化工学报 ›› 2024, Vol. 75 ›› Issue (8): 2917-2928.DOI: 10.11949/0438-1157.20240227

收稿日期:2024-03-01

修回日期:2024-06-27

出版日期:2024-08-25

发布日期:2024-08-21

通讯作者:

刘朝晖

作者简介:黄晓峰(1999—),男,硕士研究生,543931339@qq.com

Xiaofeng HUANG( ), Zhaohui LIU(

), Zhaohui LIU( ), Fan YANG

), Fan YANG

Received:2024-03-01

Revised:2024-06-27

Online:2024-08-25

Published:2024-08-21

Contact:

Zhaohui LIU

摘要:

基于再生冷却技术研究背景,在热通量100~2000 kW/m2、常压~6 MPa条件下,于Ф4 mm×1 mm高温合金钢圆管内开展了高密度吸热型碳氢燃料JP-10的流动换热特性和热裂解结焦特性实验研究。研究表明,压力2 MPa下,1204.6 kW/m2是煤油发生偏离核态沸腾的临界热通量。亚/超临界压力下JP-10部分流动换热区域可划分如下:入口效应区、强制对流换热区、(拟)过冷沸腾区、(拟)饱和沸腾区等。流体温度是主导燃料结焦的主要因素。压力2、4、6 MPa下,燃料结焦起始点流体温度分别为679、652、643℃。壁面温度在高结焦反应发生后对结焦量产生同步影响。压力升高,燃料管内结焦加剧,高温燃料在管道内停留时间增加是主要原因。

中图分类号:

黄晓峰, 刘朝晖, 杨帆. 高密度碳氢燃料JP-10流动换热及热裂解结焦实验研究[J]. 化工学报, 2024, 75(8): 2917-2928.

Xiaofeng HUANG, Zhaohui LIU, Fan YANG. Experimental investigation of high-density hydrocarbon fuel JP-10 on flow heat transfer and pyrolysis characteristics[J]. CIESC Journal, 2024, 75(8): 2917-2928.

| 密度/(g/cm3) | 闪点/K | 临界压力/MPa | 临界温度/K | 体积热值/(MJ/L) |

|---|---|---|---|---|

| 0.94 | 327.2 | 3.733 | 698 | 39.6 |

表1 碳氢燃料JP-10基本参数[32-33]

Table 1 The basic parameters of hydrocarbon fuel JP-10[32-33]

