化工学报 ›› 2025, Vol. 76 ›› Issue (10): 5495-5509.DOI: 10.11949/0438-1157.20250160

贾海林1,2,3( ), 符峥1,2,3, 温小萍1,2, 潘仕利1,2,3, 郑立刚1,2,3

), 符峥1,2,3, 温小萍1,2, 潘仕利1,2,3, 郑立刚1,2,3

收稿日期:2025-02-21

修回日期:2025-04-14

出版日期:2025-10-25

发布日期:2025-11-25

通讯作者:

贾海林

作者简介:贾海林(1980—),男,博士研究生,副教授,jiahailin@hpu.edu.cn

基金资助:

Hailin JIA1,2,3( ), Zheng FU1,2,3, Xiaoping WEN1,2, Shili PAN1,2,3, Ligang ZHENG1,2,3

), Zheng FU1,2,3, Xiaoping WEN1,2, Shili PAN1,2,3, Ligang ZHENG1,2,3

Received:2025-02-21

Revised:2025-04-14

Online:2025-10-25

Published:2025-11-25

Contact:

Hailin JIA

摘要:

为提高超细水雾对锂电池热解气体(LBPG)爆炸的抑制效果,降低常规细水雾抑爆剂潜在的腐蚀与环境风险,选用生物基表面活性剂CAB35和抗氧化剂OPC作为超细水雾添加剂,利用LBPG爆炸传播及抑爆实验系统,开展了无细水雾、纯水超细水雾、CAB35和OPC一元体系及CAB35@OPC二元体系超细水雾抑制LBPG爆炸实验研究。通过分析不同雾通量、不同浓度一元及二元体系超细水雾对LBPG爆炸超压及其峰值、爆炸火焰形状、爆炸火焰速度等参量的抑制特性,发现不同工况下的爆炸火焰均出现了Searby特征火焰。CAB35和OPC的一元体系超细水雾对LBPG爆炸均有一定抑制作用且优于纯水超细水雾,随着雾通量的增加,一元体系水雾抑制效果的增强趋势渐缓,CAB35与OPC的最佳抑爆浓度分别为0.5%(质量)和1.0%(质量)。相比之下,0.5%CAB35+1.0%OPC的二元体系超细水雾抑爆效果优于一元体系,随着二元水雾体系雾通量的增加,其抑制效果显著,火焰变形更为明显,浮力型火焰出现得更早。当雾通量为12.6 ml时,二元体系超细水雾作用下的爆炸超压峰值为14.3 kPa,相较于无水雾下降了66.3%,超压峰值时间延后了11.8 ms,火焰平均速度以及速度峰值分别为10.2 m/s和20.7 m/s,相较于纯细水雾分别下降了71.8%和68.4%。基于防火防爆理论,阐明了CAB35@OPC二元体系的协同抑爆机理。研究成果可为开发绿色高效的LBPG爆炸抑爆策略提供技术支持。

中图分类号:

贾海林, 符峥, 温小萍, 潘仕利, 郑立刚. CAB35@OPC二元体系超细水雾抑制锂电池热解气体爆炸实验研究[J]. 化工学报, 2025, 76(10): 5495-5509.

Hailin JIA, Zheng FU, Xiaoping WEN, Shili PAN, Ligang ZHENG. Experimental study on suppression of pyrolysis gas explosion of lithium battery by ultrafine water mist with the binary system of CAB35@OPC[J]. CIESC Journal, 2025, 76(10): 5495-5509.

