化工学报 ›› 2022, Vol. 73 ›› Issue (3): 1389-1402.DOI: 10.11949/0438-1157.20211358

收稿日期:2021-09-22

修回日期:2021-11-24

出版日期:2022-03-15

发布日期:2022-03-14

通讯作者:

赵之平

作者简介:毛恒(1989—),男,博士,基金资助:

Heng MAO( ),Yue WANG,Sen WANG,Weimin LIU,Jing LYU,Fuxue CHEN,Zhiping ZHAO(

),Yue WANG,Sen WANG,Weimin LIU,Jing LYU,Fuxue CHEN,Zhiping ZHAO( )

)

Received:2021-09-22

Revised:2021-11-24

Online:2022-03-15

Published:2022-03-14

Contact:

Zhiping ZHAO

摘要:

渗透汽化(PV)膜分离是一种高效节能、无污染的化工分离技术,在有机废水处理领域的应用潜力巨大。以3-氨丙基三乙氧基硅烷(APTES)改性二维ZIF-L(AZLs),将其引入聚醚嵌段酰胺(PEBA)内制备AZLs/PEBA混合基质膜,用于分离水溶液中的苯酚。系统表征了所制膜的微结构与物化特性,考察了APTES添加量、AZLs填充量、操作温度、料液浓度等对膜分离性能的影响。结果表明:AZLs均匀分散在PEBA基质中,表明两者具有良好的界面相容性。AZLs的加入使得膜疏水性增强而表面自由能降低,从而提高了PEBA膜的选择性。当分离80℃、1000 mg/kg苯酚水溶液时,AZLs/PEBA膜总通量可达2046 g/(m2·h),分离因子为25.4,并且具有一定的稳定性。所制AZLs/PEBA混合基质膜在含酚废水处理方面具有应用前景。

中图分类号:

毛恒, 王月, 王森, 刘伟民, 吕静, 陈甫雪, 赵之平. APTES改性ZIF-L/PEBA混合基质膜强化渗透汽化分离苯酚研究[J]. 化工学报, 2022, 73(3): 1389-1402.

Heng MAO, Yue WANG, Sen WANG, Weimin LIU, Jing LYU, Fuxue CHEN, Zhiping ZHAO. APTES-modified ZIF-L/PEBA mixed matrix membranes for enhancing phenol perm-selective pervaporation[J]. CIESC Journal, 2022, 73(3): 1389-1402.

图2 ZIF-L(a)、 AZLs-0.25(b)、 AZLs-0.5(c)、 AZLs-0.75 (d)和AZLs-1.0 (e)的SEM图像

Fig.2 SEM images of ZIF-L (a), AZLs-0.25 (b), AZLs-0.5 (c), AZLs-0.75 (d), and AZLs-1.0 (e)

