• •

收稿日期:2025-11-20

修回日期:2026-01-20

出版日期:2026-01-21

通讯作者:

陈黎

作者简介:宁文婧(1997—),女,博士研究生,nwj97@stu.xjtu.edu.cn

基金资助:

Wenjing NING( ), Li CHEN(

), Li CHEN( ), Wenquan TAO

), Wenquan TAO

Received:2025-11-20

Revised:2026-01-20

Online:2026-01-21

Contact:

Li CHEN

摘要:

针对质子交换膜燃料电池热电联供系统(PEMFC-CHP)的能量管理问题,本文采用动态规划(DP)算法优化系统功率分配,分析了离散点数设置与多目标权重配置的影响,并基于高斯混合模型(GMM)与期望最大化(EM)算法,从离线最优数据中提取规则,构建了数据驱动的模糊控制器(DP-FLC),以实现策略的在线应用。结果表明,选取离散点数N=200可在控制计算复杂度的同时,有效平滑PEMFC输出波动;通过多目标权重优化,系统能将PEMFC的最大功率增量限制在8.32 W,并在能耗与寿命间取得良好平衡;所提出的DP-FLC控制器继承了离线优化的优势,相比传统方法,其可将PEMFC功率波动标准差降低约56.7%,且系统能耗与DP最优解接近,验证了该在线管理策略在提升系统平稳性与能效方面的有效性。

中图分类号:

宁文婧, 陈黎, 陶文铨. 基于动态规划优化的模糊逻辑控制在热电联供系统中的应用研究[J]. 化工学报, DOI: 10.11949/0438-1157.20251287.

Wenjing NING, Li CHEN, Wenquan TAO. Application research of fuzzy logic control optimized by dynamic programming in combined heat and power system[J]. CIESC Journal, DOI: 10.11949/0438-1157.20251287.

| 参数 | 数值 |

|---|---|

| 电堆一次完整启停 (P1) | 0.00196(%/次) |

| 加载功率变化率大于10% Pfc,max 或减载功率变化率大于20% Pfc,max (P2) | 0.0000593(%/次) |

| 输出功率小于5% Pfc,max (P3) | 0.00126(%/h) |

| 输出功率大于90% Pfc,max (P4) | 0.00147(%/h) |

表1 燃料电池寿命衰减参数

Table 1 Parameter of PEMFC lifetime degradation

| 参数 | 数值 |

|---|---|

| 电堆一次完整启停 (P1) | 0.00196(%/次) |

| 加载功率变化率大于10% Pfc,max 或减载功率变化率大于20% Pfc,max (P2) | 0.0000593(%/次) |

| 输出功率小于5% Pfc,max (P3) | 0.00126(%/h) |

| 输出功率大于90% Pfc,max (P4) | 0.00147(%/h) |

| c | 0.5 | 2 | 6 | 10 |

|---|---|---|---|---|

| α(c) | 31630 | 21681 | 12934 | 15512 |

表2 c与α(c)之间的关系

Table 2 Relationship between c and α(c)

