化工学报 ›› 2024, Vol. 75 ›› Issue (6): 2201-2213.DOI: 10.11949/0438-1157.20231386

收稿日期:2023-12-28

修回日期:2024-03-26

出版日期:2024-06-25

发布日期:2024-07-03

通讯作者:

鲁波娜

作者简介:卢飞(1997—),男,硕士研究生,flu@ipe.ac.cn

基金资助:

Fei LU1,2( ), Bona LU2,3(

), Bona LU2,3( ), Guangwen XU1

), Guangwen XU1

Received:2023-12-28

Revised:2024-03-26

Online:2024-06-25

Published:2024-07-03

Contact:

Bona LU

摘要:

微型流化床因具有气体返混小和可操作性强等优点,在反应动力学测量等领域备受关注。获得流型随操作参数的变化规律,才能实现微型流化床理想流型的有效调控。采用双流体模型耦合考虑结构的相间曳力(又称多尺度CFD)模拟了一系列A类和B类颗粒在不同操作条件下的流化行为,结合颗粒浓度和气体停留时间分布(RTD)特征考察气速、床径和初始床高对气体返混行为的影响。研究表明,当微型流化床在初始鼓泡到湍动流态化之间操作时,才逼近颗粒全混流和气体近似平推流的运动状态。进一步分析气体RTD曲线形状特征(如拖尾、多峰等),提出采用斜度S<0.6作为微型流化床平推流判据,弥补了原判据[满足方差σt2<0.25且峰高E(t)h>1] 的不足,为微型反应分析仪的流型调控奠定了基础。

中图分类号:

卢飞, 鲁波娜, 许光文. 气固微型流化床反应分析仪的理想流型判据分析[J]. 化工学报, 2024, 75(6): 2201-2213.

Fei LU, Bona LU, Guangwen XU. Analysis of criteria for ideal flow patterns in gas-solid micro fluidized bed reaction analyzer[J]. CIESC Journal, 2024, 75(6): 2201-2213.

| Parameter | Value |

|---|---|

| particle diameter dp/µm | 53 |

| particle density ρp/(kg·m-3) | 1400 |

| gas density ρg/(kg·m-3) | 1.225 |

| gas viscosity µg/(Pa·s) | 1.7894×10-5 |

| minimum fluidization velocity Umf/(mm·s-1) | 4.9 |

| operating gas velocity Ug/(mm·s-1) | 4—40 |

表1 模拟验证采用的物性及操作参数

Table 1 Physical properties and operating parameters used for simulation validation

| Parameter | Value |

|---|---|

| particle diameter dp/µm | 53 |

| particle density ρp/(kg·m-3) | 1400 |

| gas density ρg/(kg·m-3) | 1.225 |

| gas viscosity µg/(Pa·s) | 1.7894×10-5 |

| minimum fluidization velocity Umf/(mm·s-1) | 4.9 |

| operating gas velocity Ug/(mm·s-1) | 4—40 |

| Type of particles | Ug/Umf | Dt/mm | Hs/mm |

|---|---|---|---|

| Geldart A(dp=92 μm, ρp=1200 kg·m-3, Ar=35.0341) | 2,3,4,5,6,7 | 5,10,15,20,30 | 10,15,20,25,30,35,40 |

| Geldart B(dp=240 μm, ρp=2644 kg·m-3, Ar=1371.1474) | 1,2,3,4,5,6 | 5,10,15,20,30 | 10,15,20,25,30,35,40 |

表2 用于流型分析的各参数变化范围

Table 2 The range of variation of various parameters used for flow pattern analysis

| Type of particles | Ug/Umf | Dt/mm | Hs/mm |

|---|---|---|---|

| Geldart A(dp=92 μm, ρp=1200 kg·m-3, Ar=35.0341) | 2,3,4,5,6,7 | 5,10,15,20,30 | 10,15,20,25,30,35,40 |

| Geldart B(dp=240 μm, ρp=2644 kg·m-3, Ar=1371.1474) | 1,2,3,4,5,6 | 5,10,15,20,30 | 10,15,20,25,30,35,40 |

