• •

收稿日期:2025-10-09

修回日期:2025-11-15

出版日期:2025-11-24

通讯作者:

庄钰

作者简介:李玲(1999—),女,硕士研究生, lliling@mail.dlut.edu.cn

Ling LI1( ), Yu ZHANG1(

), Yu ZHANG1( ), Linlin LIU1, Chao WANG2, Jian DU1

), Linlin LIU1, Chao WANG2, Jian DU1

Received:2025-10-09

Revised:2025-11-15

Online:2025-11-24

Contact:

Yu ZHANG

摘要:

针对有机朗肯循环(ORC)混合工质筛选耗时长、热物性数据缺失等问题,提出一种基于人工神经网络(ANN)与遗传算法(GA)集成的数据驱动框架,用于ORC系统的快速性能评估与混合工质智能筛选。首先利用Aspen Plus建立严格的热力学模型,采用拉丁超立方采样生成5种纯工质及其二元混合物共1600组样本数据;随后在MATLAB中构建多层前馈ANN模型,实现热效率(

中图分类号:

李玲, 庄钰, 刘琳琳, 王超, 都健. 基于ANN-GA集成的ORC混合工质智能筛选与性能优化[J]. 化工学报, DOI: 10.11949/0438-1157.20251120.

Ling LI, Yu ZHANG, Linlin LIU, Chao WANG, Jian DU. ANN-GA integrated framework for intelligent screening of ORC mixture working fluids and performance optimization[J]. CIESC Journal, DOI: 10.11949/0438-1157.20251120.

