化工学报 ›› 2024, Vol. 75 ›› Issue (2): 543-552.DOI: 10.11949/0438-1157.20231195

收稿日期:2023-11-20

修回日期:2024-01-25

出版日期:2024-02-25

发布日期:2024-04-10

通讯作者:

方嘉宾

作者简介:屠楠(1987—),女,博士,副教授,tu.nan@qq.com

基金资助:

Nan TU1( ), Xiaoqun LIU1, Chiyu WANG1, Jiabin FANG2(

), Xiaoqun LIU1, Chiyu WANG1, Jiabin FANG2( )

)

Received:2023-11-20

Revised:2024-01-25

Online:2024-02-25

Published:2024-04-10

Contact:

Jiabin FANG

摘要:

以连续进出料鼓泡流化床为研究对象,在Glicksman相似准则的基础上引入了扩散准则数,获得了具备颗粒停留时间分布(RTD)相似性的流化床相似放大准则,并明确了颗粒RTD的相似转换关系。对缩尺流化床模型与原型的流动行为及颗粒RTD进行了数值模拟分析,发现在给定的几何相似常数范围内(1<k<200),缩尺模型计算时长可由22.8天降至1.4天,且颗粒分布规律与原型相似,最大误差不超过9.24%。缩尺模型的颗粒RTD经相似转换后能够较好地预测原型颗粒RTD规律且关键特征值最大误差为17.8%。此外,改变颗粒流量、流化气速及静床高度后,缩尺模型仍能准确预测原型的颗粒RTD,其关键特征值最大误差不超过10.32%,证实了该相似准则在变工况下具有适用性,可用于快速、准确预测大型流化床颗粒RTD。

中图分类号:

屠楠, 刘晓群, 王驰宇, 方嘉宾. 连续进出料鼓泡流化床停留时间分布的相似准则研究[J]. 化工学报, 2024, 75(2): 543-552.

Nan TU, Xiaoqun LIU, Chiyu WANG, Jiabin FANG. Study on adaptability of scaling law to residence time distribution in bubbling fluidized beds with continuous operation[J]. CIESC Journal, 2024, 75(2): 543-552.

| k | Gs/ (kg/h) | u/umf | Hbed/ mm | L/ mm | H/ mm | W/ mm | dp/ μm | ρs/ (kg/m3) | ρtr/ (kg/m3) | ρg/ (kg/m3) | μg/ (kg/(m·s) ) | Ds/ (m2/s) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 56.25 | 8 | 100 | 450 | 200 | 40 | 200 | 2600 | 1405 | 1.23 | 1.79×10-5 | 2.9×10-5 |

| 10 | 1.779 | 8 | 10 | 45 | 20 | 4 | 20 | 26000 | 14050 | 12.25 | 5.66×10-6 | 9.1×10-7 |

| 50 | 0.159 | 8 | 2 | 9 | 4 | 0.8 | 4 | 130000 | 70250 | 61.25 | 2.53×10-6 | 8.1×10-8 |

| 100 | 0.056 | 8 | 1 | 4.5 | 2 | 0.4 | 2 | 260000 | 140500 | 122.5 | 1.79×10-6 | 2.9×10-8 |

| 125 | 0.040 | 8 | 0.8 | 3.6 | 1.6 | 0.32 | 1.6 | 325000 | 175625 | 153.1 | 1.60×10-6 | 2.1×10-8 |

| 160 | 0.028 | 8 | 0.625 | 2.8125 | 1.25 | 0.25 | 1.25 | 416000 | 224800 | 196 | 1.41×10-6 | 1.4×10-8 |

| 200 | 0.020 | 8 | 0.5 | 2.25 | 1 | 0.2 | 1 | 520000 | 281000 | 245 | 1.27×10-6 | 1.0×10-8 |

表1 不同 k 下对应的参数值

Table 1 The material properties, operation conditions and geometry parameters under different k

| k | Gs/ (kg/h) | u/umf | Hbed/ mm | L/ mm | H/ mm | W/ mm | dp/ μm | ρs/ (kg/m3) | ρtr/ (kg/m3) | ρg/ (kg/m3) | μg/ (kg/(m·s) ) | Ds/ (m2/s) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 56.25 | 8 | 100 | 450 | 200 | 40 | 200 | 2600 | 1405 | 1.23 | 1.79×10-5 | 2.9×10-5 |

| 10 | 1.779 | 8 | 10 | 45 | 20 | 4 | 20 | 26000 | 14050 | 12.25 | 5.66×10-6 | 9.1×10-7 |