| 项目 | 公式 |

|---|---|

| E(t)函数 | |

| 平均停留时间 | |

| 方差 | |

| 无量纲方差 | |

| 斜度S | |

| E( |

表3 停留时间分布(RTD)函数的相关公式

Table 3 The relevant formulas for the residence time distribution (RTD) function

| 项目 | 公式 |

|---|---|

| E(t)函数 | |

| 平均停留时间 | |

| 方差 | |

| 无量纲方差 | |

| 斜度S | |

| E( |

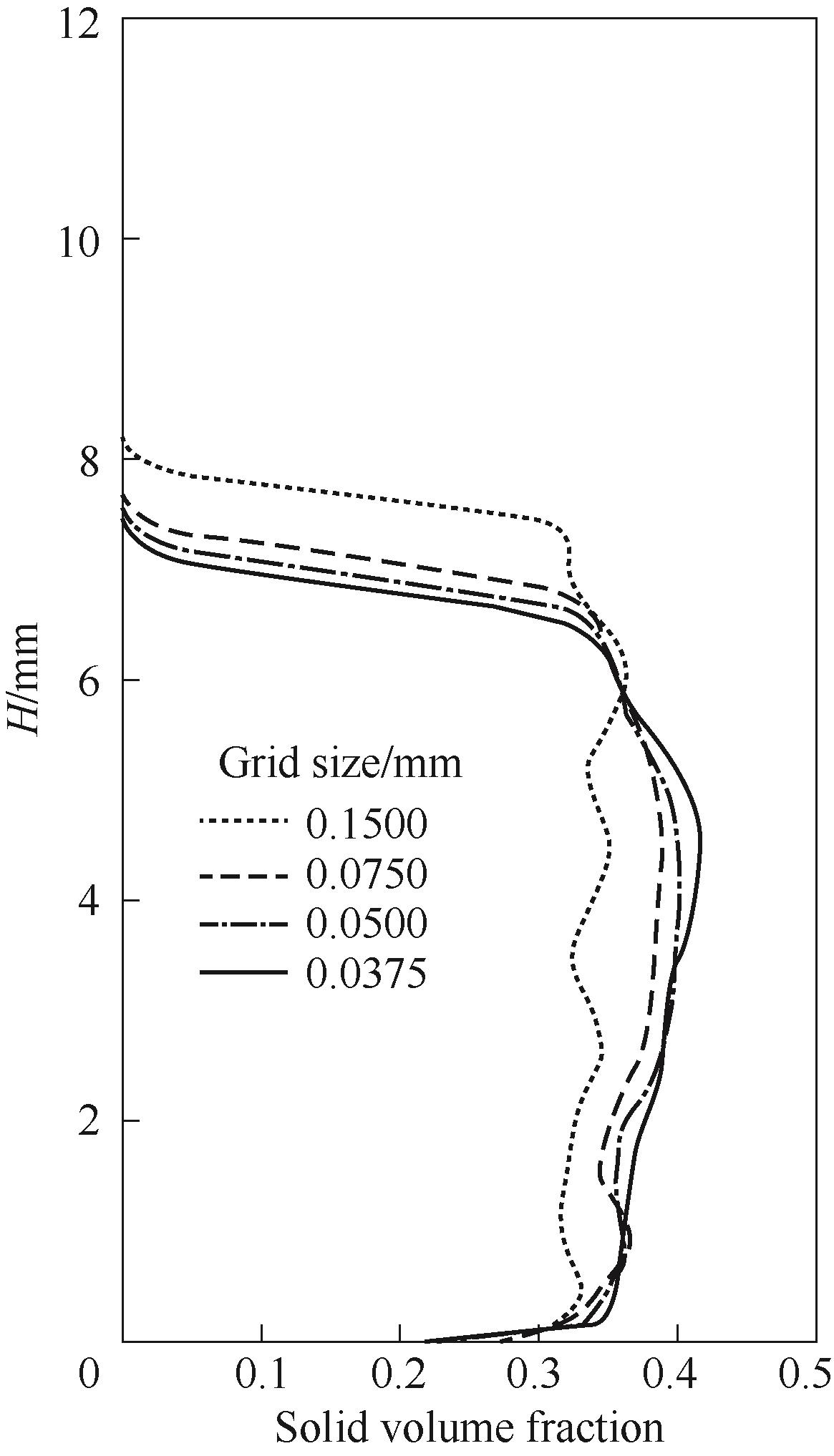

图2 时均颗粒浓度的轴向分布(dp = 53 µm,ρp = 1400 kg·m-3,ρg = 1.225 kg·m-3,μg = 1.7894×10-5 Pa·s,Ug = 15 mm·s-1)

Fig.2 The axial profiles of time-average solid concentration (dp = 53 µm, ρp = 1400 kg·m-3, ρg = 1.225 kg·m-3, μg = 1.7894×10-5 Pa·s, Ug = 15 mm·s-1)

