• •

刘璐1,2,3( ), 李玉平2, 熊巧铃2, 王腾1,2,3(

), 李玉平2, 熊巧铃2, 王腾1,2,3( )

)

收稿日期:2025-07-29

修回日期:2025-10-01

出版日期:2025-12-12

通讯作者:

王腾

作者简介:刘璐(1984—),女,博士,教授,luliu@ncepu.edu.cn

基金资助:

Lu LIU1,2,3( ), Yuping LI2, Qiaoling XIONG2, Teng WANG1,2,3(

), Yuping LI2, Qiaoling XIONG2, Teng WANG1,2,3( )

)

Received:2025-07-29

Revised:2025-10-01

Online:2025-12-12

Contact:

Teng WANG

摘要:

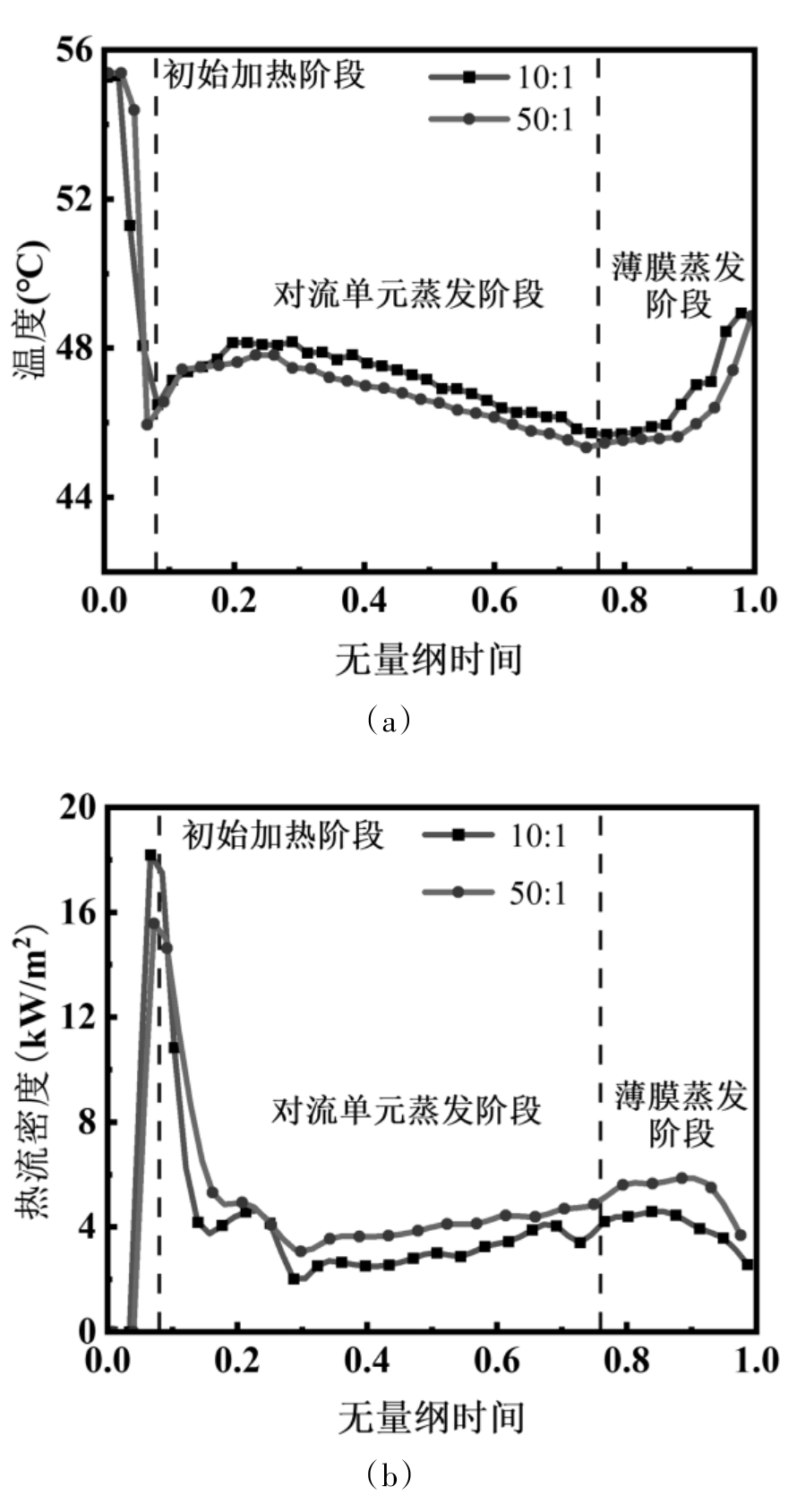

液滴在柔性基底上的蒸发现象广泛存在于柔性电子设备、生物医学等领域,其传热机理研究对设备散热设计具有重要指导意义。本文选取正戊烷为工质,在固化比为10:1和50:1的PDMS基底上开展蒸发实验,分析了表面柔性特性对液滴蒸发过程中界面温度及热通量分布的影响。实验采用非接触式温敏漆(Temperature Sensitive Paint, TSP)获取温度场分布,建立一维非稳态导热模型计算固-液界面热通量,并结合红外相机观测结果进行对照验证。