| c | 0.5 | 2 | 6 | 10 |

|---|---|---|---|---|

| α(c) | 31630 | 21681 | 12934 | 15512 |

| 离散点数 | Ifc离散间隔 (A) | SOC离散间隔 |

|---|---|---|

| 100 | 2 | 0.01 |

| 200 | 1 | 0.005 |

| 300 | 0.67 | 0.0033 |

表3 不同离散点数下Ifc与SOC离散步长设置

Table 3 Ifc and SOC step size settings under different discretization levels

| 离散点数 | Ifc离散间隔 (A) | SOC离散间隔 |

|---|---|---|

| 100 | 2 | 0.01 |

| 200 | 1 | 0.005 |

| 300 | 0.67 | 0.0033 |

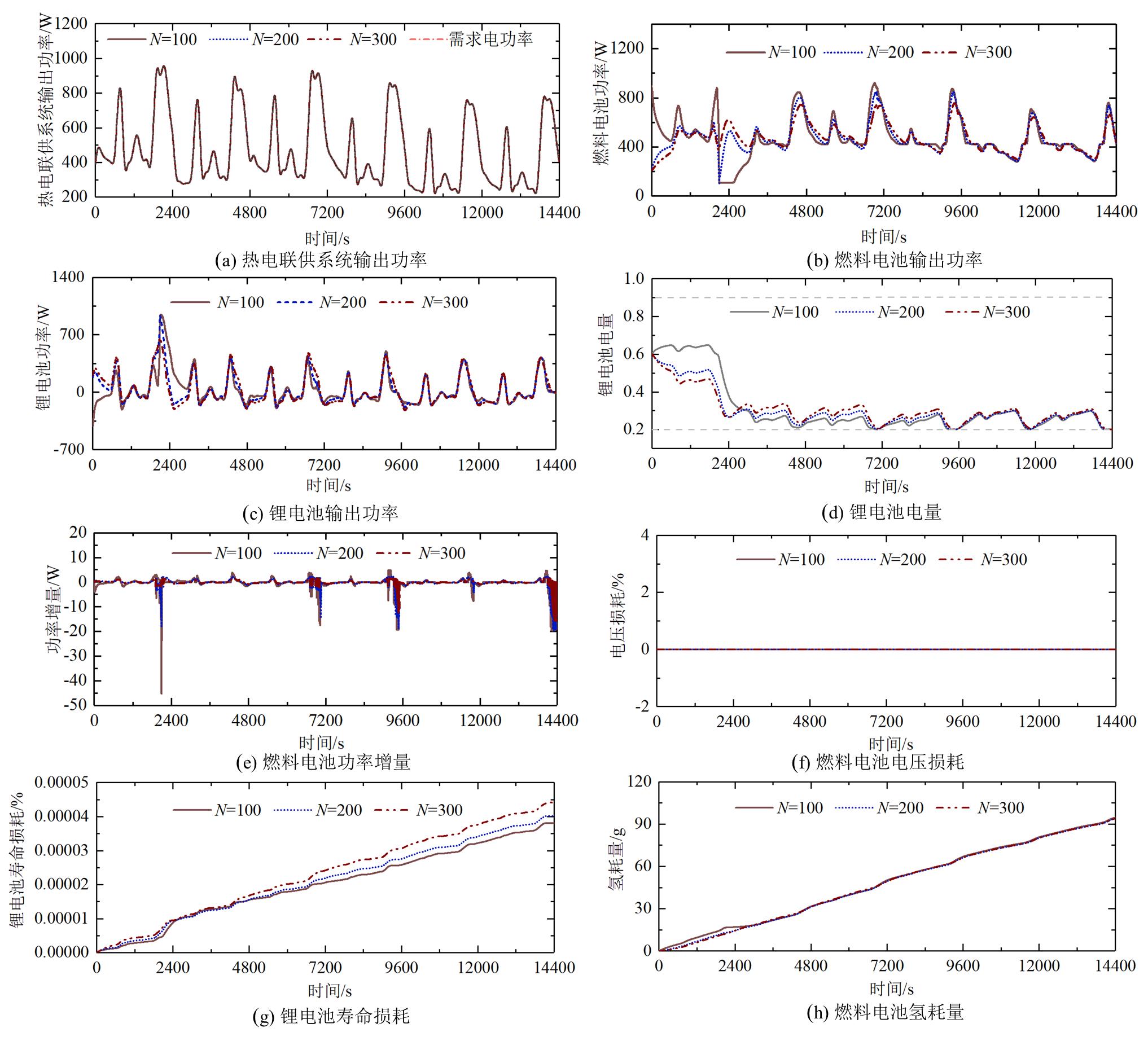

图5 不同离散点数下PEMFC-CHP的功率分配与性能指标对比注:under different discretization levels

Fig. 5 Comparison of power distribution and performance indicators of the PEMFC-CHP system

| 离散点数 | Pfc平均值/W | PEMFC变载量最大值(取绝对值)/W | Pfc标准差/W | mH2/g | Pbat标准差/W |

|---|---|---|---|---|---|

| 100 | 472.78 | 45.17 | 158.23 | 94.62 | 185.14 |

| 200 | 473.32 | 19.48 | 123.56 | 93.91 | 179.77 |

| 300 | 474.68 | 15.82 | 108.49 | 93.90 | 183.07 |

表4 不同离散点数下PEMFC与锂电池运行特性对比

Table 4 Comparison of PEMFC and lithium-ion battery operating characteristics under different discretization levels