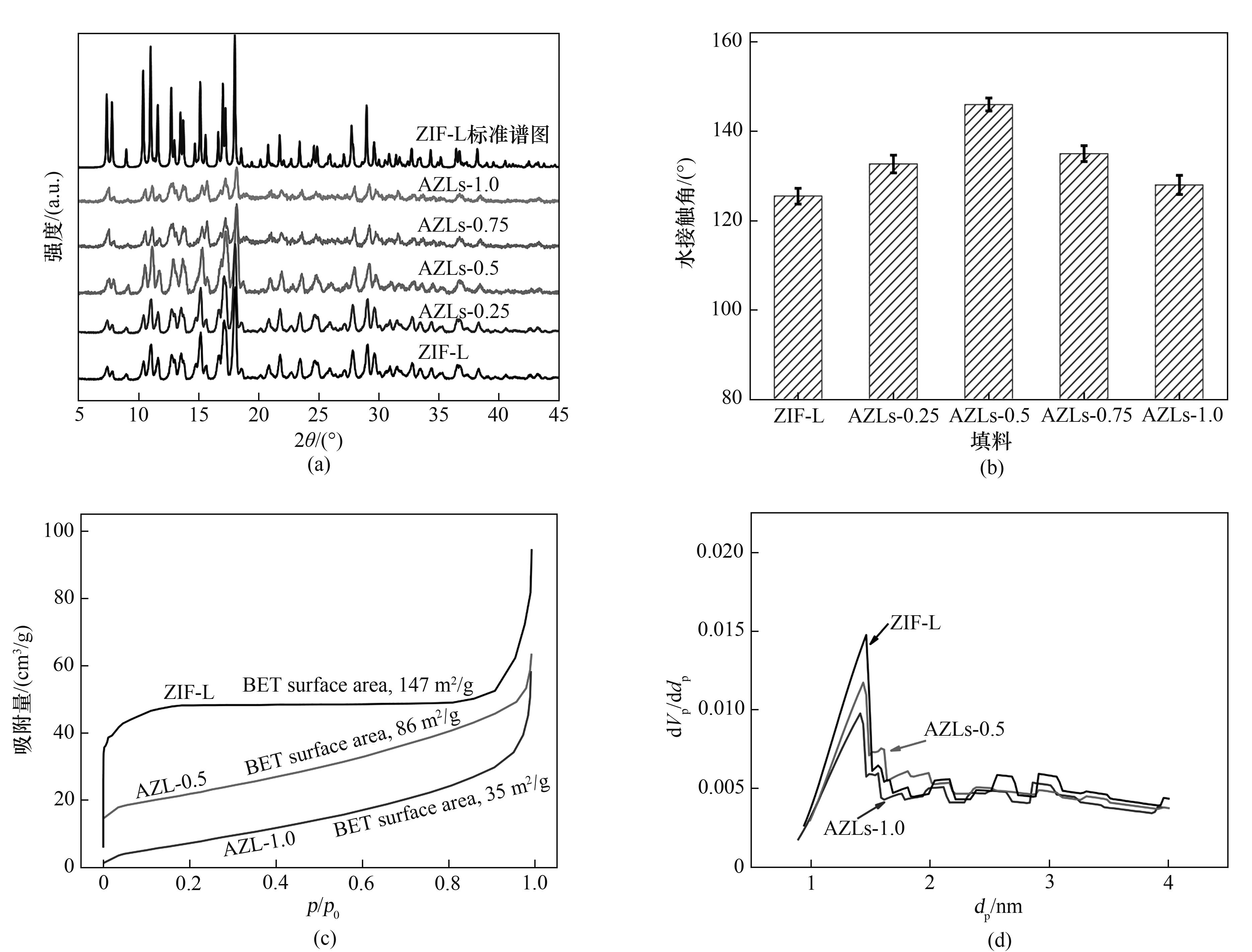

图3 AZLs的XRD谱图(a)、水接触角(b)、氮气吸附等温线(c)和孔径分布曲线(d)

Fig.3 XRD patterns (a), water contact angle (b), N2 adsorption isotherm (c), and pore size distribution curves(d) of AZLs

图4 PEBA膜(a)、 ZIF-L/PEBA-20 (b)、 AZLs-0.25/PEBA-20 (c)、 AZLs-0.5/PEBA-20 (d)、 AZLs-0.75/PEBA-20 (e)和AZLs-1.0/PEBA-20 (f)的表面SEM图像

Fig.4 Surface SEM images of PEBA membrane (a), ZIF-L/PEBA-20 (b), AZLs-0.25/PEBA-20 (c), AZLs-0.5/PEBA-20 (d), AZLs-0.75/PEBA-20 (e), and AZLs-1.0/PEBA-20 (f)