| 密度/(g/cm3) | 闪点/K | 临界压力/MPa | 临界温度/K | 体积热值/(MJ/L) |

|---|---|---|---|---|

| 0.94 | 327.2 | 3.733 | 698 | 39.6 |

| 质量流量/(g/s) | 压力/ MPa | 入口温度/℃ | 出口温度/℃ | 热通量/(kW/m2) | 长度/ mm | 实验类型 |

|---|---|---|---|---|---|---|

| 2.97 | 2 | 25 | — | 100~2000 | 380 | 流动换热(变热通量) |

| 2.97 | 6 | 25 | — | 100~1000 | 380 | 流动换热(变热通量) |

| 2.97 | 2/4/6 | — | 750 | 500 | 1080 | 高温结焦(恒热通量) |

| 2.97 | 2/4/6 | — | 750 | 1000 | 580 | 高温结焦(恒热通量) |

| 2.97 | 2/4/6 | — | 750 | 1500 | 580 | 高温结焦(恒热通量) |

| 2.97 | 2/4/6 | — | 750 | 2000 | 380 | 高温结焦(恒热通量) |

表2 流动换热及结焦实验参数

Table 2 Experimental parameters of flow heat transfer and coking

| 质量流量/(g/s) | 压力/ MPa | 入口温度/℃ | 出口温度/℃ | 热通量/(kW/m2) | 长度/ mm | 实验类型 |

|---|---|---|---|---|---|---|

| 2.97 | 2 | 25 | — | 100~2000 | 380 | 流动换热(变热通量) |

| 2.97 | 6 | 25 | — | 100~1000 | 380 | 流动换热(变热通量) |

| 2.97 | 2/4/6 | — | 750 | 500 | 1080 | 高温结焦(恒热通量) |

| 2.97 | 2/4/6 | — | 750 | 1000 | 580 | 高温结焦(恒热通量) |

| 2.97 | 2/4/6 | — | 750 | 1500 | 580 | 高温结焦(恒热通量) |

| 2.97 | 2/4/6 | — | 750 | 2000 | 380 | 高温结焦(恒热通量) |

| 参教 | 单位 | 不确定度 |

|---|---|---|

