化工学报 ›› 2025, Vol. 76 ›› Issue (2): 879-887.DOI: 10.11949/0438-1157.20241253

吴雨轩1( ), 常诚1,2(

), 常诚1,2( ), 顾雪萍1,2(

), 顾雪萍1,2( ), 冯连芳1,2, 张才亮1,2

), 冯连芳1,2, 张才亮1,2

收稿日期:2024-11-05

修回日期:2024-12-03

出版日期:2025-02-25

发布日期:2025-03-10

通讯作者:

常诚,顾雪萍

作者简介:吴雨轩(2000—),女,硕士研究生,wu_yuxuan@zju.edu.cn

基金资助:

Yuxuan WU1( ), Cheng CHANG1,2(

), Cheng CHANG1,2( ), Xueping GU1,2(

), Xueping GU1,2( ), Lianfang FENG1,2, Cailiang ZHANG1,2

), Lianfang FENG1,2, Cailiang ZHANG1,2

Received:2024-11-05

Revised:2024-12-03

Online:2025-02-25

Published:2025-03-10

Contact:

Cheng CHANG, Xueping GU

摘要:

立体异构比例影响乳聚丁二烯(polybutadiene latex,PBL)的产品性能。在反应量热装置中以过硫酸钾作为引发剂,以松香酸钠/月桂酸钾/烷基萘磺酸钠作为乳化剂,研究了在反应温度为65~75℃、引发剂投料比(对每100单位质量单体添加引发剂的质量)为0.35%~1.38%下的丁二烯乳液聚合过程;建立了乳液法自由基聚合的严格过程机理模型,运用转化率数据进行参数整定,1, 4-顺式(1, 4-cis)、1, 4-反式(1, 4-trans)和1, 2-乙烯基(1, 2-vinyl)三种立构的链增长活化能分别为39.10、38.50、13.20 kJ/mol,指前因子分别为28.37、23.90、11.70 L/(mol·s),模型可以在误差范围内预测立体异构比例。模拟结果表明:立构比例随反应时间变化,立构比例的大幅变化发生在反应初期,在转化率达到20%后,三种立构比例均趋于稳定;温度升高,1, 4-cis和1, 4-trans比例增大,1, 2-vinyl比例减小;立构比例对引发剂投料比不敏感。

中图分类号:

吴雨轩, 常诚, 顾雪萍, 冯连芳, 张才亮. 面向立体异构的丁二烯乳液聚合过程模型化[J]. 化工学报, 2025, 76(2): 879-887.

Yuxuan WU, Cheng CHANG, Xueping GU, Lianfang FENG, Cailiang ZHANG. Modeling of butadiene emulsion polymerization process for stereoisomerization[J]. CIESC Journal, 2025, 76(2): 879-887.

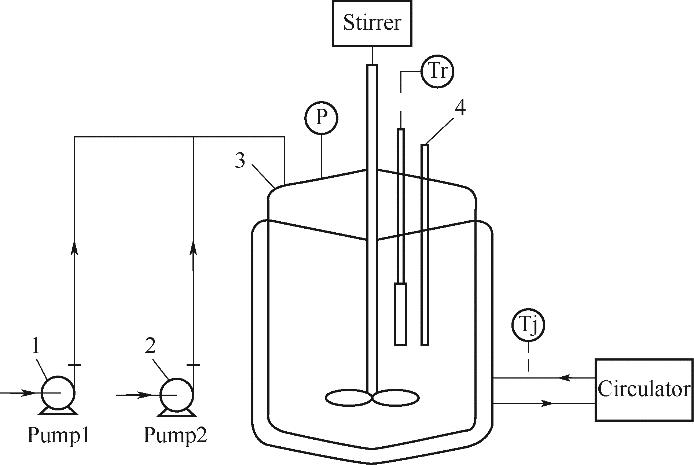

图2 反应量热系统装置图1,2—液体计量泵;3—316Ti夹套反应釜;4—电加热棒及其功率传感器

Fig.2 Reaction calorimetric apparatus1,2—liquid metering pump; 3—316Ti jacketed reactor; 4—electric heating rod and its power sensor

