, 冯玉华, 蒋旭, 王乐怡, 杨宇, 乔帆帆, 赫一凡, 喻健良. 节流作用下CO2管道放空过程的冻堵风险实验研究[J]. 化工学报, 2025, 76(4): 1898-1908. |

| [4] | 吴罗长, 杨泽宇, 颜建国, 朱旭涛, 陈阳, 王子辰. 微小方形通道内近超临界压力二氧化碳流动换热特性实验研究[J]. 化工学报, 2025, 76(4): 1583-1594. |

| [5] | 张赵雪, 李正宇, 崔文慧, 王倩, 王志平, 龚领会. 基于液氖液氮梯级蓄冷的液氢储能中冷能回收利用研究[J]. 化工学报, 2025, 76(4): 1731-1741. |

| [6] | 伏遥, 邵应娟, 钟文琪. TiO2掺杂钙基材料加压碳酸化循环储热性能实验研究[J]. 化工学报, 2025, 76(3): 1180-1190. |

| [7] | 张亦鸣, 杨鹏, 纪献兵, 任纪星, 张磊, 苗政. 多回路平板式环路热管热性能[J]. 化工学报, 2025, 76(3): 1018-1028. |

| [8] | 张履胜, 王治红, 柳青, 李雪雯, 谭仁敏. 液-液相变吸收剂捕集二氧化碳研究进展[J]. 化工学报, 2025, 76(3): 933-950. |

| [9] | 杨晋宁, 王卫凡, 徐冬, 刘毅, 翁小涵, 原野, 王志. 工业烟道气碳捕集膜技术放大研究进展[J]. 化工学报, 2025, 76(2): 504-518. |

| [10] | 宫政, 高秀鲁, 赵玲, 胡冬冬. 超临界CO2发泡PBAT/PLA复合材料及其形状记忆性能[J]. 化工学报, 2025, 76(2): 888-896. |

| [11] | 戴晓宇, 徐强, 杨晨宇, 苏筱斌, 郭烈锦. 多级混流式混输泵气液两相增压特性[J]. 化工学报, 2025, 76(2): 554-563. |

| [12] | 黄云龙, 许剑, 刘通, 元昕彤, 徐强. 气藏水平井温度分布特征及流量测试实验研究[J]. 化工学报, 2025, 76(2): 612-622. |

| [13] | 姚佳逸, 张东辉, 唐忠利, 李文彬. 基于二级双回流的变压吸附捕碳工艺研究[J]. 化工学报, 2025, 76(2): 744-754. |

| [14] | 李彦, 郭红利, 苏国庆, 张建文. 加氢装置空冷器气液两相流动与冲刷腐蚀问题[J]. 化工学报, 2025, 76(1): 141-150. |

| [15] | 任冠宇, 张义飞, 李新泽, 杜文静. 翼型印刷电路板式换热器流动传热特性数值研究[J]. 化工学报, 2024, 75(S1): 108-117. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号