CIESC Journal ›› 2025, Vol. 76 ›› Issue (6): 2580-2588.DOI: 10.11949/0438-1157.20241090

• Fluid dynamics and transport phenomena • Previous Articles Next Articles

Jiangyue GUO( ), Shoujin CHANG, Haitao HU(

), Shoujin CHANG, Haitao HU( )

)

Received:2024-09-29

Revised:2024-11-26

Online:2025-07-09

Published:2025-06-25

Contact:

Haitao HU

通讯作者:

胡海涛

作者简介:郭江悦(2001—),男,硕士研究生,20010405@sjtu.edu.cn

基金资助:CLC Number:

Jiangyue GUO, Shoujin CHANG, Haitao HU. Numerical simulation for flow condensation of methanol in horizontal tube[J]. CIESC Journal, 2025, 76(6): 2580-2588.

郭江悦, 常守金, 胡海涛. 水平管内甲醇流动冷凝数值模拟研究[J]. 化工学报, 2025, 76(6): 2580-2588.

Add to citation manager EndNote|Ris|BibTeX

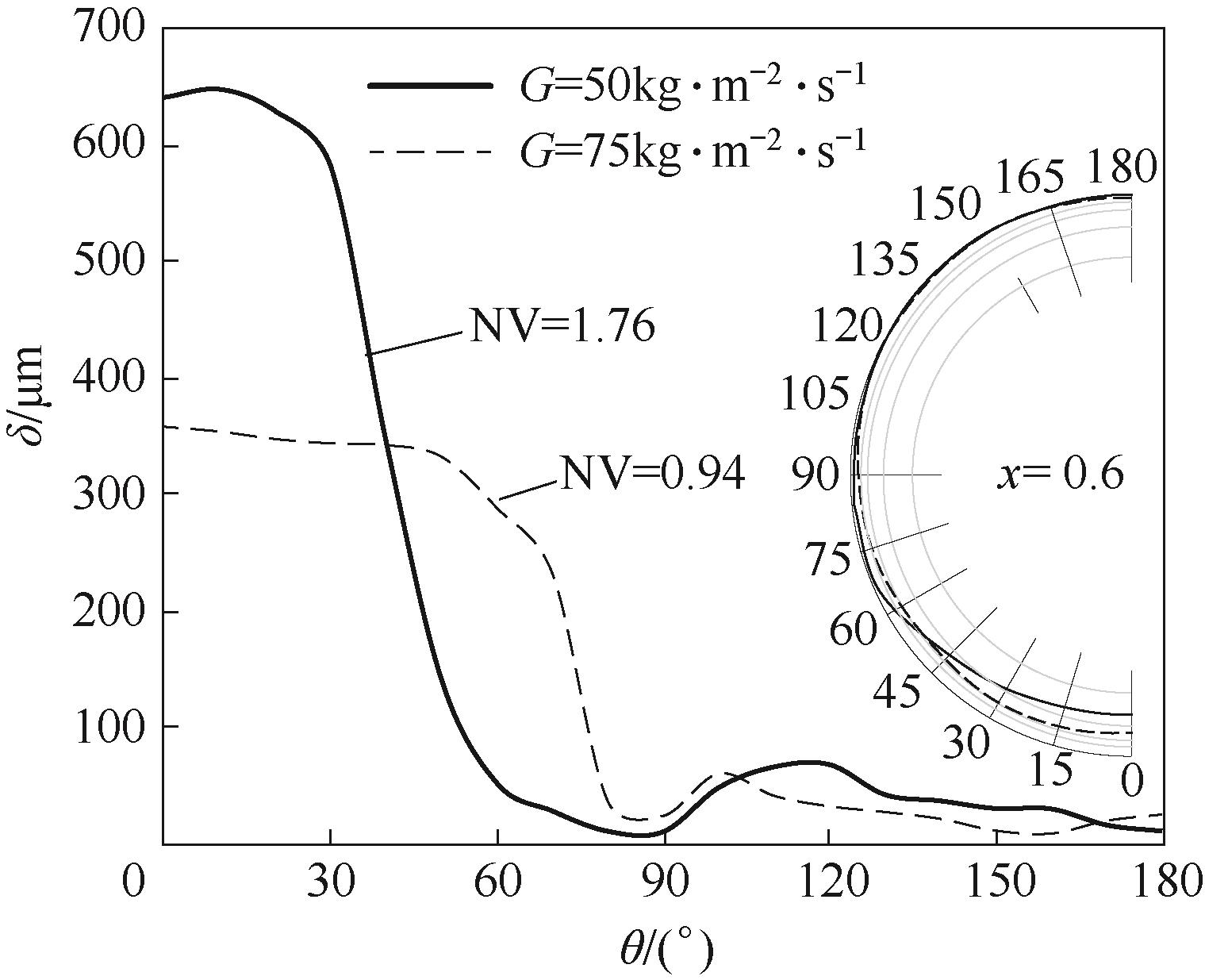

Fig.9 The variation of liquid film thickness (δ) with angle(θ) in the channel(θ=0° represents the bottom of the pipe and θ=180° represents the top of the pipe)

