化工学报 ›› 2019, Vol. 70 ›› Issue (S2): 228-236.DOI: 10.11949/0438-1157.20190512

收稿日期:2019-05-15

修回日期:2019-06-17

出版日期:2019-09-06

发布日期:2019-09-06

通讯作者:

周怀春

作者简介:郑建祥(1977—),男,博士,副教授,基金资助:

Jianxiang ZHENG( ),Yukai LI,Xiaonan SUN,Huaichun ZHOU(

),Yukai LI,Xiaonan SUN,Huaichun ZHOU( )

)

Received:2019-05-15

Revised:2019-06-17

Online:2019-09-06

Published:2019-09-06

Contact:

Huaichun ZHOU

摘要:

基于群体平衡模型(PBM)和计算流体动力学(CFD)的耦合方法模拟了湍流聚并器中黏性颗粒的聚团过程和流化行为。考虑到流体作用力和范德华力对颗粒聚团的影响,引入了聚团碰撞效率,同时考虑非球形颗粒聚团局部孔隙率沿径向逐渐增大的影响,引入分形维数。通过碰撞效率和分形维数对碰撞频率模型进行了改进。并与EDEM模拟计算结果和实验结果进行了对比。体积分数的结果显示,EDEM模拟的结果与实验结果的平均相对误差为16.34%,而改进模型与实验结果的平均相对误差仅为7.39%。而数量分数方面,EDEM模拟的结果与实验结果的平均绝对误差为5.36%,而改进模型与实验结果的平均绝对误差仅为2.28%。因此改进模型模拟结果更接近实验结果。

中图分类号:

郑建祥, 李玉凯, 孙笑楠, 周怀春. 湍流聚团过程中非球形颗粒聚团碰撞频率分析研究[J]. 化工学报, 2019, 70(S2): 228-236.

Jianxiang ZHENG, Yukai LI, Xiaonan SUN, Huaichun ZHOU. Analysis of collision frequency of non-spherical particle agglomeration during turbulent agglomeration processes[J]. CIESC Journal, 2019, 70(S2): 228-236.