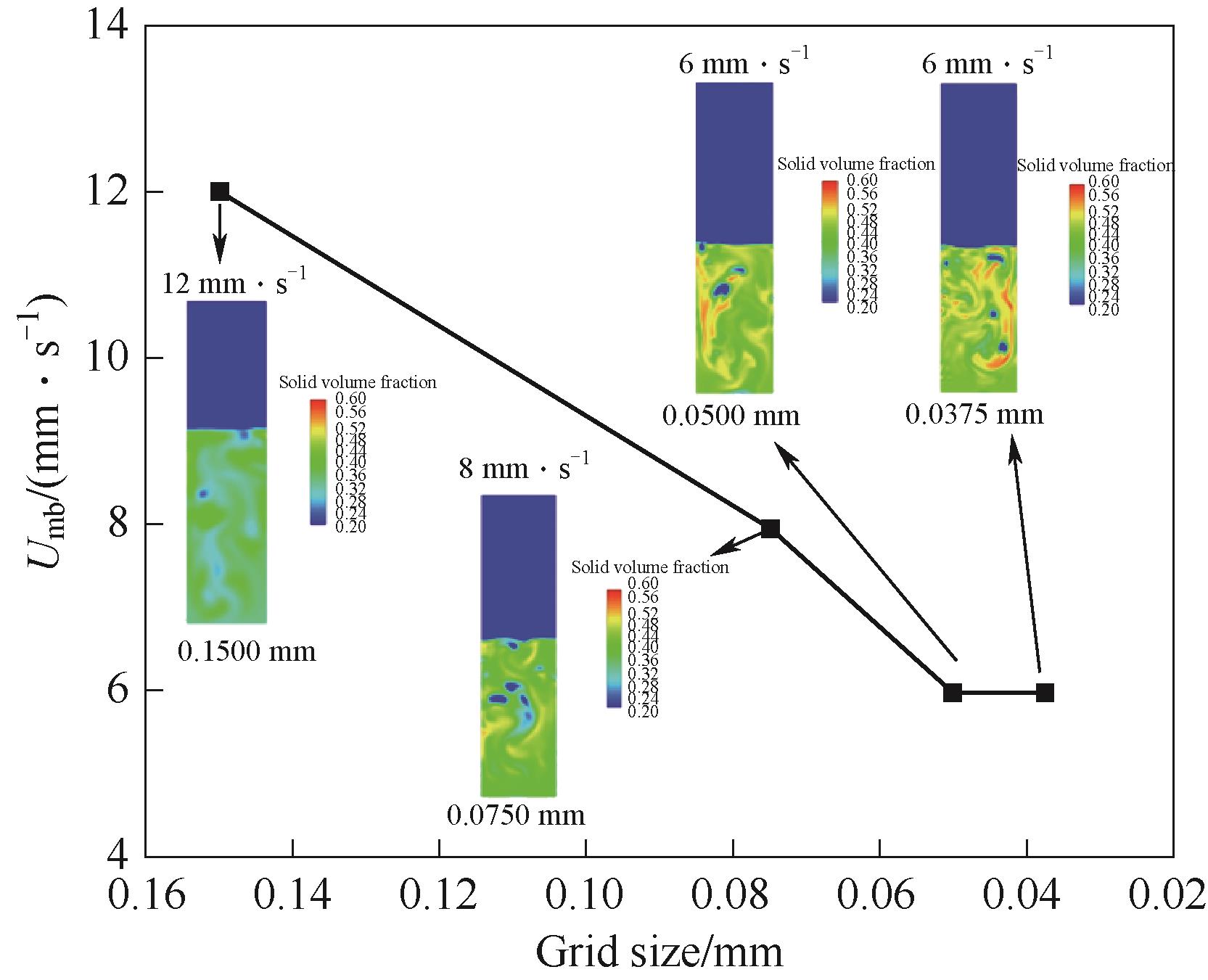

图3 起始鼓泡速度Umb随网格尺寸的变化(dp = 53 µm,ρp = 1400 kg·m-3,ρg = 1.225 kg·m-3,μg = 1.7894×10-5 Pa·s)

Fig.3 The variation of incipient bubbling fluidization velocity Umb with grid size (dp = 53 µm, ρp = 1400 kg·m-3, ρg = 1.225 kg·m-3, μg = 1.7894×10-5 Pa·s)

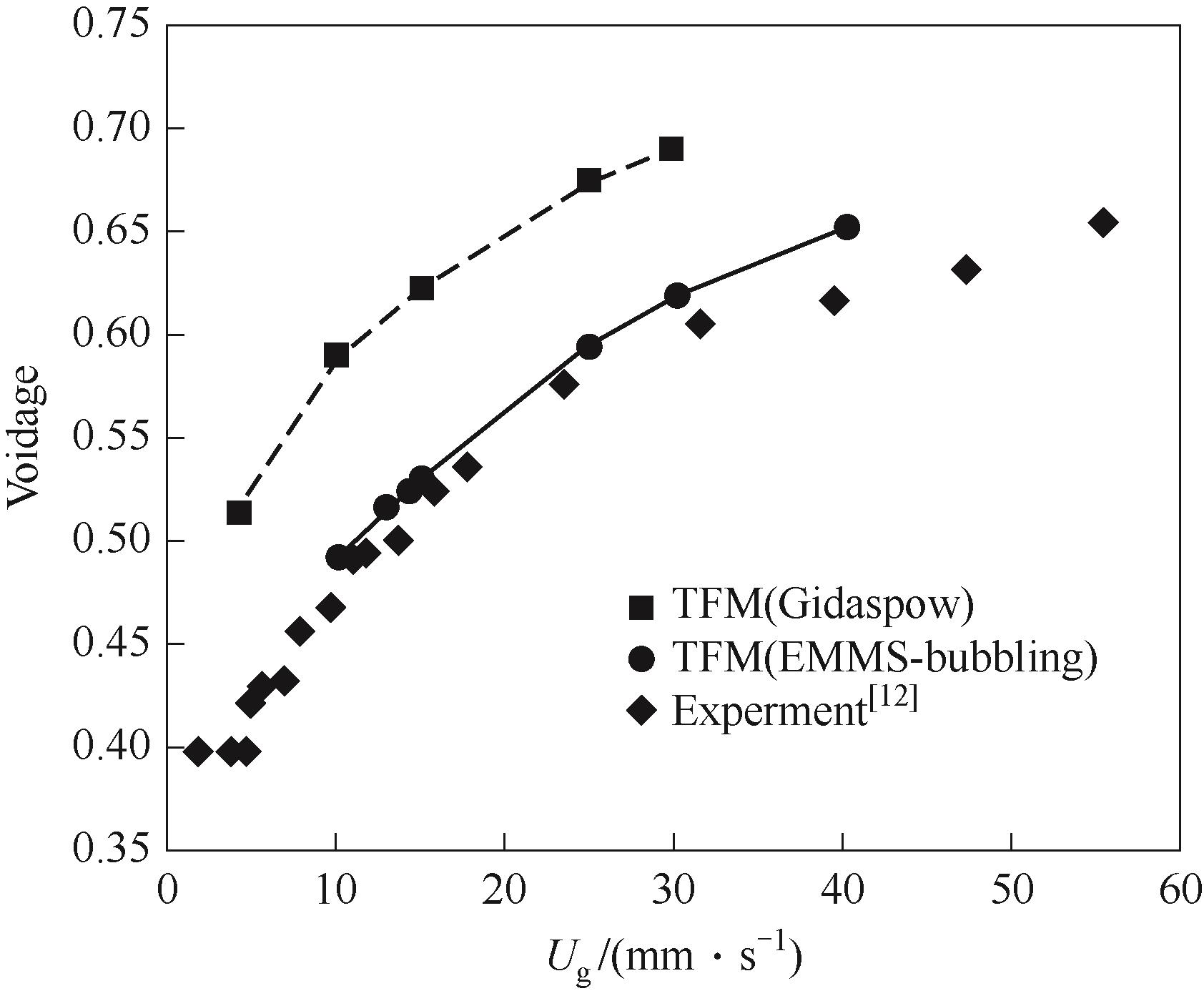

图5 不同操作气速时的床层空隙率模拟值与实验值的对比(dp = 53 µm,ρp = 1400 kg·m-3,ρg = 1.225 kg·m-3,μg = 1.7894×10-5 Pa·s,Umf = 4.9 mm·s-1)