| [1] | Poormohammadian S J, Bahadoran F, Vakili-Nezhaad G R.Recent progress in homogeneous hydrogenation of carbon dioxide to methanol[J]. Reviews in Chemical Engineering, 2023, 39(5): 783-805. |

| [2] | Huang Y, Zhu L, He Y D, et al. Carbon dioxide utilization based on exergoenvironmental sustainability assessment: a case study of CO2 hydrogenation to methanol[J]. Energy, 2023, 273: 127219. |

| [3] | Patil T, Naji A, Mondal U, et al. Sustainable methanol production from carbon dioxide: advances, challenges, and future prospects[J]. Environmental Science and Pollution Research International, 2024, 31(32): 44608-44648. |

| [4] | Liu G F, Hagelin-Weaver H, Welt B. A concise review of catalytic synthesis of methanol from synthesis gas[J]. Waste, 2023, 1(1): 228-248. |

| [5] | Li X P, Ke J C, Li R, et al. Research progress of hydrogenation of carbon dioxide to ethanol[J]. Chemical Engineering Science, 2023, 282: 119226. |

| [6] | 舒斌, 陈建宏, 熊健, 等. 碳中和目标下推动绿色甲醇发展的必要性分析[J]. 化工进展, 2023, 42(9): 4471-4478. |

| Shu B, Chen J H, Xiong J, et al. Necessity analysis of promoting the development of green methanol under the goal of carbon neutrality[J]. Chemical Industry and Engineering Progress, 2023, 42(9): 4471-4478. | |

| [7] | Vaquerizo L, Kiss A A. Thermally self-sufficient process for cleaner production of e-methanol by CO2 hydrogenation[J]. Journal of Cleaner Production, 2023, 433: 139845. |

| [8] | Gu H F, Liu J Z, Zhou X C, et al. Modelling of a novel electricity and methanol co-generation using heat recovery and CO2 capture: comprehensive thermodynamic, economic, and environmental analyses[J]. Energy, 2023, 278: 127481. |

| [9] | Schrodt J T, Gerhard E R. Simultaneous condensation of methanol and water from a noncondensing gas on vertical tubes in a bank[J]. Industrial & Engineering Chemistry Fundamentals, 1968, 7(2): 281-285. |

| [10] | Belkassmi Y, Hassanain N. Numerical study in condensing of methanol vapor in a vertical tube by mixed convection in the presence of non-condensable gas[J]. Advanced Studies in Theoretical Physics, 2012, 6(22): 1065-1076. |

| [11] | Wong S C, Tseng H H, Chen S H. Visualization experiments on the condensation process in heat pipe wicks[J]. International Journal of Heat and Mass Transfer, 2014, 68: 625-632. |

| [12] | Dobson M K, Chato J C. Condensation in smooth horizontal tubes[J]. Journal of Heat Transfer, 1998, 120(1): 193-213. |

| [13] | 吴展涛, 夏扬凯, 罗向龙, 等. 水平圆管内R245fa高温冷凝传热特性研究[J]. 工程热物理学报, 2024, 45(9): 2586-2592. |

| Wu Z T, Xia Y K, Luo X L, et al. High-temperature condensation heat transfer characteristics of R245fa in a horizontal plain tube[J]. Journal of Engineering Thermophysics, 2024, 45(9): 2586-2592. | |

| [14] | 杨英英, 李敏霞, 马一太. 水平光滑细管内R32冷凝换热的流型特性[J]. 化工学报, 2014, 65(2): 445-452. |

| Yang Y Y, Li M X, Ma Y T. Characteristics of flow pattern for condensation heat transfer of R32 in horizontal small tube[J]. CIESC Journal, 2014, 65(2): 445-452. | |