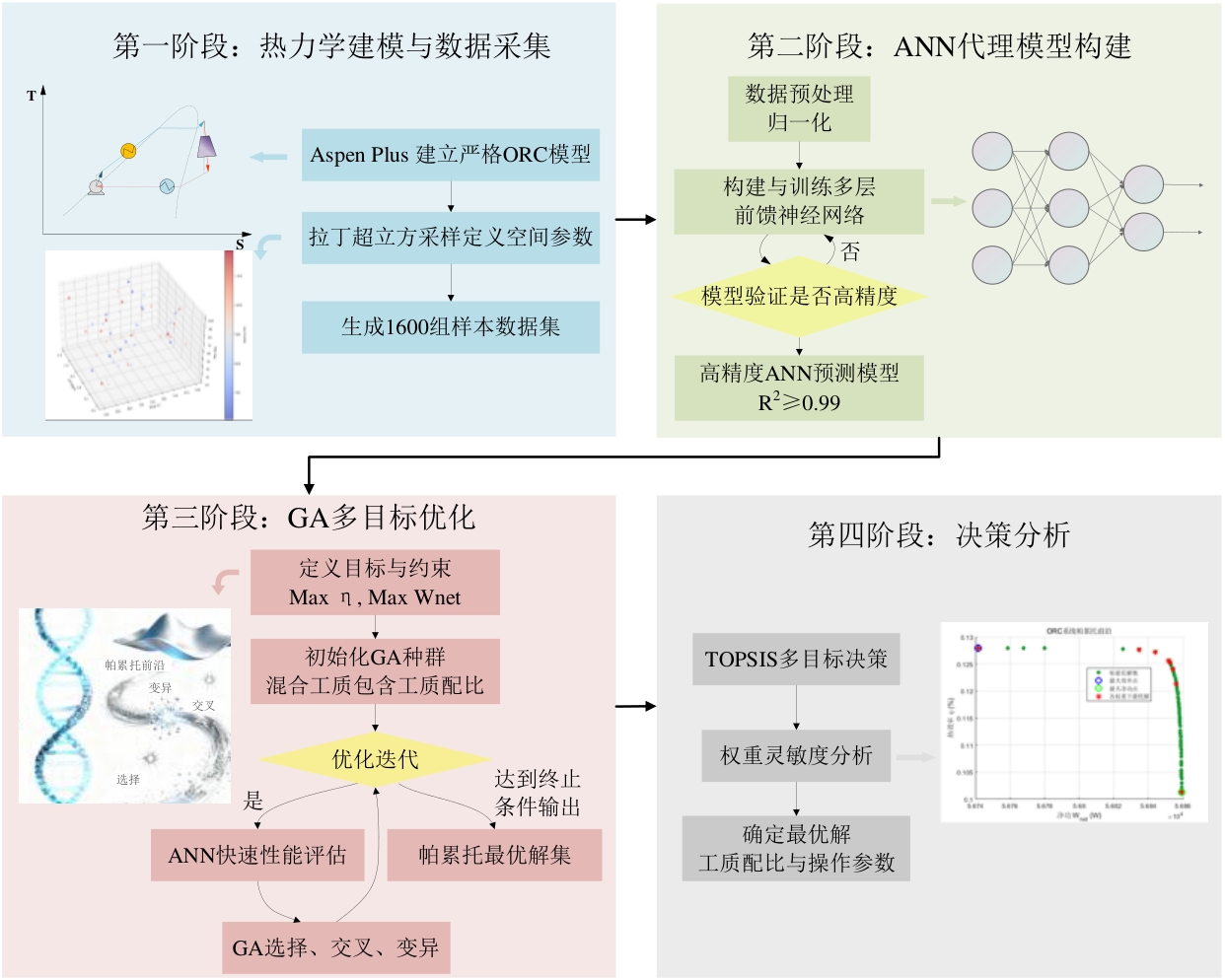

图1 ANN-GA集成的ORC混合工质筛选与优化技术路线图

Fig.1 Technical Framework of the ANN-GA Integrated Optimization for ORC Working Fluid Screening and Performance Evaluation

| 工质 | 工质类别 | 摩尔质量/(g mol-1) | 沸点/K | 临界温度/K | 临界压力/MPa | ODP | GWP |

|---|---|---|---|---|---|---|---|

| R123 | HCFC | 152.93 | 300.80 | 456.80 | 3.66 | 0 | 77 |

| R601 | HC | 72.14 | 309.21 | 469.70 | 3.37 | 0 | 11 |

| R601a | HC | 72.14 | 300.98 | 460.35 | 3.37 | 0 | 7 |

| R245fa | HFC | 134.05 | 288.29 | 427.16 | 3.26 | 0 | 950 |

| R1233zd(E) | HFC | 130.50 | 291.00 | 436.00 | 3.62 | 0 | 1 |

表1 五种工质基本参数

Table 1 Basic Parameters of Five Working Fluids

| 工质 | 工质类别 | 摩尔质量/(g mol-1) | 沸点/K | 临界温度/K | 临界压力/MPa | ODP | GWP |

|---|---|---|---|---|---|---|---|

| R123 | HCFC | 152.93 | 300.80 | 456.80 | 3.66 | 0 | 77 |

| R601 | HC | 72.14 | 309.21 | 469.70 | 3.37 | 0 | 11 |

| R601a | HC | 72.14 | 300.98 | 460.35 | 3.37 | 0 | 7 |

| R245fa | HFC | 134.05 | 288.29 | 427.16 | 3.26 | 0 | 950 |

| R1233zd(E) | HFC | 130.50 | 291.00 | 436.00 | 3.62 | 0 | 1 |

| 变量 | 验证集MSE | 测试集MSE | 验证集R2 | 测试集R2 |

|---|---|---|---|---|

| 7.67×10-4 | 3.36×10-4 | 0.9994 | 0.9999 | |

| 7.21×10-4 | 3.46×10-4 | 0.9995 | 0.9999 |

表2 神经网络预测性能

Table 2 Neural Network Predictive Performa

| 变量 | 验证集MSE | 测试集MSE | 验证集R2 | 测试集R2 |

|---|---|---|---|---|

| 7.67×10-4 | 3.36×10-4 | 0.9994 | 0.9999 | |

| 7.21×10-4 | 3.46×10-4 | 0.9995 | 0.9999 |

| 工质 | 配比 | (kg·s-1) | ||||||

|---|---|---|---|---|---|---|---|---|

| R123 | - | 2.83 | 118.82 | 143.49 | 52.76 | 1022.35 | 26.045 | 12.35 |

| R601 | - | 2.81 | 117.43 | 132.45 | 38.12 | 853.28 | 48.699 | 10.56 |

| R601a | - | 2.69 | 101.99 | 132.54 | 66.15 | 853.46 | 48.701 | 10.60 |

| R245fa | - | 3.97 | 133.95 | 182.56 | 99.78 | 1181.83 | 20.419 | 11.43 |

| R1233zd(E) | - | 2.73 | 111.63 | 182.62 | 83.26 | 1197.16 | 20.419 | 11.50 |

| R123/R601 | 9:1 | 2.12 | 105.30 | 142.82 | 44.90 | 1143.88 | 59.903 | 12.76 |

| R123/R601a | 3:7 | 3.85 | 104.27 | 139.24 | 82.15 | 1190.73 | 56.852 | 12.56 |

| R123/R245fa | 8:2 | 3.25 | 109.10 | 156.73 | 59.21 | 1188.16 | 29.704 | 12.15 |