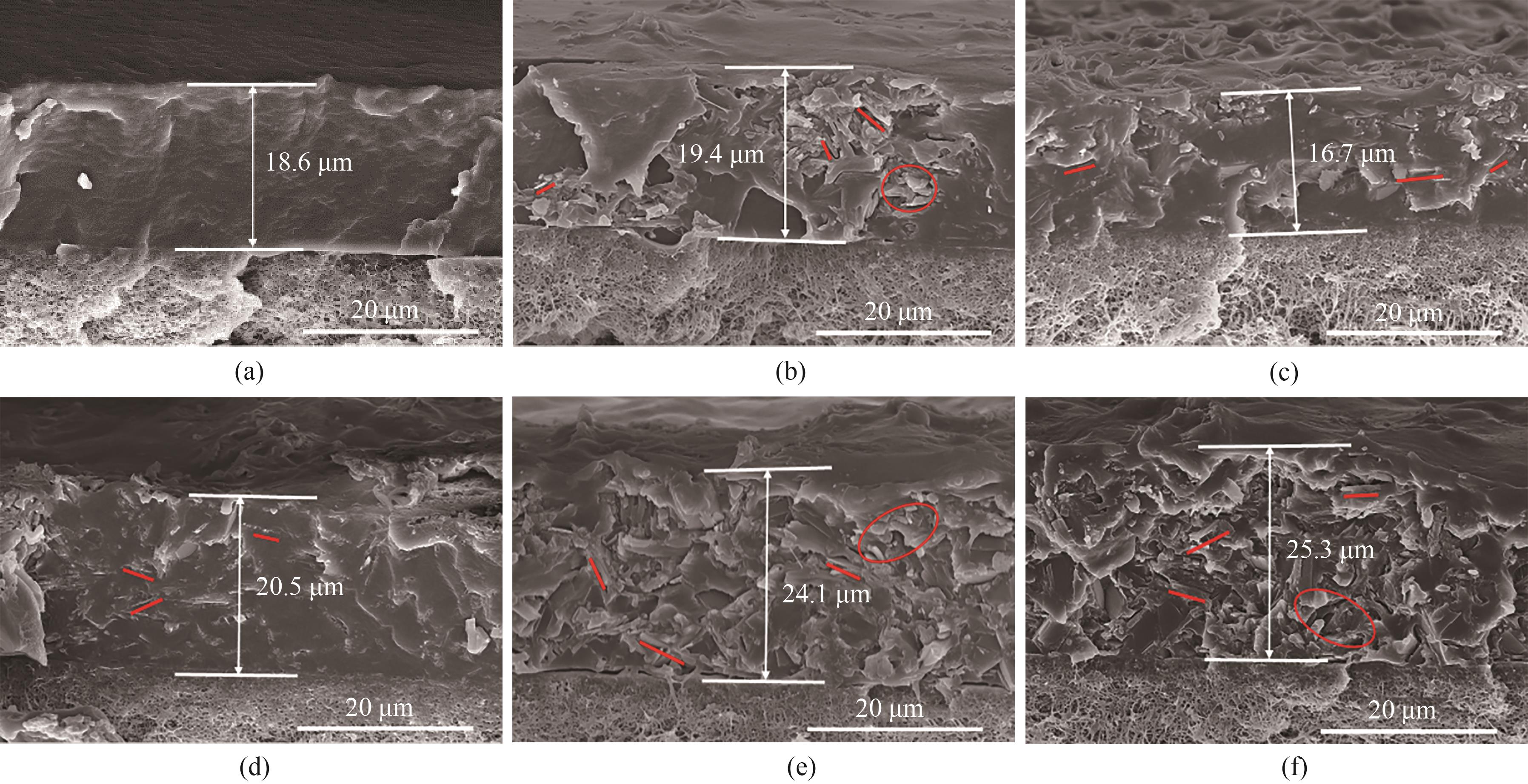

图5 PEBA膜(a)、 ZIF-L/PEBA-20 (b)、 AZLs-0.25/PEBA-20 (c)、 AZLs-0.5/PEBA-20 (d)、 AZLs-0.75/PEBA-20 (e)和AZLs-1.0/PEBA-20 (f)的断面SEM图像

Fig.5 Cross-sectional SEM images of PEBA membrane (a), ZIF-L/PEBA-20 (b), AZLs-0.25/PEBA-20 (c), AZLs-0.5/PEBA-20 (d), AZLs-0.75/PEBA-20 (e), and AZLs-1.0/PEBA-20 (f)