Fig.5 Comparison between simulated and experimental values of bed porosity at different gas velocities (dp = 53 µm, ρp = 1400 kg·m-3, ρg = 1.225 kg·m-3, μg = 1.7894×10-5 Pa·s, Umf = 4.9 mm·s-1)

| Ug/mm·s-1 | εο(Exp.) | Gidaspow | EMMS-bubbling | ||

|---|---|---|---|---|---|

| εο | Relative error/% | εο | Relative error/% | ||

| 10 | 0.4728 | 0.5912 | 25.03 | 0.4938 | 4.43 |

| 15 | 0.5168 | 0.6237 | 20.69 | 0.5230 | 2.55 |

| 25 | 0.5811 | 0.6747 | 16.11 | 0.5948 | 2.35 |

| 30 | 0.5970 | 0.6910 | 15.74 | 0.6181 | 3.53 |

表4 采用不同曳力模型时的床层空隙率模拟值与实验值的相对误差

Table 4 The relative error between simulated bed porosity and experiment using different drag models

| Ug/mm·s-1 | εο(Exp.) | Gidaspow | EMMS-bubbling | ||

|---|---|---|---|---|---|

| εο | Relative error/% | εο | Relative error/% | ||

| 10 | 0.4728 | 0.5912 | 25.03 | 0.4938 | 4.43 |

| 15 | 0.5168 | 0.6237 | 20.69 | 0.5230 | 2.55 |

| 25 | 0.5811 | 0.6747 | 16.11 | 0.5948 | 2.35 |

| 30 | 0.5970 | 0.6910 | 15.74 | 0.6181 | 3.53 |

| Type of particles | Ug/Umf | S | |||||

|---|---|---|---|---|---|---|---|

| Geldart A (dp=92 μm, ρp=1200 kg·m-3,Umf=0.0091 m·s-1, Dt/dp=109) | 2 | 3.9100 | 0.7209 | 0.8944 | 0.4498 | 0.0585 | 1.7587 |

| 3 | 2.5921 | 0.6298 | 0.3261 | 0.7338 | 0.0485 | 1.9021 | |

| 4 | 1.9510 | 0.6338 | 0.1820 | 0.9837 | 0.0478 | 1.9192 | |

| 5 | 1.5519 | 0.5924 | 0.1166 | 1.2138 | 0.0484 | 1.8837 | |

| 6 | 1.3086 | 0.5735 | 0.0840 | 1.4261 | 0.0491 | 1.8662 | |

| 7 | 1.1244 | 0.5515 | 0.0628 | 1.6330 | 0.0497 | 1.8361 | |

| Geldart B (dp=240 μm, ρp=2644 kg·m-3, Umf=0.1032 m·s-1, Dt/dp=42) | 1 | 0.7061 | 0.5523 | 0.0233 | 2.6343 | 0.0468 | 1.8601 |

| 2 | 0.3793 | 0.5826 | 0.0083 | 4.2471 | 0.0576 | 1.6109 | |

| 3 | 0.2498 | 0.6218 | 0.0047 | 5.6837 | 0.0753 | 1.4198 | |

| 4 | 0.1881 | 0.5986 | 0.0035 | 6.3570 | 0.0992 | 1.1958 | |

| 5 | 0.1558 | 1.0118 | 0.0026 | 10.2803 | 0.1087 | 1.6017 | |

| 6 | 0.1296 | 0.8004 | 0.0011 | 12.8732 | 0.0662 | 1.6684 |

表5 不同Ug时的微型流化床内气体RTD特征参数(Dt = 10 mm, Hs = 20 mm)

Table 5 The gas RTD characteristic parameters in micro fluidized beds at different operating gas velocities (Dt = 10 mm, Hs = 20 mm)

| Type of particles | Ug/Umf | S | |||||

|---|---|---|---|---|---|---|---|

| Geldart A (dp=92 μm, ρp=1200 kg·m-3,Umf=0.0091 m·s-1, Dt/dp=109) | 2 | 3.9100 | 0.7209 | 0.8944 | 0.4498 | 0.0585 | 1.7587 |

| 3 | 2.5921 | 0.6298 | 0.3261 | 0.7338 | 0.0485 | 1.9021 | |

| 4 | 1.9510 | 0.6338 | 0.1820 | 0.9837 | 0.0478 | 1.9192 | |

| 5 | 1.5519 | 0.5924 | 0.1166 | 1.2138 | 0.0484 | 1.8837 | |

| 6 | 1.3086 | 0.5735 | 0.0840 | 1.4261 | 0.0491 | 1.8662 | |

| 7 | 1.1244 | 0.5515 | 0.0628 | 1.6330 | 0.0497 | 1.8361 | |

| Geldart B (dp=240 μm, ρp=2644 kg·m-3, Umf=0.1032 m·s-1, Dt/dp=42) | 1 | 0.7061 | 0.5523 | 0.0233 | 2.6343 | 0.0468 | 1.8601 |