| R123/R1233zd(E) | 8:2 | 2.31 | 107.34 | 165.98 | 47.16 | 1121.50 | 30.626 | 12.76 |

| R601/R601a | 1:9 | 2.64 | 103.08 | 173.36 | 74.02 | 1162.24 | 58.394 | 11.54 |

| R601/R245fa | 9:1 | 1.98 | 103.98 | 123.51 | 64.13 | 1164.72 | 61.385 | 12.51 |

| R601/R1233zd(E) | 4:6 | 2.25 | 110.87 | 165.54 | 53.39 | 1180.81 | 50.736 | 11.94 |

| R601a/R245fa | 7:3 | 1.89 | 133.96 | 178.68 | 68.08 | 1172.72 | 49.366 | 11.32 |

| R601a/R1233zd(E) | 3:7 | 2.27 | 118.00 | 161.87 | 72.39 | 1127.09 | 53.636 | 12.61 |

| R245fa/R1233zd(E) | 7:3 | 2.97 | 109.26 | 205.36 | 69.98 | 1199.82 | 29.429 | 10.99 |

表3 工质的性能指标

Table 3 Performance indicators of the matrix

| 工质 | 配比 | (kg·s-1) | ||||||

|---|---|---|---|---|---|---|---|---|

| R123 | - | 2.83 | 118.82 | 143.49 | 52.76 | 1022.35 | 26.045 | 12.35 |

| R601 | - | 2.81 | 117.43 | 132.45 | 38.12 | 853.28 | 48.699 | 10.56 |

| R601a | - | 2.69 | 101.99 | 132.54 | 66.15 | 853.46 | 48.701 | 10.60 |

| R245fa | - | 3.97 | 133.95 | 182.56 | 99.78 | 1181.83 | 20.419 | 11.43 |

| R1233zd(E) | - | 2.73 | 111.63 | 182.62 | 83.26 | 1197.16 | 20.419 | 11.50 |

| R123/R601 | 9:1 | 2.12 | 105.30 | 142.82 | 44.90 | 1143.88 | 59.903 | 12.76 |

| R123/R601a | 3:7 | 3.85 | 104.27 | 139.24 | 82.15 | 1190.73 | 56.852 | 12.56 |

| R123/R245fa | 8:2 | 3.25 | 109.10 | 156.73 | 59.21 | 1188.16 | 29.704 | 12.15 |

| R123/R1233zd(E) | 8:2 | 2.31 | 107.34 | 165.98 | 47.16 | 1121.50 | 30.626 | 12.76 |

| R601/R601a | 1:9 | 2.64 | 103.08 | 173.36 | 74.02 | 1162.24 | 58.394 | 11.54 |

| R601/R245fa | 9:1 | 1.98 | 103.98 | 123.51 | 64.13 | 1164.72 | 61.385 | 12.51 |

| R601/R1233zd(E) | 4:6 | 2.25 | 110.87 | 165.54 | 53.39 | 1180.81 | 50.736 | 11.94 |

| R601a/R245fa | 7:3 | 1.89 | 133.96 | 178.68 | 68.08 | 1172.72 | 49.366 | 11.32 |

| R601a/R1233zd(E) | 3:7 | 2.27 | 118.00 | 161.87 | 72.39 | 1127.09 | 53.636 | 12.61 |

| R245fa/R1233zd(E) | 7:3 | 2.97 | 109.26 | 205.36 | 69.98 | 1199.82 | 29.429 | 10.99 |