结果表明:相较于10:1的柔性基底,液滴在固化比50:1的PDMS基底表面上蒸发速率更快,平均温度降低 0.7%-1.6%,平均热通量增大16%-25%。

中图分类号:

刘璐, 李玉平, 熊巧铃, 王腾. 柔性基底表面液滴蒸发传热特性实验研究[J]. 化工学报, DOI: 10.11949/0438-1157.20250846.

Lu LIU, Yuping LI, Qiaoling XIONG, Teng WANG. Experimental study on heat transfer characteristics of droplet evaporation on flexible substrate surfaces[J]. CIESC Journal, DOI: 10.11949/0438-1157.20250846.

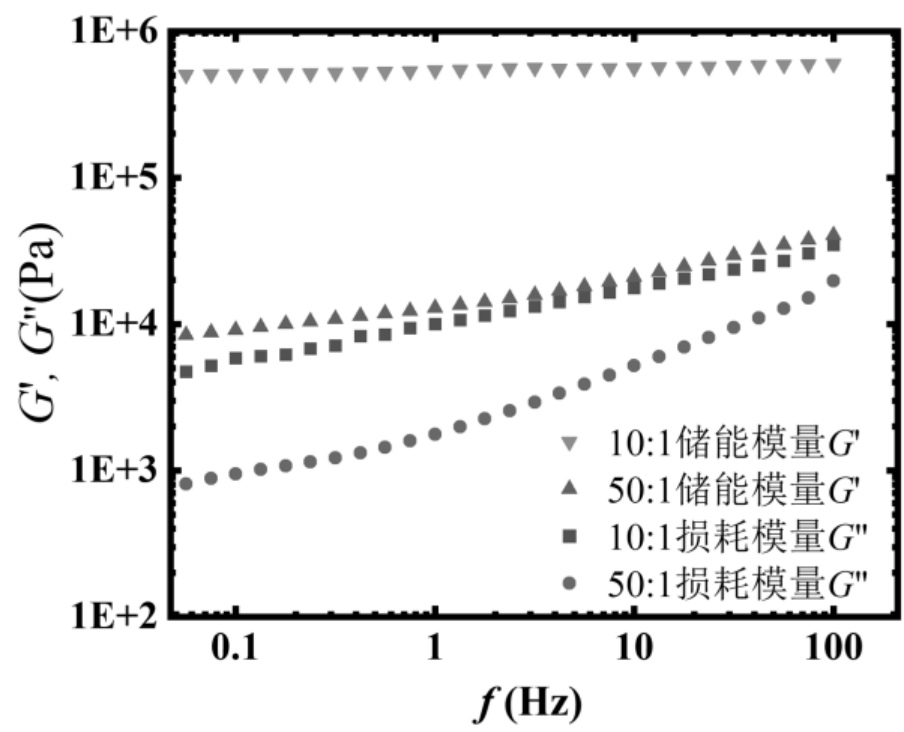

图2 不同固化比下PDMS储能模量G'和损耗模量G''随频率变化情况

Fig. 2 . Variation of the storage modulus G' and loss modulus G'' of PDMS under different conditions with frequency.