| 离散点数 | Pfc平均值/W | PEMFC变载量最大值(取绝对值)/W | Pfc标准差/W | mH2/g | Pbat标准差/W |

|---|---|---|---|---|---|

| 100 | 472.78 | 45.17 | 158.23 | 94.62 | 185.14 |

| 200 | 473.32 | 19.48 | 123.56 | 93.91 | 179.77 |

| 300 | 474.68 | 15.82 | 108.49 | 93.90 | 183.07 |

| 算例 | Jsoc权重 | JH2权重 | Jfc, loss权重 | J△P权重 | Jbat, loss权重 |

|---|---|---|---|---|---|

| 算例一 | 1 | 0 | 0 | 0 | 0 |

| 算例二 | 0 | 1 | 0 | 0 | 0 |

| 算例三 | 0 | 0 | 0.5 | 0 | 0.5 |

| 算例四 | 0 | 0 | 0.5 | 0.35 | 0.15 |

| 算例五 | 0.2 | 0.2 | 0.3 | 0.25 | 0.05 |

表5 不同优化目标及权重配置

Table 5 Different optimization objectives and weight configurations

| 算例 | Jsoc权重 | JH2权重 | Jfc, loss权重 | J△P权重 | Jbat, loss权重 |

|---|---|---|---|---|---|

| 算例一 | 1 | 0 | 0 | 0 | 0 |

| 算例二 | 0 | 1 | 0 | 0 | 0 |

| 算例三 | 0 | 0 | 0.5 | 0 | 0.5 |

| 算例四 | 0 | 0 | 0.5 | 0.35 | 0.15 |

| 算例五 | 0.2 | 0.2 | 0.3 | 0.25 | 0.05 |

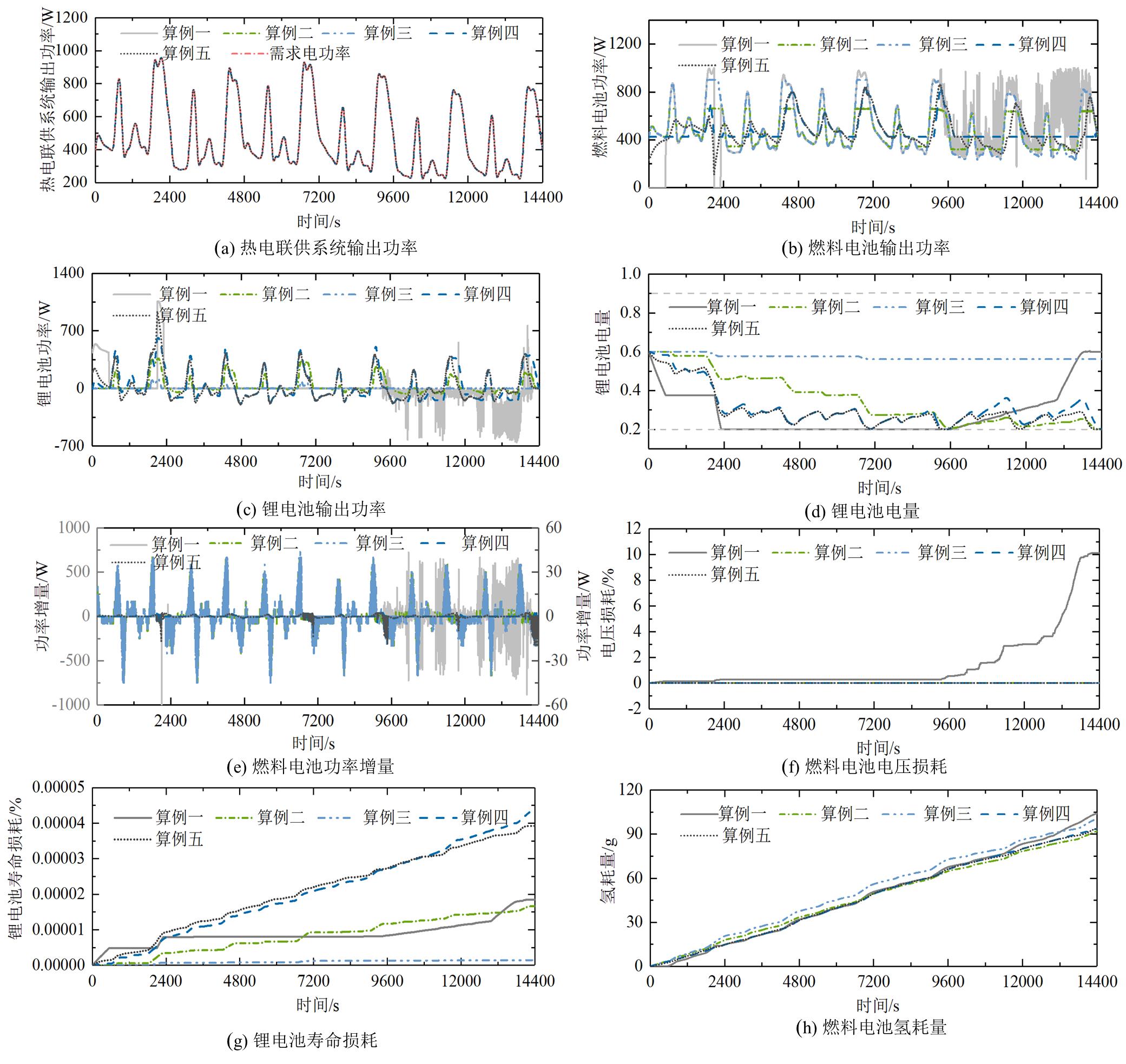

图7 不同优化目标下PEMFC-CHP功率分配与性能指标对比

Fig. 7 Comparison of power distribution and performance indicators of the PEMFC-CHP system under different optimization objectives

| 算例 | Pfc平均值/W | PEMFC变载量最大值(取绝对值)/W | Pfc标准差/W | mH2/g | Pbat标准差/W |

|---|---|---|---|---|---|

| 算例一 | 500.31 | 998.62 | 234.43 | 104.10 | 179.71 |

| 算例二 | 464.88 | 45 | 129.90 | 92.01 | 95.73 |

| 算例三 | 490.31 | 45 | 203.14 | 100.27 | 15.01 |

| 算例四 | 474.59 | 18.81 | 95.48 | 93.74 | 183.11 |

| 算例五 | 472.96 | 19.56 | 127.43 | 93.90 | 176.70 |

表6 不同优化目标下PEMFC与锂电池运行特性对比

Table 6 Comparison of PEMFC and lithium-ion battery operating characteristics under different optimization objectives

