化工学报 ›› 2022, Vol. 73 ›› Issue (7): 3068-3077.DOI: 10.11949/0438-1157.20220464

王立维1( ),王娟娟1,王永洪1,2,张新儒1,2(

),王娟娟1,王永洪1,2,张新儒1,2( ),李晋平1,2(

),李晋平1,2( )

)

收稿日期:2022-03-31

修回日期:2022-05-08

出版日期:2022-07-05

发布日期:2022-08-01

通讯作者:

张新儒,李晋平

作者简介:王立维(1997—),男,硕士研究生,基金资助:

Liwei WANG1( ),Juanjuan WANG1,Yonghong WANG1,2,Xinru ZHANG1,2(

),Juanjuan WANG1,Yonghong WANG1,2,Xinru ZHANG1,2( ),Jinping LI1,2(

),Jinping LI1,2( )

)

Received:2022-03-31

Revised:2022-05-08

Online:2022-07-05

Published:2022-08-01

Contact:

Xinru ZHANG,Jinping LI

摘要:

采用阳离子交换与Cu3(BTC)2原位合成相结合制备Cu3(BTC)2-MMT,同时,借助3-氨基丙基三乙氧基硅烷(KH550)氨基功能化制备Cu3(BTC)2-MMT-NH2杂化材料。然后,将杂化材料添加到聚乙烯胺(PVAm)基质中作为选择性涂层涂覆到聚砜(PSf)支撑体上,制备了PVAm/Cu3(BTC)2-MMT-NH2混合基质膜。通过XRD和FTIR对杂化材料的晶态结构和化学结构进行了表征,同时采用ATR-FTIR证实了Cu3(BTC)2-MMT-NH2杂化材料与PVAm基质之间存在氢键相互作用。系统性研究了PVAm/Cu3(BTC)2-MMT-NH2混合基质膜中MMT阳离子交换量、Cu3(BTC)2-MMT与KH550的质量比、Cu3(BTC)2-MMT-NH2的负载量、操作压力、湿膜厚度、操作温度以及混合气作为原料气对膜CO2渗透性、CO2/N2选择性的影响。结果表明:在纯气气氛,操作温度为25℃、操作压力为1 bar(1 bar=0.1 MPa)的条件下,当Cu3(BTC)2-MMT-NH2负载量为3%(质量)时,膜的气体分离性能最优,CO2渗透率为203 GPU(1GPU=10-6 cm3·cm-2·s-1·cmHg-1,1 cmHg=1333.22 Pa),CO2/N2选择性为100.7,远高于添加MMT、Cu3(BTC)2和MMT/Cu3(BTC)2混合物的混合基质膜。这是由于Cu3(BTC)2-MMT-NH2具有层间快速传递通道且与聚合物基质有良好的相容性。此外,混合气测试条件下,混合基质膜运行360 h,仍能保持优异的CO2分离性能稳定性。

中图分类号:

王立维, 王娟娟, 王永洪, 张新儒, 李晋平. 聚乙烯胺/Cu3(BTC)2-MMT-NH2混合基质膜的制备及气体传递性能[J]. 化工学报, 2022, 73(7): 3068-3077.

Liwei WANG, Juanjuan WANG, Yonghong WANG, Xinru ZHANG, Jinping LI. Gas transport properties of PVAm-based mixed matrix membranes by incorporating with Cu3(BTC)2-MMT-NH2[J]. CIESC Journal, 2022, 73(7): 3068-3077.

