化工学报 ›› 2021, Vol. 72 ›› Issue (7): 3801-3813.DOI: 10.11949/0438-1157.20201928

收稿日期:2020-12-28

修回日期:2021-02-05

出版日期:2021-07-05

发布日期:2021-07-05

通讯作者:

李清彪

作者简介:柯蓝婷(1988—),女,博士研究生,基金资助:

KE Lanting1( ),WANG Yuanpeng1,ZHENG Yanmei1,LI Qingbiao1,2(

),WANG Yuanpeng1,ZHENG Yanmei1,LI Qingbiao1,2( )

)

Received:2020-12-28

Revised:2021-02-05

Online:2021-07-05

Published:2021-07-05

Contact:

LI Qingbiao

摘要:

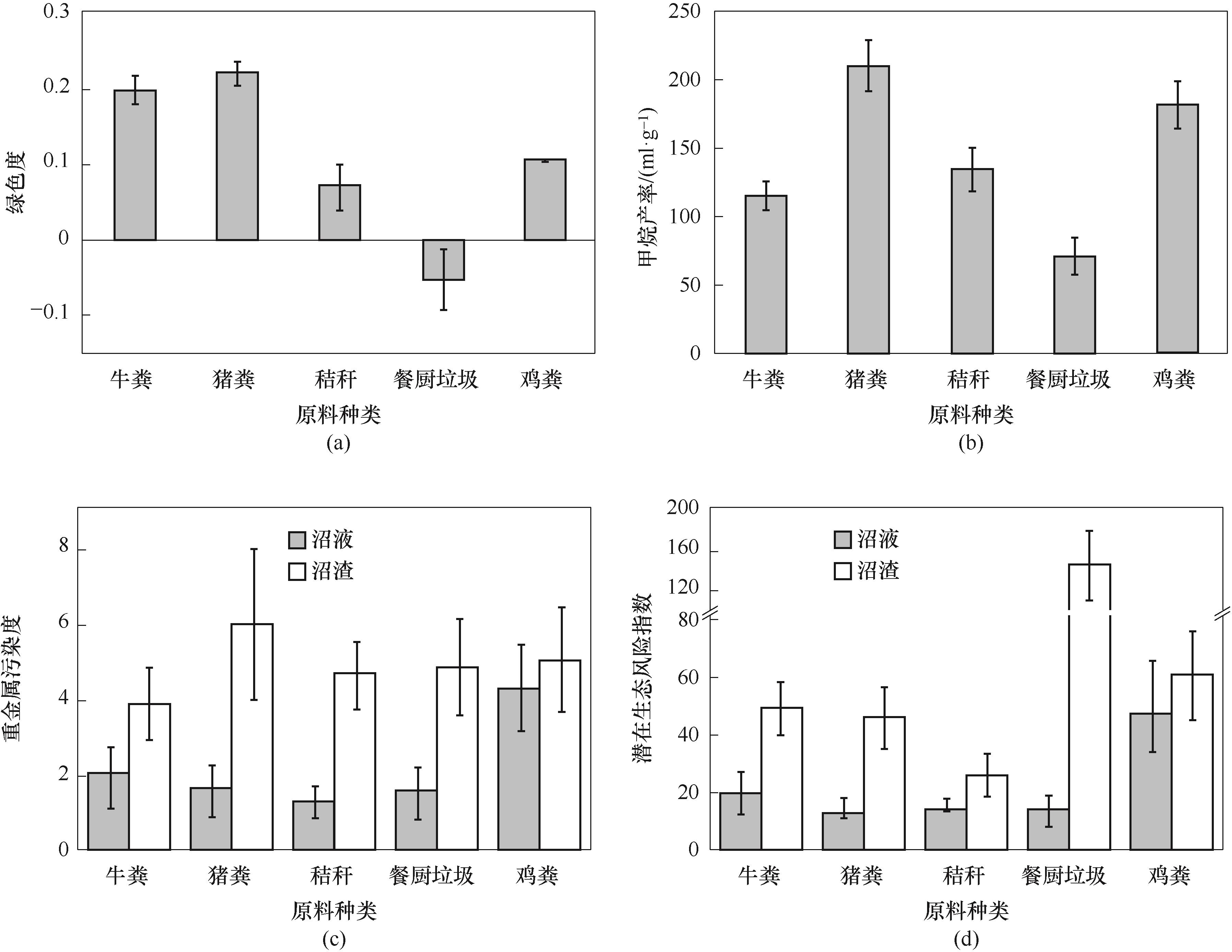

明确生物甲烷过程中原料、沼液和沼渣的组成与系统的综合评价,在优化生物甲烷系统、减少污染物排放等方面都具有重要意义。研究了牛粪、猪粪、秸秆、餐厨垃圾和鸡粪等五种典型原料的生物甲烷系统,分析原料、沼气、沼液和沼渣的组成,并在此基础上构建了包含绿色度、甲烷产率、沼液沼渣的重金属污染度和潜在生态风险四个方面的生物甲烷系统综合评价体系。研究结果表明:猪粪原料的生物甲烷系统绿色度和甲烷产率最高,分别达到0.222和212 ml·g-1,但其沼渣的重金属污染度最高;牛粪原料的生物甲烷系统绿色度较高,达到0.200,沼渣的重金属污染度最低,但甲烷产率仅有116 ml·g-1;秸秆原料的生物甲烷系统沼渣的潜在生态风险最低,沼液的重金属污染度和潜在生态风险较低,但绿色度和甲烷产率偏低;鸡粪原料的生物甲烷系统甲烷产率较高,达到183 ml·g-1,但沼液的重金属污染度和潜在生态风险都最高,且绿色度较低;餐厨垃圾原料的生物甲烷系统性能最差,绿色度和甲烷产率最低,并且沼渣的潜在生态风险最高。

中图分类号:

柯蓝婷, 王远鹏, 郑艳梅, 李清彪. 生物甲烷系统的组分分析与综合评价[J]. 化工学报, 2021, 72(7): 3801-3813.

KE Lanting, WANG Yuanpeng, ZHENG Yanmei, LI Qingbiao. Component analysis and comprehensive evaluation of biomethane systems[J]. CIESC Journal, 2021, 72(7): 3801-3813.

| 重金属 | |||

|---|---|---|---|

| As | 10 | 10 | 15 |

| Cd | 30 | 5 | 1.0 |

| Cr | 2 | 50 | 90 |

| Cu | 5 | 1000 | 50 |

| Hg | 40 | 1 | 0.25 |

| Pb | 5 | 10 | 70 |

| Zn | 1 | 1000 | 175 |

表1 重金属生物毒性系数Tri和背景参考值CRi

Table 1 Toxic response factors and background reference level of heavy metals

| 重金属 | |||

|---|---|---|---|

| As | 10 | 10 | 15 |

| Cd | 30 | 5 | 1.0 |

| Cr | 2 | 50 | 90 |

| Cu | 5 | 1000 | 50 |

| Hg | 40 | 1 | 0.25 |

| Pb | 5 | 10 | 70 |