| 工质 | cP | λ | LV | μ | σ | Tsat |

|---|---|---|---|---|---|---|

| 正戊烷 | 2296 | 0.117 | 367 | 0.22 | 18.0 | 36 |

表1 1个大气压、25℃条件下正戊烷物性参数

Table 1 Physical properties of n-pentane at 1 atmosphere and 25°C

| 工质 | cP | λ | LV | μ | σ | Tsat |

|---|---|---|---|---|---|---|

| 正戊烷 | 2296 | 0.117 | 367 | 0.22 | 18.0 | 36 |

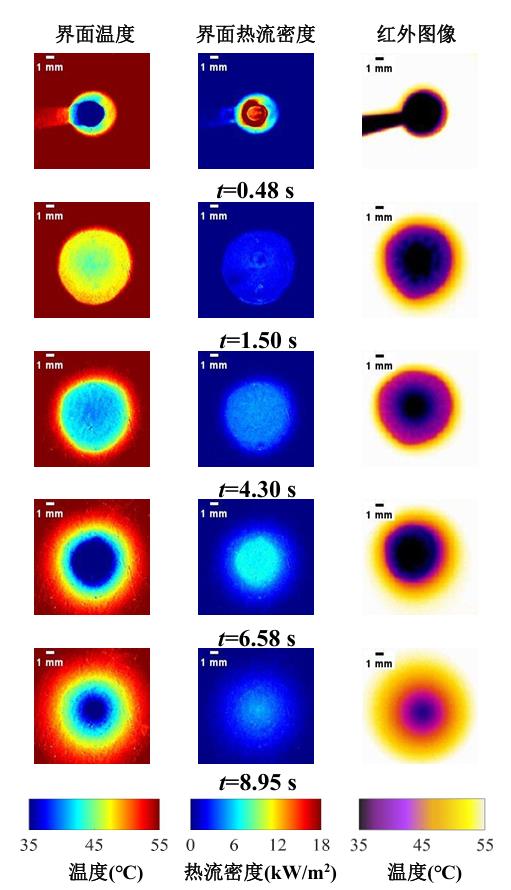

图7 正戊烷液滴在固化比10:1的PDMS蒸发过程的固-液界面温度图,界面热通量图,红外图像

Fig. 7 Interface temperature map, interfacial heat flux map, and infrared image of the solid-liquid interface during the evaporation process of n-pentane droplets on PDMS with a curing ratio of 10:1

