化工学报 ›› 2025, Vol. 76 ›› Issue (7): 3585-3595.DOI: 10.11949/0438-1157.20241224

杨鹏1( ), 尤万里2, 凌忠钱1(

), 尤万里2, 凌忠钱1( ), 曾宪阳1, 李允超1, 林佳一1, 王丽建3,4, 袁定琨1

), 曾宪阳1, 李允超1, 林佳一1, 王丽建3,4, 袁定琨1

收稿日期:2024-10-31

修回日期:2025-03-13

出版日期:2025-07-25

发布日期:2025-08-13

通讯作者:

凌忠钱

作者简介:杨鹏(1998—),男,硕士研究生,s22020804072@cjlu.edu.cn

基金资助:

Peng YANG1( ), Wanli YOU2, Zhongqian LING1(

), Wanli YOU2, Zhongqian LING1( ), Xianyang ZENG1, Yunchao LI1, Jiayi LIN1, Lijian WANG3,4, Dingkun YUAN1

), Xianyang ZENG1, Yunchao LI1, Jiayi LIN1, Lijian WANG3,4, Dingkun YUAN1

Received:2024-10-31

Revised:2025-03-13

Online:2025-07-25

Published:2025-08-13

Contact:

Zhongqian LING

摘要:

挥发性有机化合物(VOCs)的排放问题日益凸显,对生态环境及公众健康构成了严重威胁。针对治理VOCs排放问题自行设计并搭建了进气风量为200 m3/h、尺寸为2915 mm×1150 mm×2200 mm的紧凑式三室RTO实验装置,以制药行业中排放量占比较大的乙酸乙酯作为研究对象,探究在不同工况条件下紧凑式RTO装置处理乙酸乙酯废气的去除效率,热效率以及蓄热室、氧化室和出口的温度特性。实验结果表明,氧化室温度在750~850℃范围内,RTO系统对VOCs的去除效率大于97%。此外,进气风量降低可以提高乙酸乙酯的氧化分解效率,吹扫风量增加亦能提升乙酸乙酯的去除效果,阀门换向时间会影响蓄热室温度和氧化室内压力,进而影响系统的稳定性和热效率。本设计开发的紧凑式三室RTO装置在处理乙酸乙酯废气方面表现出高效性能,去除率在97%~99%之间,热效率超过96%。

中图分类号:

杨鹏, 尤万里, 凌忠钱, 曾宪阳, 李允超, 林佳一, 王丽建, 袁定琨. 紧凑式三室RTO系统处理乙酸乙酯废气性能的实验研究[J]. 化工学报, 2025, 76(7): 3585-3595.

Peng YANG, Wanli YOU, Zhongqian LING, Xianyang ZENG, Yunchao LI, Jiayi LIN, Lijian WANG, Dingkun YUAN. Experimental study on performance of compact three-chamber RTO system for treating waste gas containing ethyl acetate[J]. CIESC Journal, 2025, 76(7): 3585-3595.