| 50 | 0.159 | 8 | 2 | 9 | 4 | 0.8 | 4 | 130000 | 70250 | 61.25 | 2.53×10-6 | 8.1×10-8 |

| 100 | 0.056 | 8 | 1 | 4.5 | 2 | 0.4 | 2 | 260000 | 140500 | 122.5 | 1.79×10-6 | 2.9×10-8 |

| 125 | 0.040 | 8 | 0.8 | 3.6 | 1.6 | 0.32 | 1.6 | 325000 | 175625 | 153.1 | 1.60×10-6 | 2.1×10-8 |

| 160 | 0.028 | 8 | 0.625 | 2.8125 | 1.25 | 0.25 | 1.25 | 416000 | 224800 | 196 | 1.41×10-6 | 1.4×10-8 |

| 200 | 0.020 | 8 | 0.5 | 2.25 | 1 | 0.2 | 1 | 520000 | 281000 | 245 | 1.27×10-6 | 1.0×10-8 |

| 物理量 | 表达式 | 相似转换关系 |

|---|---|---|

| C(t) | ||

| E(t) | ||

| tm | ||

| σt2 | ||

| θ | θ=t/tm | θ1=θ2 |

| E(θ) | ||

| σθ |

表2 不同k下流化床颗粒 RTD 相似转换关系

Table 2 Similar conversion relationships of fluidized bed particle RTDs under different k