| 聚团类型 | 碰撞频率模型 | |

|---|---|---|

| 布朗聚团 | ||

| Einstein[ | (7) | |

| 考虑分形[ | (8) | |

| 修正 | (9) | |

| 湍流聚团 | ||

| Saffman和Turner[ | (10) | |

| 考虑分形[ | (11) | |

| 修正 | (12) | |

| 线性相加 | (13) | |

| 均方根 | (14) | |

| DEM[ | (15) | |

| (16) | ||

| (17) | ||

表1

Table 1 Collision frequency model 碰撞频率模型

| 聚团类型 | 碰撞频率模型 | |

|---|---|---|

| 布朗聚团 | ||

| Einstein[ | (7) | |

| 考虑分形[ | (8) | |

| 修正 | (9) | |

| 湍流聚团 | ||

| Saffman和Turner[ | (10) | |

| 考虑分形[ | (11) | |

| 修正 | (12) | |

| 线性相加 | (13) | |

| 均方根 | (14) | |

| DEM[ | (15) | |

| (16) | ||

| (17) | ||

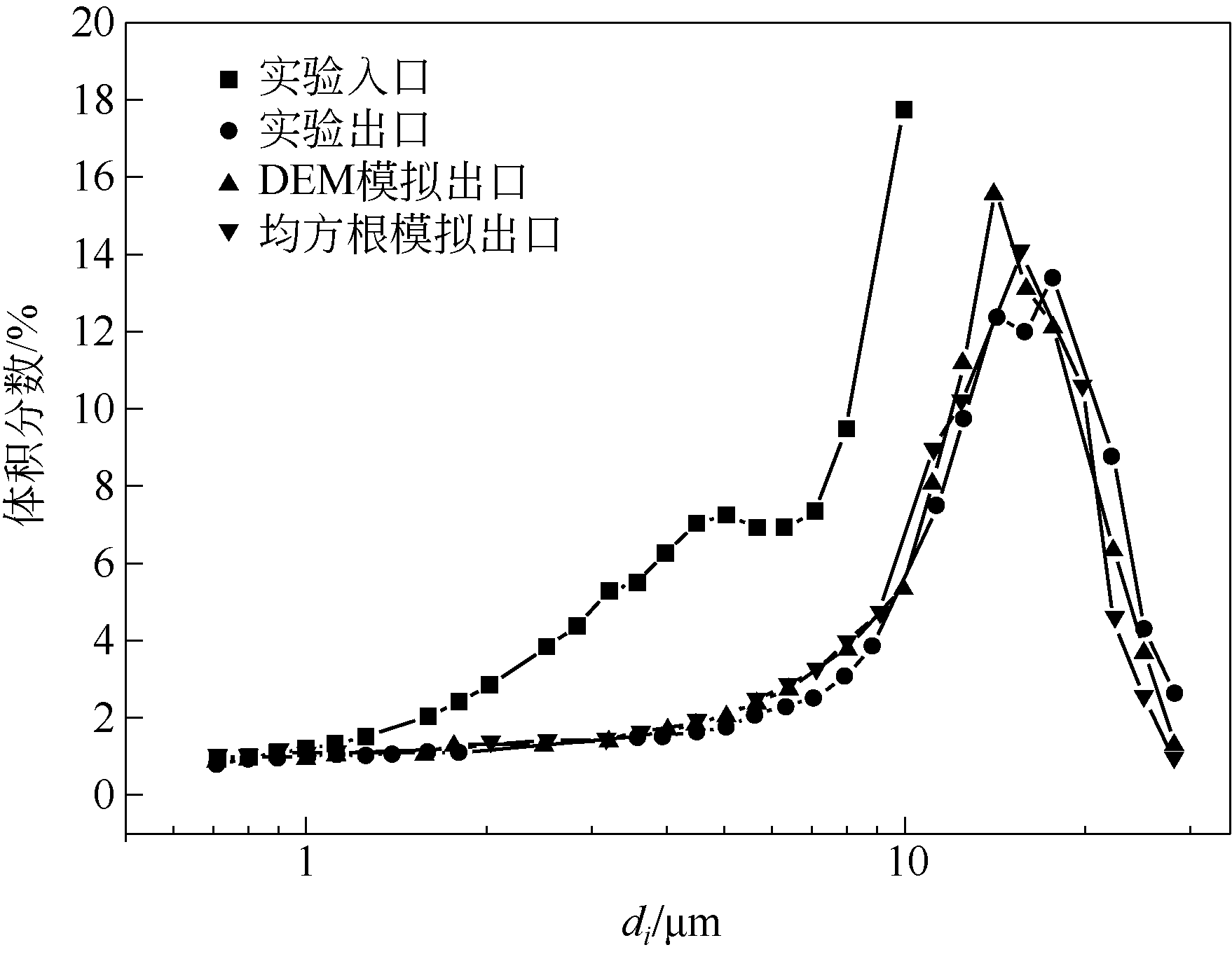

图5 EDEM模拟[式(15)]和RMS模拟[Df=2.5时式(14)]的体积分数的对比

Fig.5 Comparison of volume fractions of experimental results,EDEM simulation results [Eq.(15)] and RMS simulation results [Eq.(14) at Df=2.5]