| 氧化室温度/℃ | 乙酸乙酯浓度/(mg/m3) | 进气风量/(m3/h) | 阀门切换时间/s |

|---|---|---|---|

| 600 | 1000 | 200 | 120 |

| 650 | 1000 | 200 | 120 |

| 700 | 1000 | 200 | 120 |

| 750 | 1000 | 200 | 120 |

| 800 | 1000 | 200 | 120 |

| 850 | 1000 | 200 | 120 |

表1 氧化室温度实验工况

Table 1 Oxidation chamber temperature test operating conditions

| 氧化室温度/℃ | 乙酸乙酯浓度/(mg/m3) | 进气风量/(m3/h) | 阀门切换时间/s |

|---|---|---|---|

| 600 | 1000 | 200 | 120 |

| 650 | 1000 | 200 | 120 |

| 700 | 1000 | 200 | 120 |

| 750 | 1000 | 200 | 120 |

| 800 | 1000 | 200 | 120 |

| 850 | 1000 | 200 | 120 |

| 进气风量/(m3/h) | 乙酸乙酯浓度/(mg/m3) | 氧化室温度/℃ | 阀门切换时间/s |

|---|---|---|---|

| 100 | 1000 | 800 | 120 |

| 120 | 1000 | 800 | 120 |

| 140 | 1000 | 800 | 120 |

| 160 | 1000 | 800 | 120 |

| 180 | 1000 | 800 | 120 |

| 200 | 1000 | 800 | 120 |

表2 进气风量实验工况

Table 2 Inlet air flow test operating conditions

| 进气风量/(m3/h) | 乙酸乙酯浓度/(mg/m3) | 氧化室温度/℃ | 阀门切换时间/s |

|---|---|---|---|

| 100 | 1000 | 800 | 120 |

| 120 | 1000 | 800 | 120 |

| 140 | 1000 | 800 | 120 |

| 160 | 1000 | 800 | 120 |

| 180 | 1000 | 800 | 120 |

| 200 | 1000 | 800 | 120 |

| 吹扫风量/(m3/h) | 乙酸乙酯浓度/(mg/m3) | 氧化室温度/℃ | 进气风量/(m3/h) | 阀门切换时间/s |

|---|---|---|---|---|

| 0 | 1000 | 800 | 200 | 120 |

| 16.2 | 1000 | 800 | 200 | 120 |

| 32.4 | 1000 | 800 | 200 | 120 |

| 48.6 | 1000 | 800 | 200 | 120 |

| 64.8 | 1000 | 800 | 200 | 120 |

| 81.0 | 1000 | 800 | 200 | 120 |

表3 吹扫风量实验工况

Table 3 Purge flow rate test operating conditions

| 吹扫风量/(m3/h) | 乙酸乙酯浓度/(mg/m3) | 氧化室温度/℃ | 进气风量/(m3/h) | 阀门切换时间/s |

|---|---|---|---|---|

| 0 | 1000 | 800 | 200 | 120 |

| 16.2 | 1000 | 800 | 200 | 120 |

| 32.4 | 1000 | 800 | 200 | 120 |

| 48.6 | 1000 | 800 | 200 | 120 |

| 64.8 | 1000 | 800 | 200 | 120 |

| 81.0 | 1000 | 800 | 200 | 120 |

| 阀门切换时间/s | 乙酸乙酯浓度/(mg/m3) | 氧化室温度/℃ | 进气风量/(m3/h) |

|---|---|---|---|

| 60 | 500,1000,1500,2000,2500 | 850 | 200 |

| 120 | 500,1000,1500,2000,2500 | 850 | 200 |

| 180 | 500,1000,1500,2000,2500 | 850 | 200 |

| 240 | 500,1000,1500,2000,2500 | 850 | 200 |

表4 阀门切换时间实验工况

Table 4 Valve switching time test operating conditions

| 阀门切换时间/s | 乙酸乙酯浓度/(mg/m3) | 氧化室温度/℃ | 进气风量/(m3/h) |

|---|---|---|---|

| 60 | 500,1000,1500,2000,2500 | 850 | 200 |

| 120 | 500,1000,1500,2000,2500 | 850 | 200 |

| 180 | 500,1000,1500,2000,2500 | 850 | 200 |

| 240 | 500,1000,1500,2000,2500 | 850 | 200 |

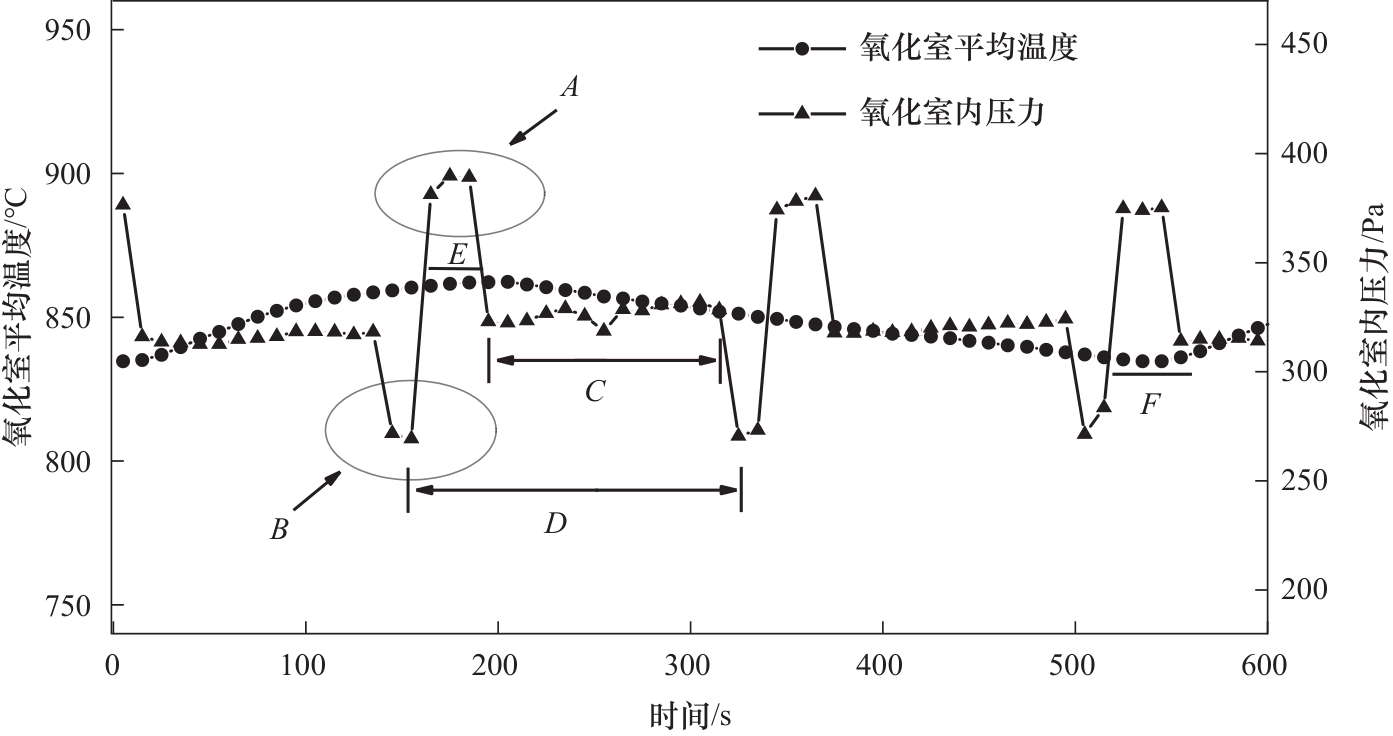

图15 阀门切换时间180 s条件下氧化室内的压力波动及氧化室平均温度