| Zn | 1 | 1000 | 175 |

| 组分 | ||

|---|---|---|

| As | 0.5 | 40 |

| Cd | 0.1 | 1.0 |

| Cr | 1.5 | 300 |

| Cu | 2 | 400 |

| Hg | 0.05 | 1.5 |

| Pb | 1 | 500 |

| Zn | 5 | 500 |

| COD | 500 | — |

| NH4+-N | 25 | — |

| PO43- | 1 | — |

表2 生物甲烷系统中各组分的背景参考值ciR

Table 2 Background reference level of component in biomethane system

| 组分 | ||

|---|---|---|

| As | 0.5 | 40 |

| Cd | 0.1 | 1.0 |

| Cr | 1.5 | 300 |

| Cu | 2 | 400 |

| Hg | 0.05 | 1.5 |

| Pb | 1 | 500 |

| Zn | 5 | 500 |

| COD | 500 | — |

| NH4+-N | 25 | — |

| PO43- | 1 | — |

| 运行参数 | 牛粪 | 猪粪 | 秸秆 | 餐厨垃圾 | 鸡粪 |

|---|---|---|---|---|---|

| 原料质量/g | 22.30 | 24.81 | 5.20 | 22.19 | 23.32 |

| TS含量/% | 28.14 | 25.01 | 92.03 | 20.67 | 25.16 |

| VS含量/% | 17.94 | 16.12 | 76.85 | 18.03 | 17.15 |

| 初始TS质量/g | 6.28 | 6.20 | 4.79 | 4.59 | 5.87 |

| 初始VS质量/g | 4.00 | 4.00 | 4.00 | 4.00 | 4.00 |

| 反应后TS质量/g | 3.51 | 3.03 | 2.82 | 2.69 | 3.05 |

| TS移除率/% | 44.11 | 51.13 | 41.13 | 41.39 | 48.04 |

| 反应体积/L | 0.20 | 0.20 | 0.20 | 0.20 | 0.20 |

表3 五种原料生物甲烷系统的基本运行情况

Table 3 Basic parameters of biomethane systems from five substrates

| 运行参数 | 牛粪 | 猪粪 | 秸秆 | 餐厨垃圾 | 鸡粪 |

|---|---|---|---|---|---|

| 原料质量/g | 22.30 | 24.81 | 5.20 | 22.19 | 23.32 |

| TS含量/% | 28.14 | 25.01 | 92.03 | 20.67 | 25.16 |

| VS含量/% | 17.94 | 16.12 | 76.85 | 18.03 | 17.15 |

| 初始TS质量/g | 6.28 | 6.20 | 4.79 | 4.59 | 5.87 |

| 初始VS质量/g | 4.00 | 4.00 | 4.00 | 4.00 | 4.00 |

| 反应后TS质量/g | 3.51 | 3.03 | 2.82 | 2.69 | 3.05 |

| TS移除率/% | 44.11 | 51.13 | 41.13 | 41.39 | 48.04 |

| 反应体积/L | 0.20 | 0.20 | 0.20 | 0.20 | 0.20 |

图3 五种典型生物质原料生物甲烷系统沼液的COD(a)、多糖(b)、氨氮(c)和磷酸根浓度(d)