| 压力p | MPa | 0.22% |

| 加热功率P | kW | 1.44% |

| 质量流量m | g/s | 0.12% |

| 外壁温Two | ℃ | 1.2℃ |

| 中心流体温度Tb | ℃ | 1.5℃,Tb<300℃;0.52%,Tb>300℃ |

| 热沉HS | kJ/kg | 2.35% |

| 传热系数h | kW/(m2·K) | 6.41% |

| 结焦质量mc | mg | 5.14% |

| 焦层厚度δ | µm | 6.51% |

表3 测量及推导参数的综合不确定度

Table 3 The combined uncertainty of the measured and derived parameters

| 参教 | 单位 | 不确定度 |

|---|---|---|

| 压力p | MPa | 0.22% |

| 加热功率P | kW | 1.44% |

| 质量流量m | g/s | 0.12% |

| 外壁温Two | ℃ | 1.2℃ |

| 中心流体温度Tb | ℃ | 1.5℃,Tb<300℃;0.52%,Tb>300℃ |

| 热沉HS | kJ/kg | 2.35% |

| 传热系数h | kW/(m2·K) | 6.41% |

| 结焦质量mc | mg | 5.14% |

| 焦层厚度δ | µm | 6.51% |

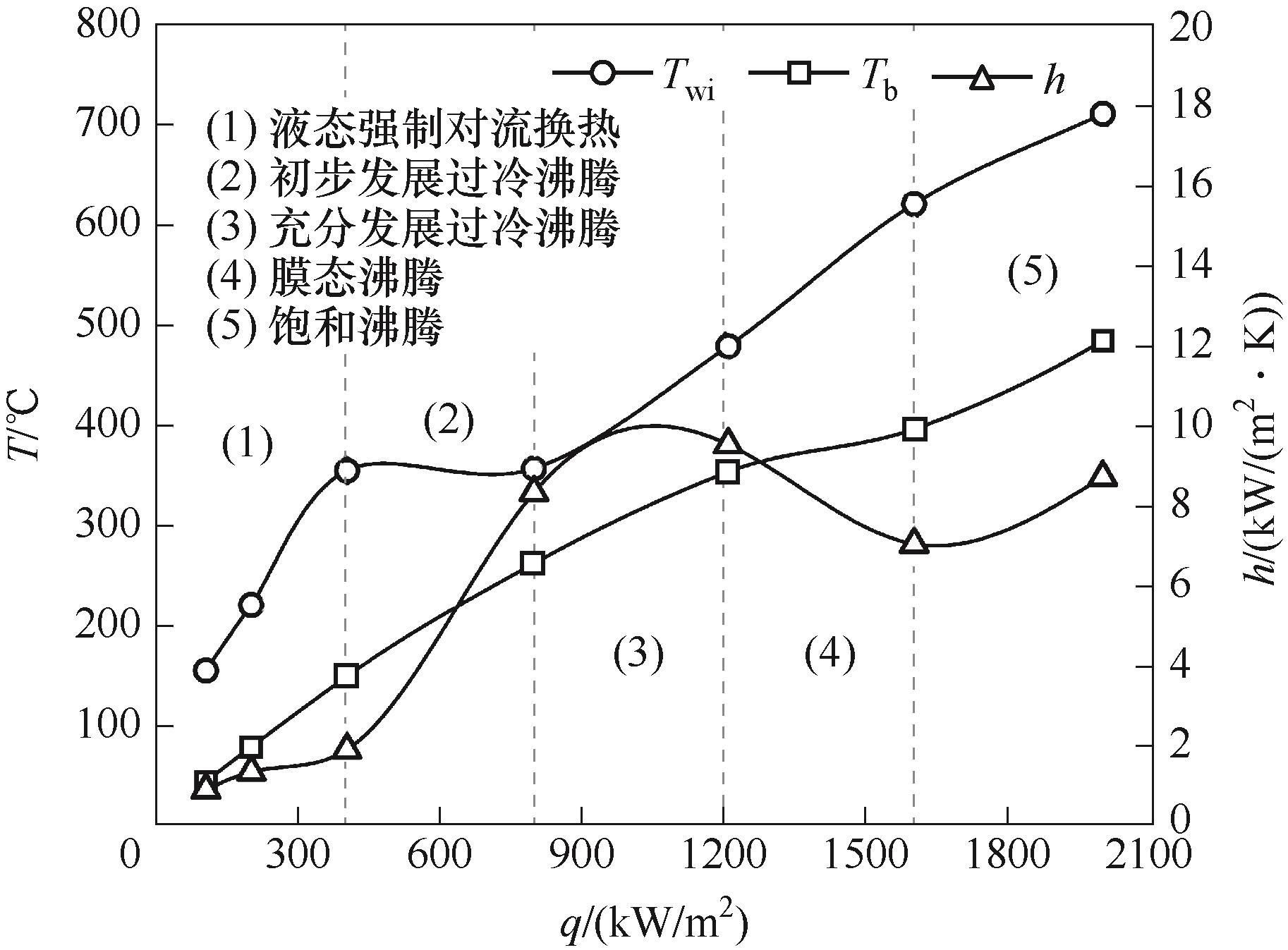

图7 亚临界压力下测温点11处换热特性随热通量变化

Fig.7 Variation of heat transfer characteristics with heat flux density at 11 temperature measurement points along the cross-sectional area under subcritical pressure

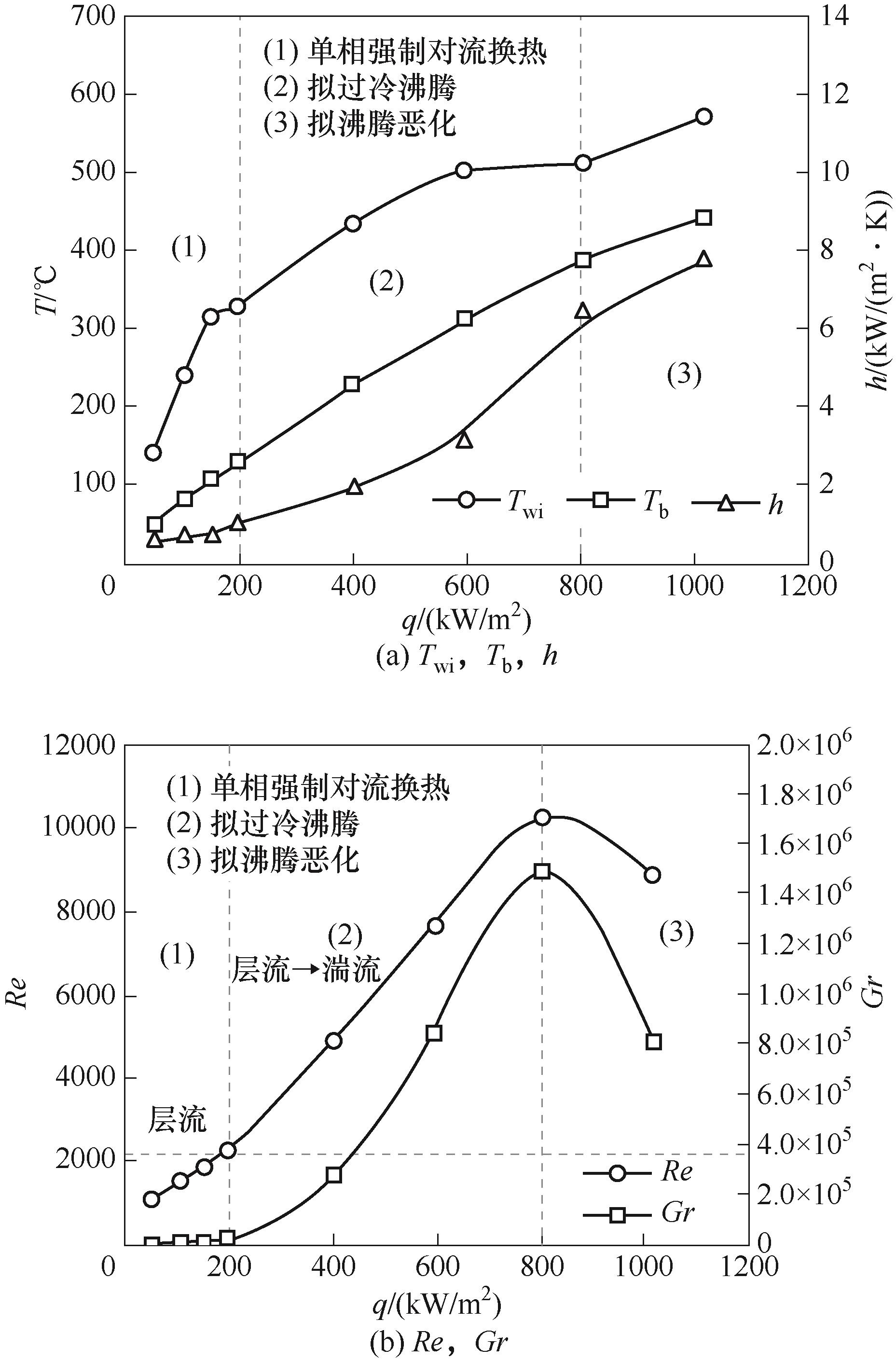

图8 超临界压力下测温点11处换热特性随热通量变化

Fig.8 Variation of heat transfer characteristics with heat flux density at 11 temperature measurement points along the cross-sectional area under supercritical pressure