| 样品 | 分离层厚度/μm | 表面自由能/(mN/m) | 断裂强度/MPa | 最大伸长率/% | 弹性模量/MPa |

|---|---|---|---|---|---|

| PEBA膜 | 18.6 | 46.5 | 2.1±0.3 | 548±23 | 98.0±4.5 |

| ZIF-L/PEBA-20 | 19.4 | 37.3 | 6.9±0.2 | 990±34 | 146.0±6.3 |

| AZLs-0.25/PEBA-20 | 16.7 | 34.8 | 8.0±0.4 | 1088±57 | 161.0±8.7 |

| AZLs-0.5/PEBA-20 | 20.5 | 30.5 | 6.8±0.5 | 726±43 | 188.0±5.7 |

| AZLs-0.75/PEBA-20 | 24.1 | 33.4 | 7.6±0.6 | 891±62 | 136.0±7.3 |

| AZLs-1.0/PEBA-20 | 25.3 | 35.1 | 6.1±0.6 | 1047±48 | 124.0±9.5 |

表1 PEBA和AZLs-X/PEBA-20膜的物化性质

Table1 Physicochemical properties of PEBA and AZLs-X/PEBA-20 membranes

| 样品 | 分离层厚度/μm | 表面自由能/(mN/m) | 断裂强度/MPa | 最大伸长率/% | 弹性模量/MPa |

|---|---|---|---|---|---|

| PEBA膜 | 18.6 | 46.5 | 2.1±0.3 | 548±23 | 98.0±4.5 |

| ZIF-L/PEBA-20 | 19.4 | 37.3 | 6.9±0.2 | 990±34 | 146.0±6.3 |

| AZLs-0.25/PEBA-20 | 16.7 | 34.8 | 8.0±0.4 | 1088±57 | 161.0±8.7 |

| AZLs-0.5/PEBA-20 | 20.5 | 30.5 | 6.8±0.5 | 726±43 | 188.0±5.7 |

| AZLs-0.75/PEBA-20 | 24.1 | 33.4 | 7.6±0.6 | 891±62 | 136.0±7.3 |

| AZLs-1.0/PEBA-20 | 25.3 | 35.1 | 6.1±0.6 | 1047±48 | 124.0±9.5 |

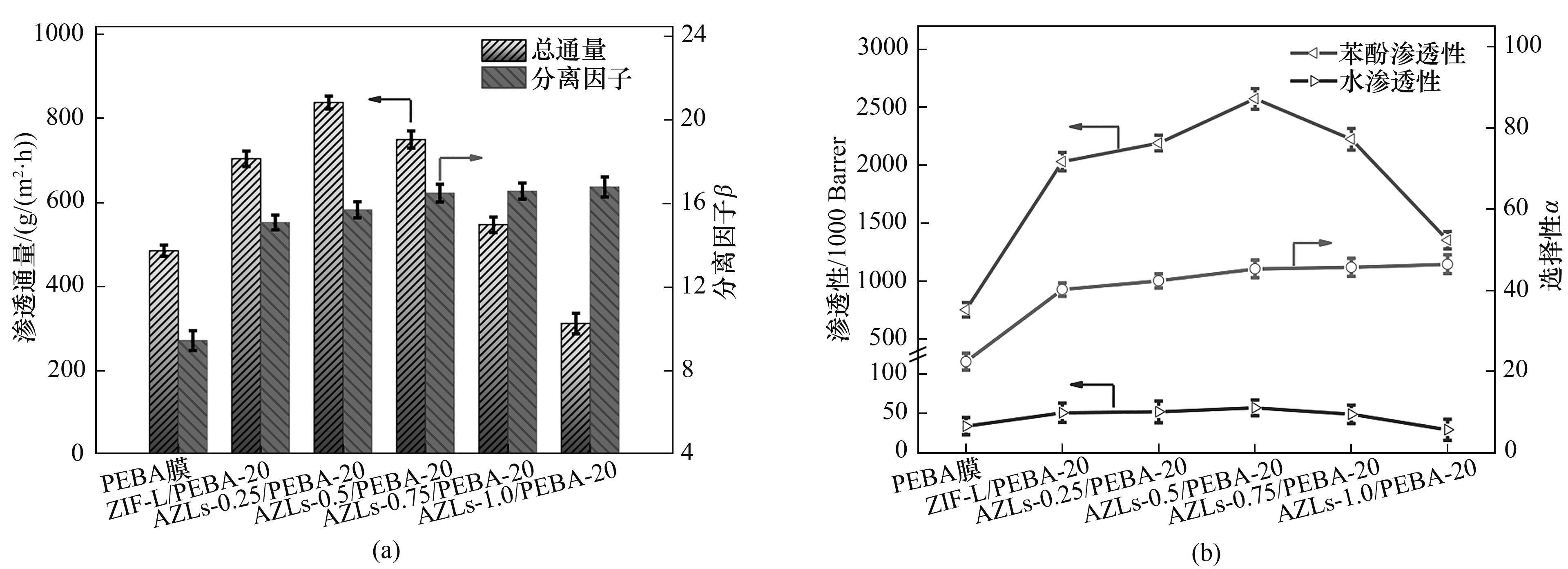

图8 不同填料对AZLs/PEBA膜分离性能的影响:渗透通量和分离因子(a);渗透性和选择性(b)(操作条件:填料量,20%(质量);苯酚浓度,1000 mg/kg;料液温度,50℃)

Fig.8 Effects of different fillers on separation performance of AZLs/PEBA membranes: permeation flux and separation factor (a); permeability and selectivity (b)(Operating conditions: filler loading, 20%(质量); phenol concentration, 1000 mg/kg; feed temperature, 50℃)

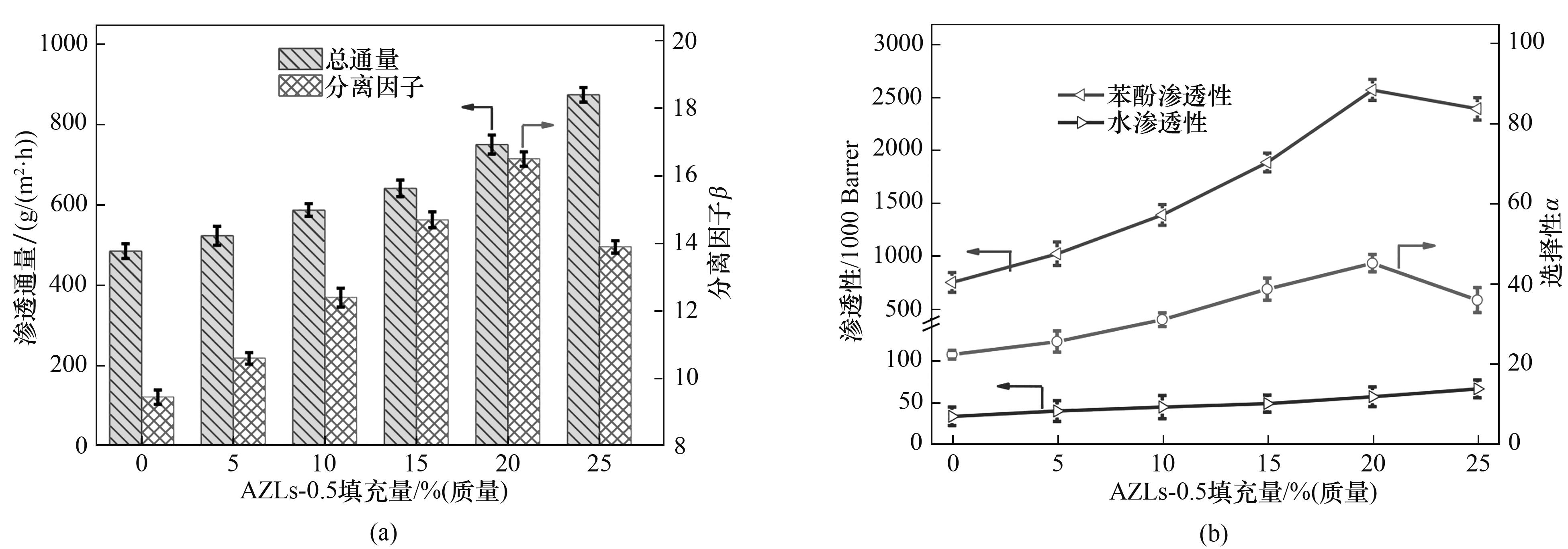

图9 AZLs-0.5填充量对AZLs-0.5/PEBA膜分离性能的影响:渗透通量和分离因子(a);渗透性和选择性 (b)(操作条件:苯酚浓度,1000 mg/kg;料液温度,50℃)

