化工学报 ›› 2024, Vol. 75 ›› Issue (9): 3329-3337.DOI: 10.11949/0438-1157.20240280

代艳辉1( ), 熊启钊1, 房强1, 杨东晓1, 王毅1, 陈杨1,2(

), 熊启钊1, 房强1, 杨东晓1, 王毅1, 陈杨1,2( ), 李晋平1,2, 李立博1,2

), 李晋平1,2, 李立博1,2

收稿日期:2024-03-08

修回日期:2024-06-05

出版日期:2024-09-25

发布日期:2024-10-10

通讯作者:

陈杨

作者简介:代艳辉(2000—),女,硕士研究生,daiyanhui2024@163.com

基金资助:

Yanhui DAI1( ), Qizhao XIONG1, Qiang FANG1, Dongxiao YANG1, Yi WANG1, Yang CHEN1,2(

), Qizhao XIONG1, Qiang FANG1, Dongxiao YANG1, Yi WANG1, Yang CHEN1,2( ), Jinping LI1,2, Libo LI1,2

), Jinping LI1,2, Libo LI1,2

Received:2024-03-08

Revised:2024-06-05

Online:2024-09-25

Published:2024-10-10

Contact:

Yang CHEN

摘要:

金属有机骨架材料(MOF)因其比表面积大、孔隙率高、结构高度可调等优势在气体吸附分离、催化、传感及生物医学等领域展现出巨大的应用潜力。但大多数MOF的孔结构在微孔范围,狭窄的孔隙环境限制了其应用过程中的传质扩散以及活性位点释放,在微孔MOF结构的基础上进行多级孔的构建则可以解决这一问题。为实现经典Cu-BTC结构上的多级孔构筑,基于原位蒸汽辅助合成加刻蚀过程开发了一步制备多级孔Cu-BTC的新方法。通过绿色刻蚀剂乙酸用量、蒸汽辅助时间的调节,获得了孔径范围可调的多级孔Cu-BTC。由于多级孔结构对传质过程和活性位点的提升作用,该材料在CO2电还原实验中展现出优秀的转化效率,最高乙烯的选择性可提升157%。通过蒸汽辅助耦合材料制备和刻蚀过程使得多级孔MOF的一步制备成为了可能,其具有的减少反应物用量和反应步骤的特点将进一步推动多级孔MOF在实际应用中的发展。

中图分类号:

代艳辉, 熊启钊, 房强, 杨东晓, 王毅, 陈杨, 李晋平, 李立博. 原位蒸汽辅助法用于一步制备多级孔Cu-BTC[J]. 化工学报, 2024, 75(9): 3329-3337.

Yanhui DAI, Qizhao XIONG, Qiang FANG, Dongxiao YANG, Yi WANG, Yang CHEN, Jinping LI, Libo LI. In situ steam-assisted method for one-step synthesis of hierarchically porous Cu-BTC[J]. CIESC Journal, 2024, 75(9): 3329-3337.