| 1 | 王在铎, 王惠, 丁楠, 等. 高超声速飞行器技术研究进展[J]. 科技导报, 2021, 39(11): 59-67. |

| Wang Z D, Wang H, Ding N, et al. Research on the development of hypersonic vehicle technology[J]. Science & Technology Review, 2021, 39(11): 59-67. | |

| 2 | Salakhutdinov G M. Development of methods of cooling liquid propellant rocket engines (ZhRDs) 1903—1970[C]//History of Rocketry and Astronautics: Proceedings of the Twenty-fourth Symposum of the International Academy of Astronautics. Dresden, Germany, 1990:115-122. |

| 3 | 仲峰泉, 范学军, 俞刚. 带主动冷却的超声速燃烧室传热分析[J]. 推进技术, 2009, 30(5): 513-517, 532. |

| Zhong F Q, Fan X J, Yu G. Heat transfer analysis for actively cooled supersonic combustor[J]. Journal of Propulsion Technology, 2009, 30(5): 513-517, 532. | |

| 4 | 杜晨慧. 高超声速飞行器综合热管理及关键技术研究进展[J]. 装备环境工程, 2023, 20(1): 43-51. |

| Du C H. Research progress on integrated thermal management and key technology of hypersonic vehicles[J]. Equipment Environmental Engineering, 2023, 20(1): 43-51. | |

| 5 | 章思龙, 秦江, 周伟星, 等. 高超声速推进再生冷却研究综述[J]. 推进技术, 2018, 39(10): 2177-2190. |

| Zhang S L, Qin J, Zhou W X, et al. Review on regenerative cooling technology of hypersonic propulsion[J]. Journal of Propulsion Technology, 2018, 39(10): 2177-2190. | |

| 6 | Giovanetti A J, Szetela E J. Long-term deposit formation in aviation turbine fuel at elevated temperature[J]. Journal of Propulsion and Power, 1986, 2(5): 450-456. |

| 7 | Xu Q, Lin G W, Li H W. Evaluation model for fast convective heat transfer characteristics of thermal cracked hydrocarbon fuel regenerative cooling channel in hydrocarbon-fueled scramjet[J]. Applied Thermal Engineering, 2021, 199: 117616. |

| 8 | Li W, Chen Z H, Wang S. Progress of actively cooled ceramic matrix composites applied in advanced propulsion systems[J]. Journal of Materials Engineering, 2012(11): 92-96. |

| 9 | Hines W S, Wolf H. Pressure oscillations associated with heat transfer to hydrocarbon fluids at supercritical pressures and temperatures[J]. ARS Journal, 1962, 32(3): 361-366. |

| 10 | Bates R, Edwards J, Meyer M. Heat transfer and deposition behavior of hydrocarbon rocket fuels[C]//41st Aerospace Sciences Meeting and Exhibit, Reno, Nevada. Reston, Virginia: AIAA, 2003: 123. |

| 11 | Hitch B, Karpuk M, Hitch B, et al. Experimental investigation of heat transfer and flow instabilities in supercritical fuels[C]//33rd Joint Propulsion Conference and Exhibit, Seattle, WA. Reston, Virginia: AIAA, 1997: 3043. |

| 12 | Zhang C B, Xu G Q, Gao L, et al. Experimental investigation on heat transfer of a specific fuel (RP-3) flows through downward tubes at supercritical pressure[J]. The Journal of Supercritical Fluids, 2012, 72: 90-99. |

| 13 | 胡琼宇, 郭亚军, 毕勤成, 等. 乳化碳氢燃料与碳氢燃料传热特性实验对比研究[J]. 热能动力工程, 2018, 33(9): 67-71. |

| Hu Q Y, Guo Y J, Bi Q C, et al. Experimental study on heat transfer characteristics of emulsified hydrocarbon fuel and hydrocarbon fuel[J]. Journal of Engineering for Thermal Energy and Power, 2018, 33(9): 67-71. | |