| w1 (单位净功权重) | w2 (热效率权重) | 最优点 | 单位净功 | 热效率 | F |

|---|---|---|---|---|---|

| 0 | 1 | R123/R601 | 59902.96 | 12.76 | 1 |

| R123/R1233zd(E) | 30626.19 | 12.76 | 1 | ||

| 0.1 | 0.9 | R123/R601 | 59902.96 | 12.76 | 0.981 |

| 0.2 | 0.8 | R123/R601 | 59902.96 | 12.76 | 0.963 |

| 0.3 | 0.7 | R123/R601 | 59902.96 | 12.76 | 0.945 |

| 0.4 | 0.6 | R123/R601 | 59902.96 | 12.76 | 0.9267 |

| 0.5 | 0.5 | R123/R601 | 59902.96 | 12.76 | 0.908 |

| 0.6 | 0.4 | R123/R601 | 61384.86 | 12.51 | 0.931 |

| 0.7 | 0.3 | R601/R245fa | 61384.86 | 12.51 | 0.943 |

| 0.8 | 0.2 | R601/R245fa | 61384.86 | 12.51 | 0.954 |

| 0.9 | 0.1 | R601/R245fa | 61384.86 | 12.51 | 0.966 |

| 1 | 0 | R601/R245fa | 61384.86 | 12.51 | 1 |

表4 权重灵敏度分析结果

Table 4 Results of weight sensitivity analysis

| w1 (单位净功权重) | w2 (热效率权重) | 最优点 | 单位净功 | 热效率 | F |

|---|---|---|---|---|---|

| 0 | 1 | R123/R601 | 59902.96 | 12.76 | 1 |

| R123/R1233zd(E) | 30626.19 | 12.76 | 1 | ||

| 0.1 | 0.9 | R123/R601 | 59902.96 | 12.76 | 0.981 |

| 0.2 | 0.8 | R123/R601 | 59902.96 | 12.76 | 0.963 |

| 0.3 | 0.7 | R123/R601 | 59902.96 | 12.76 | 0.945 |

| 0.4 | 0.6 | R123/R601 | 59902.96 | 12.76 | 0.9267 |

| 0.5 | 0.5 | R123/R601 | 59902.96 | 12.76 | 0.908 |

| 0.6 | 0.4 | R123/R601 | 61384.86 | 12.51 | 0.931 |

| 0.7 | 0.3 | R601/R245fa | 61384.86 | 12.51 | 0.943 |

| 0.8 | 0.2 | R601/R245fa | 61384.86 | 12.51 | 0.954 |

| 0.9 | 0.1 | R601/R245fa | 61384.86 | 12.51 | 0.966 |

| 1 | 0 | R601/R245fa | 61384.86 | 12.51 | 1 |

| [1] | Dong X, Liao Z W, Sun J Y, et al. Simultaneous optimization for organic Rankine cycle design and heat integration[J]. Industrial & Engineering Chemistry Research, 2020, 59(46): 20455-20471. |

| [2] | Feng Y Q, Hung T, Zhang Y N, et al. Performance comparison of low-grade ORCs (organic Rankine cycles) using R245fa, pentane and their mixtures based on the thermoeconomic multi-objective optimization and decision makings[J]. Energy, 2015, 93: 2018-2029. |

| [3] | Gürgen S, Altın İ. Novel decision-making strategy for working fluid selection in Organic Rankine Cycle: a case study for waste heat recovery of a marine diesel engine[J]. Energy, 2022, 252: 124023. |

| [4] | Gutiérrez-Arriaga C G, Abdelhady F, Bamufleh H S, et al. Industrial waste heat recovery and cogeneration involving organic Rankine cycles[J]. Clean Technologies and Environmental Policy, 2015, 17(3): 767-779. |

| [5] | Imran M, Park B S, Kim H J, et al. Thermo-economic optimization of Regenerative Organic Rankine Cycle for waste heat recovery applications[J]. Energy Conversion and Management, 2014, 87: 107-118. |

| [6] | 吴维成, 谷志卿, 鞠朋, 等. 工业低温余热回收利用研究进展[J]. 可再生能源, 2024, 42(8): 1096-1103. |

| Wu W C, Gu Z Q, Ju P, et al. Research progress in recovery and utilization of low-temperature industrial waste heat[J]. Renewable Energy Resources, 2024, 42(8): 1096-1103. | |

| [7] | Mahmoudi A, Fazli M, Morad M R. A recent review of waste heat recovery by Organic Rankine Cycle[J]. Applied Thermal Engineering, 2018, 143: 660-675. |

| [8] | Zhao D P, Deng S, Zhao L, et al. Overview on artificial intelligence in design of Organic Rankine Cycle[J]. Energy and AI, 2020, 1: 100011. |

| [9] | Lecompte S, Huisseune H, van den Broek M, et al. Review of organic Rankine cycle (ORC) architectures for waste heat recovery[J]. Renewable and Sustainable Energy Reviews, 2015, 47: 448-461. |

| [10] | Sadni F E, Salhi I, Belhora F, et al. Multi-objective optimization of energy and exergy efficiencies in orc configurations using nsga-ii and topsis[J]. Thermal Science and Engineering Progress, 2025, 63: 103606. |

| [11] | 张军辉, 刘娟芳, 陈清华. 有机朗肯循环系统最佳蒸发温度和㶲分析[J]. 化工学报, 2013, 64(3): 820-826. |

| Zhang J H, Liu J F, Chen Q H. Optimal evaporating temperature and exergy analysis for organic Rankine cycle[J]. CIESC Journal, 2013, 64(3): 820-826. | |