Fig.9 Effects of AZLs-0.5 loading on separation performance of AZLs-0.5/PEBA membranes: permeation flux and separation factor (a);permeability and selectivity (b)(Operating conditions: phenol concentration, 1000 mg/kg; feed temperature, 50℃)

图10 料液温度对AZLs-0.5/PEBA-20膜分离性能的影响:渗透通量和分离因子(a),渗透性和选择性(b);AZLs-0.5/PEBA-20膜(c)和PEBA膜(d)的lnJ-l/T关系(操作条件:苯酚浓度,1000 mg/kg)

Fig.10 Effects of feed temperature on separation performance of AZLs-0.5/PEBA-20: permeation flux and separation factor (a), permeability and selectivity (b); Arrhenius plots ofAZLs-0.5/PEBA-20 (c) and PEBA membrane (d)(Operating conditions: phenol concentration, 1000 mg/kg)

| 样品 | EA,i /( kJ/ mol) | ΔHevp,i (80 oC) /( kJ/ mol) | EP,i /( kJ/mol) | |||

|---|---|---|---|---|---|---|

| 苯酚 | 水 | 苯酚 | 水 | 苯酚 | 水 | |

| PEBA膜 | 45.31 | 34.25 | 54.67 | 41.63 | -9.36 | -7.38 |

| AZLs-0.5/PEBA-20 | 43.32 | 27.94 | -11.35 | -13.69 | ||

表2 PEBA和AZLs-0.5/PEBA-20膜内分子渗透能量分析

Table 2 Energy analysis for molecular permeation of PEBA and AZLs-0.5/PEBA-20 membranes

| 样品 | EA,i /( kJ/ mol) | ΔHevp,i (80 oC) /( kJ/ mol) | EP,i /( kJ/mol) | |||

|---|---|---|---|---|---|---|

| 苯酚 | 水 | 苯酚 | 水 | 苯酚 | 水 | |

| PEBA膜 | 45.31 | 34.25 | 54.67 | 41.63 | -9.36 | -7.38 |

| AZLs-0.5/PEBA-20 | 43.32 | 27.94 | -11.35 | -13.69 | ||

图11 料液浓度对AZLs-0.5/PEBA-20膜分离性能的影响:(a)渗透通量和分离因子;(b)渗透性和选择性(操作条件:料液温度,80℃)

Fig.11 Effects of feed concentration on separation performance of AZLs-0.5/PEBA-20: permeation flux and separation factor (a); permeability and selectivity (b)(Operating conditions: feed temperature, 80℃)

| 膜 | 温度/ ℃ | 浓度/ %(质量) | 总通量/ (g/(m2?h)) | 分离因子 | PSI | 文献 |

|---|---|---|---|---|---|---|

| PDMS | 70 | 1 | 370 | 21 | 7400 | [ |

| PEBA-4033 | 60 | 2 | 350 | 23 | 7700 | [ |

| 60 | 1 | 620 | 20 | 11780 | [ | |

| PERVAP-1060 | 60 | 2 | 6840 | 6 | 34200 | [ |

| OA-PDMS | 70 | 0.5 | 320 | 6.3 | 1696 | [ |

| ZSM-5/PDMS | 80 | 0.01 | 1590 | 4.5 | 5565 | [ |

| Polyimide | 70 | 1 | 370 | 7.5 | 2405 | [ |

| PIM-1 | 70 | 1 | 210 | 16 | 3150 | [ |

| PEBA-2533 | 70 | 0.1 | 800 | 52.6 | 41280 | [ |

| 80 | 0.1 | 1430 | 25 | 34320 | [ | |

| PU/ZSM-ECD | 80 | 0.3 | 980 | 9.3 | 8134 | [ |

| PUCD | 70 | 3 | 70 | 49 | 3360 | [ |

| PEBA/PVDF | 80 | 0.1 | 6560 | 9 | 52480 | [ |

| AZLs/PEBA | 70 | 0.1 | 1362 | 22.3 | 29011 | 本文 |

| 80 | 0.1 | 2046 | 25.4 | 49922 |

表3 不同渗透汽化膜分离苯酚水溶液分离性能对比

Table 3 Performance comparison of various pervaporation membranes in separating phenol aqueous solution