| [15] | Mondal G R, Hossain M N, Kundu A. Numerical analysis of flow condensation inside a horizontal tube: current status and possibilities[M]//Das S, Mangadoddy N, Hoffmann J. Lecture Notes in Mechanical Engineering. Singapore: Springer Nature Singapore, 2024: 229-241. |

| [16] | 张井志, 李蔚. 水平圆形与方形微小通道内R134a冷凝数值模拟[J]. 化工学报, 2016, 67(5): 1748-1754. |

| Zhang J Z, Li W. Numerical simulation of condensation in horizontal circular and square minichannels using R134a[J]. CIESC Journal, 2016, 67(5): 1748-1754. | |

| [17] | Wen J, Gu X, Liu Y C, et al. Effect of surface tension, gravity and turbulence on condensation patterns of R1234ze(E) in horizontal mini/macro-channels[J]. International Journal of Heat and Mass Transfer, 2018, 125: 153-170. |

| [18] | 谷雨, 龚路远, 郭亚丽, 等. 基于欧拉壁面液膜模型的管内蒸汽冷凝流动和液膜特性的数值模拟研究[J]. 工程热物理学报, 2024, 45(3): 764-768. |

| Gu Y, Gong L Y, Guo Y L, et al. Numerical simulation of steam condensation flow and liquid film characteristics in tubes based on Euler wall liquid film model[J]. Journal of Engineering Thermophysics, 2024, 45(3): 764-768. | |

| [19] | Hirt C W, Nichols B D. Volume of fluid (VOF) method for the dynamics of free boundaries[J]. Journal of Computational Physics, 1981, 39(1): 201-225. |

| [20] | Menter F R. Two-equation eddy-viscosity turbulence models for engineering applications[J]. AIAA Journal, 1994, 32(8): 1598-1605. |

| [21] | Lee W H. A Pressure Iteration Scheme for Two-phase Flow Modeling[M]. Washington, USA: Hemisphere Publishing, 1980: 407-432. |

| [22] | 刘纳, 李俊明. R32在水平微细圆管内凝结换热的数值模拟[J]. 化工学报, 2014, 65(11): 4246-4253. |

| Liu N, Li J M. Numerical simulation of R32 condensation heat transfer in horizontal circular microchannel[J]. CIESC Journal, 2014, 65(11): 4246-4253. | |

| [23] | 徐裕民, 孙伟珂, 于哲, 等. 换热器螺旋管冷凝换热的数值模拟与实验研究[J]. 科学技术与工程, 2023, 23(32): 13845-13853. |

| Xu Y M, Sun W K, Yu Z, et al. Numerical simulation and experimental study on spiral tube condensation heat transfer in heat exchanger[J]. Science Technology and Engineering, 2023, 23(32): 13845-13853. | |

| [24] | Bortolin S, Da Riva E, Del Col D. Condensation in a square minichannel: application of the VOF method[J]. Heat Transfer Engineering, 2014, 35(2): 193-203. |

| [25] | 杨德松. 结合实验、仿真与机器学习的管内冷凝传热特性研究[D]. 杭州: 浙江大学, 2023. |

| Yang D S. Investigation of in-tube condensation heat transfer with experiment, simulation and machine earning methods[D]. Hangzhou: Zhejiang University, 2023. | |

| [26] | Shah M M. A general correlation for heat transfer during film condensation inside pipes[J]. International Journal of Heat and Mass Transfer, 1979, 22(4): 547-556. |

| [27] | Cavallini A, Doretti L, Matkovic M, et al. Update on condensation heat transfer and pressure drop inside minichannels[J]. Heat Transfer Engineering, 2006, 27(4): 74-87. |

| [28] | Zhang M, Webb R L. Correlation of two-phase friction for refrigerants in small-diameter tubes[J]. Experimental Thermal and Fluid Science, 2001, 25(3/4): 131-139. |

| [29] | 沈坤荣. 制冷剂R410A在多种复合强化管内两相流动实验和机理研究[D]. 杭州: 浙江大学, 2020. |

| Shen K R. Experimental and mechanism research of R410A two-phase flow in horizontal enhanced tubes[D]. Hangzhou: Zhejiang University, 2020. | |

| [30] | Hu H T, Li Y H, Lei R, et al. Numerical investigation on flow condensation in zigzag channel of printed circuit heat exchanger[J]. Applied Thermal Engineering, 2024, 252: 123645. |

| [31] | Breber G, Palen J W, Taborek J. Prediction of horizontal tubeside condensation of pure components using flow regime criteria[J]. Journal of Heat Transfer, 1980, 102(3): 471-476. |