| 添加剂种类 | 名称 | 分子式 | 生产厂商 |

|---|---|---|---|

| 两性表面活性剂 | 椰油酰胺丙基甜菜碱(CAB35) | C19H38N2O3 | 飞阳生物科技有限公司 |

| 抗氧化剂 | 原花青素(OPC) | C30H26O13 | 百川生物科技有限公司 |

表1 生物基超细水雾添加剂信息

Table 1 Information of bio-based additives for ultrafine water mist

| 添加剂种类 | 名称 | 分子式 | 生产厂商 |

|---|---|---|---|

| 两性表面活性剂 | 椰油酰胺丙基甜菜碱(CAB35) | C19H38N2O3 | 飞阳生物科技有限公司 |

| 抗氧化剂 | 原花青素(OPC) | C30H26O13 | 百川生物科技有限公司 |

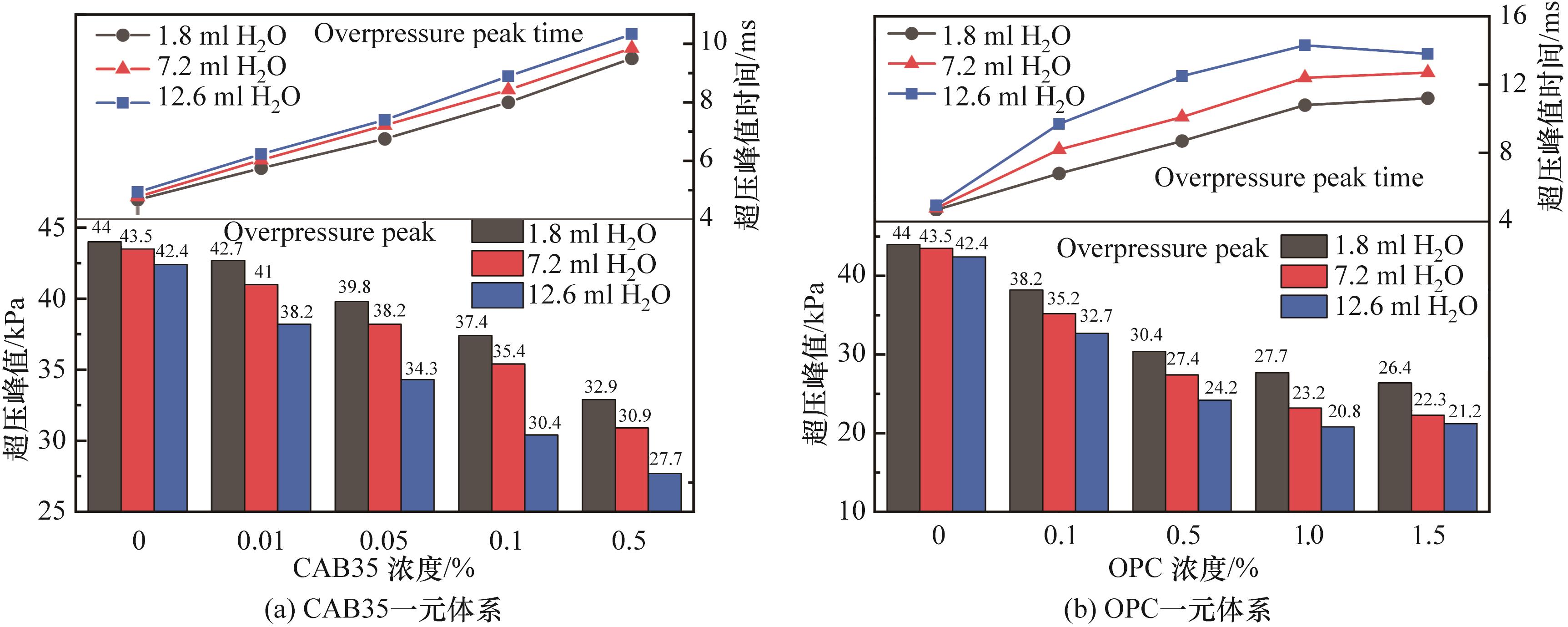

图5 纯水和一元体系超细水雾不同雾通量不同浓度下LBPG爆炸超压峰值及对应时间

Fig.5 Explosion overpressure peak and corresponding time of LBPG under the pure water and monodic system ultra-fine water mist with different fog fluxes and concentrations

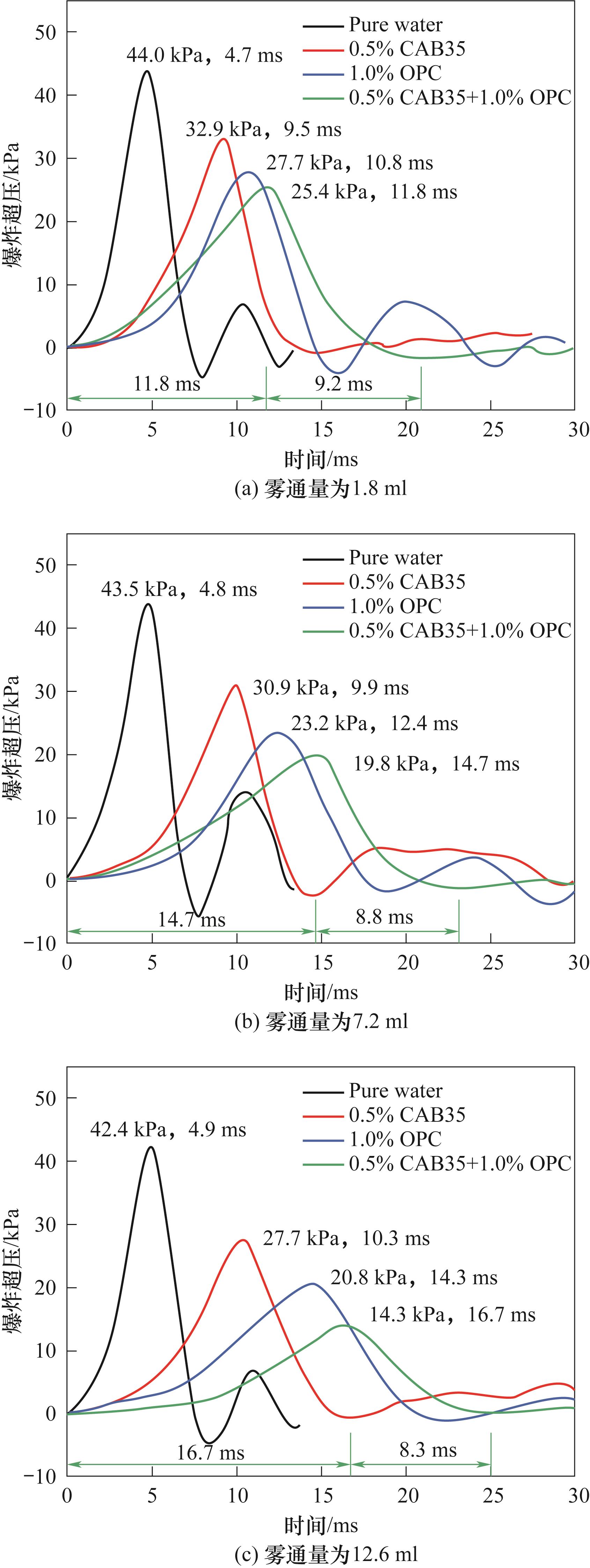

图6 纯水、一元体系和二元体系超细水雾不同雾通量下LBPG爆炸超压曲线

Fig.6 Explosion overpressure curves of LBPG under the pure water, monodic system and binary system ultra-fine water mist with different fog fluxes