| 算例 | Pfc平均值/W | PEMFC变载量最大值(取绝对值)/W | Pfc标准差/W | mH2/g | Pbat标准差/W |

|---|---|---|---|---|---|

| 算例一 | 500.31 | 998.62 | 234.43 | 104.10 | 179.71 |

| 算例二 | 464.88 | 45 | 129.90 | 92.01 | 95.73 |

| 算例三 | 490.31 | 45 | 203.14 | 100.27 | 15.01 |

| 算例四 | 474.59 | 18.81 | 95.48 | 93.74 | 183.11 |

| 算例五 | 472.96 | 19.56 | 127.43 | 93.90 | 176.70 |

| 算例 | Jsoc权重 | JH2权重 | Jfc, loss权重 | J△P权重 | Jbat, loss权重 |

|---|---|---|---|---|---|

| 算例五 | 0.2 | 0.2 | 0.3 | 0.25 | 0.05 |

| 算例六 | 0.3 | 0.3 | 0.1 | 0.25 | 0.05 |

| 算例七 | 0.3 | 0.2 | 0.1 | 0.35 | 0.05 |

| 算例八 | 0.3 | 0.15 | 0.15 | 0.35 | 0.05 |

| 算例九 | 0.3 | 0.15 | 0.1 | 0.4 | 0.05 |

表7 不同权重分配

Table 7 Different weight distributions

| 算例 | Jsoc权重 | JH2权重 | Jfc, loss权重 | J△P权重 | Jbat, loss权重 |

|---|---|---|---|---|---|

| 算例五 | 0.2 | 0.2 | 0.3 | 0.25 | 0.05 |