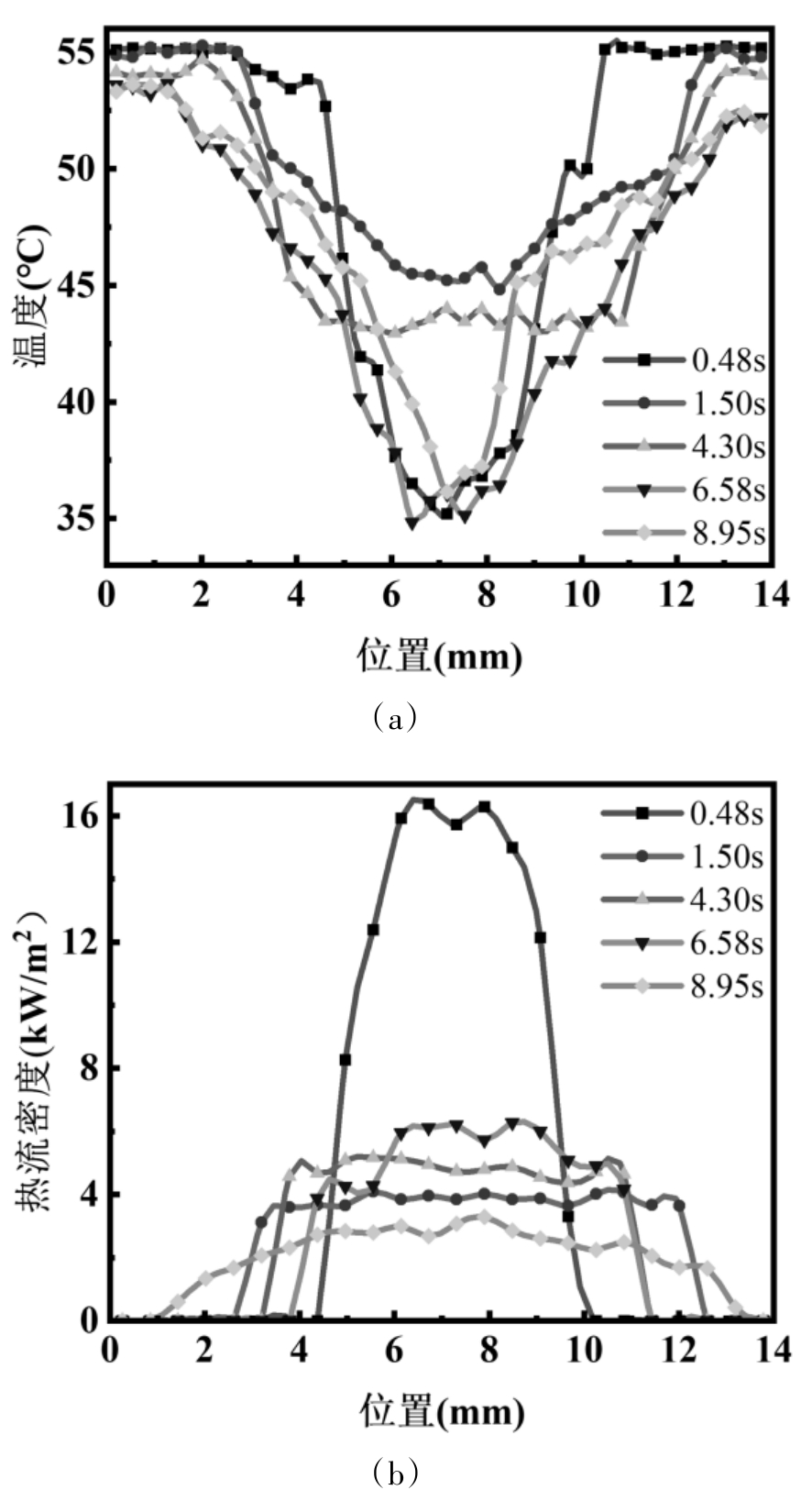

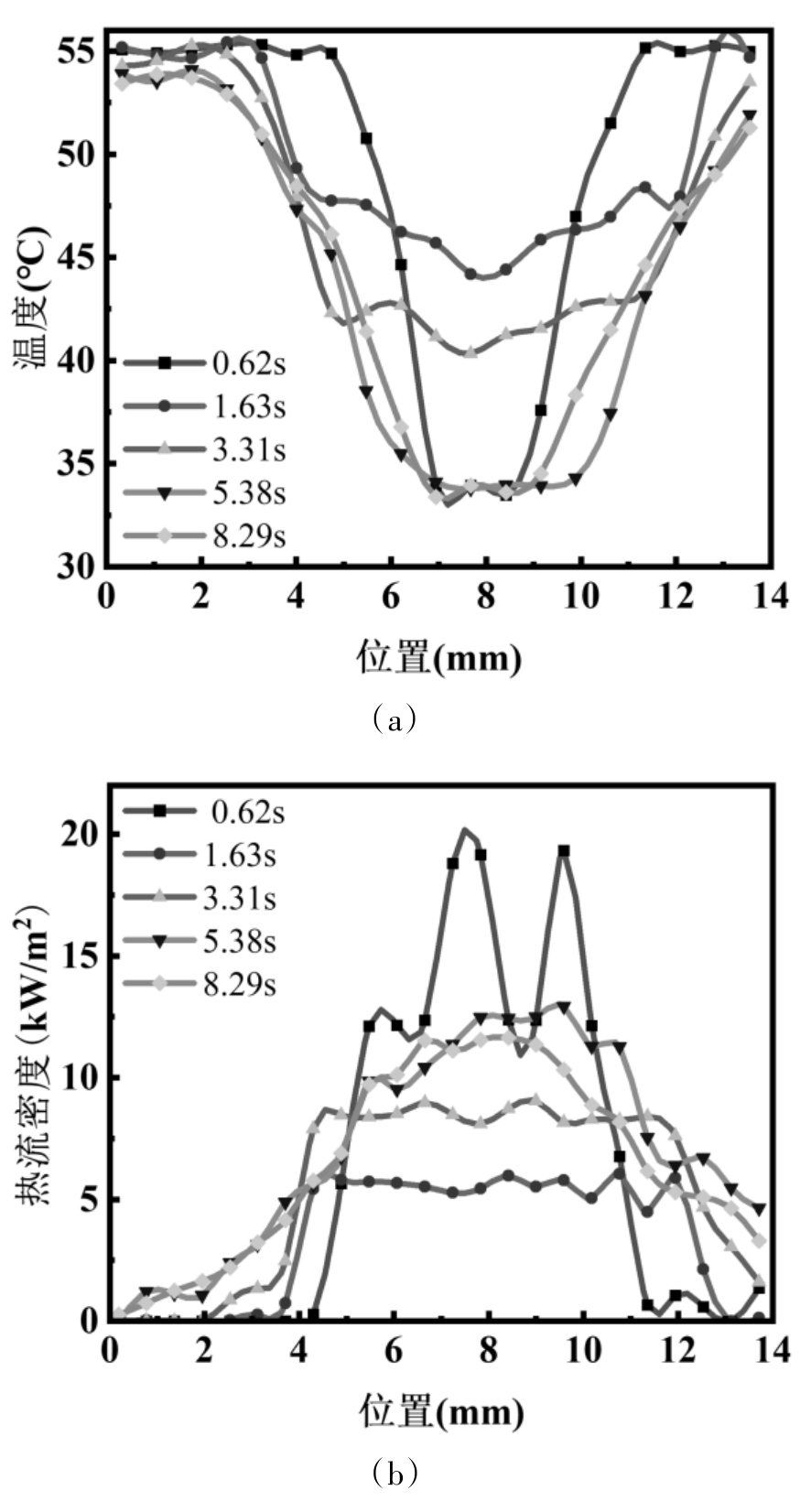

图10 正戊烷液滴在固化比为10:1的PDMS蒸发过程(a)温度分布和(b)热通量分布随时间变化

Fig. 10 (a) Temperature distribution and (b) heat flux distribution at the contact surface over time during the evaporation process of an n - pentane droplet on PDMS with a mass ratio of 10:1

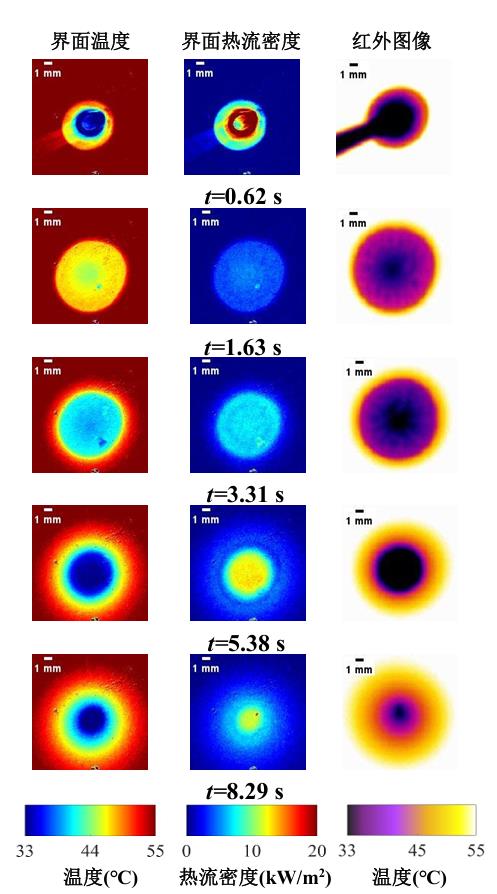

图11 正戊烷液滴在固化比50:1的PDMS蒸发过程的界面温度图,界面热通量图,红外图像

Fig. 11 Interface temperature map, interface heat flux map, and infrared image during the evaporation process of an n - pentane droplet on PDMS with a mass ratio of 50:1

图12 正戊烷液滴在固化比为50:1的PDMS蒸发过程温度分布(a)热通量分布(b)随时间变化

Fig. 12 (a) Temperature distribution and (b) heat flux distribution at the contact surface over time during the evaporation process of an n - pentane droplet on PDMS with a mass ratio of 50:1