| Alias | Reaction temperature/℃ | Feeding ratio/% |

|---|---|---|

| temp-65 | 65 | 0.69 |

| temp-70 | 70 | |

| temp-75 | 75 | |

| init-0.35 | 70 | 0.35 |

| init-0.69 | 0.69 | |

| init-1.38 | 1.38 |

表1 实验条件设计

Table 1 Design of experimental conditions

| Alias | Reaction temperature/℃ | Feeding ratio/% |

|---|---|---|

| temp-65 | 65 | 0.69 |

| temp-70 | 70 | |

| temp-75 | 75 | |

| init-0.35 | 70 | 0.35 |

| init-0.69 | 0.69 | |

| init-1.38 | 1.38 |

| Item | Reaction | Reaction rate | |

|---|---|---|---|

| init-dec | I | ||

| 1,4-cis | propagation | P m,n,l·+ Mc | |

| chat-mon | P m,n,l· + Mc | ||

| chat-agent | P m,n,l· + CTA | ||

| term-dis | P m1,n1,l1· + P m2,n2,l2· | ||

| term-comb | P m1,n1,l1· + P m2,n2,l2· | ||

| 1,4-trans | propagation | P m,n,l·+ Mt | |

| chat-mon | P m,n,l· + Mt | ||

| chat-agent | P m,n,l· + CTA | ||

| term-dis | P m1,n1,l1· + P m2,n2,l2· | ||

| term-comb | P m1,n1,l1· + P m2,n2,l2· | ||

| 1,2-vinyl | propagation | P m,n,l·+ Mv | |

| chat-mon | P m,n,l· + Mv | ||

| chat-agent | P m,n,l· + CTA | ||

| term-dis | P m1,n1,l1· + P m2,n2,l2· | ||

| term-comb | P m1,n1,l1· + P m2,n2,l2· | ||

表2 考虑立体异构的乳液聚合基元反应框架

Table 2 The stereoisomeric framework for emulsion polymerization is considered

| Item | Reaction | Reaction rate | |

|---|---|---|---|

| init-dec | I | ||

| 1,4-cis | propagation | P m,n,l·+ Mc | |

| chat-mon | P m,n,l· + Mc | ||

| chat-agent | P m,n,l· + CTA | ||

| term-dis | P m1,n1,l1· + P m2,n2,l2· | ||

| term-comb | P m1,n1,l1· + P m2,n2,l2· | ||

| 1,4-trans | propagation | P m,n,l·+ Mt | |

| chat-mon | P m,n,l· + Mt | ||

| chat-agent | P m,n,l· + CTA | ||

| term-dis | P m1,n1,l1· + P m2,n2,l2· | ||

| term-comb | P m1,n1,l1· + P m2,n2,l2· | ||

| 1,2-vinyl | propagation | P m,n,l·+ Mv | |

| chat-mon | P m,n,l· + Mv | ||

| chat-agent | P m,n,l· + CTA | ||

| term-dis | P m1,n1,l1· + P m2,n2,l2· | ||

| term-comb | P m1,n1,l1· + P m2,n2,l2· | ||

| Item | Preexponential factor① | Activation energy/(kJ/mol) |

|---|---|---|

| init-dec | 2.54×1016 | 139.50 |

| propagation | 1.20×108 | 38.93 |

| chat-mon | 8.80×106 | 54.39 |

| chat-agent | 6.62×106 | 52.20 |

| term | 2.47×1010 | 9.97 |

表3 动力学参数初值

Table 3 Initial values of dynamic parameters

| Item | Preexponential factor① | Activation energy/(kJ/mol) |

|---|---|---|

| init-dec | 2.54×1016 | 139.50 |

| propagation | 1.20×108 | 38.93 |

| chat-mon | 8.80×106 | 54.39 |

| chat-agent | 6.62×106 | 52.20 |

| term | 2.47×1010 | 9.97 |

| Item | Preexponential factor① | Activation energy/(kJ/mol) | Tref/K | |

|---|---|---|---|---|

| init-dec | 1.40×10-5 | 139.50 | 343.15 | |