| 物理量 | 表达式 | 相似转换关系 |

|---|---|---|

| C(t) | ||

| E(t) | ||

| tm | ||

| σt2 | ||

| θ | θ=t/tm | θ1=θ2 |

| E(θ) | ||

| σθ |

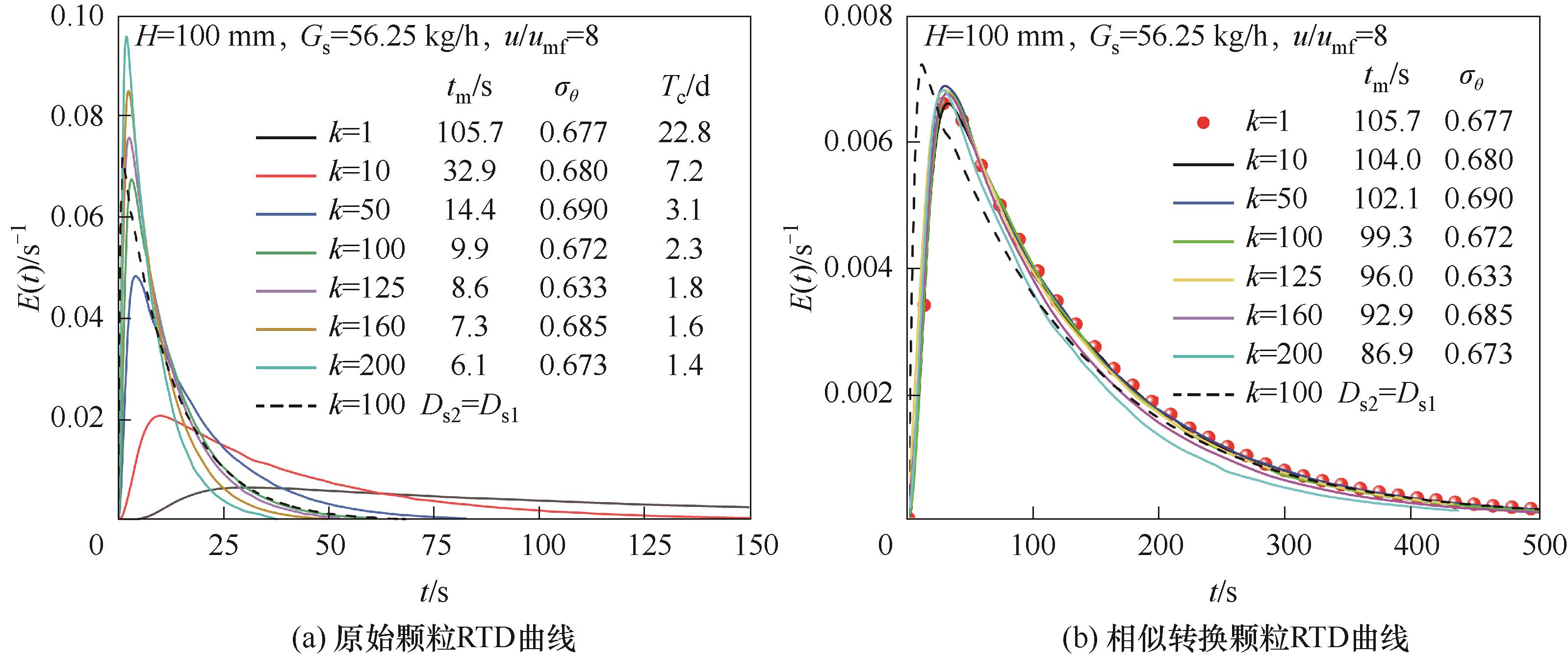

图5 原流化床模型与缩尺模型原始颗粒RTD曲线及相似转换颗粒RTD曲线

Fig.5 The original RTD curves and the similar conversion RTD curves of the scaled-down and original fluidized beds

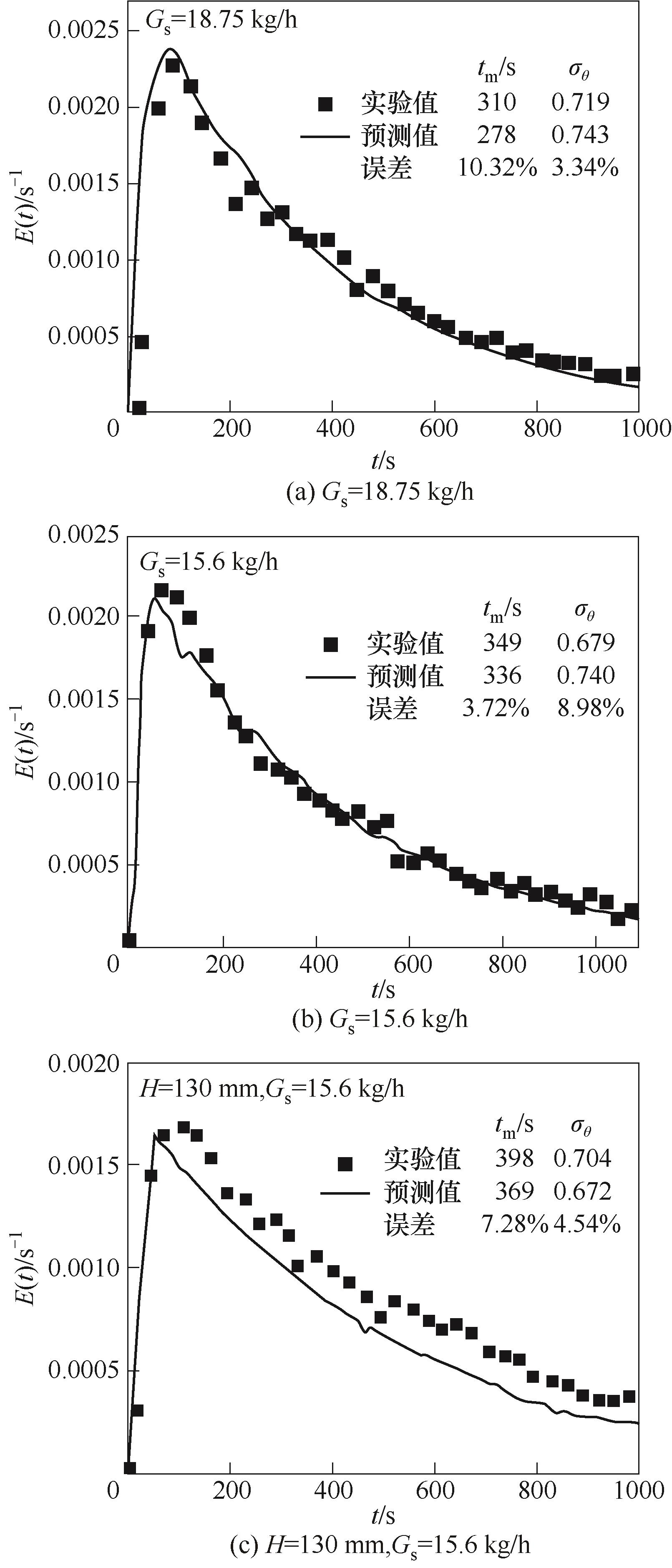

图8 变工况下缩尺模型预测结果与原型实验结果的比较

Fig.8 Comparisons of the prediction results of the scaled-down model with the experimental results of original model under variable working conditions