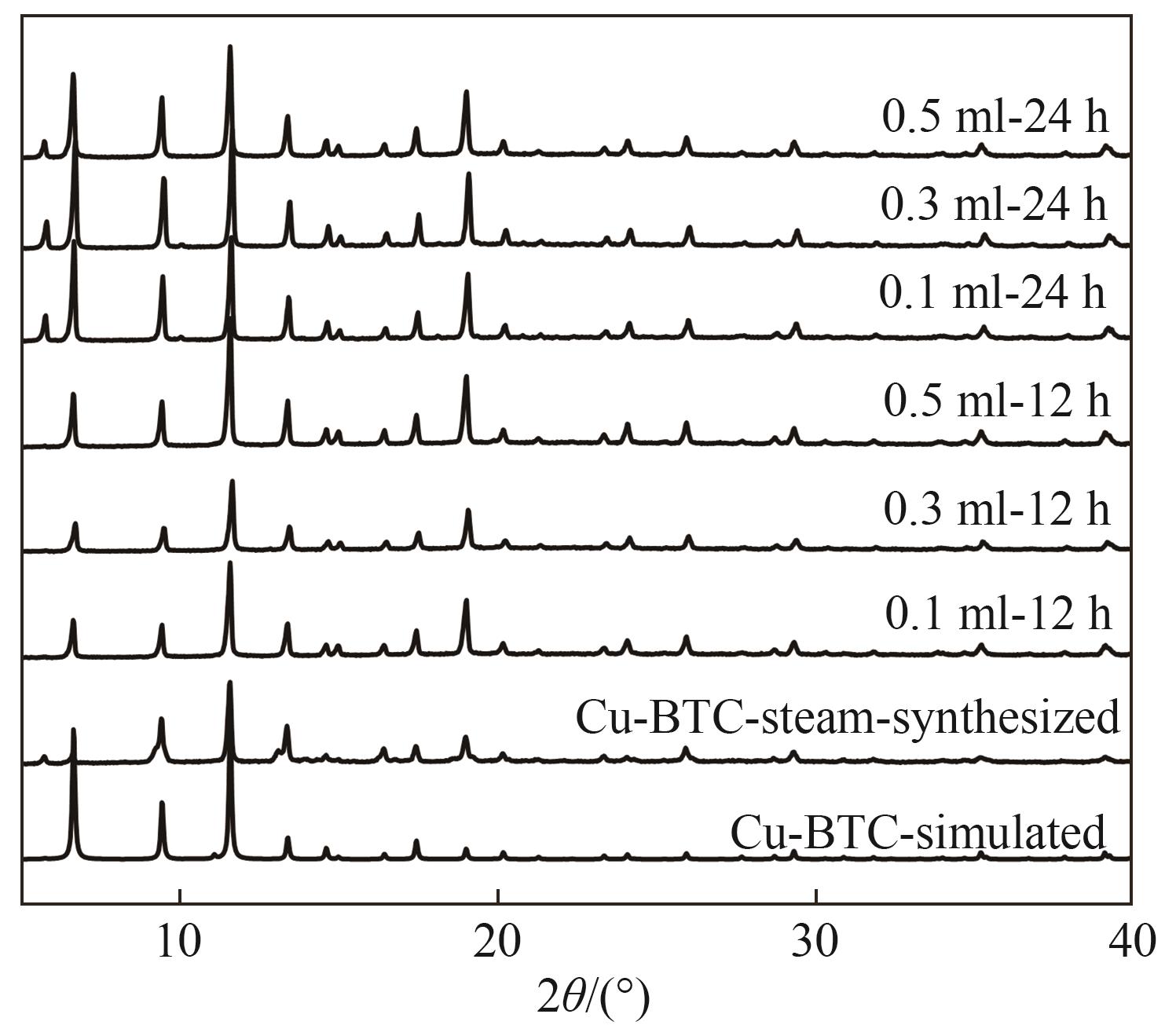

图2 蒸汽相合成Cu-BTC及不同反应时间和乙酸用量下合成HP-Cu-BTC的PXRD谱图

Fig.2 PXRD spectra of Cu-BTC synthesized in steam phase and HP-Cu-BTC synthesized with different reaction time and acetic acid dosages