| 2 | 0.3793 | 0.5826 | 0.0083 | 4.2471 | 0.0576 | 1.6109 | |

| 3 | 0.2498 | 0.6218 | 0.0047 | 5.6837 | 0.0753 | 1.4198 | |

| 4 | 0.1881 | 0.5986 | 0.0035 | 6.3570 | 0.0992 | 1.1958 | |

| 5 | 0.1558 | 1.0118 | 0.0026 | 10.2803 | 0.1087 | 1.6017 | |

| 6 | 0.1296 | 0.8004 | 0.0011 | 12.8732 | 0.0662 | 1.6684 |

| Type of particles | Dt/mm | Dt/dp | S | |||||

|---|---|---|---|---|---|---|---|---|

| Geldart A (dp=92 μm, ρp=1200 kg·m-3, Ug= 4Umf, Hs=20 mm) | 5 | 54 | 0.5778 | 0.6614 | 0.0129 | 3.7417 | 0.0387 | 2.1620 |

| 10 | 109 | 1.9510 | 0.6338 | 0.1820 | 0.9837 | 0.0478 | 1.9192 | |

| 15 | 163 | 2.8654 | 0.6841 | 0.4930 | 0.6024 | 0.0601 | 1.7262 | |

| 20 | 217 | 3.4392 | 0.7599 | 0.8653 | 0.4592 | 0.0732 | 1.5793 | |

| 30 | 326 | 4.1145 | 0.9198 | 1.6549 | 0.3429 | 0.0978 | 1.4109 | |

| Geldart B (dp=240 μm, ρp=2644 kg·m-3, Ug= 1Umf, Hs=20 mm) | 5 | 21 | 0.1858 | 0.4273 | 0.0015 | 10.3461 | 0.0428 | 1.9223 |

| 10 | 42 | 0.7061 | 0.5523 | 0.0233 | 2.6343 | 0.0468 | 1.8601 | |

| 15 | 63 | 1.0042 | 0.6624 | 0.0636 | 1.5990 | 0.0630 | 1.6057 | |

| 20 | 83 | 1.1938 | 0.7697 | 0.1053 | 1.2529 | 0.0739 | 1.4957 | |

| 30 | 125 | 1.4222 | 0.9441 | 0.1785 | 1.1184 | 0.0883 | 1.5906 |

表6 不同Dt时的微型流化床内气体RTD特征参数(Hs = 20 mm)

Table 6 The gas RTD characteristic parameters in micro fluidized beds at different bed diameters (Hs = 20 mm)

| Type of particles | Dt/mm | Dt/dp | S | |||||

|---|---|---|---|---|---|---|---|---|

| Geldart A (dp=92 μm, ρp=1200 kg·m-3, Ug= 4Umf, Hs=20 mm) | 5 | 54 | 0.5778 | 0.6614 | 0.0129 | 3.7417 | 0.0387 | 2.1620 |

| 10 | 109 | 1.9510 | 0.6338 | 0.1820 | 0.9837 | 0.0478 | 1.9192 | |

| 15 | 163 | 2.8654 | 0.6841 | 0.4930 | 0.6024 | 0.0601 | 1.7262 | |

| 20 | 217 | 3.4392 | 0.7599 | 0.8653 | 0.4592 | 0.0732 | 1.5793 | |

| 30 | 326 | 4.1145 | 0.9198 | 1.6549 | 0.3429 | 0.0978 | 1.4109 | |

| Geldart B (dp=240 μm, ρp=2644 kg·m-3, Ug= 1Umf, Hs=20 mm) | 5 | 21 | 0.1858 | 0.4273 | 0.0015 | 10.3461 | 0.0428 | 1.9223 |

| 10 | 42 | 0.7061 | 0.5523 | 0.0233 | 2.6343 | 0.0468 | 1.8601 | |

| 15 | 63 | 1.0042 | 0.6624 | 0.0636 | 1.5990 | 0.0630 | 1.6057 | |

| 20 | 83 | 1.1938 | 0.7697 | 0.1053 | 1.2529 | 0.0739 | 1.4957 | |

| 30 | 125 | 1.4222 | 0.9441 | 0.1785 | 1.1184 | 0.0883 | 1.5906 |

| Type of particles | Hs/mm | Hs/dp | S | |||||

|---|---|---|---|---|---|---|---|---|

| Geldart A (dp=92 μm, ρp=1200 kg·m-3,Ug= 4Umf, Dt=10 mm) | 10 | 109 | 2.4550 | 0.5731 | 0.2589 | 0.8171 | 0.0430 | 2.0060 |

| 15 | 163 | 2.1465 | 0.5754 | 0.2035 | 0.9209 | 0.0442 | 1.9767 | |

| 20 | 217 | 1.9510 | 0.6338 | 0.1820 | 0.9837 | 0.0478 | 1.9192 | |

| 25 | 272 | 1.7770 | 0.6331 | 0.1646 | 1.0288 | 0.0521 | 1.8282 | |

| 30 | 326 | 1.6204 | 0.6505 | 0.1605 | 1.0419 | 0.0611 | 1.6883 | |

| 35 | 380 | 1.5353 | 0.7716 | 0.1574 | 1.0896 | 0.0668 | 1.6729 | |

| 40 | 435 | 1.4118 | 0.8737 | 0.1493 | 1.1430 | 0.0749 | 1.6137 | |

| Geldart B (dp=240 μm, ρp=2644 kg·m-3, Ug= 1Umf, Dt=10 mm) | 10 | 42 | 0.9550 | 0.5111 | 0.0405 | 2.0146 | 0.0444 | 1.9239 |