Fig.3 COD (a), polysaccharide (b), NH4+-N (c) and PO43- (d) concentration of slurry from biomethane systems of five substrates

图4 五种原料生物甲烷系统的原料及沼渣中可溶性组分、半纤维素、纤维素、木质素和灰分含量

Fig.4 Solute, hemicellulose, cellulose, lignin and ash content of raw material and residue from biomethane systems of five substrates

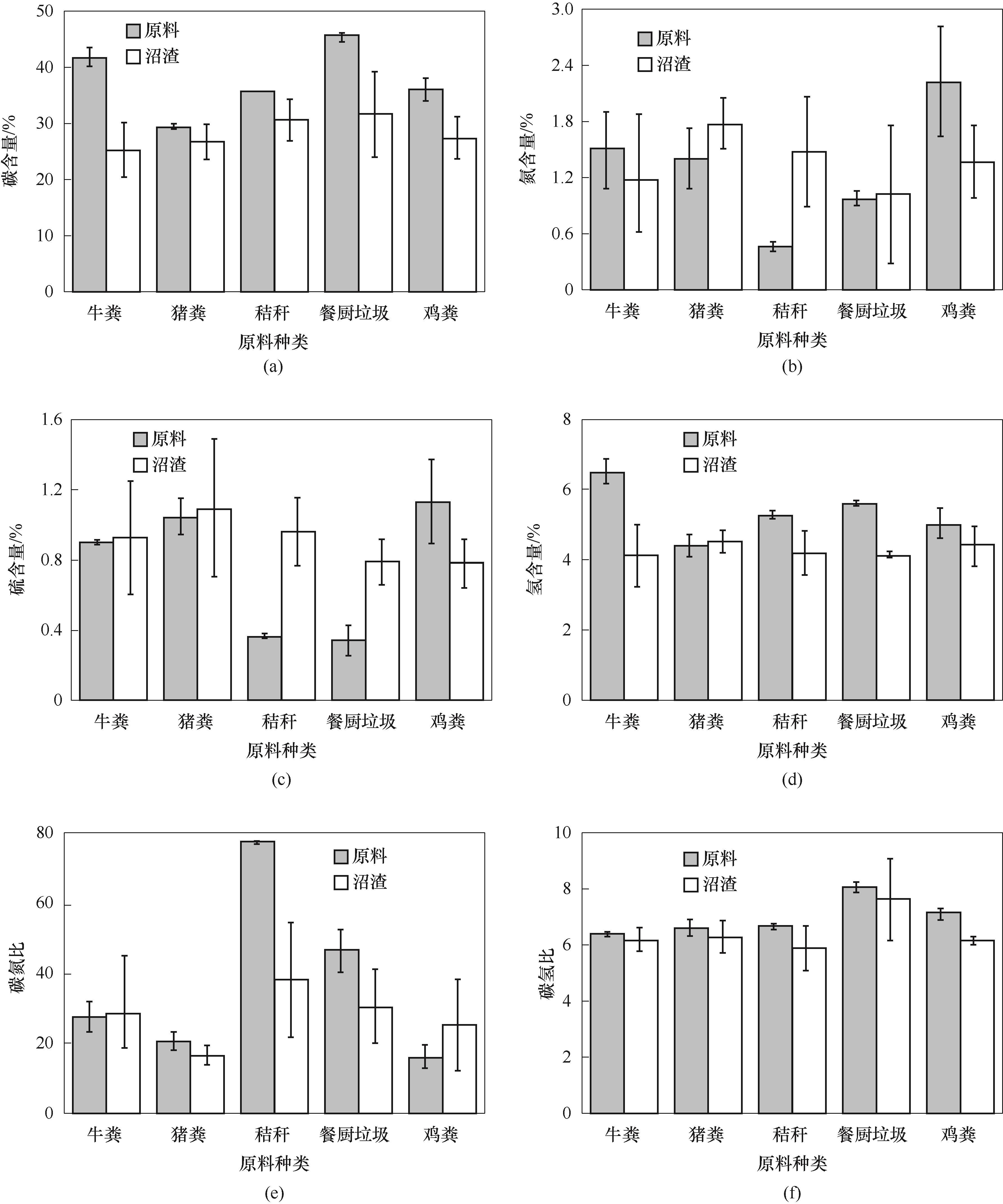

图5 五种原料生物甲烷系统原料和沼渣中碳含量(a)、氮含量(b)、硫含量(c)、氢含量(d)、碳氮比(e)和碳氢比(f)