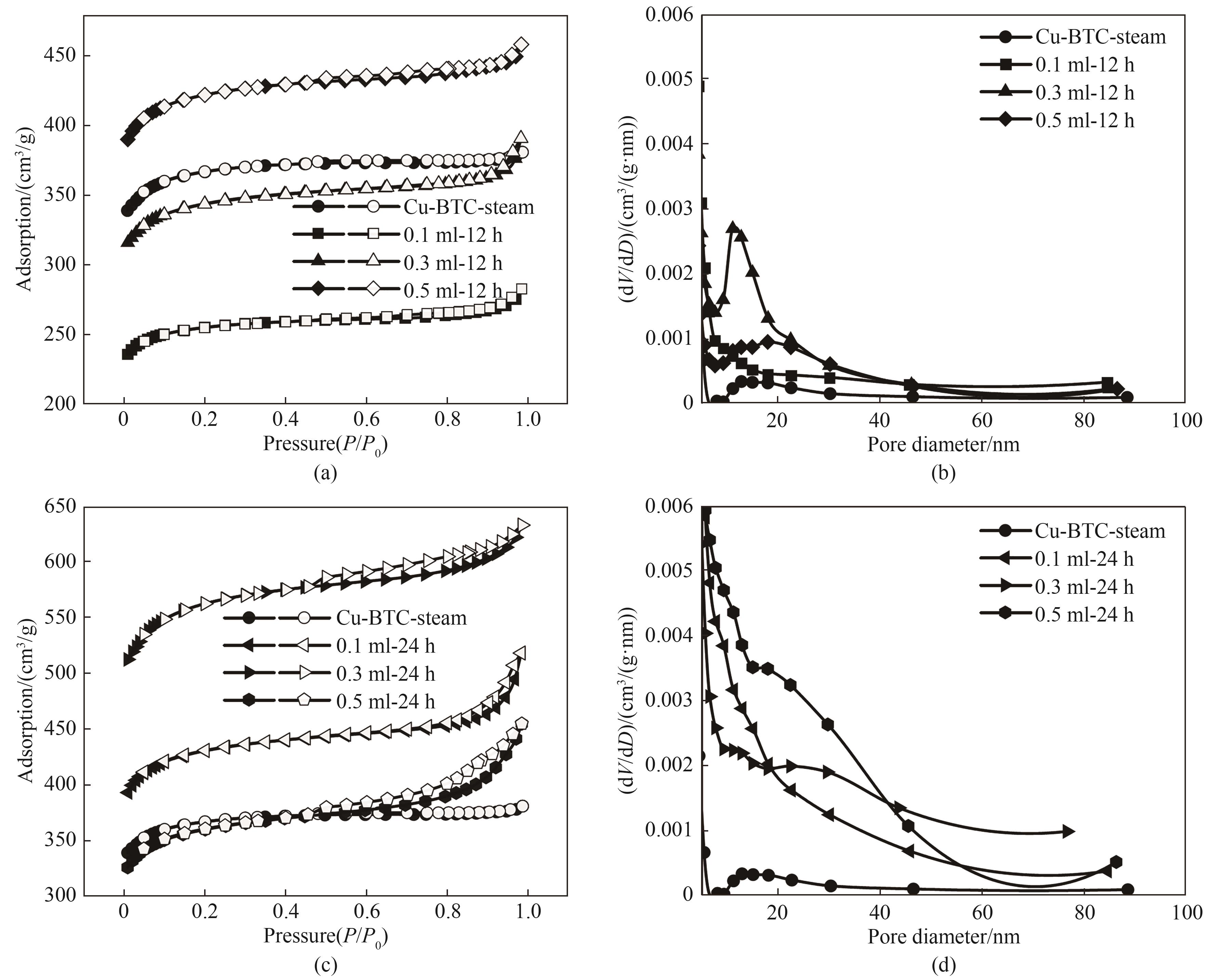

图3 蒸汽相合成HP-Cu-BTC及不同反应时间和乙酸用量下HP-Cu-BTC的77 K N2吸脱附等温线和孔径分布曲线

Fig.3 77 K N2 adsorption and desorption isotherms and pore size distribution curves of Cu-BTC synthesized in steam phase and HP-Cu-BTC with different reaction times and acetic acid dosages

| Reaction conditions | SBET/(m2/g) | Smicro /(m2/g) | Smeso/Smicro | Vt / (cm3/g) | Vmeso/ (cm3/g) | Dmeso/nm |