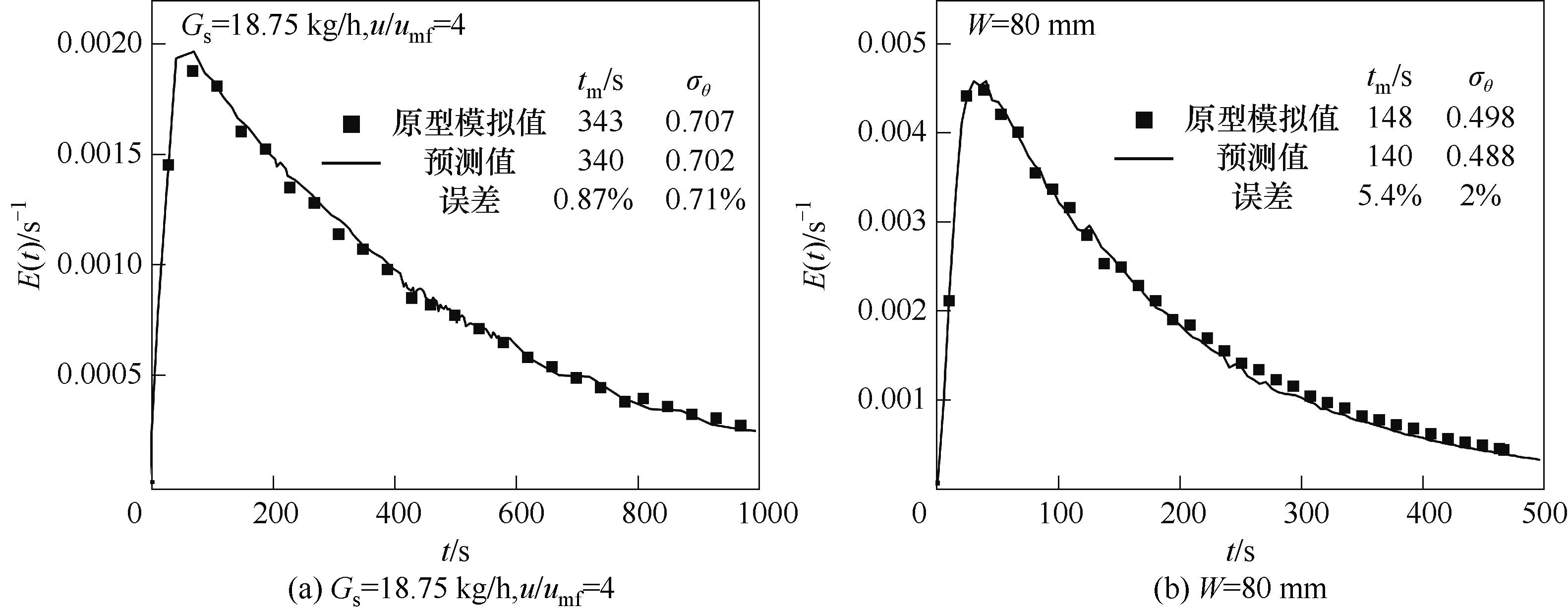

图9 变工况下缩尺模型预测结果与原型模拟结果的比较

Fig.9 Comparisons of the prediction results of the scaled-down model with the the numerical results of original model under variable working conditions

| 1 | Zhang W. A review of techniques for the process intensification of fluidized bed reactors[J]. Chinese Journal of Chemical Engineering, 2009, 17(4): 688-702. |

| 2 | 尹国亮, 黄富勤, 李冬勤. 气固鼓泡流化床的放大规律模拟研究[J]. 计算机与应用化学, 2017, 34(8): 625-628. |

| Yin G L, Huang F Q, Li D Q. Numerical simulation study on scale-up in a gas-solid bubbling fluidized bed[J]. Computers and Applied Chemistry, 2017, 34(8): 625-628. | |

| 3 | Knowlton T M, Karri S B R, Issangya A. Scale-up of fluidized-bed hydrodynamics[J]. Powder Technology, 2005, 150(2): 72-77. |

| 4 | Glicksman L R. Scaling relationships for fluidized beds[J]. Chemical Engineering Science, 1984, 39(9): 1373-1379. |

| 5 | Nicastro M T, Glicksman L R. Experimental verification of scaling relationships for fluidized bed[J]. Chemical Engineering Science, 1984, 39(9): 1381-1391. |

| 6 | Horio M, Nonaka A, Sawa Y, et al. A new similarity rule for fluidized bed scale-up[J]. AIChE Journal, 1986, 32(9): 1466-1482. |