Fig.5 C content (a), N content (b), S content (c), H content (d), C∶N (e) and C∶H (f) of raw material and residue from biomethane systems of five substrates

| 重金属种类 | 浓度分布 | 牛粪 | 猪粪 | 秸秆 | 餐厨垃圾 | 鸡粪 |

|---|---|---|---|---|---|---|

| As | 原料浓度/(mg·kg-1) | 0.516±0.061 | 0.773±0.088 | 0.412±0.056 | 0.498±0.084 | 0.731±0.013 |

| 沼液浓度/(μg·L-1) | 3.460±0.358 | 9.739±0.401 | 3.904±0.258 | 3.848±0.100 | 16.336±0.996 | |

| 沼渣浓度/(mg·kg-1) | 0.617±0.056 | 0.713±0.077 | 0.541±0.023 | 1.003±0.091 | 0.263±0.027 | |

| Cd | 原料浓度/(mg·kg-1) | 0.135±0.004 | 0.287±0.066 | 0.239±0..018 | 0.094±0.008 | 0.201±0.009 |

| 沼液浓度/(μg·L-1) | 0.590±0.029 | 0.332±0.050 | 0.162±0.017 | 0.559±0.057 | 1.106±0.098 | |

| 沼渣浓度/(mg·kg-1) | 0.421±0.050 | 0.278±0.008 | 0.376±0.051 | 0.288±0.062 | 0.478±0.010 | |

| Cr | 原料浓度/(mg·kg-1) | 5.240±0.098 | 10.329±0.935 | 3.049±0.122 | 2.926±0.435 | 1.020±0.313 |

| 沼液浓度/(μg·L-1) | 26.466±4.773 | 15.157±0.589 | 17.052±0.846 | 27.126±0.939 | 54.288±5.010 | |

| 沼渣浓度/(mg·kg-1) | 3.528±0.077 | 6.546±0.883 | 6.927±0.601 | 2.104±0.624 | 3.550±0.269 | |

| Cu | 原料浓度/(mg·kg-1) | 25.427±0.925 | 65.325±6.034 | 36.164±2.090 | 15.185±0.751 | 52.814±5.689 |

| 沼液浓度/(μg·L-1) | 102.554±8.971 | 59.666±6.817 | 28.726±2.851 | 45.549±2.013 | 178.156±8.678 | |

| 沼渣浓度/(mg·kg-1) | 64.140±6.192 | 110.277±8.713 | 71.441±6.191 | 24.857±0.844 | 78.480±4.647 | |

| Hg | 原料浓度/(mg·kg-1) | 0.124±0.019 | 0.059±0.002 | 0.048±0.003 | 0.327±0.057 | 0.028±0.002 |

| 沼液浓度/(μg·L-1) | 0.236±0.008 | 0.004±0.000 | 0.193±0.015 | 0.117±0.007 | 0.506±0.041 | |

| 沼渣浓度/(mg·kg-1) | 0.179±0.009 | 0.146±0.014 | 0.030±0.002 | 0.835±0.053 | 0.228±0.015 | |

| Pb | 原料浓度/(mg·kg-1) | 0.519±0.061 | 0.647±0.084 | 0.419±0.041 | 0.248±0.012 | 0.211±0.040 |

| 沼液浓度/(μg·L-1) | 3.420±0.074 | 1.090±0.082 | 1.736±0.093 | 1.311±0.082 | 1.999±0.080 | |

| 沼渣浓度/(mg·kg-1) | 1.094±0.053 | 0.987±0.069 | 0.734±0.031 | 0.411±0.034 | 0.500±0.039 | |

| Zn | 原料浓度/(mg·kg-1) | 173.933±9.156 | 284.267±18.677 | 238.230±19.560 | 54.942±4.733 | 212.408±11.427 |

| 沼液浓度/(μg·L-1) | 410.492±30.889 | 172.310±5.965 | 154.432±9.269 | 246.271±8.343 | 497.088±28.334 | |

| 沼渣浓度/(mg·kg-1) | 246.751±14.917 | 500.338±47.739 | 463.365±13.419 | 118.443±7.612 | 357.921±20.907 |

表4 五种原料生物甲烷系统的重金属含量

Table 4 Heavy metals content of biomethane systems from five substrates

| 重金属种类 | 浓度分布 | 牛粪 | 猪粪 | 秸秆 | 餐厨垃圾 | 鸡粪 |

|---|---|---|---|---|---|---|

| As | 原料浓度/(mg·kg-1) | 0.516±0.061 | 0.773±0.088 | 0.412±0.056 | 0.498±0.084 | 0.731±0.013 |

| 沼液浓度/(μg·L-1) | 3.460±0.358 | 9.739±0.401 | 3.904±0.258 | 3.848±0.100 | 16.336±0.996 | |

| 沼渣浓度/(mg·kg-1) | 0.617±0.056 | 0.713±0.077 | 0.541±0.023 | 1.003±0.091 | 0.263±0.027 | |