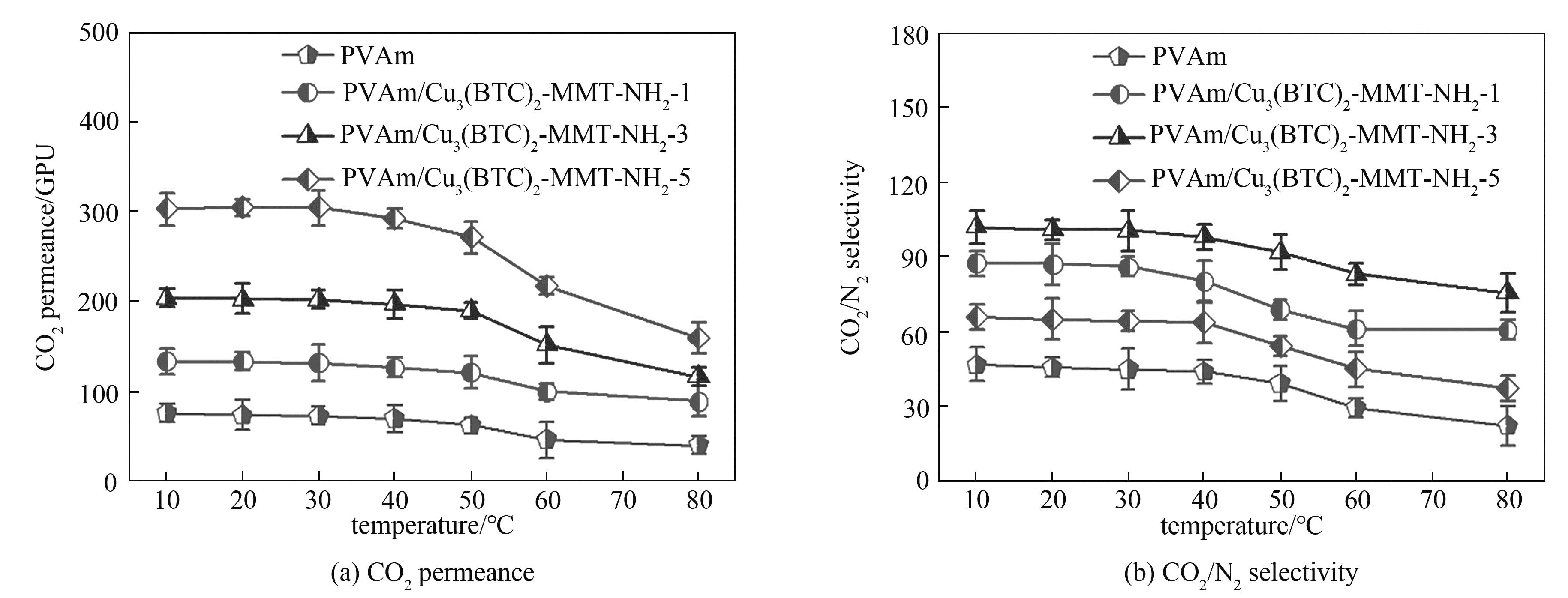

图11 操作温度对PVAm纯膜和混合基质膜CO2渗透率(a)与CO2/N2选择性(b)的影响

Fig.11 Effect of the operating temperature on the CO2 permeance (a) and the CO2/N2 selectivity (b) of the PVAm pure membrane and MMMs

图13 不同填料(负载量:3%(质量))对混合基质膜气体分离性能的影响(a);不同填料含量对混合基质膜的气体分离性能的CO2渗透率(b)和CO2/N2选择性(c)的影响

Fig.13 Gas separation performance of MMMs with different fillers (loading: 3% (mass)) (a); The effects of different filler loadings on CO2 permeance (b) and CO2/N2 selectivity (c) of MMMs gas separation performance

| 1 | Rogelj J, Huppmann D, Krey V, et al. A new scenario logic for the Paris Agreement long-term temperature goal[J]. Nature, 2019, 573(7774): 357-363. |

| 2 | Li Z Y, Zhao T, Wang J, et al. Two-step allocation of CO2 emission quotas in China based on multi-principles: going regional to provincial[J]. Journal of Cleaner Production, 2021, 305: 127173. |

| 3 | Gao W L, Liang S Y, Wang R J, et al. Industrial carbon dioxide capture and utilization: state of the art and future challenges[J]. Chemical Society Reviews, 2020, 49(23): 8584-8686. |

| 4 | Shi H T, Chai J, Lu Q Y, et al. The impact of China’s low-carbon transition on economy, society and energy in 2030 based on CO2 emissions drivers[J]. Energy, 2022, 239: 122336. |

| 5 | Zhao L, Riensche E, Blum L, et al. Multi-stage gas separation membrane processes used in post-combustion capture: energetic and economic analyses[J]. Journal of Membrane Science, 2010, 359(1/2): 160-172. |

| 6 | Yong D. Perspective on gas separation membrane materials from process economics point of view[J]. Industrial & Engineering Chemistry Research, 2020, 59(2): 556-568. |

| 7 | Comesaña-Gándara B, Chen J, Bezzu C G, et al. Redefining the Robeson upper bounds for CO2/CH4 and CO2/N2 separations using a series of ultrapermeable benzotriptycene-based polymers of intrinsic microporosity[J]. Energy & Environmental Science, 2019, 12(9): 2733-2740. |

| 8 | Zhao H Y, Xie Q, Ding X L, et al. Advanced mixed matrix membranes of Pebax embedded with amino acid ionic liquids@PIM core-shell composite nanoparticles for CO2 separation[J]. Separation and Purification Technology, 2021, 263: 118350. |

| 9 | Molavi H, Shojaei A. Mixed-matrix composite membranes based on UiO-66-derived MOFs for CO2 separation[J]. ACS Applied Materials & Interfaces, 2019, 11(9): 9448-9461. |