Fig.15 Pressure fluctuation and average temperature in oxidation chamber under 180 s valve switching time condition

| [1] | Li S W, Lin Y Z, Liu G, et al. Research status of volatile organic compound (VOC) removal technology and prospect of new strategies: a review[J]. Environmental Science: Processes & Impacts, 2023, 25(4): 727-740. |

| [2] | Huss‐Marp J, Eberlein‐König B, Breuer K, et al. Influence of short‐term exposure to airborne Der p 1 and volatile organic compounds on skin barrier function and dermal blood flow in patients with atopic eczema and healthy individuals[J]. Clinical and Experimental Allergy, 2006, 36(3): 338-345. |

| [3] | Khan A, Kanwal H, Bibi S, et al. Volatile organic compounds and neurological disorders: from exposure to preventive interventions[M]//Environmental Contaminants and Neurological Disorders. Cham, Switzerland: Springer, 2021: 201-230. |

| [4] | Garg D, Mehndiratta M M, Wasay M, et al. Air pollution and headache disorders[J]. Annals of Indian Academy of Neurology, 2022, 25(): S35-S40. |

| [5] | Denisow-Pietrzyk M. Human skin reflects air pollution—a review of the mechanisms and clinical manifestations of environment-derived skin pathologies[J]. Polish Journal of Environmental Studies, 2021, 30(4): 3433-3444. |

| [6] | Ryerson T B, Trainer M, Holloway J S, et al. Observations of ozone formation in power plant plumes and implications for ozone control strategies[J]. Science, 2001, 292(5517): 719-723. |

| [7] | 赵琳, 张英锋, 李荣焕, 等. VOC的危害及回收与处理技术[J]. 化学教育, 2015, 36(16): 1-6. |

| Zhao L, Zhang Y F, Li R H, et al. Harms, recycling and treatment technology of VOC[J]. Chinese Journal of Chemical Education, 2015, 36(16): 1-6 | |

| [8] | Zhang X Y, Gao B, Creamer A E, et al. Adsorption of VOCs onto engineered carbon materials: a review[J]. Journal of Hazardous Materials, 2017, 338: 102-123. |

| [9] | Belaissaoui B, Le Moullec Y, Favre E. Energy efficiency of a hybrid membrane/condensation process for VOC (volatile organic compounds) recovery from air: a generic approach[J]. Energy, 2016, 95: 291-302. |

| [10] | Gan G Q, Fan S Y, Li X Y, et al. Adsorption and membrane separation for removal and recovery of volatile organic compounds[J]. Journal of Environmental Sciences, 2023, 123: 96-115. |

| [11] | Yang Y, Wang G, Fang D, et al. Study of the use of a Pd-Pt-based catalyst for the catalytic combustion of storage tank VOCs[J]. International Journal of Hydrogen Energy, 2020, 45(43): 22732-22743. |