| 水雾体系 | 超压峰值 | 峰值时间特性 | ||||

|---|---|---|---|---|---|---|

| 超压峰值/kPa | 下降值/kPa | 下降比例/% | 峰值时间/ms | 延长时间/ms | 延长比例/% | |

| pure water | 44.0 | 4.0 | 8.3 | 4.7 | 0.1 | 2.2 |

| 0.5%CAB35 | 32.9 | 15.1 | 31.5 | 9.5 | 4.9 | 106.5 |

| 1.0%OPC | 27.7 | 20.3 | 42.3 | 10.8 | 6.2 | 134.8 |

| 0.5%CAB35+1.0%OPC | 25.4 | 22.6 | 47.1 | 11.8 | 7.2 | 156.9 |

表2 雾通量为1.8 ml时纯水、一元体系和二元体系超细水雾对LBPG爆炸超压峰值的影响

Table 2 Effects of the explosion overpressure peak value of LBPG under the pure water, monodic system and binary system ultra-fine water mist with the fog flux of 1.8 ml

| 水雾体系 | 超压峰值 | 峰值时间特性 | ||||

|---|---|---|---|---|---|---|

| 超压峰值/kPa | 下降值/kPa | 下降比例/% | 峰值时间/ms | 延长时间/ms | 延长比例/% | |

| pure water | 44.0 | 4.0 | 8.3 | 4.7 | 0.1 | 2.2 |

| 0.5%CAB35 | 32.9 | 15.1 | 31.5 | 9.5 | 4.9 | 106.5 |

| 1.0%OPC | 27.7 | 20.3 | 42.3 | 10.8 | 6.2 | 134.8 |

| 0.5%CAB35+1.0%OPC | 25.4 | 22.6 | 47.1 | 11.8 | 7.2 | 156.9 |

| 水雾体系 | 超压峰值 | 峰值时间特性 | ||||

|---|---|---|---|---|---|---|

| 超压峰值/kPa | 下降值/kPa | 下降比例/% | 峰值时间/ms | 延长时间/ms | 延长比例/% | |

| pure water | 43.5 | 4.5 | 9.3 | 4.8 | 0.2 | 4.3 |

| 0.5%CAB35 | 30.9 | 17.1 | 35.6 | 9.9 | 5.3 | 115.2 |

| 1.0%OPC | 23.2 | 24.8 | 51.7 | 12.4 | 7.8 | 169.6 |

| 0.5%CAB35+1.0%OPC | 19.8 | 28.2 | 58.8 | 14.7 | 10.1 | 219.8 |

表3 雾通量为7.2 ml时纯水、一元体系和二元体系超细水雾对LBPG爆炸超压峰值的影响

Table 3 Effects of the explosion overpressure peak value of LBPG under the pure water, monodic system and binary system ultra-fine water mist with the fog flux of 7.2 ml

| 水雾体系 | 超压峰值 | 峰值时间特性 | ||||

|---|---|---|---|---|---|---|

| 超压峰值/kPa | 下降值/kPa | 下降比例/% | 峰值时间/ms | 延长时间/ms | 延长比例/% | |

| pure water | 43.5 | 4.5 | 9.3 | 4.8 | 0.2 | 4.3 |

| 0.5%CAB35 | 30.9 | 17.1 | 35.6 | 9.9 | 5.3 | 115.2 |

| 1.0%OPC | 23.2 | 24.8 | 51.7 | 12.4 | 7.8 | 169.6 |

| 0.5%CAB35+1.0%OPC | 19.8 | 28.2 | 58.8 | 14.7 | 10.1 | 219.8 |

| 水雾体系 | 超压峰值 | 峰值时间特性 | ||||

|---|---|---|---|---|---|---|

| 超压峰值/kPa | 下降值/kPa | 下降比例/% | 峰值时间/ms | 延长时间/ms | 延长比例/% | |

| pure water | 42.4 | 5.6 | 11.7 | 4.9 | 0.3 | 6.5 |

| 0.5%CAB35 | 27.7 | 20.3 | 42.3 | 10.3 | 5.7 | 123.9 |

| 1.0%OPC | 20.8 | 27.2 | 56.7 | 14.3 | 9.7 | 210.9 |

| 0.5%CAB35+1.0%OPC | 14.3 | 33.7 | 70.2 | 16.7 | 12.1 | 263.7 |

表4 雾通量为12.6 ml时纯水、一元体系和二元体系超细水雾对LBPG爆炸超压峰值的影响

Table 4 Effects of the explosion overpressure peak value of LBPG under the pure water, monodic system and binary system ultra-fine water mist with the fog flux of 12.6 ml