| 算例六 | 0.3 | 0.3 | 0.1 | 0.25 | 0.05 |

| 算例七 | 0.3 | 0.2 | 0.1 | 0.35 | 0.05 |

| 算例八 | 0.3 | 0.15 | 0.15 | 0.35 | 0.05 |

| 算例九 | 0.3 | 0.15 | 0.1 | 0.4 | 0.05 |

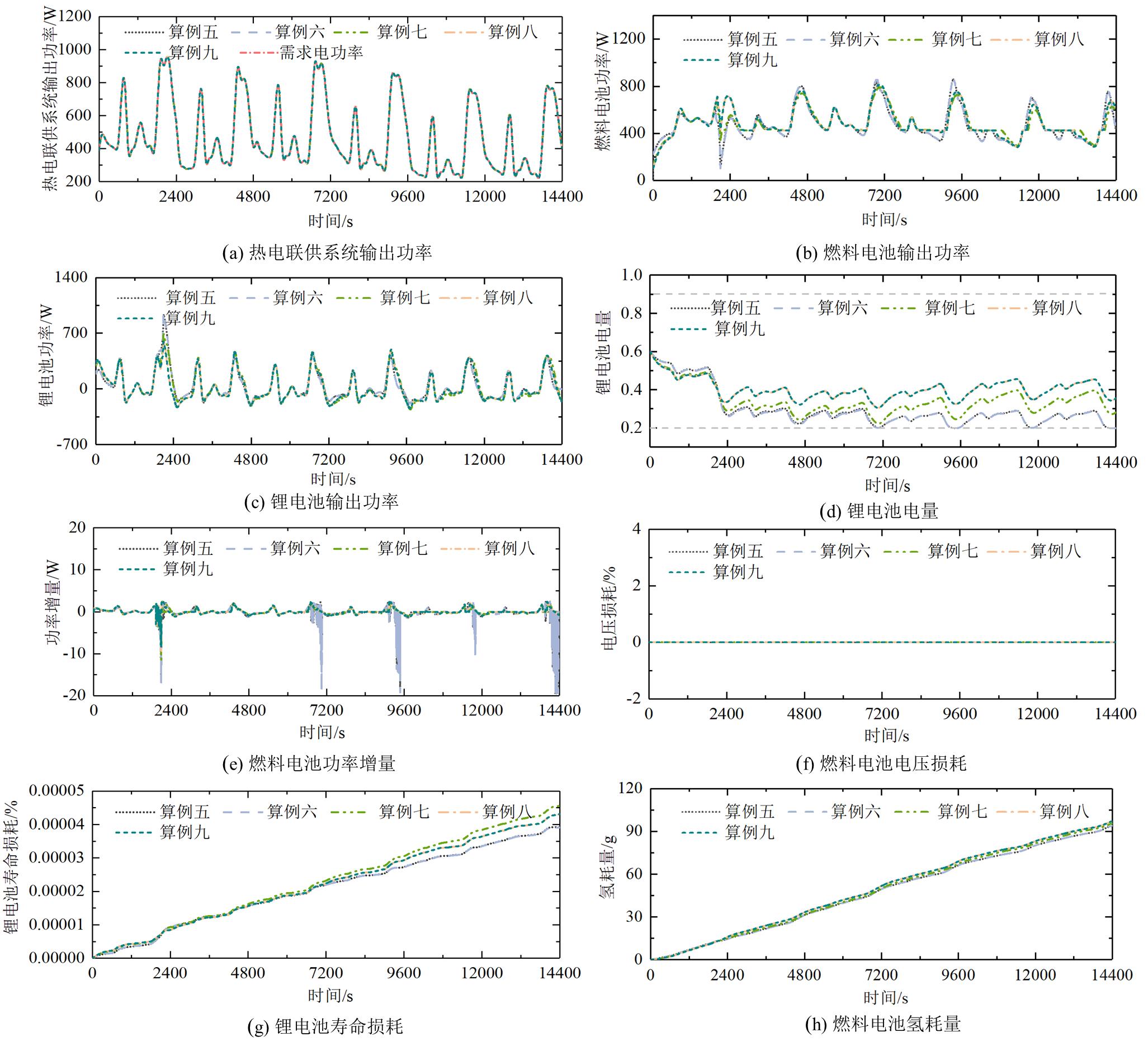

图8 不同权重配置下PEMFC-CHP功率分配与性能指标对比

Fig. 8 Comparison of power distribution and performance indicators of the PEMFC-CHP system under different weight configurations

| 算例 | Pfc平均值/W | PEMFC变载量最大值(取绝对值)/W | Pfc标准差/W | mH2/g | Pbat标准差/W |

|---|---|---|---|---|---|

| 算例五 | 472.96 | 19.56 | 127.43 | 93.90 | 176.70 |

| 算例六 | 472.93 | 19.56 | 128.91 | 93.93 | 176.78 |

| 算例七 | 482.08 | 11.48 | 110.60 | 95.66 | 185.74 |

| 算例八 | 487.42 | 9.35 | 124.25 | 97.17 | 175.06 |

| 算例九 | 487.43 | 8.32 | 124.42 | 97.17 | 175.17 |

表8 不同权重配置下PEMFC与锂电池运行特性对比

Table 8 Comparison of PEMFC and lithium-ion battery operating characteristics under different weight configurations