| [12] | 王波, 马睿, 薛国程, 等. 工业有机废气热氧化技术研究进展[J]. 化工进展,2017, 36(11): 4232-4242. |

| Wang B, Ma R, Xue G C, et al. Research progress on thermal oxidation technology for industrial organic waste gas[J]. Chemical Industry and Engineering Progress, 2017, 36(11): 4232-4242. | |

| [13] | Wang S B, Ang H M, Tade M O. Volatile organic compounds in indoor environment and photocatalytic oxidation: state of the art[J]. Environment International, 2007, 33(5): 694-705. |

| [14] | 杨显万, 孙珮石, 黄若华,等. 生物法净化低浓度挥发性有机废气研究[J]. 中国工程科学, 2001, 3(9): 64-68. |

| Yang X W, Sun P S, Huang R H, et al. Study on biological purification of low concentration volatile organic waste gas[J]. Engineering Science, 2001, 3(9): 64-68. | |

| [15] | McDonald B C, de Gouw J A, Gilman J B, et al. Vical source of urban organic emissions[J]. Science, 2018, 359(6377): 760-764. |

| [16] | 吴桂平. 蓄热式燃烧技术在有机废气处理项目的应用[J].能源与环境, 2021(4): 56-58. |

| Wu G P. Application of regenerative combustion technology in organic waste gas treatment project[J]. Energy and Environment, 2021(4): 56-58. | |

| [17] | Wang H L, Nie L, Li J, et al. Characterization and assessment of volatile organic compounds (VOCs) emissions from typical industries[J]. Chinese Science Bulletin, 2013, 58(7): 724-730. |

| [18] | Cannon B J. Dual-chamber RTO oxidizers provide cost-effective VOC compliance for metal finishers and coaters[J]. Metal Finishing, 2003, 101(1): 53-56. |

| [19] | Chou M S, Hei C M, Huang Y W. Regenerative thermal oxidation of airborne N,N-dimethylformamide and its associated nitrogen oxides formation characteristics[J]. Journal of the Air & Waste Management Association, 2007, 57(8): 991-999. |

| [20] | Amelio M, Florio G, Morrone P, et al. The influence of rotary valve distribution systems on the energetic efficiency of regenerative thermal oxidizers (RTO)[J]. International Journal of Energy Research,2008, 32(1): 24-34. |

| [21] | Hao X W, Li R X, Wang J, et al. Numerical simulation of a regenerative thermal oxidizer for volatile organic compounds treatment[J]. Environmental Engineering Research,2018, 23(4): 397-405. |

| [22] | 帅启凡, 陆建刚, 李健生. 蓄热式热力燃烧室结构模拟优化与应用效果分析[J]. 环境工程, 2022, 40(2):146-153. |

| Shuai Q F, Lu J G, Li J S. Analysis on structural simulation, optimization and application effect of a regenerative thermal oxidizer [J]. Environmental Engineering, 2022, 40(2): 146-153. | |

| [23] | Choi B S, Yi J. Simulation and optimization on the regenerative thermal oxidation of volatile organic compounds[J]. Chemical Engineering Journal, 2000, 76(2): 103-114. |

| [24] | Wang F Z, Lei X X, Hao X W. Key factors in the volatile organic compounds treatment by regenerative thermal oxidizer[J]. Journal of the Air & Waste Management Association, 2020, 70(5): 557-567. |

| [25] | You Y H, Huang H, Shao G W, et al. A three-dimensional numerical model of unsteady flow and heat transfer in ceramic honeycomb regenerator[J]. Applied Thermal Engineering,2016, 108: 1243-1250. |

| [26] | 王琛, 杨佳莹, 王宝琳, 等. 山东省化学合成类制药VOCs排放特征及影响[J]. 环境科学, 2024, 45(12): 7012-7020. |

| Wang C, Yang J Y, Wang B L, et al. Characteristics and impact of VOCs emissions from chemical synthesis pharmaceuticals in Shandong province[J]. Environmental Science, 2024, 45 (12): 7012-7020. | |

| [27] | Ma J W, Li L. VOC emitted by biopharmaceutical industries: source profiles, health risks, and secondary pollution[J]. Journal of Environmental Sciences, 2024, 135: 570-584. |

| [28] | 郝立苗, 黄妃慧, 王勇伟, 等. 蜂窝陶瓷的研究现状及应用[J]. 佛山陶瓷, 2021, 31(6): 32-39. |

| Hao L M, Huang F H, Wang Y W, et al. Research status and application of honeycomb ceramics[J]. Foshan Ceramics, 2021, 31(6): 32-39. | |