| 水雾体系 | 超压峰值 | 峰值时间特性 | ||||

|---|---|---|---|---|---|---|

| 超压峰值/kPa | 下降值/kPa | 下降比例/% | 峰值时间/ms | 延长时间/ms | 延长比例/% | |

| pure water | 42.4 | 5.6 | 11.7 | 4.9 | 0.3 | 6.5 |

| 0.5%CAB35 | 27.7 | 20.3 | 42.3 | 10.3 | 5.7 | 123.9 |

| 1.0%OPC | 20.8 | 27.2 | 56.7 | 14.3 | 9.7 | 210.9 |

| 0.5%CAB35+1.0%OPC | 14.3 | 33.7 | 70.2 | 16.7 | 12.1 | 263.7 |

| CAB35/% | 1.8 ml水雾 | 7.2 ml水雾 | 12.6 ml水雾 | |||

|---|---|---|---|---|---|---|

平面火焰出现 时间/ms | 火焰到达管口 时间/ms | 平面火焰出现 时间/ms | 火焰到达管口 时间/ms | 平面火焰出现 时间/ms | 火焰到达管口 时间/ms | |

| 0 | 7.0 | 13.7 | 7.3 | 14.4 | 8.2 | 13.8 |

| 0.01 | 8.2 | 16.8 | 9.4 | 19.2 | 11.2 | 22.1 |

| 0.05 | 9.8 | 19.8 | 12.8 | 24.4 | 14.7 | 27.7 |

| 0.1 | 11.8 | 24.0 | 13.5 | 26.7 | 15.1 | 29.3 |

| 0.5 | 14.5 | 27.3 | 15.3 | 29.9 | 16.4 | 32.1 |

表5 CAB35一元体系超细水雾不同雾通量下平面火焰出现时间和火焰到达管道末端时间

Table 5 The time of plane flame appearing and the time of flame reaching the end of the pipeline under the monodic system ultra-fine water mist with CAB35 at the different fog fluxes

| CAB35/% | 1.8 ml水雾 | 7.2 ml水雾 | 12.6 ml水雾 | |||

|---|---|---|---|---|---|---|

平面火焰出现 时间/ms | 火焰到达管口 时间/ms | 平面火焰出现 时间/ms | 火焰到达管口 时间/ms | 平面火焰出现 时间/ms | 火焰到达管口 时间/ms | |

| 0 | 7.0 | 13.7 | 7.3 | 14.4 | 8.2 | 13.8 |

| 0.01 | 8.2 | 16.8 | 9.4 | 19.2 | 11.2 | 22.1 |

| 0.05 | 9.8 | 19.8 | 12.8 | 24.4 | 14.7 | 27.7 |

| 0.1 | 11.8 | 24.0 | 13.5 | 26.7 | 15.1 | 29.3 |

| 0.5 | 14.5 | 27.3 | 15.3 | 29.9 | 16.4 | 32.1 |

| OPC/% | 1.8 ml水雾 | 7.2 ml水雾 | 12.6 ml水雾 | |||

|---|---|---|---|---|---|---|

平面火焰出现 时间/ms | 火焰到达管口 时间/ms | 平面火焰出现 时间/ms | 火焰到达管口 时间/ms | 平面火焰出现 时间/ms | 火焰到达管口 时间/ms | |

| 0.1 | 9.3 | 18.2 | 11.8 | 20.2 | 13.4 | 26.3 |

| 0.5 | 12.0 | 22.0 | 14.5 | 25.8 | 16.6 | 30.1 |

| 1.0 | 15.4 | 29.3 | 18.2 | 34.1 | 21.3 | 39.7 |

| 1.5 | 12.6 | 25.1 | 12.4 | 23.9 | 13.1 | 24.1 |

表6 OPC一元体系超细水雾不同雾通量下平面火焰出现时间和火焰到达管道末端时间

Table 6 The time of plane flame appearing and the time of flame reaching the end of the pipeline under the monodic system ultra-fine water mist with OPC at the different fog fluxes

| OPC/% | 1.8 ml水雾 | 7.2 ml水雾 | 12.6 ml水雾 | |||

|---|---|---|---|---|---|---|

平面火焰出现 时间/ms | 火焰到达管口 时间/ms | 平面火焰出现 时间/ms | 火焰到达管口 时间/ms | 平面火焰出现 时间/ms | 火焰到达管口 时间/ms | |