| 7 | Zhang J W, Gao W, Zhao Z G, et al. Adaptability verification of scaling law to solid mixing and segregation behavior in bubbling fluidized bed[J]. Powder Technology, 2012, 228: 206-209. |

| 8 | Glicksman L R, Hyre M, Woloshun K. Simplified scaling relationships for fluidized beds[J]. Powder Technology, 1993, 77(2): 177-199. |

| 9 | Brue E, Brown R C. Use of pressure fluctuations to validate hydrodynamic similitude in fluidized media: bubbling beds[J]. Powder Technology, 2001, 119(2/3): 117-127. |

| 10 | Bricout V, Louge M Y. A verification of Glicksman's reduced scaling under conditions analogous to pressurized circulating fluidization[J]. Chemical Engineering Science, 2004, 59(13): 2633-2638. |

| 11 | Sanderson J, Rhodes M J. Hydrodynamic similarity of solids motion and mixing in bubbling fluidized beds[J]. AIChE Journal, 2003, 49(9): 2317-2327. |

| 12 | 王晓翠, 骆新江. 大颗粒流化床放大准则简化与冷态验证[J]. 化学反应工程与工艺, 2011, 27(4): 297-303. |

| Wang X C, Luo X J. Simplification and cold-model verification of scaling laws for large-particle fluidized bed[J]. Chemical Reaction Engineering and Technology, 2011, 27(4): 297-303. | |

| 13 | Sanderson P J, Lim K S, Sidorenko I, et al. Hydrodynamic similarity in bubbling fluidized beds: the importance of the solid-to-gas density ratio[J]. Industrial & Engineering Chemistry Research, 2004, 43(18): 5466-5473. |

| 14 | Shirvanian P A, Calo J M. Hydrodynamic scaling of a rectangular spouted vessel with a draft duct[J]. Chemical Engineering Journal, 2004, 103(1/2/3): 29-34. |

| 15 | van Ommen J R, Teuling M, Nijenhuis J, et al. Computational validation of the scaling rules for fluidized beds[J]. Powder Technology, 2006, 163(1/2): 32-40. |

| 16 | Sanderson J, Wang S, Rhodes M J, et al. An investigation of fluidized bed scaling laws by DEM simulation[C]//The 12th International Conference on Fluidization - New Horizons in Fluidization Engineering, 2007: 671-678. |

| 17 | Di Maio F P, Di Renzo A. Verification of scaling criteria for bubbling fluidized beds by DEM–CFD simulation[J]. Powder Technology, 2013, 248: 161-171. |

| 18 | 高巍, 张聚伟, 汪印, 等. 连续进出料鼓泡流化床颗粒停留时间分布[J]. 过程工程学报, 2012, 12(1): 9-13. |

| Gao W, Zhang J W, Wang Y, et al. Residence time distribution of particles in a bubbling fluidized bed with their continuous input and output[J]. The Chinese Journal of Process Engineering, 2012, 12(1): 9-13. | |

| 19 | Zou Z, Zhao Y L, Zhao H, et al. Hydrodynamic and solids residence time distribution in a binary bubbling fluidized bed: 3D computational study coupled with the structure-based drag model[J]. Chemical Engineering Journal, 2017, 321: 184-194. |

| 20 | Eder C, Hofer G, Beer J, et al. Particle mixing in bubbling fluidized bed reactors with immersed heat exchangers and continuous particle exchange[J]. Industrial & Engineering Chemistry Research, 2020, 59(44): 19736-19750. |

| 21 | Kong W B, Wang B, Baeyens J, et al. Solids mixing in a shallow cross-flow bubbling fluidized bed[J]. Chemical Engineering Science, 2018, 187: 213-222. |

| 22 | Bachmann P, Bück A, Tsotsas E. Experimental investigation and correlation of the Bodenstein number in horizontal fluidized beds with internal baffles[J]. Powder Technology, 2017, 308: 378-387. |

| 23 | 都艺伟, 吴新, 刘道洁, 等. 内置螺旋挡板流化床颗粒停留时间分布[J]. 过程工程学报, 2018, 18(3): 484-490. |

| Du Y W, Wu X, Liu D J, et al. Residence time distribution of particles in fluidized bed with spiral internal[J]. The Chinese Journal of Process Engineering, 2018, 18(3): 484-490. | |

| 24 | 兰斌, 徐骥, 刘志成, 等. 连续操作密相流化床颗粒停留时间分布特性模拟放大研究[J]. 化工学报, 2021, 72(1): 521-533. |