| 10 | Jamil A, Oh P C, Shariff A M. Polyetherimide-montmorillonite mixed matrix hollow fibre membranes: effect of inorganic/organic montmorillonite on CO2/CH4 separation[J]. Separation and Purification Technology, 2018, 206: 256-267. |

| 11 | Zhang Y Y, Feng X, Yuan S, et al. Challenges and recent advances in MOF-polymer composite membranes for gas separation[J]. Inorganic Chemistry Frontiers, 2016, 3(7): 896-909. |

| 12 | Jia M M, Feng Y, Qiu J H, et al. Amine-functionalized MOFs@GO as filler in mixed matrix membrane for selective CO2 separation[J]. Separation and Purification Technology, 2019, 213: 63-69. |

| 13 | Chui S S, Lo S M, Charmant J P, et al. A chemically functionalizable nanoporous material[J]. Science, 1999, 283(5405): 1148-1150. |

| 14 | Dong J Q, Zhou W R, Su Y H, et al. Enhanced mechanical, thermal, and barrier properties of poly (3-hydroxybutyrate-co-3-hydroxyhexanoate)/montmorillonite nanocomposites using silane coupling agent[J]. Polymer Composites, 2020, 41(11): 4538-4549. |

| 15 | Wang Y H, Li L, Zhang X R, et al. Polyvinylamine/graphene oxide/PANI@CNTs mixed matrix composite membranes with enhanced CO2/N2 separation performance[J]. Journal of Membrane Science, 2019, 589: 117246. |

| 16 | Dong L L, Zhang C F, Bai Y X, et al. High-performance PEBA2533-functional MMT mixed matrix membrane containing high-speed facilitated transport channels for CO2/N2 separation[J]. ACS Sustainable Chemistry & Engineering, 2016, 4(6): 3486-3496. |

| 17 | Al-Janabi N, Hill P, Torrente-Murciano L, et al. Mapping the Cu-BTC metal-organic framework (HKUST-1) stability envelope in the presence of water vapour for CO2 adsorption from flue gases[J]. Chemical Engineering Journal, 2015, 281(1): 669-677. |

| 18 | Zhang C, Liao P Y, Wang H, et al. Preparation of novel bimetallic CuZn-BTC coordination polymer nanorod for methanol synthesis from CO2 hydrogenation[J]. Materials Chemistry and Physics, 2018, 215: 211-220. |

| 19 | Xu R, Wang Z, Wang M, et al. High nanoparticles loadings mixed matrix membranes via chemical bridging-crosslinking for CO2 separation[J]. Journal of Membrane Science, 2019, 573: 455-464. |

| 20 | Xu S S, Huang H L, Guo X Y, et al. Highly selective gas transport channels in mixed matrix membranes fabricated by using water-stable Cu-BTC[J]. Separation and Purification Technology, 2021, 257: 117979. |

| 21 | Wang M, Wang Z, Li N, et al. Relationship between polymer-filler interfaces in separation layers and gas transport properties of mixed matrix composite membranes[J]. Journal of Membrane Science, 2015, 495: 252-268. |

| 22 | Liu N, Cheng J, Hou W, et al. Pebax-based mixed matrix membranes loaded with graphene oxide/core shell ZIF-8@ZIF-67 nanocomposites improved CO2 permeability and selectivity[J]. Journal of Applied Polymer Science, 2021, 138(23): 50553. |

| 23 | Yuan Y, Qiao Z H, Xu J Y, et al. Mixed matrix membranes for CO2 separations by incorporating microporous polymer framework fillers with amine-rich nanochannels[J]. Journal of Membrane Science, 2021, 620: 118923. |

| 24 | Gao Y Q, Qiao Z H, Zhao S, et al. In situ synthesis of polymer grafted ZIFs and application in mixed matrix membrane for CO2 separation[J]. Journal of Materials Chemistry A, 2018, 6(7): 3151-3161. |

| 25 | Liao J Y, Wang Z, Gao C Y, et al. A high performance PVAm-HT membrane containing high-speed facilitated transport channels for CO2 separation[J]. Journal of Materials Chemistry A, 2015, 3(32): 16746-16761. |

| 26 | Deng L Y, Kim T J, Hägg M B. Facilitated transport of CO2 in novel PVAm/PVA blend membrane[J]. Journal of Membrane Science, 2009, 340(1/2): 154-163. |

| 27 | Zhao S, Cao X C, Ma Z J, et al. Mixed-matrix membranes for CO2/N2 separation comprising a poly(vinylamine) matrix and metal-organic frameworks[J]. Industrial & Engineering Chemistry Research, 2015, 54(18): 5139-5148. |