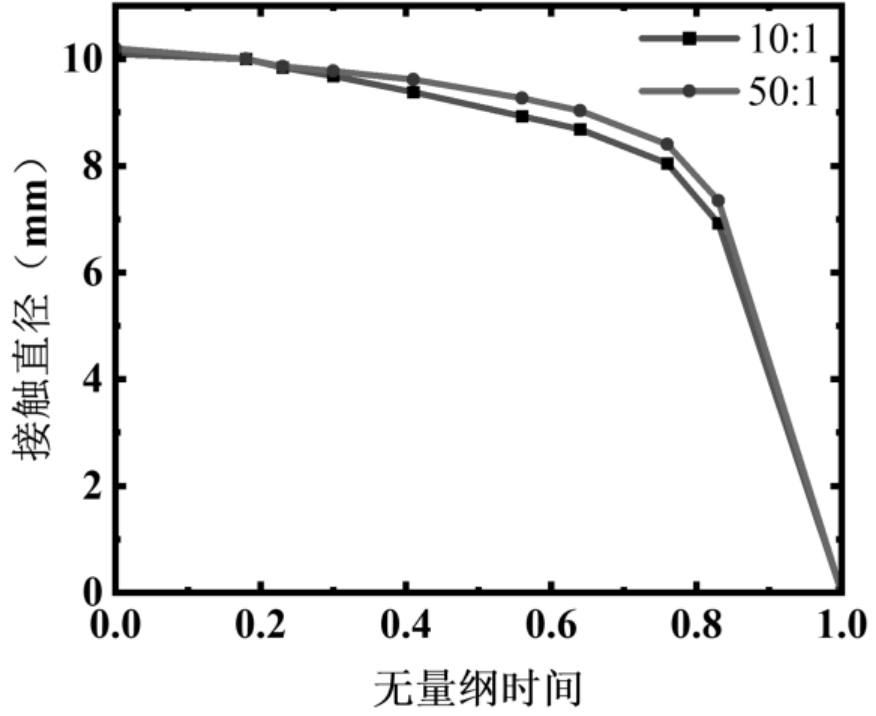

图13 正戊烷液滴在不同固化比PDMS表面蒸发过程中无量纲时间下液滴接触直径的变化图像

Figure 13 Images of the variation in contact diameter of n-pentane droplets at the dimensionless time during evaporation on PDMS surfaces with different curing ratios

图14 正戊烷液滴在不同固化比PDMS上蒸发过程的平均温度(a)和平均热通量(b)随时间变化

Fig. 14 (a) Mean temperature and (b) mean heat flux over time during the evaporation process of an n - pentane droplet on PDMS with different mass ratios

| PDMS固化比 | QTSP(J) | Qth(J) | 相对误差 |

|---|---|---|---|

| 10:1 | 3.372 | 2.936 | 14.85 |

| 50:1 | 3.258 | 2.936 | 10.97 |

表2 液滴于PDMS蒸发过程热流量校核结果

Table 2 Verification results of the heat flux during the droplet evaporation process on PDMS

| PDMS固化比 | QTSP(J) | Qth(J) | 相对误差 |

|---|---|---|---|

| 10:1 | 3.372 | 2.936 | 14.85 |

| 50:1 | 3.258 | 2.936 | 10.97 |

| [1] | Gleason K, Voota H, Putnam S A. Steady-state droplet evaporation: Contact angle influence on the evaporation efficiency[J]. International Journal of Heat and Mass Transfer, 2016, 101: 418-426. |

| [2] | 周致富, 陈斌, 白飞龙, 等. 新型喷嘴R404a闪蒸瞬态喷雾冷却传热特性[J]. 化工学报, 2015, 66(S1): 100-105. |

| Zhou Z F, Chen B, Bai F L, et al. Heat transfer dynamics of R404a flashing pulsed spray cooling using expansion-chamber nozzle [J]. CIESC Journal, 2015, 66(S1): 100-105. | |

| [3] | Putnam S A, Briones A M, Byrd L W, et al. Microdroplet evaporation on superheated surfaces[J]. International Journal of Heat and Mass Transfer, 2012, 55: 5793-5807. |

| [4] | Wang C, Xu R N, Song Y, et al. Study on water droplet flash evaporation in vacuum spray cooling[J]. International Journal of Heat and Mass Transfer, 2017, 112: 279-288. |

| [5] | Li F, Jiang J M, Shen N T, et al. Flexible microfluidic colorimetric detection chip integrated with ABTS·+ and Co@MnO2 nanozyme catalyzed TMB reaction systems for bio-enzyme free detection of sweat uric acid[J]. Analytica Chimica Acta, 2024, 1299: 342453. |

| [6] | 马学虎, 兰忠, 王凯, 等. 舞动的液滴:界面现象与过程调控[J]. 化工学报, 2018, 69(1): 9-43. |

| Ma X H, Lan Z, Wang K,et al. Dancing droplet: interface phenomena and process regulation[J]. CIESC Journal, 2018, 69(1): 9-43. | |

| [7] | Lorenzini D, Li W M, Joshi Y. Flow boiling in flexible polymer microgaps for embedded cooling in high-power applications[J]. ASME Journal of Heat and Mass Transfer, 2023, 145(4):041603. |