| [12] | Wang S K, Liu C, Zhang S J, et al. Multi-objective optimization and fluid selection of organic Rankine cycle (ORC) system based on economic-environmental-sustainable analysis[J]. Energy Conversion and Management, 2022, 254: 115238. |

| [13] | 徐建. 中低温余热发电有机朗肯循环系统性能分析及优化研究[D]. 上海: 上海交通大学, 2012. |

| Xu J. Performance analysis and optimization research of mid-low- temperature waste heat power generation using organic Rankine cycle[D]. Shanghai: Shanghai Jiao Tong University, 2012. | |

| [14] | Chen Y, Ni W J. Investigation on working fluid selection of organic Rankine cycle for low temperature waste heat utilization[J]. Energy Conservation & Environmental Protection, 2020(4): 60-62. |

| [15] | Li L, Zhuang Y, Huang Y J, et al. An efficient sequential synthesis model for optimization of steam-organic Rankine cycles and work–heat integration[J]. Industrial & Engineering Chemistry Research, 2025, 64(23): 11459-11473. |

| [16] | Kang L X, Tang J P, Liu Y Z. Optimal design of an organic Rankine cycle system considering the expected variations on heat sources[J]. Energy, 2020, 213: 118841. |

| [17] | Huang X J, Lu P, Luo X L, et al. Synthesis and simultaneous MINLP optimization of heat exchanger network, steam Rankine cycle, and organic Rankine cycle[J]. Energy, 2020, 195: 116922. |

| [18] | Fu C, Gundersen T. Correct integration of compressors and expanders in above ambient heat exchanger networks[J]. Energy, 2016, 116: 1282-1293. |

| [19] | Huang Y J, Xing Y F, Zhuang Y, et al. An extended superstructure-based model for synthesis of compression-heat-integrated heat exchanger networks coupled with multiple utilities[J]. Industrial & Engineering Chemistry Research, 2024, 63(21): 9456-9470. |

| [20] | Huang Y J, Zhuang Y, Xing Y F, et al. Multi-objective optimization for work-integrated heat exchange network coupled with interstage multiple utilities[J]. Energy, 2023, 273: 127240. |

| [21] | 王金江, 鲁振杰, 安维峥, 等. ORC发电系统工艺过程预警诊断技术研究与展望[J]. 化工学报, 2025, 76(7): 3137-3152. |

| Wang J J, Lu Z J, An W Z, et al. Research and prospect of early warning and diagnosis technology for ORC power generation system process[J]. CIESC Journal, 2025, 76(7): 3137-3152. | |

| [22] | Lee J Y, Chen P L, Xie P S, et al. Design of multi-cycle organic Rankine cycle systems for low-grade heat utilisation[J]. Energy, 2024, 310: 133252. |

| [23] | 刘杰, 陈江平, 祁照岗. 低温有机朗肯循环的热力学分析[J]. 化工学报, 2010, 61(S2): 9-14. |

| Liu J, Chen J P, Qi Z G. Thermodynamic analysis of low temperature organic Rankine cycle[J]. CIESC Journal, 2010, 61(S2): 9-14. | |

| [24] | Santos M N P, da Silva Sá Ravagnani M A, Costa C B B. Optimal integration of an Organic Rankine Cycle to a process using a heuristic approach[J]. Brazilian Journal of Chemical Engineering, 2021, 38(4): 653-667. |

| [25] | Quoilin S, Aumann R, Grill A, et al. Dynamic modeling and optimal control strategy of waste heat recovery Organic Rankine Cycles[J]. Applied Energy, 2011, 88(6): 2183-2190. |

| [26] | 韩中合, 杜燕, 王智. 有机朗肯循环低温余热回收系统的工质选择[J]. 化工进展, 2014, 33(9): 2279-2285. |

| Han Z H, Du Y, Wang Z. Medium selection of organic Rankine cycle(ORC) in low temperature waste heat[J]. Chemical Industry and Engineering Progress, 2014, 33(9): 2279-2285. | |

| [27] | Li L, Zheng Y L, Fang S, et al. A two-layer optimization framework for combined heat and power with an enhanced organic rankine cycle[J]. Chemical Engineering Research and Design, 2025, 223: 466-477. |

| [28] | 侯中兰, 魏新利, 马新灵, 等. 循环水流量对ORC余热发电系统性能影响的试验分析[J]. 化工学报, 2019, 70(9): 3283-3290. |