| Cd | 原料浓度/(mg·kg-1) | 0.135±0.004 | 0.287±0.066 | 0.239±0..018 | 0.094±0.008 | 0.201±0.009 |

| 沼液浓度/(μg·L-1) | 0.590±0.029 | 0.332±0.050 | 0.162±0.017 | 0.559±0.057 | 1.106±0.098 | |

| 沼渣浓度/(mg·kg-1) | 0.421±0.050 | 0.278±0.008 | 0.376±0.051 | 0.288±0.062 | 0.478±0.010 | |

| Cr | 原料浓度/(mg·kg-1) | 5.240±0.098 | 10.329±0.935 | 3.049±0.122 | 2.926±0.435 | 1.020±0.313 |

| 沼液浓度/(μg·L-1) | 26.466±4.773 | 15.157±0.589 | 17.052±0.846 | 27.126±0.939 | 54.288±5.010 | |

| 沼渣浓度/(mg·kg-1) | 3.528±0.077 | 6.546±0.883 | 6.927±0.601 | 2.104±0.624 | 3.550±0.269 | |

| Cu | 原料浓度/(mg·kg-1) | 25.427±0.925 | 65.325±6.034 | 36.164±2.090 | 15.185±0.751 | 52.814±5.689 |

| 沼液浓度/(μg·L-1) | 102.554±8.971 | 59.666±6.817 | 28.726±2.851 | 45.549±2.013 | 178.156±8.678 | |

| 沼渣浓度/(mg·kg-1) | 64.140±6.192 | 110.277±8.713 | 71.441±6.191 | 24.857±0.844 | 78.480±4.647 | |

| Hg | 原料浓度/(mg·kg-1) | 0.124±0.019 | 0.059±0.002 | 0.048±0.003 | 0.327±0.057 | 0.028±0.002 |

| 沼液浓度/(μg·L-1) | 0.236±0.008 | 0.004±0.000 | 0.193±0.015 | 0.117±0.007 | 0.506±0.041 | |

| 沼渣浓度/(mg·kg-1) | 0.179±0.009 | 0.146±0.014 | 0.030±0.002 | 0.835±0.053 | 0.228±0.015 | |

| Pb | 原料浓度/(mg·kg-1) | 0.519±0.061 | 0.647±0.084 | 0.419±0.041 | 0.248±0.012 | 0.211±0.040 |

| 沼液浓度/(μg·L-1) | 3.420±0.074 | 1.090±0.082 | 1.736±0.093 | 1.311±0.082 | 1.999±0.080 | |

| 沼渣浓度/(mg·kg-1) | 1.094±0.053 | 0.987±0.069 | 0.734±0.031 | 0.411±0.034 | 0.500±0.039 | |

| Zn | 原料浓度/(mg·kg-1) | 173.933±9.156 | 284.267±18.677 | 238.230±19.560 | 54.942±4.733 | 212.408±11.427 |

| 沼液浓度/(μg·L-1) | 410.492±30.889 | 172.310±5.965 | 154.432±9.269 | 246.271±8.343 | 497.088±28.334 | |

| 沼渣浓度/(mg·kg-1) | 246.751±14.917 | 500.338±47.739 | 463.365±13.419 | 118.443±7.612 | 357.921±20.907 |

图7 五种原料生物甲烷系统绿色度(a)、甲烷产率(b)、沼液沼渣重金属污染度(c)和沼液沼渣潜在生态风险情况(d)

Fig.7 Green degree (a), methane yield (b), contamination degree (c) and risk indices (d) of biomethane systems from five substrates

| Raw materials | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| EUP | ECP | GWP | EUP | ECP | |||||

| Slurry | Residue | Slurry | Residue | ||||||

| CAM | -0.24382 | -0.16872 | -0.00741 | -0.00287 | -0.04395 | -0.05687 | -0.00036 | -0.10063 | 0.20044 |

| SM | -0.20177 | -0.28099 | -0.00603 | -0.00436 | -0.07127 | -0.05886 | -0.00021 | -0.12024 | 0.22180 |

| St | -0.11954 | -0.16757 | -0.00713 | -0.00359 | -0.05011 | -0.05375 | -0.00015 | -0.10172 | 0.07066 |

| KW | -0.15366 | -0.09018 | -0.00805 | -0.00256 | -0.16480 | -0.04585 | -0.00023 | -0.07413 | -0.05178 |

| CHM | -0.24622 | -0.19075 | -0.00644 | -0.00404 | -0.15710 | -0.05133 | -0.00059 | -0.11157 | 0.10590 |

表5 五种原料生物甲烷系统绿色度情况

Table 5 Green degree of biomethane systems from five substrates

| Raw materials | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| EUP | ECP | GWP | EUP | ECP | |||||