| 0.1 | 9.3 | 18.2 | 11.8 | 20.2 | 13.4 | 26.3 |

| 0.5 | 12.0 | 22.0 | 14.5 | 25.8 | 16.6 | 30.1 |

| 1.0 | 15.4 | 29.3 | 18.2 | 34.1 | 21.3 | 39.7 |

| 1.5 | 12.6 | 25.1 | 12.4 | 23.9 | 13.1 | 24.1 |

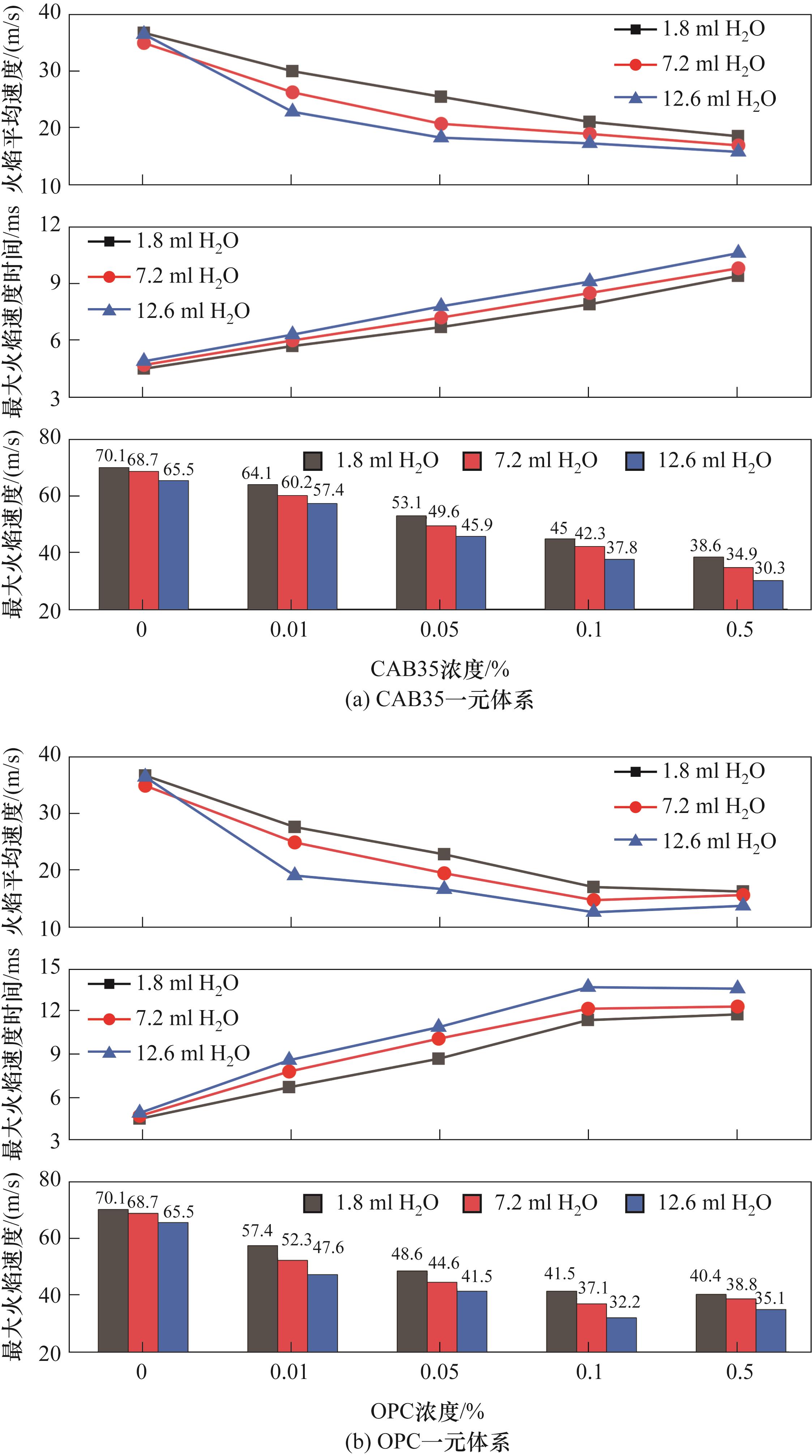

图10 一元体系超细水雾雾通量对LBPG爆炸火焰速度传播特性的影响

Fig.10 Effect of fog fluxes of the monodic system ultra-fine water mist on the velocity propagation characteristics of LBPG explosion flame

图11 纯水、一元体系和二元体系超细水雾不同雾通量下LBPG爆炸火焰传播速度曲线

Fig.11 LBPG explosion flame velocity curve under the pure water, monodic system and binary system ultra-fine water mist with different fog fluxes

| 水雾体系 | 1.8 ml水雾 | 7.2 ml水雾 | 12.6 ml水雾 | |||

|---|---|---|---|---|---|---|

| 火焰速度峰值/(m/s) | 平均速度/(m/s) | 火焰速度峰值/(m/s) | 平均速度/(m/s) | 火焰速度峰值/(m/s) | 平均速度/(m/s) | |

| pure water | 70.1 | 36.5 | 68.7 | 34.7 | 65.5 | 36.2 |

| 0.5%CAB35 | 38.6 | 18.3 | 34.9 | 16.7 | 30.3 | 15.6 |

| 1.0%OPC | 41.5 | 17 | 37.1 | 14.7 | 32.2 | 12.6 |

| 0.5%CAB35+1.0%OPC | 36.1 | 16.2 | 27.6 | 12.6 | 20.7 | 10.2 |

表7 纯水、一元体系和二元体系超细水雾不同雾通量下LBPG爆炸火焰最大速度与平均速度

Table 7 Maximum and average velocity of LBPG explosion flame under the pure water, monodic system and binary system ultra-fine water mist with different fog fluxes

| 水雾体系 | 1.8 ml水雾 | 7.2 ml水雾 | 12.6 ml水雾 | |||

|---|---|---|---|---|---|---|

| 火焰速度峰值/(m/s) | 平均速度/(m/s) | 火焰速度峰值/(m/s) | 平均速度/(m/s) | 火焰速度峰值/(m/s) | 平均速度/(m/s) | |

| pure water | 70.1 | 36.5 | 68.7 | 34.7 | 65.5 | 36.2 |

| 0.5%CAB35 | 38.6 | 18.3 | 34.9 | 16.7 | 30.3 | 15.6 |

| 1.0%OPC | 41.5 | 17 | 37.1 | 14.7 | 32.2 | 12.6 |

| 0.5%CAB35+1.0%OPC | 36.1 | 16.2 | 27.6 | 12.6 | 20.7 | 10.2 |

| [1] | 张强, 王超, 李欣蔚, 等. 考虑典型电能替代的配电网新能源接纳能力研究[J]. 可再生能源, 2023, 41(10): 1414-1420. |