| [29] | Iijima S, Nakayama K, Kuchar D, et al. Optimum conditions for effective decomposition of toluene as VOC gas by pilot-scale regenerative thermal oxidizer[J]. World Academy of Science, Engineering and Technology, 2008, 2: 1589-1594. |

| [30] | 王洋. 耦合多步反应的VOCs蓄热燃烧过程数值模拟[D]. 镇江: 江苏科技大学, 2023. |

| Wang Y. Numerical simulation of VOCs regenerative combustion process coupled with multi-step reaction[D]. Zhenjiang: Jiangsu University of Science and Technology, 2023. | |

| [31] | 王姣. 蓄热式热氧化炉在处理挥发性有机气体中的关键因素研究[D]. 哈尔滨: 哈尔滨工业大学, 2018. |

| Wang J. Research on key factors of regenerative thermal oxidation furnace in treating volatile organic gases[D]. Harbin: Harbin Institute of Technology, 2018. |

| [1] | 孙云龙, 徐肖肖, 黄永方, 郭纪超, 陈卫卫. 水平光滑管内CO2流动沸腾的非绝热可视化研究[J]. 化工学报, 2025, 76(S1): 230-236. |

| [2] | 郭纪超, 徐肖肖, 孙云龙. 基于植物工厂中的CO2浓度气流模拟及优化研究[J]. 化工学报, 2025, 76(S1): 237-245. |

| [3] | 石一帆, 柯钢, 陈浩, 黄孝胜, 叶芳, 李成娇, 郭航. 大型高低温环境实验室温度控制仿真[J]. 化工学报, 2025, 76(S1): 268-280. |

| [4] | 孔繁臣, 张硕, 唐明生, 邹慧明, 胡舟航, 田长青. 二氧化碳直线压缩机气体轴承模拟[J]. 化工学报, 2025, 76(S1): 281-288. |

| [5] | 李卫, 陈浩, 柯钢, 黄孝胜, 李成娇, 郭航, 叶芳. 高原环境适应性试验室模拟平台新风系统仿真[J]. 化工学报, 2025, 76(S1): 360-369. |

| [6] | 何婷, 张开, 林文胜, 陈利琼, 陈家富. 沼气超临界压力低温脱碳-液化耦合流程研究[J]. 化工学报, 2025, 76(S1): 418-425. |

| [7] | 赵美, 甘雨欣, 赵绍磊, 杨令, 王亭杰. 硅橡胶用纳米二氧化硅表面有机修饰及补强机理研究进展[J]. 化工学报, 2025, 76(7): 3125-3136. |

| [8] | 董泽明, 娄聚伟, 王楠, 陈良奇, 王江峰, 赵攀. 含余热回收的超临界压缩二氧化碳储能系统热力学特性研究[J]. 化工学报, 2025, 76(7): 3477-3486. |

| [9] | 范振宁, 梁海宁, 房茂立, 赫一凡, 于帅, 闫兴清, 安佳然, 乔帆帆, 喻健良. CO2管道不同相态节流放空特性研究与对比[J]. 化工学报, 2025, 76(7): 3742-3751. |

| [10] | 吴雷, 胡紫璇, 高渊, 刘长波, 曹虎生, 刘田田, 朱瑞玉, 周军. 微波联合生物炭活化过硫酸盐氧化修复多环芳烃污染土壤研究[J]. 化工学报, 2025, 76(7): 3659-3670. |

| [11] | 王树宇, 薛志亮, 朱静, 付鑫, 周永刚, 胡一鸣, 黄群星. 废弃全钢胎颗粒热解过程中质量和形态变化研究[J]. 化工学报, 2025, 76(7): 3459-3467. |

| [12] | 卢煦旸, 徐强, 康浩鹏, 史健, 曹泽水, 郭烈锦. 化学链制氢系统中磁铁矿氧载体的CO还原特性研究[J]. 化工学报, 2025, 76(7): 3286-3294. |

| [13] | 刘沁雯, 叶恒冰, 张逸伟, 朱法华, 钟文琪. 煤与禽类粪便混合燃料的加压富氧燃烧特性研究[J]. 化工学报, 2025, 76(7): 3487-3497. |

| [14] | 段浩, 王文超, 刘栋, 尹晓军, 胡二江, 曾科. 甲醇喷射时刻对甲醇/柴油双直喷发动机性能的影响[J]. 化工学报, 2025, 76(7): 3552-3560. |

| [15] | 丁宏鑫, 干文翔, 赵雍洋, 贾润泽, 康子祺, 赵玉隆, 向勇. X65钢焊接接头在超临界CO2相及富H2O相中的腐蚀机理研究[J]. 化工学报, 2025, 76(7): 3426-3435. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号