| 膜 | 温度/ ℃ | 浓度/ %(质量) | 总通量/ (g/(m2?h)) | 分离因子 | PSI | 文献 |

|---|---|---|---|---|---|---|

| PDMS | 70 | 1 | 370 | 21 | 7400 | [ |

| PEBA-4033 | 60 | 2 | 350 | 23 | 7700 | [ |

| 60 | 1 | 620 | 20 | 11780 | [ | |

| PERVAP-1060 | 60 | 2 | 6840 | 6 | 34200 | [ |

| OA-PDMS | 70 | 0.5 | 320 | 6.3 | 1696 | [ |

| ZSM-5/PDMS | 80 | 0.01 | 1590 | 4.5 | 5565 | [ |

| Polyimide | 70 | 1 | 370 | 7.5 | 2405 | [ |

| PIM-1 | 70 | 1 | 210 | 16 | 3150 | [ |

| PEBA-2533 | 70 | 0.1 | 800 | 52.6 | 41280 | [ |

| 80 | 0.1 | 1430 | 25 | 34320 | [ | |

| PU/ZSM-ECD | 80 | 0.3 | 980 | 9.3 | 8134 | [ |

| PUCD | 70 | 3 | 70 | 49 | 3360 | [ |

| PEBA/PVDF | 80 | 0.1 | 6560 | 9 | 52480 | [ |

| AZLs/PEBA | 70 | 0.1 | 1362 | 22.3 | 29011 | 本文 |

| 80 | 0.1 | 2046 | 25.4 | 49922 |

| 1 | Cao X T, Wang K A, Feng X S. Removal of phenolic contaminants from water by pervaporation[J]. Journal of Membrane Science, 2021, 623: 119043. |

| 2 | Jin M Y, Lin Y Q, Liao Y, et al. Development of highly-efficient ZIF-8@PDMS/PVDF nanofibrous composite membrane for phenol removal in aqueous-aqueous membrane extractive process[J]. Journal of Membrane Science, 2018, 568: 121-133. |

| 3 | Khan R, Ul Haq I, Mao H, et al. Enhancing the pervaporation performance of PEBA/PVDF membrane by incorporating MAF-6 for the separation of phenol from its aqueous solution[J]. Separation and Purification Technology, 2021, 256: 117804. |

| 4 | Mao H, Li S H, Xu L H, et al. Zeolitic imidazolate frameworks in mixed matrix membranes for boosting phenol/water separation: crystal evolution and preferential orientation[J]. Journal of Membrane Science, 2021, 638: 119611. |

| 5 | Han T T, Xiao Y L, Tong M M, et al. Synthesis of CNT@MIL-68(Al) composites with improved adsorption capacity for phenol in aqueous solution[J]. Chemical Engineering Journal, 2015, 275: 134-141. |

| 6 | Tian W, Lin J, Zhang H, et al. Enhanced removals of micropollutants in binary organic systems by biomass derived porous carbon/peroxymonosulfate[J]. Journal of Hazardous Materials, 2021, 408: 124459. |

| 7 | 齐亚兵, 杨清翠. 煤化工废水脱酚技术研究进展[J]. 应用化工, 2021, 50(5): 1414-1419. |

| Qi Y B, Yang Q C. Research progress on removal of phenols from coal chemical wastewater[J]. Applied Chemical Industry, 2021, 50(5): 1414-1419. | |

| 8 | Mao H, Li S H, Zhang A S, et al. Furfural separation from aqueous solution by pervaporation membrane mixed with metal organic framework MIL-53(Al) synthesized via high efficiency solvent-controlled microwave[J]. Separation and Purification Technology, 2021, 272: 118813. |

| 9 | 方丽君, 王景梅, 林巧靖, 等. 二苯并-18-冠醚-6/聚醚嵌段酰胺膜富集水中苯酚性能研究[J]. 化工学报, 2021, 72(7): 3716-3727. |

| Fang L J, Wang J M, Lin Q J, et al. Enrichment of phenol in water by dibenzo-18-crown ether-6/polyether block amide membrane[J]. CIESC Journal, 2021, 72(7): 3716-3727. | |

| 10 | Ji Y, Chen G, Liu G, et al. Ultrathin membranes with a polymer/nanofiber interpenetrated structure for high-efficiency liquid separations[J]. ACS Applied Materials & Interfaces, 2019, 11(40): 36717-36726. |

| 11 | Yang D C, Tian D X, Xue C, et al. Tuned fabrication of the aligned and opened CNT membrane with exceptionally high permeability and selectivity for bioalcohol recovery[J]. Nano Letters, 2018, 18(10): 6150-6156. |

| 12 | 牟春霞, 张时雨, 邹昀, 等. 疏水SiO2填充PDMS膜分离水中乙酸正丁酯的性能[J]. 化工学报, 2017, 68(6): 2407-2414. |

| Mu C X, Zhang S Y, Zou Y, et al. Separation of n-butyl acetate from aqueous solution using PDMS membrane filled with hydrophobic SiO2 [J]. CIESC Journal, 2017, 68(6): 2407-2414. | |

| 13 | Xu S, Zhang H, Yu F, et al. Enhanced ethanol recovery of PDMS mixed matrix membranes with hydrophobically modified ZIF-90[J]. Separation and Purification Technology, 2018, 206: 80-89. |

| 14 | Wang H, Liu Y L, Li J. Designer metal-organic frameworks for size-exclusion-based hydrocarbon separations: progress and challenges[J]. Advanced Materials, 2020, 32(44): 2002603. |