| 14 | 郑鑫. 高热流下超临界航空煤油流动与换热特性数值模拟研究[D]. 哈尔滨: 哈尔滨工业大学, 2017. |

| Zheng X. Numerical simulation of flow and heat transfer characteristics of supercritical aviation kerosene under high heat flux[D]. Harbin: Harbin Institute of Technology, 2017. | |

| 15 | 邹吉军, 张香文, 王莅, 等. 高密度烃燃料合成进展[J]. 化学推进剂与高分子材料, 2008, 6(1): 26-30. |

| Zou J J, Zhang X W, Wang L, et al. Synthesis advance of high-density hydrocarbon fuels[J]. Chemical Propellants & Polymeric Materials, 2008, 6(1): 26-30. | |

| 16 | 姬鹏飞. 典型管路RP-3航空煤油热氧化结焦沉积特性研究[D]. 南京: 南京航空航天大学, 2018. |

| Ji P F. Study on thermal oxidation coking deposition characteristics of RP-3 aviation kerosene in typical pipeline[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2018. | |

| 17 | Pei X Y, Hou L Y. Effect of dissolved oxygen concentration on coke deposition of kerosene[J]. Fuel Processing Technology, 2016, 142: 86-91. |

| 18 | Spadaccini L J, Sobel D R, Huang H. Deposit formation and mitigation in aircraft fuels[J]. Journal of Engineering for Gas Turbines and Power, 2001, 123(4): 741-746. |

| 19 | Edwards T, Zabarnick S. Supercritical fuel deposition mechanisms[J]. Industrial & Engineering Chemistry Research, 1993, 32(12): 3117-3122. |

| 20 | 琚印超, 徐国强, 郭隽, 等. 压力对航空煤油RP-3结焦的影响[J]. 北京航空航天大学学报, 2010, 36(3): 257-260. |

| Ju Y C, Xu G Q, Guo J, et al. Effects of pressure on the coking characteristic of jet fuel RP-3[J]. Journal of Beijing University of Aeronautics and Astronautics, 2010, 36(3): 257-260. | |

| 21 | 程想, 冯松, 陈强, 等. 纽带管内吸热型碳氢燃料结焦及流动换热特性实验研究[J]. 西安交通大学学报, 2020, 54(6): 133-139. |

| Cheng X, Feng S, Chen Q, et al. Experimental investigation on the flow and heat transfer characteristics of endothermic hydrocarbon fuel during coking in circular tubes with twisted-tape inserts[J]. Journal of Xi'an Jiaotong University, 2020, 54(6): 133-139. | |

| 22 | Fu Y C, Wen J, Tao Z, et al. Surface coking deposition influences on flow and heat transfer of supercritical hydrocarbon fuel in helical tubes[J]. Experimental Thermal and Fluid Science, 2017, 85: 257-265. |

| 23 | Tao Z, Fu Y C, Xu G Q, et al. Experimental study on influences of physical factors to supercritical RP-3 surface and liquid-space thermal oxidation coking[J]. Energy & Fuels, 2014, 28(9): 6098-6106. |

| 24 | Wang Y, Zhao Y, Liang C, et al. Molecular-level modeling investigation of n-decane pyrolysis at high temperature[J]. Journal of Analytical and Applied Pyrolysis, 2017, 128: 412-422. |

| 25 | Jiang R P, Liu G Z, Zhang X W. Thermal cracking of hydrocarbon aviation fuels in regenerative cooling microchannels[J]. Energy & Fuels, 2013, 27(5): 2563-2577. |

| 26 | Vandewiele N M, Magoon G R, Van Geem K M, et al. Experimental and modeling study on the thermal decomposition of jet propellant-10[J]. Energy & Fuels, 2014, 28(8): 4976-4985. |

| 27 | 王静, 张香文, 郭伟, 等. 供氢剂和结焦抑制剂对正十二烷超临界热裂解沉积的影响[J]. 石油学报(石油加工), 2006, 22(5): 39-43. |

| Wang J, Zhang X W, Guo W, et al. Effects of hydrogen donors and coking-inhibitors on pyrolytic deposition of n-dodecane under supercritical condition[J]. Acta Petrolei Sinica (Petroleum Processing Section), 2006, 22(5): 39-43. | |

| 28 | Yang Z N, Li G Z, Yuan H, et al. Efficient coke inhibition in supercritical thermal cracking of hydrocarbon fuels by a little ethanol over a bifunctional coating[J]. Energy & Fuels, 2017, 31(7): 7060-7068. |