| Hou Z L, Wei X L, Ma X L, et al. Experimental analysis of circulating water flow rate on performance of ORC waste heat power generation system[J]. CIESC Journal, 2019, 70(9): 3283-3290. | |

| [29] | Scaccabarozzi R, Tavano M, Invernizzi C M, et al. Comparison of working fluids and cycle optimization for heat recovery ORCs from large internal combustion engines[J]. Energy, 2018, 158: 396-416. |

| [30] | Permana D I, Fagioli F, De Lucia M, et al. Performance evaluation, prediction analysis and optimization of experimental ORC using artificial neural networks (ANN)[J]. Energy Nexus, 2025, 18: 100383. |

| [31] | Pavão L V, Costa C B B, Ravagnani M A S S. Multiple utilities targeting in energy integration considering rigorous temperature-enthalpy relations[J]. Chemical Engineering Science, 2023, 276: 118763. |

| [1] | 汪思远, 刘国强, 熊通, 晏刚. 窗式空调器轴流风机的风速非均匀分布特性及其对冷凝器流路优化设计的影响规律[J]. 化工学报, 2025, 76(S1): 205-216. |

| [2] | 孔繁臣, 张硕, 唐明生, 邹慧明, 胡舟航, 田长青. 二氧化碳直线压缩机气体轴承模拟[J]. 化工学报, 2025, 76(S1): 281-288. |

| [3] | 卓森庆, 陈华, 陈伟, 尚彬, 刘恒恒, 古汤汤, 白韡, 王龙炎, 曹昊敏, 丁国良. 多联式空调系统APF性能仿真的模型开发与软件实现[J]. 化工学报, 2025, 76(S1): 370-376. |

| [4] | 密晓光, 孙国刚, 程昊, 张晓慧. 印刷电路板式天然气冷却器性能仿真模型和验证[J]. 化工学报, 2025, 76(S1): 426-434. |

| [5] | 张文锋, 郭玮, 张新玉, 曹昊敏, 丁国良. 铝管铝翅片换热器模型开发及软件实现[J]. 化工学报, 2025, 76(S1): 84-92. |

| [6] | 燕子腾, 詹飞龙, 丁国良. 空调用套管式分流器结构设计及分流效果验证[J]. 化工学报, 2025, 76(S1): 152-159. |

| [7] | 曹潇风, 张华海, 王江云, 王利民. 锥形气体层流元件结构设计及流动特性研究[J]. 化工学报, 2025, 76(9): 4440-4448. |

| [8] | 朱春梦, 李增, 柳楠, 赵云鹏, 石孝刚, 蓝兴英. 基于自编码器和多尺度符号转移熵的FCC沉降器跑剂故障检测[J]. 化工学报, 2025, 76(9): 4512-4523. |

| [9] | 赵婧, 董书辰, 李高洋, 黄友科, 石浩森, 缪舒文, 谭辰妍, 朱唐琦, 李永帅, 潘慧, 凌昊. 基于电化学模型的电池性能模拟与优化[J]. 化工学报, 2025, 76(9): 4922-4932. |

| [10] | 田鹏, 张忠林, 任超, 孟国超, 郝晓刚, 刘叶刚, 侯起旺, ABUDULA Abuliti, 官国清. 基于自热再生的一种低温甲醇洗工艺建模与优化[J]. 化工学报, 2025, 76(9): 4601-4612. |

| [11] | 郭旭, 贾继宁, 姚克俭. 基于优化CNN-BiLSTM神经网络的间歇精馏过程建模[J]. 化工学报, 2025, 76(9): 4613-4629. |

| [12] | 王杰, 林渠成, 张先明. 基于分解算法的混合气体多级膜分离系统全局优化[J]. 化工学报, 2025, 76(9): 4670-4682. |

| [13] | 范夏雨, 孙建辰, 李可莹, 姚馨雅, 商辉. 机器学习驱动液态有机储氢技术的系统优化[J]. 化工学报, 2025, 76(8): 3805-3821. |

| [14] | 赫亚庆, 王维庆, 池映天, 李佳蓉, 王海云, 张新燕, 刘博文. 考虑不均匀性的SOEC电堆3D建模优化分析[J]. 化工学报, 2025, 76(8): 4129-4144. |

| [15] | 李科, 谢昊琳, 文键. 耦合多重蒸气冷却屏的液氢储罐绝热性能的多目标遗传算法优化[J]. 化工学报, 2025, 76(8): 4217-4227. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号