| 算例 | Pfc平均值/W | PEMFC变载量最大值(取绝对值)/W | Pfc标准差/W | mH2/g | Pbat标准差/W |

|---|---|---|---|---|---|

| 算例五 | 472.96 | 19.56 | 127.43 | 93.90 | 176.70 |

| 算例六 | 472.93 | 19.56 | 128.91 | 93.93 | 176.78 |

| 算例七 | 482.08 | 11.48 | 110.60 | 95.66 | 185.74 |

| 算例八 | 487.42 | 9.35 | 124.25 | 97.17 | 175.06 |

| 算例九 | 487.43 | 8.32 | 124.42 | 97.17 | 175.17 |

| 算例 | Pfc平均值/W | PEMFC变载量最大值(取绝对值)/W | Pfc标准差/W | mH2/g | Pbat标准差/W |

|---|---|---|---|---|---|

| 算例九 | 487.43 | 8.32 | 124.42 | 97.17 | 175.17 |

| FLC | 474.16 | 80.55 | 217.96 | 98.54 | 43.58 |

| DP-FLC | 491.78 | 76.44 | 94.27 | 100.70 | 162.63 |

表9 不同优化方案下PEMFC与锂电池运行特性对比

Table 9 Comparison of PEMFC and lithium-ion battery operating characteristics under different optimization schemes

| 算例 | Pfc平均值/W | PEMFC变载量最大值(取绝对值)/W | Pfc标准差/W | mH2/g | Pbat标准差/W |

|---|---|---|---|---|---|

| 算例九 | 487.43 | 8.32 | 124.42 | 97.17 | 175.17 |

| FLC | 474.16 | 80.55 | 217.96 | 98.54 | 43.58 |

| DP-FLC | 491.78 | 76.44 | 94.27 | 100.70 | 162.63 |

| [1] | 国家发改委发布«氢能产业发展中长期规划( 2021—2035年)»[J]. 稀土信息, 2022(4): 26-32. |

| The national development and reform commission issued the medium and long-term plan for the development of hydrogen energy industry (2021-2035)[J]. Rare Earth Information, 2022(4): 26-32. | |

| [2] | 刘铠诚, 王松岑, 何桂雄, 等. 家庭用户燃料电池热电联供系统能量管理策略及配置优化[J]. 综合智慧能源, 2025, 47(10): 77-87. |

| Liu K C, Wang S C, He G X, et al. Energy management strategy and configuration optimization of fuel cell combined heat and power system for household consumers[J]. Integrated Intelligent Energy, 2025, 47(10): 77-87. | |

| [3] | 于承雪,张心周,张科,等. 小型氢燃料电池的应用现状及发展趋势[J]. 电池工业,2021, 25(6): 317-320. |

| Yu C X, Zhang X Z, Zhang K, et al. Application and development of small hydrogen fuel cell[J]. Chinese Battery Industry, 2021, 25(6): 317-320. | |

| [4] | Macias Fernandez A, Kandidayeni M, Boulon L, et al. An adaptive state machine based energy management strategy for a multi-stack fuel cell hybrid electric vehicle[J]. IEEE Transactions on Vehicular Technology, 2020, 69(1): 220-234. |

| [5] | Ning W J, Lyu X B, Yuan Y, et al. Comprehensive evaluation of proton exchange membrane fuel cell-based combined heat and power system with Lithium-ion battery under rule-based strategy[J]. Journal of Energy Storage, 2024, 88: 111620. |

| [6] | Yuan Y, Chen L, Lyu X B, et al. Modeling and optimization of a residential PEMFC-based CHP system under different operating modes[J]. Applied Energy, 2024, 353: 122066. |

| [7] | Lyu X B, Yuan Y, Ning W J, et al. Investigation and optimization of PEMFC-CHP systems based on Chinese residential thermal and electrical consumption data[J]. Applied Energy, 2024, 356: 122337. |

| [8] | 王文斌. 面向办公楼宇的氢燃料电池热电联供系统运行策略优化[D]. 济南:山东大学,2024. |

| Wang W B. Optimization of operating strategies for hydrogen fuel cell combined heat and power systems for office buildings[D]. Jinan: Shandong University, 2024. | |

| [9] | Lü X Q, Wu Y B, Lian J, et al. Energy management and optimization of PEMFC/battery mobile robot based on hybrid rule strategy and AMPSO[J]. Renewable Energy, 2021, 171: 881-901. |

| [10] | Zhu X X, Wang P, Zhang H, et al. A highly efficient, low-carbon CCHP system and its comprehensive optimization for an integrated medical and nursing complex[J]. Renewable Energy, 2024, 227: 120538. |

| [11] | Fares D, Chedid R, Panik F, et al. Dynamic programming technique for optimizing fuel cell hybrid vehicles[J]. International Journal of Hydrogen Energy, 2015, 40(24): 7777-7790. |

| [12] | Zhou W, Yang L, Cai Y S, et al. Dynamic programming for new energy vehicles based on their work modes Part II: Fuel cell electric vehicles[J]. Journal of Power Sources, 2018, 407: 92-104. |