| Zhang Q, Wang C, Li X W, et al. Study on new energy acceptance capacity of distribution network considering wind power and photovoltaic complementation and typical power substitution[J]. Renewable Energy Resources, 2023, 41(10): 1414-1420. | |

| [2] | Wang Y, Yu T M, Chen J, et al. Advances in safety of lithium-ion batteries for energy storage: hazard characteristics and active suppression techniques[J]. Energy Reviews, 2025, 4(1): 100117. |

| [3] | Neigum K, Wang Z L. Technology, economic, and environmental analysis of second-life batteries as stationary energy storage: a review[J]. Journal of Energy Storage, 2024, 103: 114393. |

| [4] | Zhao L Y, Li W, Luo W Y, et al. Numerical study of critical conditions for thermal runaway of lithium-ion battery pack during storage[J]. Journal of Energy Storage, 2024, 84: 110901. |

| [5] | 陶致格, 朱顺兵, 侯双平, 等. 锂电池储能电站火灾与消防安全防护技术综合研究[J]. 储能科学与技术, 2024, 13(2): 536-545. |

| Tao Z G, Zhu S B, Hou S P, et al. Comprehensive research on fire and safety protection technology for lithium battery energy storage power stations[J]. Energy Storage Science and Technology, 2024, 13(2): 536-545. | |

| [6] | 李正力, 李肖辉, 王京, 等. 锂离子电池储能电站热失控预警与防护研究进展[J]. 高压电器, 2024, 60(1): 87-99. |

| Li Z L, Li X H, Wang J, et al. Research progress on thermal runaway warning and protection of lithium-ion battery in energy storage power station[J]. High Voltage Apparatus, 2024, 60(1): 87-99. | |

| [7] | Mao B B, Yu S H, Zhang X K, et al. Characterization of the deflagration behavior of the lithium-ion battery module within a confined space under different ventilation conditions[J]. Process Safety and Environmental Protection, 2024, 184: 1034-1040. |

| [8] | 秦鹏. 磷酸铁锂电池热失控产热产气规律及火焰主控机制研究[D]. 合肥: 中国科学技术大学, 2022. |

| Qin P. Study on the law of heat and gas production and flame control mechanism of lithium iron phosphate battery due to thermal runaway[D]. Hefei: University of Science and Technology of China, 2022. | |

| [9] | Tang X J, Hu J, Liu T, et al. Experimental investigation on the cooling effect of fully submerged fine water mist on lithium-ion batteries in confined space[J]. Applied Thermal Engineering, 2024, 239: 122166. |

| [10] | Xu J J, Duan Q L, Zhang L, et al. Experimental study of the cooling effect of water mist on 18650 lithium-ion battery at different initial temperatures[J]. Process Safety and Environmental Protection, 2022, 157: 156-166. |

| [11] | Zhang Y, Peng W, Liu X Y, et al. Experimental study on suppression of thermal runaway in lithium-ion battery by mixed particle size water mist[J]. Process Safety and Environmental Protection, 2023, 179: 189-198. |

| [12] | 吴静云, 黄峥, 郭鹏宇. 储能用磷酸铁锂(LFP)电池消防技术研究进展[J]. 储能科学与技术, 2019, 8(3): 495-499. |

| Wu J Y, Huang Z, Guo P Y. Research progress on fire protection technology of LFP lithium-ion battery used in energy storage power station[J]. Energy Storage Science and Technology, 2019, 8(3): 495-499. | |

| [13] | Moinuddin K, Mahmud H I, Joseph P, et al. An experimental study on the suppression of shielded fires by water mist sprays in a compartment[J]. Fire Safety Journal, 2025, 152: 104339. |

| [14] | Peng W, Zhang Y, Zhang S J, et al. Experimental study on the inhibition effect of water mist containing additives on the thermal runaway of lithium battery[J]. Process Safety and Environmental Protection, 2024, 182: 999-1007. |

| [15] | Liang T S, Bai X L, Zhang D F, et al. A comparative study of ultrafine water mist extinguishing hydrocarbon pool fires with or without potassium salts[J]. Thermal Science and Engineering Progress, 2023, 39: 101655. |

| [16] | 秦文茜, 王喜世, 谷睿, 等. 超细水雾作用下瓦斯的爆炸压力及升压速率[J]. 燃烧科学与技术, 2012, 18(1): 90-95. |

| Qin W X, Wang X S, Gu R, et al. Methane explosion overpressure and overpressure rise rate with suppression by ultra-fine water mist[J]. Journal of Combustion Science and Technology, 2012, 18(1): 90-95. | |

| [17] | Song Y F, Zhang Q. Quantitative research on gas explosion inhibition by water mist[J]. Journal of Hazardous Materials, 2019, 363: 16-25. |

| [18] | 余明高, 赵万里, 安安. 超细水雾作用下瓦斯火焰抑制特性研究[J]. 采矿与安全工程学报, 2011, 28(3): 493-498. |

| Yu M G, Zhao W L, An A. Study on the inhibiting effectiveness on gas flame under the effort of ultra-fine water mist[J]. Journal of Mining & Safety Engineering, 2011, 28(3): 493-498. | |