|---|---|---|---|---|---|---|

| 0.1 ml-12 h | 1005 | 887 | 0.13 | 0.41 | 0.09 | 11 |

| 0.3 ml-12 h | 1355 | 1177 | 0.15 | 0.58 | 0.15 | 11 |

| 0.5 ml-12 h | 1663 | 1465 | 0.13 | 0.68 | 0.13 | 10 |

| 0.1 ml-24 h | 1689 | 1459 | 0.16 | 0.77 | 0.23 | 11 |

| 0.3 ml-24 h | 2209 | 1893 | 0.17 | 0.94 | 0.24 | 15 |

| 0.5 ml-24 h | 1401 | 1193 | 0.17 | 0.68 | 0.24 | 18 |

表1 不同反应条件下得到的HP-Cu-BTC的孔结构参数

Table 1 The pore structure parameters of HP-Cu-BTC obtained by different reaction conditions

| Reaction conditions | SBET/(m2/g) | Smicro /(m2/g) | Smeso/Smicro | Vt / (cm3/g) | Vmeso/ (cm3/g) | Dmeso/nm |

|---|---|---|---|---|---|---|

| 0.1 ml-12 h | 1005 | 887 | 0.13 | 0.41 | 0.09 | 11 |

| 0.3 ml-12 h | 1355 | 1177 | 0.15 | 0.58 | 0.15 | 11 |

| 0.5 ml-12 h | 1663 | 1465 | 0.13 | 0.68 | 0.13 | 10 |

| 0.1 ml-24 h | 1689 | 1459 | 0.16 | 0.77 | 0.23 | 11 |

| 0.3 ml-24 h | 2209 | 1893 | 0.17 | 0.94 | 0.24 | 15 |

| 0.5 ml-24 h | 1401 | 1193 | 0.17 | 0.68 | 0.24 | 18 |

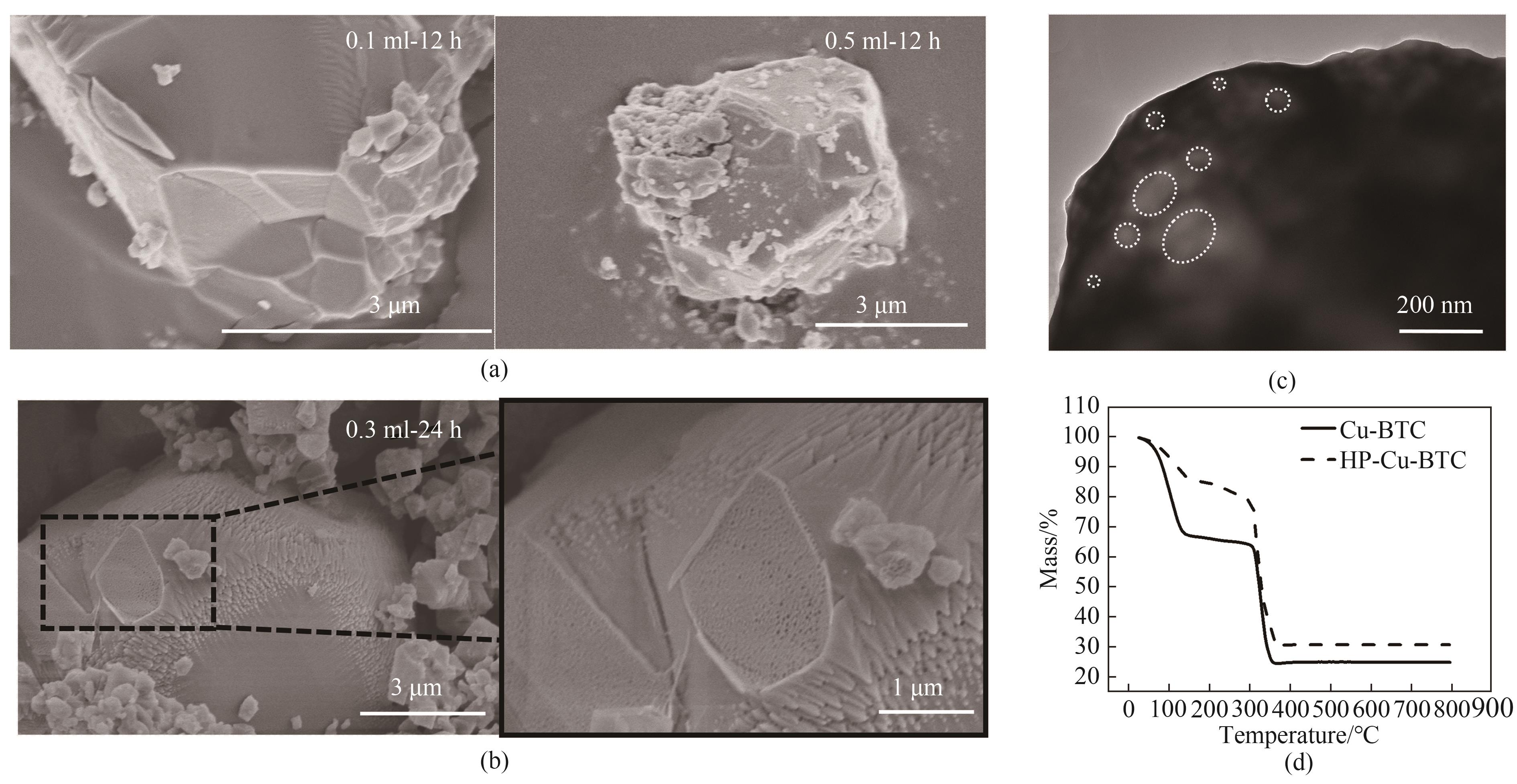

图4 (a)、(b) 不同反应时间和乙酸用量下HP-Cu-BTC的SEM图;(c) 反应时间24 h和乙酸用量0.3 ml时HP-Cu-BTC的TEM图;(d) 原始Cu-BTC及反应时间24 h和乙酸用量0.3 ml时HP-Cu-BTC的TG曲线

Fig. 4 (a),(b) SEM images of HP-Cu-BTC at different reaction times and acetic acid dosages; (c) TEM image of HP-Cu-BTC at reaction time of 24 h and acetic acid dosage of 0.3 ml; (d) TG curves of origional Cu-BTC and HP-Cu-BTC at reaction time of 24 h and acetic acid dosage of 0.3 ml