| [13] | Hong Z H, Li Q, Han Y, et al. An energy management strategy based on dynamic power factor for fuel cell/battery hybrid locomotive[J]. International Journal of Hydrogen Energy, 2018, 43(6): 3261-3272. |

| [14] | Li H, Ravey A, N'Diaye A, et al. Online adaptive equivalent consumption minimization strategy for fuel cell hybrid electric vehicle considering power sources degradation[J]. Energy Conversion and Management, 2019, 192: 133-149. |

| [15] | Huang X J, Zhang J Y, Ou K, et al. Deep reinforcement learning-based health-conscious energy management for fuel cell hybrid electric vehicles in model predictive control framework[J]. Energy, 2024, 304: 131769. |

| [16] | Liu H Y, Fan A L, Li Y P, et al. Multi-objective hierarchical energy management strategy for fuel cell/battery hybrid power ships[J]. Applied Energy, 2025, 379: 124981. |

| [17] | 刘偲艳,葛庆. 氢燃料汽车混合动力系统能量管理优化策略[J]. 电气技术,2024, 25(9): 22-26. |

| Liu S Y, Ge Q. Energy management optimization strategy for hydrogen fuel vehicle hybrid power system[J]. Electrical Engineering, 2024, 25(9): 22-26. | |

| [18] | Chang H W, Xu X X, Shen J, et al. Performance analysis of a micro-combined heating and power system with PEM fuel cell as a prime mover for a typical household in North China[J]. International Journal of Hydrogen Energy, 2019, 44(45): 24965-24976. |

| [19] | Hou X K, Sun R F, Huang J K, et al. A hybrid combined heat and power system based on PEM fuel cell design for high-speed zero carbon service area[J]. International Journal of Hydrogen Energy, 2023, 48(83): 32527-32539. |

| [20] | Sui S, Rasheed R, Li Q L, et al. Technoeconomic modelling and environmental assessment of a modern PEMFC CHP system: a case study of an eco-house at University of Nottingham[J]. Environmental Science and Pollution Research, 2019, 26(29): 29883-29895. |

| [21] | 杜浩. 基于能量源等寿命设计的复合储能燃料电池汽车分层能量管理策略[D]. 重庆:重庆大学,2022. |

| Du H. Hierarchical energy management strategy of composite energy storage fuel cell vehicle based on energy source equal life design[D]. Chongqing: Chongqing University, 2022. | |

| [22] | Zhou Y, Wang J J, Liu Y, et al. Incorporating deep learning of load predictions to enhance the optimal active energy management of combined cooling, heating and power system[J]. Energy, 2021, 233: 121134. |

| [23] | Tao S Y, Chen W R, Gan R, et al. Energy management strategy based on dynamic programming with durability extension for fuel cell hybrid tramway[J]. Railway Engineering Science, 2021, 29(3): 299-313. |

| [24] | Zhou H X, Yu Z W, Wu X H, et al. Dynamic programming improved online fuzzy power distribution in a demonstration fuel cell hybrid bus[J]. Energy, 2023, 284: 128549. |

| [25] | 王志福,徐崧,罗崴. 基于动态规划的燃料电池车能量管理策略研究[J]. 太阳能学报,2023, 44(10): 550-556. |

| Wang Z F, Xu S, Luo W. Research on energy management strategy of fuel cell vehicle based on dynamic programming[J]. Acta Energiae Solaris Sinica, 2023, 44(10): 550-556. | |

| [26] | Jabeen S, Baig M, Awais M M. ANFIS learning using expectation maximization based Gaussian mixture model and multilayer perceptron learning[J]. Applied Soft Computing, 2023,149: 110958. |

| [27] | Gu F L, Zhang H, Wang W W, et al. An expectation-maximization algorithm for blind separation of noisy mixtures using Gaussian mixture model[J]. Circuits, Systems, and Signal Processing, 2017, 36(7): 2697-2726. |

| [28] | Pantula P D, Miriyala S S, Mitra K. An evolutionary neuro-fuzzy C-means clustering technique[J]. Engineering Applications of Artificial Intelligence, 2020, 89: 103435. |

| [29] | Chen Y X, Zhou S S, Zhang X M, et al. Improved fuzzy c-means clustering by varying the fuzziness parameter[J]. Pattern Recognition Letters, 2022, 157: 60-66. |

| [30] | Prillo S, Deng Y, Boyeau P, et al. CherryML: scalable maximum likelihood estimation of phylogenetic models[J]. Nature Methods, 2023, 20(8): 1232-1236. |