| 1,4-cis | propagation | 28.37 | 39.10 | 343.15 |

| chat-mon | 4.07×10-2 | 42.24 | 343.15 | |

| chat-agent | 25.80 | 41.31 | 343.15 | |

| term-dis | 2.02×107 | 9.90 | 343.15 | |

| term-comb | 2.02×107 | 9.90 | 343.15 | |

| 1,4-trans | propagation | 23.90 | 38.50 | 343.15 |

| chat-mon | 4.07×10-2 | 42.24 | 343.15 | |

| chat-agent | 25.80 | 41.31 | 343.15 | |

| term-dis | 2.02×107 | 9.90 | 343.15 | |

| term-comb | 2.02×107 | 9.90 | 343.15 | |

| 1,2-vinyl | propagation | 11.70 | 13.20 | 343.15 |

| chat-mon | 4.07×10-2 | 42.24 | 343.15 | |

| chat-agent | 25.80 | 41.31 | 343.15 | |

| term-dis | 2.02×107 | 9.90 | 343.15 | |

| term-comb | 2.02×107 | 9.90 | 343.15 | |

表4 三种立体异构的动力学参数

Table 4 Dynamic parameters of three stereoisomers

| Item | Preexponential factor① | Activation energy/(kJ/mol) | Tref/K | |

|---|---|---|---|---|

| init-dec | 1.40×10-5 | 139.50 | 343.15 | |

| 1,4-cis | propagation | 28.37 | 39.10 | 343.15 |

| chat-mon | 4.07×10-2 | 42.24 | 343.15 | |

| chat-agent | 25.80 | 41.31 | 343.15 | |

| term-dis | 2.02×107 | 9.90 | 343.15 | |

| term-comb | 2.02×107 | 9.90 | 343.15 | |

| 1,4-trans | propagation | 23.90 | 38.50 | 343.15 |

| chat-mon | 4.07×10-2 | 42.24 | 343.15 | |

| chat-agent | 25.80 | 41.31 | 343.15 | |

| term-dis | 2.02×107 | 9.90 | 343.15 | |

| term-comb | 2.02×107 | 9.90 | 343.15 | |

| 1,2-vinyl | propagation | 11.70 | 13.20 | 343.15 |

| chat-mon | 4.07×10-2 | 42.24 | 343.15 | |

| chat-agent | 25.80 | 41.31 | 343.15 | |

| term-dis | 2.02×107 | 9.90 | 343.15 | |

| term-comb | 2.02×107 | 9.90 | 343.15 | |

| Alias | Stereoisomer ratios/% | Simulation results/% | 1H NMR results/% | Relative error/% |

|---|---|---|---|---|

| temp-65 | 1,4-cis | 42.9 | 42.8 | 0.23 |

| 1,4-trans | 36.9 | 35.0 | 5.43 | |

| 1,2-vinyl | 20.3 | 22.2 | 8.56 | |

| temp-70 | 1,4-cis | 44.3 | 44.7 | 0.89 |

| 1,4-trans | 37.4 | 38.4 | 2.60 | |

| 1,2-vinyl | 18.3 | 16.9 | 8.28 | |

| temp-75 | 1,4-cis | 45.5 | 44.0 | 3.41 |

| 1,4-trans | 38.2 | 39.5 | 3.29 | |

| 1,2-vinyl | 16.3 | 16.5 | 1.21 | |

| init-0.35 | 1,4-cis | 44.5 | 37.5 | 5.20 |

| 1,4-trans | 37.1 | 43.5 | 8.40 | |

| 1,2-vinyl | 18.4 | 18.9 | 6.98 | |

| init-0.69 | 1,4-cis | 44.3 | 44.7 | 0.89 |

| 1,4-trans | 37.4 | 38.4 | 2.60 | |

| 1,2-vinyl | 18.3 | 16.9 | 8.28 | |

| init-1.38 | 1,4-cis | 44.3 | 42.1 | 5.23 |

| 1,4-trans | 37.4 | 40.2 | 6.97 | |

| 1,2-vinyl | 18.3 | 17.8 | 2.81 |

表5 反应终点立构比例的模拟与1H NMR结果

Table 5 Simulation results and 1H NMR results of end-point stereoisomer ratios

| Alias | Stereoisomer ratios/% | Simulation results/% | 1H NMR results/% | Relative error/% |