| 1 | Li L B, Lin R B, Krishna R, et al. Ethane/ethylene separation in a metal-organic framework with iron-peroxo sites[J]. Science, 2018, 362(6413): 443-446. |

| 2 | Li J R, Ma Y G, McCarthy M C, et al. Carbon dioxide capture-related gas adsorption and separation in metal-organic frameworks[J]. Coordination Chemistry Reviews, 2011, 255(15/16): 1791-1823. |

| 3 | 李建惠, 兰天昊, 陈杨, 等. MOF复合材料在气体吸附分离中的研究进展[J]. 化工学报, 2021, 72(1): 167-179. |

| Li J H, Lan T H, Chen Y, et al. Research progress of MOF-based composites for gas adsorption and separation[J]. CIESC Journal, 2021, 72(1): 167-179. | |

| 4 | Kreno L E, Leong K, Farha O K, et al. Metal-organic framework materials as chemical sensors[J]. Chemical Reviews, 2012, 112(2): 1105-1125. |

| 5 | Furukawa H, Cordova K E, O'Keeffe M, et al. The chemistry and applications of metal-organic frameworks[J]. Science, 2013, 341(6149): 1230444. |

| 6 | Li R, Zhang W, Zhou K. Metal-organic-framework-based catalysts for photoreduction of CO2 [J]. Advanced Materials, 2018, 30(35): 1705512. |

| 7 | 王磊, 蒋勇, 钟达忠, 等. 碳化的MOF用于电催化还原二氧化碳制备乙烯和乙醇[J]. 化工学报, 2022, 73(8): 3576-3585. |

| Wang L, Jiang Y, Zhong D Z, et al. Carbonized metal-organic framework for carbon dioxide reduction to ethylene and ethanol[J]. CIESC Journal, 2022, 73(8): 3576-3585. | |