| [31] | Ning W J, Lyu X B, Liao P C, et al. Performance analysis of a 1-kW PEMFC-CHP system under different rule-based energy management strategies in China[J]. Renewable Energy, 2025, 248: 123110. |

| [32] | Chang H W, Wan Z M, Zheng Y, et al. Energy- and exergy-based working fluid selection and performance analysis of a high-temperature PEMFC-based micro combined cooling heating and power system[J]. Applied Energy, 2017, 204: 446-458. |

| [33] | Chen M, Rincon-Mora G A. Accurate electrical battery model capable of predicting runtime and I-V performance[J]. IEEE Transactions on Energy Conversion, 2006, 21(2): 504-511. |

| [34] | Pei P C, Chang Q F, Tang T. A quick evaluating method for automotive fuel cell lifetime[J]. International Journal of Hydrogen Energy, 2008, 33(14): 3829-3836. |

| [35] | Liu S N, Cheng H Y, Jung S, et al. Novel energy management strategy for fuel cell/battery hybrid energy systems combining MPC and deep reinforcement learning[J]. Energy Conversion and Management, 2025, 341: 120081. |

| [1] | 马爱华, 赵帅, 王林, 常明慧. 太阳能吸收制冷循环动态特性仿真方法研究[J]. 化工学报, 2025, 76(S1): 318-325. |

| [2] | 吴成云, 孙浩然. 民用飞机空调系统性能仿真与燃油代偿损失研究[J]. 化工学报, 2025, 76(S1): 351-359. |

| [3] | 肖鑫, 杨耿, 王云峰. 基于TRNSYS的太阳能梯级蓄热热泵系统模拟[J]. 化工学报, 2025, 76(S1): 393-400. |

| [4] | 王三一, 黄文来. 电化学合成氨流程建模与优化[J]. 化工学报, 2025, 76(9): 4474-4486. |

| [5] | 张彬怡, 孙少东, 姚谦, 蔡文河, 张惠宇, 李成新. 煤制甲醇耦合固体氧化物燃料电池混合系统研究[J]. 化工学报, 2025, 76(9): 4658-4669. |

| [6] | 周轶磊, 李智, 彭鑫. 基于代理模型的连续重整反应过程自优化控制结构设计[J]. 化工学报, 2025, 76(9): 4499-4511. |

| [7] | 李科, 谢昊琳, 文键. 耦合多重蒸气冷却屏的液氢储罐绝热性能的多目标遗传算法优化[J]. 化工学报, 2025, 76(8): 4217-4227. |

| [8] | 陆学瑞, 周帼彦, 方琦, 俞孟正, 张秀成, 涂善东. 固体氧化物燃料电池外重整器积炭效应数值模拟研究[J]. 化工学报, 2025, 76(7): 3295-3304. |

| [9] | 王珺仪, 夏章讯, 景粉宁, 王素力. 基于重整气的高温聚合物电解质膜燃料电池电化学阻抗谱弛豫时间分布研究[J]. 化工学报, 2025, 76(7): 3509-3520. |

| [10] | 王子恒, 李文怀, 周嵬. 图形电极在固体氧化物燃料电池中的应用[J]. 化工学报, 2025, 76(7): 3153-3171. |

| [11] | 李琳, 王明媚, 宋二伟, 王雯雯, 张耀昌, 王二强. 异戊二烯-正戊烷分离工艺的热力学分析及优化[J]. 化工学报, 2025, 76(6): 2549-2558. |

| [12] | 娄嘉诚, 常福城, 刘也铭, 李志斌, 李熙, 李会雄. 1000 MW超超临界直流锅炉水冷壁瞬态响应特性的建模与仿真研究[J]. 化工学报, 2025, 76(6): 2638-2651. |

| [13] | 翟祥瑞, 张伟, 张倩倩, 曲玖哲, 杨绪飞, 邓雅军, 宇波. 基于外场扰动的固液相变储能主动强化换热技术[J]. 化工学报, 2025, 76(4): 1432-1446. |

| [14] | 梁铣, 张晓燕, 魏亦军, 郑云芳, 高全涵, 徐迈, 王凤武. 碱性膜燃料电池中聚电解质的耐久性研究进展[J]. 化工学报, 2025, 76(4): 1447-1462. |

| [15] | 刘彦贝, 王若名, 刘娟, Raza Taimoor, 陆玉正, Raza Rizwan, 朱斌, 李松波, 安胜利, 云斯宁. CeO2@La0.6Sr0.4Co0.2Fe0.8O3-δ 电解质的制备及半导体离子燃料电池性能研究[J]. 化工学报, 2025, 76(3): 1353-1362. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号