| d/μm | 入口/ % | 实验 出口/% | 出口 (EDEM模拟) | 出口 (修正耦合模拟) | ||

|---|---|---|---|---|---|---|

体积 分数/% | 相对 误差/% | 体积 分数/% | 相对 误差/% | |||

| <2.5 | 12.43 | 2.25 | 2.65 | 17.78 | 2.15 | 4.44 |

| 2.5~5 | 31.44 | 4.55 | 5.25 | 15.38 | 4.15 | 8.79 |

| 5~10 | 56.13 | 14.88 | 17.24 | 15.86 | 16.21 | 8.94 |

| 10~20 | 0 | 56.24 | 70.02 | 7.33 | 66.53 | 1.98 |

| >20 | 0 | 13.09 | 4.84 | 63.03 | 10.96 | 16.27 |

表2 不同粒径范围内颗粒体积分数的变化

Table 2 Variation of particle volume fraction in different particle size ranges

| d/μm | 入口/ % | 实验 出口/% | 出口 (EDEM模拟) | 出口 (修正耦合模拟) | ||

|---|---|---|---|---|---|---|

体积 分数/% | 相对 误差/% | 体积 分数/% | 相对 误差/% | |||

| <2.5 | 12.43 | 2.25 | 2.65 | 17.78 | 2.15 | 4.44 |

| 2.5~5 | 31.44 | 4.55 | 5.25 | 15.38 | 4.15 | 8.79 |

| 5~10 | 56.13 | 14.88 | 17.24 | 15.86 | 16.21 | 8.94 |

| 10~20 | 0 | 56.24 | 70.02 | 7.33 | 66.53 | 1.98 |

| >20 | 0 | 13.09 | 4.84 | 63.03 | 10.96 | 16.27 |

| d/μm | 入口/ % | 实验出口/ % | 出口(EDEM模拟) | 出口(修正耦合模拟) | ||

|---|---|---|---|---|---|---|

数量 分数/% | 绝对 误差/% | 数量 分数/% | 绝对 误差/% | |||

| <2.5 | 70.03 | 73.16 | 76.76 | 3.6 | 74.55 | 1.39 |

| 2.5~5 | 27.12 | 18.60 | 7.27 | 11.33 | 13.45 | 5.15 |

| 5~10 | 2.85 | 4.53 | 5.67 | 1.14 | 4.83 | 0.3 |

| 10~20 | 0 | 3.42 | 8.21 | 4.79 | 6.22 | 2.8 |

| >20 | 0 | 0.28 | 2.09 | 1.81 | 0.95 | 0.67 |

表3 不同粒径范围内颗粒数量分数的变化

Table 3 Variation of agglomeration number fraction in different particle size ranges

| d/μm | 入口/ % | 实验出口/ % | 出口(EDEM模拟) | 出口(修正耦合模拟) | ||

|---|---|---|---|---|---|---|

数量 分数/% | 绝对 误差/% | 数量 分数/% | 绝对 误差/% | |||

| <2.5 | 70.03 | 73.16 | 76.76 | 3.6 | 74.55 | 1.39 |

| 2.5~5 | 27.12 | 18.60 | 7.27 | 11.33 | 13.45 | 5.15 |

| 5~10 | 2.85 | 4.53 | 5.67 | 1.14 | 4.83 | 0.3 |

| 10~20 | 0 | 3.42 | 8.21 | 4.79 | 6.22 | 2.8 |

| >20 | 0 | 0.28 | 2.09 | 1.81 | 0.95 | 0.67 |

| 1 | LiH, ZhangJ, ZhaoY, et al. Wettability of fly ashes from four coal-fired power plants in China[J]. Industrial & Engineering Chemistry Research, 2011, 50(13): 7763-7771. |

| 2 | IlyasS U, PendyalaR, MarneniN. Preparation, sedimentation, and agglomeration of nanofluids[J]. Chemical Engineering & Technology, 2014, 37(12): 2011-2021. |

| 3 | BorchertC, SundmacherK. Crystal aggregation in a flow tube: image‐based observation[J]. Chemical Engineering & Technology, 2011, 34(4): 545-556. |

| 4 | 郑建祥, 许帅, 王京阳, 等. 基于微分代数积分矩量法的聚并器超细颗粒聚团研究[J]. 化工学报, 2017, 68(1): 119-128. |

| ZhengJ X, XuS, WangJ Y, et al. Study on agglomeration of ultrafine particles by agglomerator based on differential algebraic integral moment method[J]. CIESC Journal, 2017, 68(1): 119-128. | |

| 5 | LiH, HongR, WangZ. Fluidizing ultrafine powders with circulating fluidized bed[J]. Chemical Engineering Science, 1999, 54(22): 5609-5615. |

| 6 | IlyasS U, PendyalaR, MarneniN. Dispersion behaviour and agglomeration effects of zinc oxide nanoparticles in ethanol water mixtures[J]. Materials Research Innovations, 2014, 18(suppl.6: 179-183. |

| 7 | WangZ, KwaukM, LiH. Fluidization of fine particles[J]. Chemical Engineering Science, 1998, 53(3): 377-395. |

| 8 | ZhengZ, LiH, ZhuQ, et al. Experimental study and numerical simulation of bubbling fluidized beds with fine particles in two and three dimensions[J]. Industrial & Engineering Chemistry Research, 2013, 52(33): 11302-11312. |

| 9 | ValverdeJ M, CastellanosaA, QuintanillaaM A S, et al. Effect of inclination on gas-fluidized beds of fine cohesive powders[J]. Powder Technology, 2008, 182(3): 398-405. |

| 10 | 郑建祥, 王京阳, 许帅. 聚并器内颗粒聚团数值模拟[J]. 东北电力大学学报, 2017, 37(4): 52-55. |

| ZhengJ X, WangJ Y, XuS. Numerical simulation of particle aggregation in a clusterer[J]. Journal of Northeast Electric Power University, 2017, 37(4): 52-55. | |

| 11 | WangY, ZouZ, LiH, et al. A new drag model for TFM simulation of gas-solid bubbling fluidized beds with Geldart-B particles[J]. Particuology, 2014, 15(4): 151-159. |

| 12 | 刘含笑, 姚宇平, 郦建国. 凝聚器二维单扰流柱流场中颗粒凝并模拟[J]. 动力工程学报, 2015, 35(4): 292-297. |

| LiuH X, YaoY P, LiJ G. Simulation of particle coagulation in two-dimensional single spoiler flow field of condenser[J]. Journal of Power Engineering, 2015, 35(4): 292-297. | |