| 8 | 童海峰, 陈再平, 刘伟, 等. 金属有机框架基敏感材料及其在气体传感器中的应用[J]. 科学通报, 2023, 68(27): 3594-3613. |

| Tong H F, Chen Z P, Liu W, et al. Metal-organic framework based sensing materials for the application of gas sensors[J]. Chinese Science Bulletin, 2023, 68(27): 3594-3613. | |

| 9 | Xu W L, Thapa K B, Ju Q, et al. Heterogeneous catalysts based on mesoporous metal-organic frameworks[J]. Coordination Chemistry Reviews, 2018, 373: 199-232. |

| 10 | Bradshaw D, El-Hankari S, Lupica-Spagnolo L. Supramolecular templating of hierarchically porous metal-organic frameworks[J]. Chemical Society Reviews, 2014, 43(16): 5431-5443. |

| 11 | Kabtamu D M, Wu Y N, Li F T. Hierarchically porous metal-organic frameworks: synthesis strategies, structure(s), and emerging applications in decontamination[J]. Journal of Hazardous Materials, 2020, 397: 122765. |

| 12 | Cai G R, Ma X, Kassymova M, et al. Large-scale production of hierarchically porous metal-organic frameworks by a reflux-assisted post-synthetic ligand substitution strategy[J]. ACS Central Science, 2021, 7(8): 1434-1440. |

| 13 | Chen Y, Dai Y H, Xiong Q Z, et al. Synthesis of hierarchically porous Cu-BTC through phase-controlled etching[J]. Chemical Engineering Science, 2024, 297: 120293. |

| 14 | Choi K M, Jeon H J, Kang J K, et al. Heterogeneity within order in crystals of a porous metal-organic framework[J]. Journal of the American Chemical Society, 2011, 133(31): 11920-11923. |

| 15 | Shen K, Zhang L, Chen X D, et al. Ordered macro-microporous metal-organic framework single crystals[J]. Science, 2018, 359(6372): 206-210. |

| 16 | Kim D, Coskun A. Template-directed approach towards the realization of ordered heterogeneity in bimetallic metal-organic frameworks[J]. Angewandte Chemie International Edition, 2017, 56(18): 5071-5076. |

| 17 | 林羲栋, 唐友臣, 苏权飞, 等. 层次孔碳材料:结构设计、功能改性及新能源器件应用[J]. 化工学报, 2020, 71(6): 2586-2598. |

| Lin X D, Tang Y C, Su Q F, et al. Hierarchical porous carbon materials: structure design, functional modification and new energy devices applications[J]. CIESC Journal, 2020, 71(6): 2586-2598. | |

| 18 | Qiu L G, Xu T, Li Z Q, et al. Hierarchically micro- and mesoporous metal-organic frameworks with tunable porosity[J]. Angewandte Chemie International Edition, 2008, 47(49): 9487-9491. |

| 19 | Wu Y N, Li F T, Zhu W, et al. Metal-organic frameworks with a three-dimensional ordered macroporous structure: dynamic photonic materials[J]. Angewandte Chemie International Edition, 2011, 50(52): 12518-12522. |

| 20 | Wang S H, Fan Y N, Teng J, et al. Nanoreactor based on macroporous single crystals of metal-organic framework[J]. Small, 2016, 12(41): 5702-5709. |

| 21 | Cui J C, Gao N, Yin X P, et al. Microfluidic synthesis of uniform single-crystalline MOF microcubes with a hierarchical porous structure[J]. Nanoscale, 2018, 10(19): 9192-9198. |

| 22 | Jing P, Zhang S Y, Chen W J, et al. A macroporous metal-organic framework with enhanced hydrophobicity for efficient oil adsorption[J]. Chemistry, 2018, 24(15): 3754-3759. |

| 23 | Doan H V, Sartbaeva A, Eloi J C, et al. Defective hierarchical porous copper-based metal-organic frameworks synthesised via facile acid etching strategy[J]. Scientific Reports, 2019, 9(1): 10887. |