| 15 | Jayaramulu K, Geyer F, Schneemann A, et al. Hydrophobic metal-organic frameworks[J]. Advanced Materials, 2019, 31(32): 1900820. |

| 16 | Liu Q, Li Y, Li Q, et al. Mixed-matrix hollow fiber composite membranes comprising of PEBA and MOF for pervaporation separation of ethanol/water mixtures[J]. Separation and Purification Technology, 2019, 214: 2-10. |

| 17 | Zhang A S, Li S H, Ahmad A, et al. Coordinate covalent grafted ILs-modified MIL-101/PEBA membrane for pervaporation: adsorption simulation and separation characteristics[J]. Journal of Membrane Science, 2021, 619: 118807. |

| 18 | Wang H, Tang S H, Ni Y X, et al. Covalent cross-linking for interface engineering of high flux UiO-66-TMS/PDMS pervaporation membranes[J]. Journal of Membrane Science, 2020, 598: 117791. |

| 19 | Chen R Z, Yao J F, Gu Q F, et al. A two-dimensional zeolitic imidazolate framework with a cushion-shaped cavity for CO2 adsorption[J]. Chemical Communications, 2013, 49(82): 9500. |

| 20 | 王艳芳, 毛恒, 蔡玮玮, 等. ZIF-L/PDMS混合基质膜蒸气渗透耦合发酵强化乙醇生产效率的研究[J]. 化工学报, 2021, 72(10): 5226-5236. |

| Wang Y F, Mao H, Cai W W, et al. Enhancing ethanol production efficiency by ZIF-L/PDMS mixed matrix membrane via vapor permeation-fermentation coupling process[J]. CIESC Journal, 2021, 72(10): 5226-5236. | |

| 21 | Mao H, Zhen H G, Ahmad A, et al. Highly selective and robust PDMS mixed matrix membranes by embedding two-dimensional ZIF-L for alcohol permselective pervaporation[J]. Journal of Membrane Science, 2019, 582: 307-321. |

| 22 | Li Q Q, Cheng L, Shen J, et al. Improved ethanol recovery through mixed-matrix membrane with hydrophobic MAF-6 as filler[J]. Separation and Purification Technology, 2017, 178: 105-112. |

| 23 | Owens D K, Wendt R C. Estimation of the surface free energy of polymers[J]. Journal of Applied Polymer Science, 1969, 13(8): 1741-1747. |

| 24 | 路姣姣, 毛恒, 王涛, 等. HNTs填充PDMS膜的制备及其分离ABE-水体系的研究[J]. 膜科学与技术, 2020, 40(1): 53-63. |

| Lu J J, Mao H, Wang T, et al. Preparation of HNTs filled PDMS membranes for the separation of ABE from aqueous solution[J]. Membrane Science and Technology, 2020, 40(1): 53-63. | |

| 25 | Kulkarni S S, Kittur A A, Aralaguppi M I, et al. Synthesis and characterization of hybrid membranes using poly(vinyl alcohol) and tetraethylorthosilicate for the pervaporation separation of water-isopropanol mixtures[J]. Journal of Applied Polymer Science, 2004, 94(3): 1304-1315. |

| 26 | Wang S F, Mahalingam D, Sutisna B, et al. 2D-dual-spacing channel membranes for high performance organic solvent nanofiltration[J]. Journal of Materials Chemistry A, 2019, 7(19): 11673-11682. |

| 27 | Pan F, Cheng Q, Jia H, et al. Facile approach to polymer–inorganic nanocomposite membrane through a biomineralization-inspired process[J]. Journal of Membrane Science, 2010, 357: 171-177. |

| 28 | Liu S N, Liu G P, Shen J, et al. Fabrication of MOFs/PEBA mixed matrix membranes and their application in bio-butanol production[J]. Separation and Purification Technology, 2014, 133: 40-47. |

| 29 | Kolokolov D I, Stepanov A G, Jobic H. Mobility of the 2-methylimidazolate linkers in ZIF-8 probed by 2H NMR: saloon doors for the guests[J]. The Journal of Physical Chemistry C, 2015, 119(49): 27512-27520. |

| 30 | Khan A, Ali M, Ilyas A, et al. ZIF-67 filled PDMS mixed matrix membranes for recovery of ethanol via pervaporation[J]. Separation and Purification Technology, 2018, 206: 50-58. |

| 31 | Feng X S, Huang R Y M. Estimation of activation energy for permeation in pervaporation processes[J]. Journal of Membrane Science, 1996, 118(1): 127-131. |

| 32 | Liu W P, Li Y F, Meng X X, et al. Embedding dopamine nanoaggregates into a poly(dimethylsiloxane) membrane to confer controlled interactions and free volume for enhanced separation performance[J]. Journal of Materials Chemistry A, 2013, 1(11): 3713. |

| 33 | Wang X L, Chen J X, Fang M Q, et al. ZIF-7/PDMS mixed matrix membranes for pervaporation recovery of butanol from aqueous solution[J]. Separation and Purification Technology, 2016, 163: 39-47. |