| Slurry | Residue | Slurry | Residue | ||||||

| CAM | -0.24382 | -0.16872 | -0.00741 | -0.00287 | -0.04395 | -0.05687 | -0.00036 | -0.10063 | 0.20044 |

| SM | -0.20177 | -0.28099 | -0.00603 | -0.00436 | -0.07127 | -0.05886 | -0.00021 | -0.12024 | 0.22180 |

| St | -0.11954 | -0.16757 | -0.00713 | -0.00359 | -0.05011 | -0.05375 | -0.00015 | -0.10172 | 0.07066 |

| KW | -0.15366 | -0.09018 | -0.00805 | -0.00256 | -0.16480 | -0.04585 | -0.00023 | -0.07413 | -0.05178 |

| CHM | -0.24622 | -0.19075 | -0.00644 | -0.00404 | -0.15710 | -0.05133 | -0.00059 | -0.11157 | 0.10590 |

| 1 | Patinvoh R J, Taherzadeh M J. Challenges of biogas implementation in developing countries[J]. Current Opinion in Environmental Science & Health, 2019, 12: 30-37. |

| 2 | Ferreira S F, Buller L S, Berni M, et al. Environmental impact assessment of end-uses of biomethane[J]. Journal of Cleaner Production, 2019, 230: 613-621. |

| 3 | Xiao Y Q, Yang H N, Yang H, et al. Improved biogas production of dry anaerobic digestion of swine manure[J]. Bioresource Technology, 2019, 294: 122188. |

| 4 | Gu Y, Chen X H, Liu Z G, et al. Effect of inoculum sources on the anaerobic digestion of rice straw[J]. Bioresource Technology, 2014, 158: 149-155. |

| 5 | Zhang T, Yang Y H, Xie D T. Insights into the production potential and trends of China's rural biogas[J]. International Journal of Energy Research, 2015, 39(8): 1068-1082. |

| 6 | Scheutz C, Fredenslund A M. Total methane emission rates and losses from 23 biogas plants[J]. Waste Management, 2019, 97: 38-46. |

| 7 | Wang S L, Jena U, Das K C. Biomethane production potential of slaughterhouse waste in the United States[J]. Energy Conversion and Management, 2018, 173: 143-157. |

| 8 | Scarlat N, Fahl F, Dallemand J F, et al. A spatial analysis of biogas potential from manure in Europe[J]. Renewable and Sustainable Energy Reviews, 2018, 94: 915-930. |

| 9 | Holm-Nielsen J B, Al Seadi T, Oleskowicz-Popiel P. The future of anaerobic digestion and biogas utilization[J]. Bioresource Technology, 2009, 100(22): 5478-5484. |

| 10 | Baena-Moreno F M, Malico I, Rodríguez-Galán M, et al. The importance of governmental incentives for small biomethane plants in South Spain[J]. Energy, 2020, 206: 118158. |

| 11 | Cucchiella F, D'Adamo I, Gastaldi M. An economic analysis of biogas-biomethane chain from animal residues in Italy[J]. Journal of Cleaner Production, 2019, 230: 888-897. |

| 12 | Giwa A S, Ali N, Ahmad I, et al. Prospects of China's biogas: fundamentals, challenges and considerations[J]. Energy Reports, 2020, 6: 2973-2987. |

| 13 | 北极星环保网. 2017年沼气发电市场前景分析: 2020年总量将达440亿立方米 [EB/OL]. [2020-11-29].. |

| Beijixing Environmental Protection Network. Biogas generation prospect analysis: the biogas production will reach 44 billion m3 by 2020 [EB/OL]. [2020-11-29].. | |

| 14 | Li K, Liu R H, Sun C. Comparison of anaerobic digestion characteristics and kinetics of four livestock manures with different substrate concentrations[J]. Bioresource Technology, 2015, 198: 133-140. |

| 15 | Dai X H, Hua Y, Liu R, et al. Biomethane production by typical straw anaerobic digestion: deep insights of material compositions and surface properties[J]. Bioresource Technology, 2020, 313: 123643. |

| 16 | Mao C L, Feng Y Z, Wang X J, et al. Review on research achievements of biogas from anaerobic digestion[J]. Renewable and Sustainable Energy Reviews, 2015, 45: 540-555. |

| 17 | Li H, Chen Z, Fu D, et al. Improved ADM1 for modelling C, N, P fates in anaerobic digestion process of pig manure and optimization approaches to biogas production[J]. Renewable Energy, 2020, 146: 2330-2336. |

| 18 | 武斌, 张香平, 许亚晶, 等. 生物甲烷系统技术评价与集成的研究进展[J]. 化工进展, 2014, 33(7): 1659-1670. |

| Wu B, Zhang X P, Xu Y J, et al. Progress of evaluation and integration of biomethane system[J]. Chemical Industry and Engineering Progress, 2014, 33(7): 1659-1670. | |

| 19 | Mahanty B, Zafar M, Han M J, et al. Optimization of co-digestion of various industrial sludges for biogas production and sludge treatment: methane production potential experiments and modeling[J]. Waste Management, 2014, 34(6): 1018-1024. |

| 20 | Zhang T, Liu L, Song Z, et al. Biogas production by co-digestion of goat manure with three crop residues[J]. PLoS One, 2013, 8(6): e66845. |