| 24 | Koo J, Hwang I C, Yu X J, et al. Hollowing out MOFs: hierarchical micro- and mesoporous MOFs with tailorable porosity via selective acid etching[J]. Chemical Science, 2017, 8(10): 6799-6803. |

| 25 | Mofokeng T P, Ipadeola A K, Tetana Z N, et al. Defect-engineered nanostructured Ni/MOF-derived carbons for an efficient aqueous battery-type energy storage device[J]. ACS Omega, 2020, 5(32): 20461-20472. |

| 26 | Xi D Y, Sun Q M, Xu J, et al. In situ growth-etching approach to the preparation of hierarchically macroporous zeolites with high MTO catalytic activity and selectivity[J]. Journal of Materials Chemistry A, 2014, 2(42): 17994-18004. |

| 27 | Zhang W N, Liu Y Y, Lu G, et al. Mesoporous metal-organic frameworks with size-, shape-, and space-distribution-controlled pore structure[J]. Advanced Materials, 2015, 27(18): 2923-2929. |

| 28 | Cao S, Gody G, Zhao W, et al. Hierarchical bicontinuous porosity in metal-organic frameworks templated from functional block co-oligomer micelles[J]. Chemical Science, 2013, 4(9): 3573-3577. |

| 29 | Wee L H, Wiktor C, Turner S, et al. Copper benzene tricarboxylate metal-organic framework with wide permanent mesopores stabilized by Keggin polyoxometallate ions[J]. Journal of the American Chemical Society, 2012, 134(26): 10911-10919. |

| 30 | Albolkany M K, Liu C Y, Wang Y, et al. Molecular surgery at microporous MOF for mesopore generation and renovation[J]. Angewandte Chemie International Edition, 2021, 60(26): 14601-14608. |

| 31 | Chen Y, Yang C Y, Wang X Q, et al. Vapor phase solvents loaded in zeolite as the sustainable medium for the preparation of Cu-BTC and ZIF-8[J]. Chemical Engineering Journal, 2017, 313: 179-186. |

| 32 | Niu L, Wu T Z, Chen M, et al. Conductive metal-organic frameworks for supercapacitors[J]. Advanced Materials, 2022, 34(52): 2200999. |

| 33 | Wehring M, Gascon J, Dubbeldam D, et al. Self-diffusion studies in CuBTC by PFG NMR and MD simulations[J]. The Journal of Physical Chemistry C, 2010, 114(23): 10527-10534. |

| 34 | Gutov O V, Molina S, Escudero-Adán E C, et al. Modulation by amino acids: toward superior control in the synthesis of zirconium metal-organic frameworks[J]. Chemistry, 2016, 22(38): 13582-13587. |

| 35 | Zhao N N, Xu T F, Wang K R, et al. Experimental study of physical-chemical properties modification of coal after CO2 sequestration in deep unmineable coal seams[J]. Greenhouse Gases: Science and Technology, 2018, 8(3): 510-528. |

| 36 | Li H, Meng F C, Zhang S Y, et al. Crystal-growth-dominated fabrication of metal-organic frameworks with orderly distributed hierarchical porosity[J]. Angewandte Chemie International Edition, 2020, 59(6): 2457-2464. |

| 37 | Li Y K, Lu L, Lyu S, et al. Activated coke preparation by physical activation of coal and biomass co-carbonized chars[J]. Journal of Analytical and Applied Pyrolysis, 2021, 156: 105137. |

| 38 | 白晓芳, 陈为, 王白银, 等. 二氧化碳电化学还原的研究进展[J]. 物理化学学报, 2017, 33(12): 2388-2403. |

| Bai X F, Chen W, Wang B Y, et al. Recent progress on electrochemical reduction of carbon dioxide[J]. Acta Physico-Chimica Sinica, 2017, 33(12): 2388-2403. | |

| 39 | Zhang Y, Zhang X L, Zhu Y L, et al. The origin of the electrocatalytic activity for CO2 reduction associated with metal-organic frameworks[J]. ChemSusChem, 2020, 13(10): 2552-2556. |