|---|---|---|---|---|

| temp-65 | 1,4-cis | 42.9 | 42.8 | 0.23 |

| 1,4-trans | 36.9 | 35.0 | 5.43 | |

| 1,2-vinyl | 20.3 | 22.2 | 8.56 | |

| temp-70 | 1,4-cis | 44.3 | 44.7 | 0.89 |

| 1,4-trans | 37.4 | 38.4 | 2.60 | |

| 1,2-vinyl | 18.3 | 16.9 | 8.28 | |

| temp-75 | 1,4-cis | 45.5 | 44.0 | 3.41 |

| 1,4-trans | 38.2 | 39.5 | 3.29 | |

| 1,2-vinyl | 16.3 | 16.5 | 1.21 | |

| init-0.35 | 1,4-cis | 44.5 | 37.5 | 5.20 |

| 1,4-trans | 37.1 | 43.5 | 8.40 | |

| 1,2-vinyl | 18.4 | 18.9 | 6.98 | |

| init-0.69 | 1,4-cis | 44.3 | 44.7 | 0.89 |

| 1,4-trans | 37.4 | 38.4 | 2.60 | |

| 1,2-vinyl | 18.3 | 16.9 | 8.28 | |

| init-1.38 | 1,4-cis | 44.3 | 42.1 | 5.23 |

| 1,4-trans | 37.4 | 40.2 | 6.97 | |

| 1,2-vinyl | 18.3 | 17.8 | 2.81 |

| 18 | Jing Y, Sheares V V. Polar, functionalized diene-based materials(1): Bulk, solution, and emulsion free radical polymerization of 2-cyanomethyl-1,3-butadiene[J]. Macromolecules, 2000, 33(17): 6255-6261. |

| 19 | Binder J L. Microstructures of polybutadienes and butadiene-styrene copolymers[J]. Rubber Chemistry and Technology, 1955, 28(1): 121-130. |

| 20 | Abdollahi M, Rahmatpour A, Khoshniyat A R. Effect of the carboxylic acid monomer type on the emulsifier-free emulsion copolymerization of styrene and butadiene[J]. Journal of Applied Polymer Science, 2007, 106(2): 828-836. |

| 21 | Yan K, Luo Y W. Significantly suppressed chain transfer to monomer reactions in RAFT emulsion polymerization of styrene[J]. Industrial & Engineering Chemistry Research, 2019, 58(46): 20969-20975. |

| 22 | Safinejad A, Pourmahdian S, Hadavand B S. Emulsifier-free emulsion polymerization of acrylonitrile-butadiene-carboxylic acid monomers: a kinetic study based on polymerization pressure profile[J]. Journal of Dispersion Science and Technology, 2020, 41(2): 157-167. |

| 23 | 魏佑宝. 乳液丁苯工业聚合过程模拟[D]. 杭州: 浙江大学, 2001. |

| Wei Y B. Simulation of industrial polymerization process of emulsion styrene-butadiene[D]. Hangzhou: Zhejiang University, 2001. | |

| 24 | Saldívar-Guerra E, Infante-Martínez R, Islas-Manzur J M. Mathematical modeling of the production of elastomers by emulsion polymerization in trains of continuous reactors[J]. Processes, 2020, 8(11): 1508. |

| 25 | He G, Luo T, Dang Y G, et al. Combined mechanistic and genetic programming approach to modeling pilot NBR production: influence of feed compositions on rubber mooney viscosity[J]. RSC Advances, 2021, 11(2): 817-829. |

| 26 | Carpio R R, Feital T, Câmara M M, et al. Digital twin for the SBR cold emulsion copolymerization process[J]. Macromolecular Reaction Engineering, 2024, 18(3): 2300055. |

| 27 | 冯连芳, 顾雪萍, 王凯. 搅拌反应器中反应热的实时监测Ⅰ确定性动态模型的量热法[J]. 化学反应工程与工艺, 1999, 15(1): 65-70. |

| Feng L F, Gu X P, Wang K. On-line calorimetry for supervising batch reactor[J]. Chemical Reaction Engineering and Technology, 1999, 15(1): 65-70. | |

| 28 | Roberts D E. Heats of polymerization — a summary of published values and their relation to structure[J]. Journal of Research of the National Bureau of Standards, 1950, 44(3): 221. |

| 29 | Makhiyanov N. Determination of configurational isomers in polybutadienes by 1H and 13C NMR spectroscopy[J]. Polymer Science Series A, 2012, 54(2): 69-80. |

| 30 | 谷立广, 王晓工, 刘德山, 等. 共缩聚物序列结构的1H-NMR研究[J]. 清华大学学报(自然科学版), 1992, 32(3): 75-81. |

| Gu L G, Wang X G, Liu D S, et al. Study on sequence structure of copolycondensation polymer by 1H-NMR[J]. Journal of Tsinghua University (Science and Technology), 1992, 32(3): 75-81. | |