| [19] | 余明高, 董艳军, 潘荣锟, 等. 超细水雾抑制瓦斯燃烧火焰的实验研究[J]. 河南理工大学学报(自然科学版), 2011, 30(3): 249-256. |

| Yu M G, Dong Y J, Pan R K, et al. Experimental study on restraining flame of gas burning by ultra-fine water mist[J]. Journal of Henan Polytechnic University (Natural Science), 2011, 30(3): 249-256. | |

| [20] | 余明高, 杨克, 贾海林, 等. 超细水雾抑制受限空间煤燃烧的试验研究[J]. 安全与环境学报, 2009, 9(6): 132-136. |

| Yu M G, Yang K, Jia H L, et al. Role of ultra-fine mist spray technology in restraining coal-mine combustion in a limited space[J]. Journal of Safety and Environment, 2009, 9(6): 132-136. | |

| [21] | Liu Z Q, Zhong X X, Lu Y S, et al. Suppression characteristics of water mist containing alkali metal compounds in natural gas explosions[J]. Case Studies in Thermal Engineering, 2024, 62: 105196. |

| [22] | Jiang H P, Bi M S, Huang L, et al. Suppression mechanism of ultrafine water mist containing phosphorus compounds in methane/coal dust explosions[J]. Energy, 2022, 239: 121987. |

| [23] | Liu Z Q, Zhong X X, Zhang Q, et al. Experimental study on using water mist containing potassium compounds to suppress methane/air explosions[J]. Journal of Hazardous Materials, 2020, 394: 122561. |

| [24] | 裴蓓, 康亚祥, 余明高, 等. 点火延迟时间对CO2-超细水雾的抑爆特性影响[J]. 化工学报, 2022, 73(12): 5672-5684. |

| Pei B, Kang Y X, Yu M G, et al. Effect of ignition delay time on explosion suppression characteristics of CO2-ultra-fine water mist[J]. CIESC Journal, 2022, 73(12): 5672-5684. | |

| [25] | Pei B, Lyu H, Wu Z Q, et al. Study on the synergistic effect of inert gas and ultrafine water mist on hydrogen explosion suppression[J]. International Journal of Hydrogen Energy, 2024, 82: 531-543. |

| [26] | 贾海林, 翟汝鹏, 李第辉, 等. 三种盐类超细水雾抑制管道内甲烷-空气预混气爆炸的差异性[J]. 爆炸与冲击, 2020, 40(8): 42-53. |

| Jia H L, Zhai R P, Li D H, et al. Differences of premixed methane-air explosion in pipelines suppressed by three ultrafine water mists containing different salts[J]. Explosion and Shock Waves, 2020, 40(8): 42-53. | |

| [27] | 贾海林, 项海军, 李第辉, 等. 含NaCl超细水雾对不同阻塞率管道内爆炸的抑制[J]. 爆炸与冲击, 2020, 40(4): 34-43. |

| Jia H L, Xiang H J, Li D H, et al. Suppression of explosion in pipelines with different blocking ratios by ultrafine water mist containing sodium chloride[J]. Explosion and Shock Waves, 2020, 40(4): 34-43. | |

| [28] | 杨克, 纪虹, 邢志祥, 等. 含草酸钾的超细水雾抑制甲烷爆炸的特性[J]. 化工学报, 2018, 69(12): 5359-5369. |

| Yang K, Ji H, Xing Z X, et al. Characteristics on methane explosion suppression by ultrafine water mist containing potassium oxalate [J]. CIESC Journal, 2018, 69(12): 5359-5369. | |

| [29] | Cao X Y, Zhou Y Q, Wang Z R, et al. Experimental research on hydrogen/air explosion inhibition by the ultrafine water mist[J]. International Journal of Hydrogen Energy, 2022, 47(56): 23898-23908. |

| [30] | Cao X Y, Bi M S, Ren J J, et al. Experimental research on explosion suppression affected by ultrafine water mist containing different additives[J]. Journal of Hazardous Materials, 2019, 368: 613-620. |

| [31] | Pu M Z, Ren J J, Wang Y F, et al. Dedusting and inhibition of methane-coal dust hybrid explosion by ultrafine water mist containing SDS surfactant[J]. Powder Technology, 2024, 441: 119844. |

| [32] | Nguyen T A, Nguyen T B, Tran D Q, et al. Bio-functional nanocellulose/lignocellulose-based polyurethane nanocomposite foams with enhanced flame retardancy, thermal conductivity, and thermal stability[J]. International Journal of Biological Macromolecules, 2025, 305(Pt 1): 141133. |

| [33] | Zhang X, Guan Q H, Xiao Q K, et al. Enhanced thermal and mechanical properties of flame-retardant expandable graphite modified silk fibroin-based rigid polyurethane foam[J]. Case Studies in Thermal Engineering, 2024, 64: 105418. |

| [34] | Akdogan E, Erdem M. A comprehensive research of low-density bio-based rigid polyurethane foams from sugar beet pulp-based biopolyol: from closed-cell towards open-cell structure[J]. Industrial Crops and Products, 2023, 200: 116809. |

| [35] | Zhou G, Li Y Y, Liu Y, et al. Preparation of environment-friendly gel-protein foam and its fire suppression performance for lithium-ion batteries[J]. Fuel, 2025, 384: 133979. |