| 15 | 63 | 0.8087 | 0.5265 | 0.0299 | 2.3322 | 0.0457 | 1.8861 | |

| 20 | 83 | 0.7061 | 0.5523 | 0.0233 | 2.6343 | 0.0468 | 1.8601 | |

| 25 | 104 | 0.6222 | 0.5502 | 0.0188 | 2.9247 | 0.0487 | 1.8197 | |

| 30 | 125 | 0.5472 | 0.5480 | 0.0148 | 3.2993 | 0.0493 | 1.8054 | |

| 35 | 146 | 0.4666 | 0.4142 | 0.0129 | 3.6054 | 0.0593 | 1.6823 | |

| 40 | 167 | 0.4140 | 0.5820 | 0.0092 | 4.3143 | 0.0535 | 1.7861 |

表7 不同Hs时的微型流化床内气体RTD特征参数(Dt = 10 mm)

Table 7 The gas RTD characteristic parameters in micro fluidized beds at different static bed heights (Dt = 10 mm)

| Type of particles | Hs/mm | Hs/dp | S | |||||

|---|---|---|---|---|---|---|---|---|

| Geldart A (dp=92 μm, ρp=1200 kg·m-3,Ug= 4Umf, Dt=10 mm) | 10 | 109 | 2.4550 | 0.5731 | 0.2589 | 0.8171 | 0.0430 | 2.0060 |

| 15 | 163 | 2.1465 | 0.5754 | 0.2035 | 0.9209 | 0.0442 | 1.9767 | |

| 20 | 217 | 1.9510 | 0.6338 | 0.1820 | 0.9837 | 0.0478 | 1.9192 | |

| 25 | 272 | 1.7770 | 0.6331 | 0.1646 | 1.0288 | 0.0521 | 1.8282 | |

| 30 | 326 | 1.6204 | 0.6505 | 0.1605 | 1.0419 | 0.0611 | 1.6883 | |

| 35 | 380 | 1.5353 | 0.7716 | 0.1574 | 1.0896 | 0.0668 | 1.6729 | |

| 40 | 435 | 1.4118 | 0.8737 | 0.1493 | 1.1430 | 0.0749 | 1.6137 | |

| Geldart B (dp=240 μm, ρp=2644 kg·m-3, Ug= 1Umf, Dt=10 mm) | 10 | 42 | 0.9550 | 0.5111 | 0.0405 | 2.0146 | 0.0444 | 1.9239 |

| 15 | 63 | 0.8087 | 0.5265 | 0.0299 | 2.3322 | 0.0457 | 1.8861 | |

| 20 | 83 | 0.7061 | 0.5523 | 0.0233 | 2.6343 | 0.0468 | 1.8601 | |

| 25 | 104 | 0.6222 | 0.5502 | 0.0188 | 2.9247 | 0.0487 | 1.8197 | |

| 30 | 125 | 0.5472 | 0.5480 | 0.0148 | 3.2993 | 0.0493 | 1.8054 | |

| 35 | 146 | 0.4666 | 0.4142 | 0.0129 | 3.6054 | 0.0593 | 1.6823 | |

| 40 | 167 | 0.4140 | 0.5820 | 0.0092 | 4.3143 | 0.0535 | 1.7861 |

| 1 | Di Renzo A, Scala F, Heinrich S. Recent advances in fluidized bed hydrodynamics and transport phenomena-progress and understanding[J]. Processes, 2021, 9(4): 639-642. |

| 2 | 王荘, 吕潇, 邵媛媛, 等. 流态化的往昔寻觅及未来启示[J]. 化工学报, 2021, 72(12): 5904-5927. |

| Wang Z, Lyu X, Shao Y Y, et al. Early exploration of fluidization theory and its inspiration to the future[J]. CIESC Journal, 2021, 72(12): 5904-5927. | |

| 3 | Han Z N, Yue J R, Geng S L, et al. State-of-the-art hydrodynamics of gas-solid micro fluidized beds[J]. Chemical Engineering Science, 2020, 232: 116345. |

| 4 | Qie Z P, Alhassawi H, Sun F, et al. Characteristics and applications of micro fluidized beds (MFBs)[J]. Chemical Engineering Journal, 2021, 428(2): 131330. |

| 5 | Potic B, Kersten S, Ye M, et al. Fluidization with hot compressed water in micro-reactors[J]. Chemical Engineering Science, 2005, 60(22): 5982-5990. |

| 6 | Scott D S, Piskorz J. Low rate entrainment feeder for fine solids[J]. Industrial & Engineering Chemistry Fundamentals, 1982, 21(3): 319-322. |

| 7 | Liu X J, Hao W Q, Wang K X, et al. Acquiring real kinetics of reactions in the inhibitory atmosphere containing product gases using micro fluidized bed[J]. AIChE Journal, 2021, 67(9): e17325. |

| 8 | Yu J, Yao C B, Zeng X, et al. Biomass pyrolysis in a micro-fluidized bed reactor: characterization and kinetics[J]. Chemical Engineering Journal, 2011, 168(2): 839-847. |

| 9 | Saadatkhah N, Carillo Garcia A, Ackermann S, et al. Experimental methods in chemical engineering: thermogravimetric analysis—TGA[J]. The Canadian Journal of Chemical Engineering, 2020, 98(1): 34-43. |