| 29 | Gao M Y, Hou L Y, Zhang X X, et al. Coke deposition inhibition for endothermic hydrocarbon fuels in a reforming catalyst-coated reactor[J]. Energy & Fuels, 2019, 33(7): 6126-6133. |

| 30 | Outcalt S L, Laesecke A. Measurements of density and speed of sound of JP-10 and a comparison to rocket propellants and jet fuels[J]. Energy & Fuels, 2011, 25(3): 1132-1139. |

| 31 | Nakra S, Green R J, Anderson S L. Thermal decomposition of JP-10 studied by micro-flowtube pyrolysis-mass spectrometry[J]. Combustion and Flame, 2006, 144(4): 662-674. |

| 32 | Guisinger S, Rippen M. Critical properties determination of advanced fuels[J]. Preprints-American Chemical Society Division of Petroleum Chemistry, 1989, 34: 885-896. |

| 33 | 张家庆, 刘朝晖, 李宇, 等. 碳氢燃料JP-10高温液态黏度测量和推算模型构建方法研究[J]. 化工学报, 2022, 73(1): 153-161. |

| Zhang J Q, Liu Z H, Li Y, et al. Viscosity measurements and prediction model construction for liquid JP-10 at high-temperature conditions[J]. CIESC Journal, 2022, 73(1): 153-161. |

| [1] | 卢飞, 鲁波娜, 许光文. 气固微型流化床反应分析仪的理想流型判据分析[J]. 化工学报, 2024, 75(6): 2201-2213. |

| [2] | 屠楠, 刘晓群, 王驰宇, 方嘉宾. 连续进出料鼓泡流化床停留时间分布的相似准则研究[J]. 化工学报, 2024, 75(2): 543-552. |

| [3] | 王峰, 张顺鑫, 余方博, 刘亚, 郭烈锦. 光催化CO2还原制碳氢燃料系统优化策略研究[J]. 化工学报, 2023, 74(1): 29-44. |

| [4] | 陈昇, 王梦钶, 鲁波娜, 李秀峰, 刘岑凡, 刘梦溪, 范怡平, 卢春喜. 原料油汽化特性对催化裂化反应结焦过程影响的CFD模拟[J]. 化工学报, 2022, 73(7): 2982-2995. |

| [5] | 徐玲玲, 蒲亮. 基于热短路问题的仿生地埋管换热器模拟[J]. 化工学报, 2021, 72(S1): 134-139. |

| [6] | 赵晶, 李伯耿, 卜志扬, 范宏. 微通道内低黏聚合物流体的停留时间分布研究[J]. 化工学报, 2021, 72(8): 4030-4038. |

| [7] | 胡丹丹, 耿素龙, 曾玺, 王芳, 岳君容, 许光文. 返混对气-固反应特性测试和活化能表征的影响[J]. 化工学报, 2021, 72(3): 1354-1363. |

| [8] | 黄正梁, 王超, 郭燕妮, 杨遥, 孙婧元, 王靖岱, 阳永荣. 基于停留时间分布的缠绕管内二次流研究[J]. 化工学报, 2021, 72(2): 921-927. |

| [9] | 兰斌, 徐骥, 刘志成, 王军武. 连续操作密相流化床颗粒停留时间分布特性模拟放大研究[J]. 化工学报, 2021, 72(1): 521-533. |

| [10] | 陈玮玮, 方贤德, 鹿世化, 林福建, 张烨. 飞行器燃料再生冷却热管理系统参数设计[J]. 化工学报, 2020, 71(S1): 204-211. |

| [11] | 王少伦, 杨宏. 高效包埋硝化活性填料硝化特性及应用研究[J]. 化工学报, 2020, 71(5): 2305-2311. |

| [12] | 田凤国, 朱田, 孔德正, 雷鸣. 非均匀布风流化床内大颗粒停留时间特性[J]. 化工学报, 2020, 71(4): 1520-1527. |

| [13] | 李春利, 李景玉, 张明霞. 隔壁塔内半圆填料层中壁流与返混特性研究[J]. 化工学报, 2020, 71(4): 1460-1468. |

| [14] | 王志远,丁旭东,王博研,邢志宏. 硫化物和硫/磷化合物的添加方式对石脑油热裂解结焦影响的研究[J]. 化工学报, 2020, 71(11): 5320-5336. |

| [15] | 梁咏诗, 赵香龙, 秦强, 郭屹, 程易. 气流床气化炉的CPFD数值模拟[J]. 化工学报, 2019, 70(9): 3291-3299. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号