| [36] | Yang K, Zhang P, Yue C X, et al. Experimental research on methane/air explosion inhibition using ultrafine water mist containing methane oxidizing bacteria[J]. Journal of Loss Prevention in the Process Industries, 2020, 67: 104256. |

| [37] | 杨克, 杜晓阳, 邢志祥, 等. 含茶多酚细水雾抑制甲烷爆炸有效性试验研究[J]. 消防科学与技术, 2023, 42(12): 1688-1693. |

| Yang K, Du X Y, Xing Z X, et al. Experimental study on the effectiveness of water mist containing tea polyphenols in inhibiting methane explosion[J]. Fire Science and Technology, 2023, 42(12): 1688-1693. | |

| [38] | 叶锦昊, 侯军辉, 张正国, 等. 100Ah磷酸铁锂软包电池的热失控特性及产气行为[J]. 储能科学与技术, 2025, 14(2): 636-647. |

| Ye J H, Hou J H, Zhang Z G, et al. Thermal runaway characteristics and gas generation behavior of 100 Ah lithium iron phosphate pouch cell[J]. Energy Storage Science and Technology, 2025, 14(2): 636-647. | |

| [39] | Liu L, Dong Q, Kong Y M, et al. The effect of B-type procyanidin on free radical and metal ion induced β-lactoglobulin glyco-oxidation via mass spectrometry and interaction analysis[J]. Food Research International, 2023, 168: 112744. |

| [40] | Wan H W, Wang C, Zhang Q. Thermal energy propagation characteristics and hazard effects of hydrogen cloud explosion[J]. Applied Thermal Engineering, 2024, 257: 124396. |

| [41] | Cao X Y, Zhou J Y, Lu Y W, et al. Research on the synergy effect of water mist containing additives and flame-retardant system on the syngas explosion inhibition[J]. Applied Thermal Engineering, 2024, 255: 124004. |

| [42] | 裴蓓, 郝治斌, 徐天祥, 等. 表面活性剂对含盐双流体细水雾灭火效能的影响[J]. 化工学报, 2024, 75(9): 3369-3378. |

| Pei B, Hao Z B, Xu T X, et al. Effect of surfactants on fire extinguishing efficiency of salted double fluid fine water mist[J]. CIESC Journal, 2024, 75(9): 3369-3378. | |

| [43] | Clanet C, Searby G. On the “tulip flame” phenomenon[J]. Combustion and Flame, 1996, 105(1/2): 225-238. |

| [44] | Zheng K, Jia Q H, Song Z Y, et al. Numerical investigation of premixed syngas/air flame evolution in a closed duct with tulip flame formation[J]. Renewable Energy, 2024, 236: 121431. |

| [45] | Mendoza-Wilson A M, Castro-Arredondo S I, Balandrán-Quintana R R. Computational study of the structure-free radical scavenging relationship of procyanidins[J]. Food Chemistry, 2014, 161: 155-161. |

| [46] | 裴蓓, 胡紫维, 韩谕良, 等. 含改性氯化合物对N2/细水雾抑制LPG爆炸影响研究[J]. 爆炸与冲击, 2024, 44(11): 171-182. |

| Pei B, Hu Z W, Han Y L, et al. Study on influence of modified chlorine-containing compounds on N2/water mist to suppress LPG explosion[J]. Explosion and Shock Waves, 2024, 44(11): 171-182. |

| [1] | 王燕, 何佳, 杨晶晶, 林晨迪, 纪文涛. 草酸盐和碳酸氢盐抑制聚乙烯粉尘爆炸特性[J]. 化工学报, 2022, 73(9): 4207-4216. |

| [2] | 裴蓓, 康亚祥, 余明高, 郭佳琪, 韦双明, 陈立伟. 点火延迟时间对CO2-超细水雾的抑爆特性影响[J]. 化工学报, 2022, 73(12): 5672-5684. |

| [3] | 纪文涛, 李璐, 李忠, 何佳, 杨晶晶, 王燕. 聚磷酸铵抑制PMMA粉尘爆炸特性研究[J]. 化工学报, 2022, 73(1): 461-469. |

| [4] | 梁天水, 王宗莹, 高坤, 李润婉, 王铮, 钟委, 赵军. 基于cup burner的含铁基添加剂超细水雾灭火有效性分析[J]. 化工学报, 2019, 70(3): 1236-1242. |

| [5] | 杨克, 纪虹, 邢志祥, 黄维秋, 王宇, 张平. 含草酸钾的超细水雾抑制甲烷爆炸的特性[J]. 化工学报, 2018, 69(12): 5359-5369. |

| [6] | 纪虹, 杨克, 黄维秋, 王宇, 左嘉琦. 超细水雾协同甲烷氧化菌降解与抑制甲烷爆炸的实验研究[J]. 化工学报, 2017, 68(11): 4461-4468. |

| [7] | 武克忠, 李建玲, 张建军. 多元醇PE-AMP二元体系相图 [J]. 化工学报, 2008, 59(4): 814-819. |

| [8] | 尉小明; 雷群芳; 刘刚强; 林瑞森. 醇+1,2-二氯乙烷、醇+环己酮二元体系热导率的测定和推算 [J]. CIESC Journal, 2001, 52(12): 1078-1082. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号