| 21 | Fernández-Rodríguez J, Pérez M, Romero L I. Comparison of mesophilic and thermophilic dry anaerobic digestion of OFMSW: kinetic analysis[J]. Chemical Engineering Journal, 2013, 232: 59-64. |

| 22 | Perez M, Romero L I, Sales D. Organic matter degradation kinetics in an anaerobic thermophilic fluidised bed bioreactor[J]. Anaerobe, 2001, 7(1): 25-35. |

| 23 | Li Y Q, Zhang R H, Chen C, et al. Biogas production from co-digestion of corn stover and chicken manure under anaerobic wet, hemi-solid, and solid state conditions[J]. Bioresource Technology, 2013, 149: 406-412. |

| 24 | Akbulut A, Kose R, Akbulut A. Technical and economic assessments of biogas production in a family size digester utilizing different feedstock rotations: Döğer case study[J]. International Journal of Green Energy, 2014, 11(2): 113-128. |

| 25 | Nasr N, Elbeshbishy E, Hafez H, et al. Comparative assessment of single-stage and two-stage anaerobic digestion for the treatment of thin stillage[J]. Bioresource Technology, 2012, 111: 122-126. |

| 26 | Li H L, Lindmark J, Nordlander E, et al. Using the solid digestate from a wet anaerobic digestion process as an energy resource[J]. Energy Technology, 2013, 1(1): 94-101. |

| 27 | Zheng X R, Liu Y Q, Huang J M, et al. The influence of variables on the bioavailability of heavy metals during the anaerobic digestion of swine manure[J]. Ecotoxicology and Environmental Safety, 2020, 195: 110457. |

| 28 | Kuo W C, Sneve M A, Parkin G F. Formation of soluble microbial products during anaerobic treatment[J]. Water Environment Research, 1996, 68(3): 279-285. |

| 29 | Wang Y J, Feng L S, Zhao X S, et al. Characteristics of volatile compounds removal in biogas slurry of pig manure by ozone oxidation and organic solvents extraction[J]. Journal of Environmental Sciences, 2013, 25(9): 1800-1807. |

| 30 | Chen W L, Lin S C, Huang C H, et al. Wide-scope screening for pharmaceutically active substances in a leafy vegetable cultivated under biogas slurry irrigation[J]. Science of the Total Environment, 2021, 750: 141519. |

| 31 | 李祎雯, 曲英华, 徐奕琳, 等. 不同发酵原料沼液的养分含量及变化[J]. 中国沼气, 2012, 30(3): 17-20, 24. |

| Li Y W, Qu Y H, Xu Y L, et al. Change of nutrition contents of biogas slurry with different fermentation raw materials[J]. China Biogas, 2012, 30(3): 17-20, 24. | |

| 32 | 靳红梅, 常志州, 叶小梅, 等. 江苏省大型沼气工程沼液理化特性分析[J]. 农业工程学报, 2011, 27(1): 291-296. |

| Jin H M, Chang Z Z, Ye X M, et al. Physical and chemical characteristics of anaerobically digested slurry from large-scale biogas project in Jiangsu Province[J]. Transactions of the Chinese Society of Agricultural Engineering, 2011, 27(1): 291-296. | |

| 33 | 柯蓝婷, 王海涛, 王远鹏, 等. 不同来源家庭户用沼气池沼液成分分析及风险评价[J]. 化工学报, 2014, 65(5): 1840-1847. |

| Ke L T, Wang H T, Wang Y P, et al. Component analysis and risk assessment of anaerobically digested slurry from households in China[J]. CIESC Journal, 2014, 65(5): 1840-1847. | |

| 34 | 国家环境保护总局. 水和废水监测分析方法[M]. 4版. 北京: 中国环境出版社, 2002. |

| State Environmental Protection Administration. Water and Wastewater Monitoring and Analysis Methods[M]. 4th ed. Beijing: China Environmental Science Press, 2002. | |

| 35 | Hakanson L. An ecological risk index for aquatic pollution control: a sedimentological approach[J]. Water Research, 1980, 14(8): 975-1001. |

| 36 | Zhang X P, Li C S, Fu C, et al. Environmental impact assessment of chemical process using the green degree method[J]. Industrial & Engineering Chemistry Research, 2008, 47(4): 1085-1094. |

| 37 | Yan R Y, Li Z X, Diao Y Y, et al. Green process for methacrolein separation with ionic liquids in the production of methyl methacrylate[J]. AIChE Journal, 2011, 57(9): 2388-2396. |

| 38 | 付超, 张香平, 闫瑞一, 等. 绿色度方法中环境影响因子权值的确定[J]. 计算机与应用化学, 2008, 25(9): 1068-1074. |

| Fu C, Zhang X P, Yan R Y, et al. Weighting factors of environmental impact categories in green degree method[J]. Computers and Applied Chemistry, 2008, 25(9): 1068-1074. | |