| 31 | Washington I D. Dynamic modelling of emulsion polymerization for the continuous production of nitrile rubber[D]. Waterloo: University of Waterloo, 2008. |

| 1 | Riccò T, Pavan A, Danusso F. Dynamic transition of grafted polybutadiene in ABS resins[J]. Polymer, 1975, 16(9): 685-689. |

| 2 | Wu S T, Chen M, Wu G F, et al. Variation of core-shell structural particles and their toughening behavior in poly(vinyl chloride) (PVC) matrix[J]. Journal of Polymer Research, 2015, 22(5): 82. |

| 3 | Medeiros A M S, Bourgeat-Lami E, McKenna T F L. Styrene-butadiene rubber by miniemulsion polymerization using in situ generated surfactant[J]. Polymers, 2020, 12(7): 1476. |

| 4 | Yin S, Lu Z H, Bai H R, et al. Functionalized GO/hydroxy-terminated polybutadiene composites with high anti-migration and ablation resistance performance[J]. Polymers, 2022, 14(16): 3315. |

| 5 | Kalenda P. Using the maleinized liquid polybutadiene as a binder for the anticorrosive coatings[J]. Pigment & Resin Technology, 2002, 31(1): 17-26. |

| 6 | Hou G Y, Tao W, Liu J, et al. Effect of the structural characteristics of solution styrene-butadiene rubber on the properties of rubber composites[J]. Journal of Applied Polymer Science, 2018, 135(24): e45749. |

| 7 | 吴宇. 低顺式聚丁二烯合成及其应用于连续本体法高抗冲ABS制备研究[D]. 兰州: 兰州大学, 2013. |

| Wu Y. Study on the synthesis of LCBR and which used to prepare high impact ABS[D]. Lanzhou: Lanzhou University, 2013. | |

| 8 | Kumar A, Mohanty S, Gupta V K. Butadiene rubber: synthesis, microstructure, and role of catalysts[J]. Rubber Chemistry and Technology, 2021, 94(3): 393-409. |

| 9 | 罗梦, 宋玉栋, 郑盛之, 等. ABS树脂废水胶乳浓度对破乳的影响[J]. 化工学报, 2016, 67(11): 4837-4842. |

| Luo M, Song Y D, Zheng S Z, et al. Effect of latex concentration in ABS resin wastewater on demulsification[J]. CIESC Journal, 2016, 67(11): 4837-4842. | |

| 10 | 徐林, 张春庆, 王雪. 不同微观结构聚丁二烯橡胶的自由基接枝反应[J]. 合成橡胶工业, 2021, 44(2): 87-92. |

| Xu L, Zhang C Q, Wang X. Radical grafting reaction of polybutadiene rubber with different microstructure[J]. China Synthetic Rubber Industry, 2021, 44(2): 87-92. | |

| 11 | Lin J, Wang F, Zhang C Y, et al. Copolymerization of 1,3-butadiene with phenyl/phenethyl substituted 1,3-butadienes: a direct strategy to access pendant phenyl functionalized polydienes[J]. RSC Advances, 2021, 11(38): 23184-23191. |

| 12 | 赫炜, 朱寒, 刘天保, 等. 稀土顺丁橡胶BRNd 40和BRNd 60性能对比[J]. 合成橡胶工业, 2019, 42(5): 363-370. |

| He W, Zhu H, Liu T B, et al. Performance comparison of rare-earth cis-1,4-polybutadiene rubber BRNd 40 and BRNd 60[J]. China Synthetic Rubber Industry, 2019, 42(5): 363-370. | |

| 13 | Short J N, Kraus G, Zelinski R P, et al. Polybutadienes of controlled cis, trans and vinyl structures[J]. Rubber Chemistry and Technology, 1959, 32(2): 614-627. |

| 14 | 陶燕春. 偶联剂Si747原位改性白炭黑增强溶聚丁苯橡胶复合材料的结构与性能研究[D]. 北京: 北京化工大学, 2016. |

| Tao Y C. Study of structure and properties in solution polymerized styrene-butadiene rubbers filled with silica in-situ modified by Si747[D]. Beijing: Beijing University of Chemical Technology, 2016. | |