| Lan B, Xu J, Liu Z C, et al. Simulation of scale-up effect of particle residence time distribution characteristics in continuously operated dense-phase fluidized beds[J]. CIESC Journal, 2021, 72(1): 521-533. | |

| 25 | Lan B, Xu J, Zhao P J, et al. Scale-up effect of residence time distribution of polydisperse particles in continuously operated multiple-chamber fluidized beds[J]. Chemical Engineering Science, 2021, 244: 116809. |

| 26 | Zhang J W, Xu G W. Scale-up of bubbling fluidized beds with continuous particle flow based on particle-residence-time distribution[J]. Particuology, 2015, 19: 155-163. |

| 27 | Geng S J, Qian Y N, Zhan J H, et al. Prediction of solids residence time distribution in cross-flow bubbling fluidized bed[J]. Powder Technology, 2017, 320: 555-564. |

| 28 | 王维, 李佑楚. 颗粒流体两相流模型研究进展[J]. 化学进展, 2000, 12(2): 208-217. |

| Wang W, Li Y C. Progress of the simulation of particle fluid two phase flow[J]. Progress in Chemistry, 2000, 12(2): 208-217. | |

| 29 | Lee J L, Lim E W C. Comparisons of Eulerian-Eulerian and CFD-DEM simulations of mixing behaviors in bubbling fluidized beds[J]. Powder Technology, 2017, 318: 193-205. |

| 30 | Hua L N, Zhao H, Li J, et al. Solid residence time distribution in a cross-flow dense fluidized bed with baffles[J]. Chemical Engineering Science, 2019, 200: 320-335. |

| 31 | Schouten J C, Vander Stappen M L M, Van Den Bleek C M. Scale-up of chaotic fluidized bed hydrodynamics[J]. Chemical Engineering Science, 1996, 51(10): 1991-2000. |

| 32 | Villa Briongos J, Guardiola J. New methodology for scaling hydrodynamic data from a 2D-fluidized bed[J]. Chemical Engineering Science, 2005, 60(18): 5151-5163. |

| 33 | Detamore M S, Swanson M A, Frender K R, et al. A kinetic-theory analysis of the scale-up of circulating fluidized beds[J]. Powder Technology, 2001, 116(2/3): 190-203. |

| [1] | 周尧, 杨小平, 倪一程, 刘继平, 魏进家, 严俊杰. 应用于新型环路热管的两相引射器数值模拟[J]. 化工学报, 2024, 75(1): 268-278. |

| [2] | 王义江, 孙莉, 刘梦涵, 杨金宏, 王国元. 基于响应面法的矿用翅片管空冷器参数优化[J]. 化工学报, 2024, 75(1): 279-291. |

| [3] | 崔怡洲, 李成祥, 翟霖晓, 刘束玉, 石孝刚, 高金森, 蓝兴英. 亚毫米气泡和常规尺寸气泡气液两相流流动与传质特性对比[J]. 化工学报, 2024, 75(1): 197-210. |

| [4] | 王俊男, 何呈祥, 王忠东, 朱春英, 马友光, 付涛涛. T型微混合器内均相混合的数值模拟[J]. 化工学报, 2024, 75(1): 242-254. |

| [5] | 赵碧丹, 代伊杨, 王军武, 张永民. CFD-DEM-IBM方法探究流化床倾斜挡板内构件受力特性[J]. 化工学报, 2024, 75(1): 255-267. |

| [6] | 宋嘉豪, 王文. 斯特林发动机与高温热管耦合运行特性研究[J]. 化工学报, 2023, 74(S1): 287-294. |

| [7] | 张思雨, 殷勇高, 贾鹏琦, 叶威. 双U型地埋管群跨季节蓄热特性研究[J]. 化工学报, 2023, 74(S1): 295-301. |

| [8] | 叶展羽, 山訸, 徐震原. 用于太阳能蒸发的折纸式蒸发器性能仿真[J]. 化工学报, 2023, 74(S1): 132-140. |

| [9] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [10] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [11] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [12] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [13] | 韩晨, 司徒友珉, 朱斌, 许建良, 郭晓镭, 刘海峰. 协同处理废液的多喷嘴粉煤气化炉内反应流动研究[J]. 化工学报, 2023, 74(8): 3266-3278. |

| [14] | 程小松, 殷勇高, 车春文. 不同工质在溶液除湿真空再生系统中的性能对比[J]. 化工学报, 2023, 74(8): 3494-3501. |

| [15] | 刘文竹, 云和明, 王宝雪, 胡明哲, 仲崇龙. 基于场协同和 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号