| 39 | 邢赜. 沼液营养物的沸石吸附回收与利用[D]. 重庆: 西南大学, 2013. |

| Xing Z. Adsorption and its utilization of nutrient from biogas slurry by zeolite[D]. Chongqing: Southwest University, 2013. | |

| 40 | 李恒, 柯蓝婷, 王海涛, 等. 低劣生物质厌氧产甲烷过程的模拟研究进展[J]. 化工学报, 2014, 65(5): 1577-1586. |

| Li H, Ke L T, Wang H T, et al. Simulation research on anaerobic digestion biogas generation from low-grade biomass[J]. CIESC Journal, 2014, 65(5): 1577-1586. | |

| 41 | Labatut R A, Angenent L T, Scott N R. Biochemical methane potential and biodegradability of complex organic substrates[J]. Bioresource Technology, 2011, 102(3): 2255-2264. |

| 42 | Triolo J M, Sommer S G, Møller H B, et al. A new algorithm to characterize biodegradability of biomass during anaerobic digestion: influence of lignin concentration on methane production potential[J]. Bioresource Technology, 2011, 102(20): 9395-9402. |

| 43 | Li W W, Khalid H, Amin F R, et al. Biomethane production characteristics, kinetic analysis, and energy potential of different paper wastes in anaerobic digestion[J]. Renewable Energy, 2020, 157: 1081-1088. |

| 44 | Li H, Tan F, Ke L T, et al. Mass balances and distributions of C, N, and P in the anaerobic digestion of different substrates and relationships between products and substrates[J]. Chemical Engineering Journal, 2016, 287: 329-336. |

| [1] | 康飞, 吕伟光, 巨锋, 孙峙. 废锂离子电池放电路径与评价研究[J]. 化工学报, 2023, 74(9): 3903-3911. |

| [2] | 党玉荣, 莫春兰, 史科锐, 方颖聪, 张子杨, 李作顺. 综合评价模型联合遗传算法的混合工质ORC系统性能研究[J]. 化工学报, 2023, 74(5): 1884-1895. |

| [3] | 陈瑞哲, 程磊磊, 顾菁, 袁浩然, 陈勇. 纤维增强树脂复合材料化学回收技术研究进展[J]. 化工学报, 2023, 74(3): 981-994. |

| [4] | 叶茂林, 谭烽华, 李宇萍, 廖玉河, 王晨光, 马隆龙. 农林废弃物气化合成混合醇生命周期环境影响分析[J]. 化工学报, 2022, 73(3): 1369-1378. |

| [5] | 朱振林, 王松林, 姜冰雪, 李家旭, 邓维, 吴海强, 杨轩, 刘平伟, 王文俊. 聚酯生物降解及评价方法研究[J]. 化工学报, 2022, 73(1): 110-121. |

| [6] | 吴延鹏, 栾珊珊, 苏伟, 邢奕, 钱付平. 钢铁厂原料堆粉尘无组织排放抑制技术进展[J]. 化工学报, 2021, 72(S1): 53-62. |

| [7] | 张溪,张立龙,李瑞,吴玉龙. 基于能量集成的秸秆生物质快速热解生命周期评价[J]. 化工学报, 2021, 72(5): 2792-2800. |

| [8] | 贾小平, 石磊, 杨友麒. 工业园区生态化发展的挑战与过程系统工程的机遇[J]. 化工学报, 2021, 72(5): 2373-2391. |

| [9] | 叶珍珍, 陈鑫祺, 汪剑, 李博凡, 崔超婕, 张刚, 钱陆明, 金鹰, 骞伟中. 离子液体型超级电容器软包高温老化性能评测研究[J]. 化工学报, 2021, 72(12): 6351-6360. |

| [10] | 刘秀峰, 张诗, 周志杰, 郑浩, 王成泽, 时红远, 李梦杰. 换热器结构优化与换热性能评价指标研究[J]. 化工学报, 2020, 71(S1): 98-105. |

| [11] | 赵文英, 李文文, 孙晓岩, 曹晓荣, 项曙光. 基于PR立方型状态方程普遍化温度函数的研究与评价[J]. 化工学报, 2020, 71(3): 1234-1245. |

| [12] | 乔俊飞, 贺增增, 杜胜利. 基于混合评价指标的自组织模糊神经网络设计研究[J]. 化工学报, 2019, 70(7): 2606-2615. |

| [13] | 罗琳, 杨博, 李宏光. 基于动态多属性决策方法的工业过程控制性能评价[J]. 化工学报, 2018, 69(S1): 87-94. |

| [14] | 常圣强, 李望良, 张晓宇, 马力强, 鲁长波, 安高军. 生物质气化发电技术研究进展[J]. 化工学报, 2018, 69(8): 3318-3330. |

| [15] | 史策, 虞骥, 高栋, 王海彬, 姚善泾, 林东强. 单抗制备的过程模拟和经济性分析[J]. 化工学报, 2018, 69(7): 3198-3207. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号