| 28 | Vakharia V, Salim W, Wu D Z, et al. Scale-up of amine-containing thin-film composite membranes for CO2 capture from flue gas[J]. Journal of Membrane Science, 2018, 555: 379-387. |

| 29 | He Y P, Wang Z, Dong S L, et al. Polymeric composite membrane fabricated by 2-aminoterephthalic acid chemically cross-linked polyvinylamine for CO2 separation under high temperature[J]. Journal of Membrane Science, 2016, 518: 60-71. |

| 30 | Wang Y H, Li L, Zhang X R, et al. Polyvinylamine/amorphous metakaolin mixed-matrix composite membranes with facilitated transport carriers for highly efficient CO2/N2 separation[J]. Journal of Membrane Science, 2020, 599: 117828. |

| [1] | 裴仁花, 王永洪, 张新儒, 李晋平. 碳纳米管/环糊精金属有机骨架协同强化混合基质膜的CO2分离[J]. 化工学报, 2022, 73(9): 3904-3914. |

| [2] | 于喆淼, 王志, 生梦龙, 邢广宇, 王纪孝. 界面聚合法制备用于脱氮提纯CH4的N2优先渗透ZIF-90/聚酰胺混合基质膜[J]. 化工学报, 2022, 73(7): 3273-3286. |

| [3] | 毛恒, 王月, 王森, 刘伟民, 吕静, 陈甫雪, 赵之平. APTES改性ZIF-L/PEBA混合基质膜强化渗透汽化分离苯酚研究[J]. 化工学报, 2022, 73(3): 1389-1402. |

| [4] | 靳卓, 王永洪, 张新儒, 白雪, 李晋平. Pebax/a-MoS2/MIP-202混合基质膜的制备及CO2分离性能[J]. 化工学报, 2022, 73(10): 4527-4538. |

| [5] | 张照曦,钟梅,李建,亚力昆江?吐尔逊. 改性蒙脱土对新疆和丰煤热解行为的影响[J]. 化工学报, 2022, 73(1): 402-410. |

| [6] | 王艳芳,毛恒,蔡玮玮,张傲率,徐李昊,赵之平. ZIF-L/PDMS混合基质膜蒸气渗透耦合发酵强化乙醇生产效率的研究[J]. 化工学报, 2021, 72(10): 5226-5236. |

| [7] | 周毅,王永洪,张新儒,李晋平. PEBA/氮硫共掺杂多孔碳球混合基质膜的制备及CO2分离性能研究[J]. 化工学报, 2021, 72(10): 5237-5246. |

| [8] | 王维, 姜雪迎, 李悦, 苏丽萍, 邹昀, 童张法. 亲水型ZSM-5分子筛填充PVA膜及分离乙酸乙酯/水的应用[J]. 化工学报, 2020, 71(8): 3807-3818. |

| [9] | 高殷,王永洪,张新儒,李晋平,凌军. SPEEK/PSI半互穿网络共混膜的制备及其CO2分离研究[J]. 化工学报, 2020, 71(12): 5813-5820. |

| [10] | 陈宇飞, 耿成宝, 楚洪月, 汪波涛, 郭红缘, 岳春艳. 蒙脱土/聚醚砜-双马来酰亚胺复合材料微观形貌及性能[J]. 化工学报, 2018, 69(S1): 148-154. |

| [11] | 侯蒙杰, 张新儒, 王永洪, 李晋平, 刘成岑, 凌军. 聚乙烯胺/埃洛石纳米管混合基质膜的制备及其CO2/N2分离[J]. 化工学报, 2018, 69(9): 4106-4113. |

| [12] | 周艺璇, 王志, 董晨曦, 王耀, 王纪孝. 双胍基化聚乙烯胺改性制备抗生物污染反渗透膜[J]. 化工学报, 2018, 69(2): 858-865. |

| [13] | 曹晓畅, 王志, 乔志华, 王纪孝, 许振良. 一步法制备含氨基化合物的非对称CO2分离膜[J]. 化工学报, 2018, 69(11): 4778-4787. |

| [14] | 黄雪, 尹垚骐, 张步宁, 冯光炷. 蒙脱土结构和性质对催化不饱和脂肪酸二聚化反应的影响[J]. 化工学报, 2017, 68(S1): 210-217. |

| [15] | 李婷婷, 赵乐乐, 郑子良, 王振军, 张瑞平. 右旋布洛芬/尿素改性蒙脱土复合物的制备及体外释药性能[J]. 化工学报, 2017, 68(9): 3631-3637. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号