| 13 | 刘岑凡, 张楠, 王维. 鼓泡床中基于气泡结构的多相反应模型[J]. 化工学报, 2018, 69(5): 2057-2062. |

| LiuC F, ZhangN, WangW. Multiphase reaction model based on bubble structure in bubbling beds[J]. CIESC Journal, 2018, 69(5): 2057-2062. | |

| 14 | 吕小林. 基于气泡和聚团的结构模型及其应用[J]. 化工进展, 2017, 36: 72. |

| LüX L. Structural model based on bubbles and agglomeration and its application[J]. Chemical Industry and Engineering Progress, 2017, 36: 72. | |

| 15 | 宋素芳, 郝振华, 董立波, 等. bubble-based EMMS/PFB模型的建立及在加压流化床浓相段的应用[J]. 化工学报, 2017, 68(8): 46-53. |

| SongS F, HaoZ H, DongL B, et al. Establishment of bubble-based EMMS/PFB model and its application in pressurized fluidized bed dense phase section[J]. CIESC Journal, 2017, 68(8): 46-53. | |

| 16 | XuC, ZhuJ. Experimental and theoretical study on the agglomeration arising from fluidization of cohesive particles—effects of mechanical vibration[J]. Chemical Engineering Science, 2005, 60(23): 6529-6541. |

| 17 | TaoZ, LiH. Force balance modelling for agglomerating fluidization of cohesive particles[J]. Powder Technology, 2000, 111(1): 60-65. |

| 18 | WangL, MarchisioD L, VigilR D, et al. CFD simulation of aggregation and breakage processes in laminar Taylor-Couette flow[J]. Journal of Colloid & Interface Science, 2005, 282(2): 380-396. |

| 19 | MarchisioD L, VigilR D, FoxR O. Quadrature method of moments for aggregation-breakage processes[J]. J. Colloid Interface Sci., 2003, 258(2): 322-334. |

| 20 | PinskyM, KhainA, ShapiroM. Collisions of small drops in a turbulent flow (I): Collision efficiency. Problem formulation and preliminary results[J]. Journal of the Atmospheric Sciences, 1997, 56(15): 2585-2600. |

| 21 | CameronI T, WangF Y, ImmanuelC D, et al. Process systems modelling and applications in granulation: a review[J]. Chemical Engineering Science, 2005, 60(14): 3723-3750. |

| 22 | SunJ, BattagliaF. Hydrodynamic modeling of particle rotation for segregation in bubbling gas-fluidized beds[J]. Chemical Engineering Science, 2006, 61(5): 1470-1479. |

| 23 | SongS, LuS, ZhangY, et al. Aggregation rate of fine particles in turbulent flows[J]. Journal of Dispersion Science and Technology, 2004, 25(1): 8. |

| 24 | LuG, ThirdJ R, MüllerC R. Effect of wall rougheners on cross-sectional flow characteristics for non-spherical particles in a horizontal rotating cylinder[J]. Particuology, 2014, 12(1): 44-53. |

| 25 | MartínL D, FabreA, OmmenJ R V. The fractal scaling of fluidized nanoparticle agglomerates[J]. Chemical Engineering Science, 2014, 112(12): 79-86. |

| 26 | NamC H, PfefferR, DaveR N, et al. Aerated vibrofluidization of silica nanoparticles[J]. AIChE Journal, 2004, 50(8): 1776-1785. |

| 27 | ValverdeJ M, CastellanosA. Fluidization of nanoparticles: a modified Richardson‐Zaki Law[J]. AIChE Journal, 2010, 52(2): 838-842. |

| 28 | 章鹏飞, 米建春, 潘祖明. 装置元件排列间距和颗粒浓度对细颗粒湍流聚并的影响[J]. 中国电机工程学报, 2016, 36(6): 1625-1632. |

| ZhangP F, MiJ C, PanZ M. Influences of elemental arrangement and particle concentration on fine particle amalgamation[J]. Proceedings of the CSEE, 2016, 36(6): 1625-1632. | |

| 29 | 杨岳. 基于雷诺时均NS方程的船体绕流数值研究[D]. 大连: 大连海事大学, 2016. |

| YangY. Numerical study of hull flow around the Reynolds time-averaged NS equation [D]. Dalian : Dalian Maritime University, 2016. | |

| 30 | 郑建祥, 王京阳, 李玉凯, 等. 基于修正的颗粒动理学模型超细颗粒聚团流动模拟研究[J]. 热能动力工程, 2019, 34(2): 117-123. |

| ZhengJ X, WangJ Y, LiY K, et al. Simulation of ultrafine particle agglomeration flow based on modified particle kinetic model[J]. Thermal Energy Engineering, 2019, 34(2): 117-123. | |