| 40 | Wen C F, Zhou M, Wu X F, et al. A copper coordination polymer precatalyst with asymmetric building units for selective CO2-to-C2H4 electrolysis[J]. Journal of Materials Chemistry A, 2023, 11(23): 12121-12129. |

| [1] | 秦晗淞, 李国梁, 闫昊, 冯翔, 刘熠斌, 陈小博, 杨朝合. 多级孔ZSM-5分子筛中油酸甲酯催化裂解吸附和扩散行为模拟研究[J]. 化工学报, 2024, 75(5): 1870-1881. |

| [2] | 莫滨宇, 张雅馨, 刘国振, 刘公平, 金万勤. 面向一/二价离子分离的金属有机骨架膜研究进展[J]. 化工学报, 2024, 75(4): 1183-1197. |

| [3] | 余娅洁, 李静茹, 周树锋, 李清彪, 詹国武. 基于天然生物模板构建纳米材料及集成催化剂研究进展[J]. 化工学报, 2023, 74(7): 2735-2752. |

| [4] | 裴仁花, 王永洪, 张新儒, 李晋平. 碳纳米管/环糊精金属有机骨架协同强化混合基质膜的CO2分离[J]. 化工学报, 2022, 73(9): 3904-3914. |

| [5] | 王毅, 熊启钊, 陈杨, 杨江峰, 李立博, 李晋平. 锆基金属有机骨架材料用于氨吸附性能的研究[J]. 化工学报, 2022, 73(4): 1772-1780. |

| [6] | 王结祥, 李洪国, 叶松寿, 郑进保, 陈秉辉. 卤素负载锌-腺嘌呤骨架材料的构建及无助剂催化CO2环加成反应[J]. 化工学报, 2021, 72(7): 3686-3695. |

| [7] | 王莹, 郑柏树, 王刘盛, 汪冠宇, 曾文江, 汪朝旭, 阳庆元. 锆基金属-有机骨架材料分离放射性气体Rn的计算筛选研究[J]. 化工学报, 2021, 72(5): 2688-2696. |

| [8] | 汪宇, 张禹, 童微雯, 叶光华, 周兴贵, 袁渭康. 锂离子电池电极中多级孔道结构设计[J]. 化工学报, 2021, 72(12): 6340-6350. |

| [9] | 任雪宇, 曹景沛, 姚乃瑜, 赵小燕, 冯晓博, 刘天龙, 赵云鹏. 模板法调控多级孔ZSM-5催化褐煤挥发分制备轻质芳烃的研究[J]. 化工学报, 2021, 72(11): 5620-5632. |

| [10] | 李建惠, 兰天昊, 陈杨, 杨江峰, 李立博, 李晋平. MOF复合材料在气体吸附分离中的研究进展[J]. 化工学报, 2021, 72(1): 167-179. |

| [11] | 刘普旭, 贺朝辉, 李立博, 李晋平. 高稳定双金属MOF材料用于低浓度乙烷的高效分离[J]. 化工学报, 2020, 71(9): 4211-4218. |

| [12] | 狄玲, 陈放, 付荣荣, 杨辰, 邢杨, 王晓宁. 富电子LMOF对有机农药的检测机理研究[J]. 化工学报, 2020, 71(8): 3830-3838. |

| [13] | 杨通, 何小波, 银凤翔. M-MOF-74(M=Ni, Co, Zn)的制备及其电化学催化合成氨性能[J]. 化工学报, 2020, 71(6): 2857-2870. |

| [14] | 马会霞,周峰,武光,傅杰,乔凯. 多级孔HZSM-5分子筛催化快速热解生物质制芳烃[J]. 化工学报, 2020, 71(11): 5200-5207. |

| [15] | 杨凯, 阮雪华, 代岩, 王佳铭, 贺高红. 氨基MIL-101(Cr)强化CO2分离性能的混合基质膜优化制备[J]. 化工学报, 2020, 71(1): 329-336. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号