| [32] | 谷雨. 真空条件下蒸汽水平管内冷凝流动与换热特性研究[D]. 辽宁: 大连理工大学, 2023. |

| Gu Y. Study on condensation flow and heat transfer characteristics of steam in horizontal tubes under vacuum conditions[D]. Dalian: Dalian University of Technology, 2023. |

| [1] | Hongxin YU, Ningbo WANG, Yanhua GUO, Shuangquan SHAO. Numerical investigation on the flow and heat transfer characteristics of plate heat exchanger in dynamic ice storage system [J]. CIESC Journal, 2025, 76(S1): 106-113. |

| [2] | Wei SU, Dahai ZHAO, Xu JIN, Zhongyan LIU, Jing LI, Xiaosong ZHANG. Delaying condensation frosting using biphilic surfaces coupled with spatial control of liquid desiccant [J]. CIESC Journal, 2025, 76(S1): 140-151. |

| [3] | Haolei DUAN, Haoyuan CHEN, Kunfeng LIANG, Lin WANG, Bin CHEN, Yong CAO, Chenguang ZHANG, Shuopeng LI, Dengyu ZHU, Yaru HE, Dapeng YANG. Performance analysis and comprehensive evaluation of thermal management system schemes with low GWP refrigerants [J]. CIESC Journal, 2025, 76(S1): 54-61. |

| [4] | Xianchao REN, Yaxiu GU, Shaobin DUAN, Wenzhu JIA, Hanlin LI. Experimental study on heat and mass transfer performance of elliptical tube-fin evaporative condenser [J]. CIESC Journal, 2025, 76(S1): 75-83. |

| [5] | Junpeng WANG, Jiaqi FENG, Enbo ZHANG, Bofeng BAI. Study on flow and cavitation characteristic in zigzag and array labyrinth valve core structures [J]. CIESC Journal, 2025, 76(S1): 93-105. |

| [6] | Linhui YUAN, Yu WANG. Heat dissipation performance of single server immersion jet liquid cooling system [J]. CIESC Journal, 2025, 76(S1): 160-169. |

| [7] | Zixiang ZHAO, Zhongdi DUAN, Haoran SUN, Hongxiang XUE. Numerical modelling of water hammer induced by two phase flow with large temperature difference [J]. CIESC Journal, 2025, 76(S1): 170-180. |

| [8] | Hao HUANG, Wen WANG, Longkun HE. Simulation and analysis on precooling process of membrane LNG carriers [J]. CIESC Journal, 2025, 76(S1): 187-194. |

| [9] | Bo HUANG, Hao HUANG, Wen WANG, Longkun HE. Analysis of temperature field of membrane liquid cargo in a LNG carrier [J]. CIESC Journal, 2025, 76(S1): 195-204. |

| [10] | Siyuan WANG, Guoqiang LIU, Tong XIONG, Gang YAN. Characteristics of non-uniform wind velocity distribution in window air conditioner axial fans and their impact on optimizing condenser circuit optimization [J]. CIESC Journal, 2025, 76(S1): 205-216. |

| [11] | Qingtai CAO, Songyuan GUO, Jianqiang LI, Zan JIANG, Bin WANG, Rui ZHUAN, Jingyi WU, Guang YANG. Numerical study on influence of perforated plate on retention performance of liquid oxygen tank under negative gravity [J]. CIESC Journal, 2025, 76(S1): 217-229. |

| [12] | Jiuchun SUN, Yunlong SANG, Haitao WANG, Hao JIA, Yan ZHU. Study on influence of jet flow on slurry transport characteristics in slurry chamber of shield tunneling machines [J]. CIESC Journal, 2025, 76(S1): 246-257. |

| [13] | Junlong KONG, Yang BI, Yao ZHAO, Yanjun DAI. Simulation experiment on direct cooling thermal management system for energy storage batteries [J]. CIESC Journal, 2025, 76(S1): 289-296. |

| [14] | Ting HE, Shuyang HUANG, Kun HUANG, Liqiong CHEN. Research on the coupled process of natural gas chemical absorption decarbonization and high temperature heat pump based on waste heat utilization [J]. CIESC Journal, 2025, 76(S1): 297-308. |

| [15] | Lingban WANG, Yifei SUN, Yuhao BU, Zhenbin XU, Xian SUN, Hanfeng SHAO, Changyu SUN, Guangjin CHEN. Study on the methane hydrates exploitation by depressurization in a large-scale fan column-shaped reactor [J]. CIESC Journal, 2025, 76(6): 2958-2973. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||