| 10 | McDonough J, Law R, Reay D, et al. Fluidization in small-scale gas-solid 3D-printed fluidized beds[J]. Chemical Engineering Science, 2019, 200: 294-309. |

| 11 | Liu X H, Xu G W, Gao S Q. Micro fluidized beds: wall effect and operability[J]. Chemical Engineering Journal, 2008, 137(2): 302-307. |

| 12 | Wang F, Fan L S. Gas-solid fluidization in mini- and micro-channels[J]. Industrial & Engineering Chemistry Research, 2011, 50(8): 4741-4751. |

| 13 | Vanni F, Caussat B, Ablitzer C, et al. Effects of reducing the reactor diameter on the fluidization of a very dense powder[J]. Powder Technology, 2015, 277: 268-274. |

| 14 | Guo Q J, Xu Y, Yue X. Fluidization characteristics in micro-fluidized beds of various inner diameters[J]. Chemical Engineering & Technology, 2009, 32(12): 1992-1999. |

| 15 | Rao A, Curtis J S, Hancock B C, et al. The effect of column diameter and bed height on minimum fluidization velocity[J]. AIChE Journal, 2010, 56(9): 2304-2311. |

| 16 | Trachsel F, Günther A, Khan S, et al. Measurement of residence time distribution in microfluidic systems[J]. Chemical Engineering Science, 2005, 60(21): 5729-5737. |

| 17 | 胡丹丹, 耿素龙, 曾玺, 等. 返混对气-固反应特性测试和活化能表征的影响[J]. 化工学报, 2021, 72(3): 1354-1363. |

| Hu D D, Geng S L, Zeng X, et al. Gas back-mixing characteristics and the effects on gas-solid reaction behavior and activation energy characterization[J]. CIESC Journal, 2021, 72(3): 1354-1363. | |

| 18 | Geng S L, Han Z N, Yue J R, et al. Conditioning micro fluidized bed for maximal approach of gas plug flow[J]. Chemical Engineering Journal, 2018, 351: 110-118. |

| 19 | Wang C, Han Z N, Bai H L, et al. Further analysis of the near-plug gas flow conditions in micro gas-solid fluidized beds[J]. Powder Technology, 2022, 404: 117508. |

| 20 | 李铁男, 赵碧丹, 赵鹏, 等. 气固流化床启动阶段挡板内构件受力特性的CFD-DEM模拟[J]. 化工学报, 2022, 73(6): 2649-2661. |

| Li T N, Zhao B D, Zhao P, et al. CFD-DEM simulation of the force acting on immersed baffles during the start-up stage of a gas-solid fluidized bed[J]. CIESC Journal, 2022, 73(6): 2649-2661. | |

| 21 | Moliner C, Marchelli F, Spanachi N, et al. CFD simulation of a spouted bed: comparison between the discrete element method (DEM) and the two fluid model (TFM)[J]. Chemical Engineering Journal, 2019, 377: 120466. |

| 22 | 林俊杰, 罗坤, 王帅, 等. Coarse-grained CFD-DEM方法在不同流态流化床中的模拟验证[J]. 化工学报, 2019, 70(5): 1702-1712. |

| Lin J J, Luo K, Wang S, et al. Verification of coarse-grained CFD-DEM method in multiple flow regimes[J]. CIESC Journal, 2019, 70(5): 1702-1712. | |

| 23 | Wang J W, van der Hoef M A, Kuipers J A M. Why the two-fluid model fails to predict the bed expansion characteristics of Geldart A particles in gas-fluidized beds: a tentative answer[J]. Chemical Engineering Science, 2009, 64(3): 622-625. |

| 24 | Liu X X, Zhu C Q, Geng S J, et al. Two-fluid modeling of Geldart A particles in gas-solid micro-fluidized beds[J]. Particuology, 2015, 21(4): 118-127. |

| 25 | Fullmer W D, Hrenya C M. Quantitative assessment of fine-grid kinetic-theory-based predictions of mean-slip in unbounded fluidization[J]. AIChE Journal, 2016, 62(1): 11-17. |

| 26 | Radl S, Sundaresan S. A drag model for filtered Euler-Lagrange simulations of clustered gas-particle suspensions[J]. Chemical Engineering Science, 2014, 117: 416-425. |

| 27 | Li S J, Zhao P, Xu J, et al. Direct comparison of CFD-DEM simulation and experimental measurement of Geldart A particles in a micro-fluidized bed[J]. Chemical Engineering Science, 2021, 242: 116725. |

| 28 | Li S J, Zhao P, Xu J, et al. CFD-DEM simulation of polydisperse gas-solid flow of Geldart A particles in bubbling micro-fluidized beds[J]. Chemical Engineering Science, 2022, 253: 117551. |

| 29 | Geldart D. Types of gas fluidization[J]. Powder Technology, 1973, 7(5): 285-292. |

| 30 | Syamlal M, Rogers W, Obrien T J. MFIX documentation theory guide[R]. USDOE Morgantown Energy Technology Center (METC), WV (United States), 1993. |

| 31 | Ahmadi G, Ma D. A thermodynamical formulation for dispersed multiphase turbulent flow(1): Basic theory[J]. International Journal of Multiphase Flow, 1990, 16(2): 323-340. |

| 32 | Ma D, Ahmadi G. A thermodynamical formulation for dispersed multiphase turbulent flow(2): Simple shear flows for dense mixtures[J]. International Journal of Multiphase Flow, 1990, 16(2): 341-351. |