| 15 | 袁泉, 李云龙, 王世杰, 等. 用分子动力学模拟研究丁二烯微观结构对丁腈橡胶物理力学性能的影响[J]. 合成橡胶工业, 2022, 45(2): 95-99. |

| Yuan Q, Li Y L, Wang S J, et al. Studies on effect of butadiene microstructure on physical and mechanical properties of nitrile rubber by molecular dynamics simulation[J]. China Synthetic Rubber Industry, 2022, 45(2): 95-99. | |

| 16 | Condon F E. Influence of temperature of polymerization on the structural composition of emulsion polymers of butadiene[J]. Journal of Polymer Science, 1953, 11(2): 139-149. |

| 17 | Friedmann G, Brosse N. Stereospecific emulsion polymerization of 2-phenyl-1,3-butadiene[J]. European Polymer Journal, 1991, 27(8): 747-749. |

| [1] | 高越, 李丁, 高玉苗. 有机污染场地土壤催化氧化修复技术研究[J]. 化工学报, 2025, 76(3): 1297-1304. |

| [2] | 彭子林, 周蕾, 邓庆航, 叶光华, 周兴贵. 包含偏硅酸影响的3D NAND磷酸湿法刻蚀动力学[J]. 化工学报, 2025, 76(2): 645-653. |

| [3] | 党法璐, 孙志国, 高照, 王刚, 陈政宇, 张霖宙, 连竞存, 刘美佳, 张忠东, 刘超伟. 原油一步法催化裂解制低碳烯烃:实验和反应路径研究[J]. 化工学报, 2025, 76(2): 667-685. |

| [4] | 贾艳萍, 马艳菊, 管文昕, 杨彬, 张健, 张兰河. 响应面法优化Fe0/H2O2体系降解染料废水的工艺条件及机理[J]. 化工学报, 2025, 76(1): 348-362. |

| [5] | 胡术刚, 田国庆, 刘文娟, 徐广飞, 刘华清, 张建, 王艳龙. 纳米零价铁的制备及氧化还原技术的应用进展[J]. 化工学报, 2024, 75(9): 3041-3055. |

| [6] | 张丽萍, 孟晓荣, 宋锦峰, 杜金晶. VO2@KH550/570@PS复合薄膜的制备及其热致相变性能[J]. 化工学报, 2024, 75(9): 3348-3359. |

| [7] | 马君霞, 李林涛, 熊伟丽. 基于Tri-training GPR的半监督软测量建模方法[J]. 化工学报, 2024, 75(7): 2613-2623. |

| [8] | 陈彦伶, 袁炳志, 王丽伟, 张宸, 朱涵玉. 非平衡条件下金属氯化物-氨工质对的吸附动力学研究[J]. 化工学报, 2024, 75(6): 2252-2261. |

| [9] | 程骁恺, 历伟, 王靖岱, 阳永荣. 镍催化可控/活性自由基聚合反应研究进展[J]. 化工学报, 2024, 75(4): 1105-1117. |

| [10] | 曾玉娇, 肖炘, 杨刚, 张意博, 郑光明, 李防, 汪凤玲. 基于机理与数据混合驱动的湿法磷酸生产过程代理建模与优化[J]. 化工学报, 2024, 75(3): 936-944. |

| [11] | 贾艳萍, 阴东旭, 徐静仪, 张海丰, 张兰河. Fe2+/Mn2+活化亚硫酸盐降解盐酸土霉素的机理研究[J]. 化工学报, 2024, 75(2): 647-658. |

| [12] | 连斌, 龙妍, 徐啟蕾, 单宝明, 王学重, 张方坤. 间歇冷却结晶过程模型参数及操作敏感性分析[J]. 化工学报, 2024, 75(12): 4587-4595. |

| [13] | 王茂先, 孙启典, 付哲, 华放, 纪晔, 程易. 分子水平动力学模型和机器学习方法相结合研究废弃塑料热解[J]. 化工学报, 2024, 75(11): 4320-4332. |

| [14] | 陈贵梅, 谢雨芸, 杨有威, 高艳, 王春英. 类普鲁士蓝衍生物活化过一硫酸盐降解罗丹明B[J]. 化工学报, 2024, 75(10): 3804-3814. |

| [15] | 李文宁, 陆敏, 殷俞. 钴高度分散于还原氧化石墨烯用于高级氧化降解有机污染物[J]. 化工学报, 2024, 75(10): 3793-3803. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号