| 31 | AhujaG N, PatwardhanA W. CFD and experimental studies of solids hold-up distribution and circulation patterns in gas-solid fluidized beds[J]. Chemical Engineering Journal, 2008, 143(1/2/3): 147-160. |

| 32 | EinsteinA. Investigation on the Theory of the Brownian Movement[M]. New York: Dover,1956. |

| 33 | ParkS H, LeeK W, OttoE, et al. The log-normal size distribution theory of Brownian agglomeration for the entire particle size range[J]. Journal of Aerosol Science, 1997, 28(28): S23-S24. |

| 34 | TanH S, GoldschmidtM J V, BoerefijnR, et al. Building population balance model for fluidized bed melt granulation: lessons from kinetic theory of granular flow[J]. Powder Technology, 2004, 142(2): 103-109. |

| 35 | GengJ, ParkH, SajoE. Simulation of aerosol coagulation and deposition under multiple flow regimes with arbitrary computational precision[J]. Aerosol Science & Technology, 2013, 47(5): 530-542. |

| 36 | GoldsteinR. Fluid Mechanics Measurements [M]. 2nd Ed. Boca Raton: CRC Press, 1996: 80-96. |

| 37 | SaffmanP G, TurnerJ S. On the collision of drops in turbulent clouds[J]. Journal of Fluid Mechanics, 1956, 1(1): 16. |

| [1] | 刘道银, 陈柄岐, 张祖扬, 吴琰. 颗粒聚团结构对曳力特性影响的数值模拟[J]. 化工学报, 2023, 74(6): 2351-2362. |

| [2] | 牛犁, 刘梦溪, 王海北. 密相流化床中介尺度流动结构的流体力学特性研究[J]. 化工学报, 2022, 73(6): 2622-2635. |

| [3] | 石孝刚, 王成秀, 高金森, 蓝兴英. 提升管反应器介尺度结构影响规律的数值模拟研究[J]. 化工学报, 2022, 73(6): 2708-2721. |

| [4] | 管小平, 杨宁. 基于介尺度稳定性条件的多相流曳力与群体平衡模型[J]. 化工学报, 2022, 73(6): 2427-2437. |

| [5] | 辛亚男, 张建文, 张淑珍, 姜爱国. 螺旋内槽管内天然气-水-表面活性剂体系的水合物生成动力学计算[J]. 化工学报, 2018, 69(6): 2463-2473. |

| [6] | 高凯歌, 雷玉庄, 李海念, 周勇. 超细粉在声场导向管喷流床中的聚团尺寸预测模型[J]. 化工学报, 2017, 68(6): 2290-2297. |

| [7] | 郑建祥, 许帅, 王京阳, 史梦燚, 汪龙. 基于微分代数积分矩量法的聚并器超细颗粒聚团研究[J]. 化工学报, 2017, 68(1): 119-128. |

| [8] | 吴迎亚, 彭丽, 和宁宁, 高金森, 蓝兴英. 基于DEM模拟气固循环流化床提升管内颗粒聚团特性[J]. 化工学报, 2016, 67(8): 3321-3330. |

| [9] | 吕林英, 蓝兴英, 吴迎亚, 燕兰玲, 高金森, 徐春明. FCC提升管反应器中颗粒聚团对裂化反应的影响[J]. 化工学报, 2015, 66(8): 2920-2928. |

| [10] | 刘作华, 孙瑞祥, 王运东, 陶长元, 刘仁龙. 刚-柔组合搅拌桨强化流体混沌混合[J]. 化工学报, 2014, 65(9): 3340-3349. |

| [11] | 刘作华, 孙瑞祥, 王运东, 陶长元, 刘仁龙. 刚-柔组合搅拌桨强化流体混沌混合[J]. 化工学报, 2014, 65(9): 0-0. |

| [12] | 王擎,戈建新,贾春霞,许晓飞. 干馏终温对油砂半焦表面特性的影响[J]. 化工进展, 2014, 33(04): 891-895. |

| [13] | 彭鑫, 张雨薇, 王梦凡, 齐崴, 苏荣欣, 何志敏. 酶活性部位柔性的分形分析[J]. 化工学报, 2013, 64(2): 671-675. |

| [14] | 丁程兵,陈迁乔,钟 秦. 三种湍流模型下搅拌釜内气含率特性的模拟[J]. 化工进展, 2013, 32(11): 2569-2573. |

| [15] | 丁云飞, 殷帅, 廖云丹, 吴会军. 纳微结构疏水表面结霜过程及抑霜特性[J]. 化工学报, 2012, 63(10): 3213-3219. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号