| 33 | Gidaspow D, Bezburuah R, Ding J. Hydrodynamics of circulating fluidized beds: kinetic theory approach[R]. Illinois Inst. Tech.of, Chicago, (United States)IL. Dept. of Chemical Engineering, 1991. |

| 34 | Schaeffer D G. Instability in the evolution equations describing incompressible granular flow[J]. Journal of Differential Equations, 1987, 66(1): 19-50. |

| 35 | Yang Z, Lu B N, Wang W. Coupling artificial neural network with EMMS drag for simulation of dense fluidized beds[J]. Chemical Engineering Science, 2021, 246: 117003. |

| 36 | Hong K, Shi Z S, Ullah A, et al. Extending the bubble-based EMMS model to CFB riser simulations[J]. Powder Technology, 2014, 266: 424-432. |

| 37 | Patil D J, van Sint Annaland M, Kuipers J A M. Critical comparison of hydrodynamic models for gas-solid fluidized beds(part Ⅱ): Freely bubbling gas-solid fluidized beds[J]. Chemical Engineering Science, 2005, 60(1): 73-84. |

| 38 | Hulme I, Clavelle E, van der Lee L, et al. CFD modeling and validation of bubble properties for a bubbling fluidized bed[J]. Industrial & Engineering Chemistry Research, 2005, 44(12): 4254-4266. |

| 39 | Cao J T, Cheng Z H, Fang Y T, et al. Simulation and experimental studies on fluidization properties in a pressurized jetting fluidized bed[J]. Powder Technology, 2008, 183(1): 127-132. |

| 40 | Levenspiel O. Tracer Technology: Modeling the Flow of Fluids[M]. Berlin: Springer Science & Business Media, 2011: 5-26. |

| 41 | Guío-Pérez D C, Pröll T, Hofbauer H. Solids residence time distribution in the secondary reactor of a dual circulating fluidized bed system[J]. Chemical Engineering Science, 2013, 104: 269-284. |

| 42 | Ham J H, Platzer B. Semi-empirical equations for the residence time distributions in disperse systems(part 1): Continuous phase[J]. Chemical Engineering & Technology, 2004, 27(11): 1172-1178. |

| [1] | 徐嘉宇, 陈飞国, 徐骥, 葛蔚. 颗粒体系的多尺度混合指数[J]. 化工学报, 2024, 75(6): 2214-2221. |

| [2] | 黄斌, 丰生杰, 傅程, 张威. 液滴撞击单丝铺展特性的数值研究[J]. 化工学报, 2024, 75(6): 2233-2242. |

| [3] | 李娟, 曹耀文, 朱章钰, 石雷, 李佳. 仿生正形尾鳍结构微通道流动与传热特性数值研究及结构优化[J]. 化工学报, 2024, 75(5): 1802-1815. |

| [4] | 李静, 张方芳, 王帅帅, 徐建华, 张朋远. 凹腔结构对正丁烷部分预混火焰可燃极限的影响[J]. 化工学报, 2024, 75(5): 2081-2090. |

| [5] | 谢磊, 徐永生, 林梅. 不同截面肋柱-软尾结构单相流动传热比较[J]. 化工学报, 2024, 75(5): 1787-1801. |

| [6] | 王文雅, 张玮, 楼小玲, 钟若菲, 陈冰冰, 贠军贤. 纳米纤维素嵌合型晶胶微球的多微管成形与模拟[J]. 化工学报, 2024, 75(5): 2060-2071. |

| [7] | 王金山, 王世学, 朱禹. 冷却表面温差对高温质子交换膜燃料电池性能的影响[J]. 化工学报, 2024, 75(5): 2026-2035. |

| [8] | 李怡菲, 董新宇, 王为术, 刘璐, 赵一璠. 微肋板表面干冰升华喷雾冷却传热数值模拟[J]. 化工学报, 2024, 75(5): 1830-1842. |

| [9] | 刘帆, 张芫通, 陶成, 胡成玉, 杨小平, 魏进家. 歧管式射流微通道液冷散热性能[J]. 化工学报, 2024, 75(5): 1777-1786. |

| [10] | 吉笑盈, 郑园, 李晓鹏, 杨振, 张维, 邱诗蕊, 张倩颖, 罗沧海, 孙东鹏, 陈东, 李东亮. 微流控可控制备液滴、颗粒和胶囊及其应用[J]. 化工学报, 2024, 75(4): 1455-1468. |

| [11] | 谷世良, 谭博仁, 程全中, 姚玮洁, 董志鹏, 许峰, 王勇. 轴流泵式混合室内水力学特征的数值模拟[J]. 化工学报, 2024, 75(3): 815-822. |

| [12] | 徐百平, 梁瑞凤, 喻慧文, 吴桂群, 肖书平. 双螺杆挤出机强化三角形转子作用下的腔内分布混合模拟[J]. 化工学报, 2024, 75(3): 858-866. |

| [13] | 李乃良, 刘常松, 杜雪平, 张一帆, 韩东太. 基于Hurst指数的严重段塞流多尺度分形特性[J]. 化工学报, 2024, 75(2): 484-492. |

| [14] | 屠楠, 刘晓群, 王驰宇, 方嘉宾. 连续进出料鼓泡流化床停留时间分布的相似准则研究[J]. 化工学报, 2024, 75(2): 543-552. |

| [15] | 崔怡洲, 李成祥, 翟霖晓, 刘束玉, 石孝刚, 高金森, 蓝兴英. 亚毫米气泡和常规尺寸气泡气液两相流流动与传质特性对比[J]. 化工学报, 2024, 75(1): 197-210. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号