| [8] | Ye M Z, Yang X, Wang J, et al. Effects of elastic pillars on fluid-flow and heat transfer enhancement in a micro-channel[J]. Thermal Science, 2023, 27(1 Part A): 275-287. |

| [9] | Yu Y S, Huang X F, Sun L, et al. Evaporation of ethanol/water mixture droplets on micro-patterned PDMS surfaces[J]. International Journal of Heat and Mass Transfer, 2019, 144: 118708. |

| [10] | Wang Z L, Wang X H, Miao Q, et al. Spontaneous motion and rotation of acid droplets on the surface of a liquid metal[J]. Langmuir, 2021, 37(14): 4370-4379. |

| [11] | Gong Z, Ren J Y, Si P F, et al. Effects of fluid–structure interaction on natural convection heat transfer in a square cavity divided by vertically flexible walls[J]. Applied Thermal Engineering, 2025, 265: 125616. |

| [12] | Goon P. Heat transfer enhancement by a wall-mounted flexible vortex generator with an inclination angle[J]. International Journal of Heat and Mass Transfer, 2020, 148: 119053. |

| [13] | Dong C H, Zhang Y F, Yu J X, et al. Study on the adhesion behaviors between droplet and polydimethylsiloxane film[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2021, 629: 127502. |

| [14] | Nekoonam N, Vera G, Goralczyk A, et al. Controllable wetting transitions on photoswitchable physical gels[J]. ACS Applied Materials & Interfaces, 2023, 15(28): 27234-27242. |

| [15] | Pu G, Severtson S J. Water evaporation on highly viscoelastic polymer surfaces[J]. Langmuir, 2012, 28(26): 10007-10014. |

| [16] | Tarozzi L, Muscio A, Tartarini P. Experimental tests of dropwise cooling on infrared-transparent media[J]. Experimental Thermal and Fluid Science, 2007, 31(8): 857-865. |

| [17] | Sodtke C, Ajaev V S, Stephan P. Evaporation of thin liquid droplets on heated surfaces[J]. Heat and Mass Transfer, 2007, 43(7): 649-657. |

| [18] | Liu T S, Sullivan J P, Asai K,et al. Pressure and temperature sensitive paints[M]. Cham: Springer International Publishing, 2021. |

| [19] | Liu T S, Campbell B T, Sullivan J P. Fluorescent paint for measurement of heat transfer in shock - turbulent boundary layer interaction[J]. Experimental Thermal and Fluid Science, 1995, 10(1): 101-112. |

| [20] | Liu T S, Campbell B T, Burns S P . et al. Temperature- and pressure-sensitive luminescent paints in aerodynamics[J]. Applied Mechanics Reviews, 1997, 50(4): 227-246. |

| [21] | Francom M, Kim J. Experimental investigation into the heat transfer mechanism of oscillating heat pipes using temperature sensitive paint[J]. Journal of Heat Transfer, 2021, 143(4): 041901. |

| [22] | Matsuda Y, Kawanami O, Orimo R, et al. Simultaneous measurement of gas-liquid interface motion and temperature distribution on heated surface using temperature-sensitive paint[J]. International Journal of Heat and Mass Transfer, 2020, 153: 119567. |

| [23] | 张扣立, 周嘉穗, 孔荣宗, 等. CARDC激波风洞TSP技术研究进展[J]. 空气动力学学报, 2016, 34(6): 738-743. |

| Zhang K L, Zhou J S, Kong R Z, et al. Development of TSP technique in shock tunnel of CARDC[J]. Acta Aerodynamica Sinica, 2016, 34(6): 738-743. | |

| [24] | Liu L, Zhang K Q, Liu H Y, et al. Experimental study on the interfacial heat transfer of sessile droplet evaporation using temperature-sensitive paint[J]. Experimental Thermal and Fluid Science, 2021, 128: 110436. |

| [25] | Vo Q, Mitra S, Lin M, et al. Unsteady wetting of soft solids[J]. Journal of Colloid and Interface Science, 2024, 664: 478-486. |

| [26] | Chen K Y, Li J, Wei C Q, et al. Soft wetting: Substrate softness- and time-dependent droplet/bubble adhesion [J]. Journal of Colloid and Interface Science, 2024, 662: 87-98. |

| [27] | Xu Q, Wilen L A, Jensen K E, et al. Viscoelastic and poroelastic relaxations of soft solid surfaces[J]. Physical Review Letters, 2020, 125(23): 238002. |