| 34 | Wu P, Field R W, England R, et al. A fundamental study of organofunctionalised PDMS membranes for the pervaporative recovery of phenolic compounds from aqueous streams[J]. Journal of Membrane Science, 2001, 190(2): 147-157. |

| 35 | Kujawski W, Warszawski A, Ratajczak W, et al. Application of pervaporation and adsorption to the phenol removal from wastewater[J]. Separation and Purification Technology, 2004, 40(2): 123-132. |

| 36 | Böddeker K W, Bengtson G, Bode E. Pervaporation of low volatility aromatics from water[J]. Journal of Membrane Science, 1990, 53(1/2): 143-158. |

| 37 | Ye H, Yan X, Zhang X, et al. Pervaporation properties of oleyl alcohol-filled polydimethylsiloxane membranes for the recovery of phenol from wastewater[J]. Iranian Polymer Journal, 2017, 26(8): 639-649. |

| 38 | Li D, Yao J, Sun H, et al. Recycling of phenol from aqueous solutions by pervaporation with ZSM-5/PDMS/PVDF hollow fiber composite membrane[J]. Applied Surface Science, 2018, 427: 288-297. |

| 39 | Pithan F, Staudt-Bickel C. Crosslinked copolyimide membranes for phenol recovery from process water by pervaporation[J]. ChemPhysChem, 2003, 4(9): 967-973. |

| 40 | Budd P, Elabas E, Ghanem B, et al. Solution-processed, organophilic membrane derived from a polymer of intrinsic microporosity[J]. Advanced Materials, 2004, 16(5): 456-459. |

| 41 | Hao X G, Pritzker M, Feng X S. Use of pervaporation for the separation of phenol from dilute aqueous solutions[J]. Journal of Membrane Science, 2009, 335(1/2): 96-102. |

| 42 | Ye H, Zhang X, Zhao Z X, et al. Pervaporation performance of surface-modified zeolite/PU mixed matrix membranes for separation of phenol from water[J]. Iranian Polymer Journal, 2017, 26(3): 193-203. |

| 43 | Ye H, Wang J, Wang Y, et al. Effects of simultaneous chemical cross-linking and physical filling on separation performances of PU membranes[J]. Iranian Polymer Journal, 2013, 22(8): 623-633. |

| [1] | 邵苛苛, 宋孟杰, 江正勇, 张旋, 张龙, 高润淼, 甄泽康. 水平方向上冰中受陷气泡形成和分布实验研究[J]. 化工学报, 2023, 74(S1): 161-164. |

| [2] | 吴延鹏, 李晓宇, 钟乔洋. 静电纺丝纳米纤维双疏膜油性细颗粒物过滤性能实验分析[J]. 化工学报, 2023, 74(S1): 259-264. |

| [3] | 杨百玉, 寇悦, 姜峻韬, 詹亚力, 王庆宏, 陈春茂. 炼化碱渣湿式氧化预处理过程DOM的化学转化特征[J]. 化工学报, 2023, 74(9): 3912-3920. |

| [4] | 赵亚欣, 张雪芹, 王荣柱, 孙国, 姚善泾, 林东强. 流穿模式离子交换层析去除单抗聚集体[J]. 化工学报, 2023, 74(9): 3879-3887. |

| [5] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [6] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [7] | 胡建波, 刘洪超, 胡齐, 黄美英, 宋先雨, 赵双良. 有机笼跨细胞膜易位行为的分子动力学模拟研究[J]. 化工学报, 2023, 74(9): 3756-3765. |

| [8] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [9] | 刘爽, 张霖宙, 许志明, 赵锁奇. 渣油及其组分黏度的分子层次组成关联研究[J]. 化工学报, 2023, 74(8): 3226-3241. |

| [10] | 胡亚丽, 胡军勇, 马素霞, 孙禹坤, 谭学诣, 黄佳欣, 杨奉源. 逆电渗析热机新型工质开发及电化学特性研究[J]. 化工学报, 2023, 74(8): 3513-3521. |

| [11] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [12] | 张佳怡, 何佳莉, 谢江鹏, 王健, 赵鹬, 张栋强. 渗透汽化技术用于锂电池生产中N-甲基吡咯烷酮回收的研究进展[J]. 化工学报, 2023, 74(8): 3203-3215. |

| [13] | 张瑞航, 曹潘, 杨锋, 李昆, 肖朋, 邓春, 刘蓓, 孙长宇, 陈光进. ZIF-8纳米流体天然气乙烷回收工艺的产品纯度关键影响因素分析[J]. 化工学报, 2023, 74(8): 3386-3393. |

| [14] | 杨欣, 彭啸, 薛凯茹, 苏梦威, 吴燕. 分子印迹-TiO2光电催化降解增溶PHE废水性能研究[J]. 化工学报, 2023, 74(8): 3564-3571. |

| [15] | 张缘良, 栾昕奇, 苏伟格, 李畅浩, 赵钟兴, 周利琴, 陈健民, 黄艳, 赵祯霞. 离子液体复合萃取剂选择性萃取尼古丁的研究及DFT计算[J]. 化工学报, 2023, 74(7): 2947-2956. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号