| [28] | Dogru S, Aksoy B, Bayraktar H, et al. Poisson's ratio of pdms thin films [J]. Polymer Testing, 2018, 69: 375-384. |

| [29] | 李冰杰, 张舒蕾, 董新宇, 等. 基于双层温敏漆测温的固着液滴蒸发传热特性研究[J]. 实验流体力学, 2023: 1-9. (2023-03-27). . |

| Li B J, Zhang S L, Dong X Y, et al. Study on evaporation heat transfer characteristics of sessile droplets based on temperature measurement of double layer temperature sensitive paint[J/OL]. Journal of Experiments in Fluid Mechanics, 2023: 1-9. (2023-03-27). . | |

| [30] | Gibbons M J, Robinson A J. Heat transfer characteristics of single cone-jet electrosprays[J]. International Journal of Heat and Mass Transfer, 2017, 113: 70-83. |

| [31] | Gibbons M J, Di Marco P, Robinson A J. Local heat transfer to an evaporating superhydrophobic droplet[J]. International Journal of Heat and Mass Transfer, 2018, 121: 641-652. |

| [1] | 黄博, 黄灏, 王文, 贺隆坤. 薄膜型LNG船液货舱温度场计算分析[J]. 化工学报, 2025, 76(S1): 195-204. |

| [2] | 马晓文, 程扬帆, 李世周, 梁茹萍, 鲍忠奥. 粒径对TiH2粉尘云燃爆特性及温度分布特征的影响[J]. 化工学报, 2025, 76(8): 4341-4349. |

| [3] | 黄云龙, 许剑, 刘通, 元昕彤, 徐强. 气藏水平井温度分布特征及流量测试实验研究[J]. 化工学报, 2025, 76(2): 612-622. |

| [4] | 向千禧, 杨小康, 孙嘉琦, 谢峰, 邵志刚. 质子交换膜水电解池分布特性研究[J]. 化工学报, 2024, 75(11): 4359-4368. |

| [5] | 李正涛, 袁志杰, 贺高红, 姜晓滨. 疏水界面上的NaCl液滴蒸发过程内环流调控机制研究[J]. 化工学报, 2023, 74(5): 1904-1913. |

| [6] | 张舒蕾, 李冰杰, 蒋健, 董新宇, 刘璐. 凸面恒温基底上固着液滴蒸发特性研究[J]. 化工学报, 2022, 73(12): 5537-5546. |

| [7] | 张绍志, 李扬, 徐以洋, 郑幼明, 栾天, 卢衡. 基于红外测温的文物冷冻干燥监测技术[J]. 化工学报, 2020, 71(S1): 245-251. |

| [8] | 王慧儒, 刘振宇, 姚元鹏, 吴慧英. 组合相变材料强化固液相变传热可视化实验[J]. 化工学报, 2019, 70(4): 1263-1271. |

| [9] | 傅允准, 李鹏魁, 巨永林. LNG船B型液货舱绝热材料破损对蒸发率的影响模拟分析[J]. 化工学报, 2018, 69(S2): 500-504. |

| [10] | 傅允准, 武双, 林继超, 巨永林, 牛伟琛. B型液化天然气模拟舱绝热材料破损对蒸发率影响的实验研究[J]. 化工学报, 2018, 69(S2): 123-127. |

| [11] | 张弘喆, 贾先剑, 郭航, 郭青, 闫小克, 叶芳, 马重芳. 冷却水参数对钠钾合金热管传热性能影响[J]. 化工学报, 2017, 68(S1): 105-110. |

| [12] | 郭晨宁, 黄冬梅, 张明振, 赵玉法. 乳胶泡沫引火位置对火蔓延特性的影响[J]. 化工学报, 2017, 68(9): 3623-3630. |

| [13] | 刘厦, 刘石, 任婷. 基于SA-ELM的声学层析成像温度分布重建算法[J]. 化工学报, 2017, 68(6): 2434-2446. |

| [14] | 傅允准, 祁亮, 巨永林, 杜兴慧. LNG船B型液货舱温度场模拟分析[J]. 化工学报, 2015, 66(S2): 153-157. |

| [15] | 王永伟, 淮秀兰, 李勋锋, 蔡军, 席文宣. 局部强内热源移动球床温度分布特性[J]. 化工学报, 2015, 66(S1): 117-122. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号