化工学报 ›› 2025, Vol. 76 ›› Issue (S1): 289-296.DOI: 10.11949/0438-1157.20241306

• 能源和环境工程 • 上一篇

孔俊龙1,2( ), 毕扬1,2, 赵耀1,2, 代彦军1,2(

), 毕扬1,2, 赵耀1,2, 代彦军1,2( )

)

收稿日期:2024-11-15

修回日期:2024-11-19

出版日期:2025-06-25

发布日期:2025-06-26

通讯作者:

代彦军

作者简介:孔俊龙(2000—),男,博士研究生,evankhang@sjtu.edu.cn

基金资助:

Junlong KONG1,2( ), Yang BI1,2, Yao ZHAO1,2, Yanjun DAI1,2(

), Yang BI1,2, Yao ZHAO1,2, Yanjun DAI1,2( )

)

Received:2024-11-15

Revised:2024-11-19

Online:2025-06-25

Published:2025-06-26

Contact:

Yanjun DAI

摘要:

储能电池在能量存储领域的广泛应用要求高效的热管理系统确保其安全与性能。冷媒直冷技术因其优良的均温性和高效能,在电池热管理领域受到关注。系统通过直冷板流道中的制冷剂两相汽化过程实现电池组的高效温控和温度均匀性控制。实验结果显示,在环境温度25℃下,系统在500 W热载荷、40 Hz压缩机频率的标准工况下,冷板表面温度均匀,最大温差控制在0.4℃以内。同时,冷板间温度差异小,平均温度极差仅为0.28℃,系统温度均匀性良好。通过优化压缩机频率等运行参数可进一步提升系统性能。研究结果可为储能电池热管理系统的优化设计提供参考。

中图分类号:

孔俊龙, 毕扬, 赵耀, 代彦军. 储能电池直冷热管理系统的模拟实验[J]. 化工学报, 2025, 76(S1): 289-296.

Junlong KONG, Yang BI, Yao ZHAO, Yanjun DAI. Simulation experiment on direct cooling thermal management system for energy storage batteries[J]. CIESC Journal, 2025, 76(S1): 289-296.

| 设备 | 类型 | 特性参数 |

|---|---|---|

| 压缩机 | 涡旋变频压缩机 | 排量14.1 ml/r,转速1000~7200 r/min |

| 储液器 | R134a适用 | 容积0.5 L |

| 板式换热器 | 铜钎焊板式换热器 | 冷媒-冷媒换热,单片换热面积0.01 m2,片数22 |

| 电子膨胀阀 | 永磁型直动式步进电机 | 阀口通径1.65 mm,开度调节范围0~500 |

| 模拟热源 | 硅橡胶加热垫 | 单块最大加热功率1000 W,数量4 |

| 功率调节器 | 单相接触式 | 输入电压220 V,输出电压0~250 V,输出电流4 A |

| 空冷器 | 翅片换热器 | 尺寸760 mm×500 mm×22 mm,管排数1,管间距25 mm,管外径9.52 mm,翅片类型波纹片 |

表1 实验台架重要部件参数

Table 1 Parameters of important components of experimental bench

| 设备 | 类型 | 特性参数 |

|---|---|---|

| 压缩机 | 涡旋变频压缩机 | 排量14.1 ml/r,转速1000~7200 r/min |

| 储液器 | R134a适用 | 容积0.5 L |

| 板式换热器 | 铜钎焊板式换热器 | 冷媒-冷媒换热,单片换热面积0.01 m2,片数22 |

| 电子膨胀阀 | 永磁型直动式步进电机 | 阀口通径1.65 mm,开度调节范围0~500 |

| 模拟热源 | 硅橡胶加热垫 | 单块最大加热功率1000 W,数量4 |

| 功率调节器 | 单相接触式 | 输入电压220 V,输出电压0~250 V,输出电流4 A |

| 空冷器 | 翅片换热器 | 尺寸760 mm×500 mm×22 mm,管排数1,管间距25 mm,管外径9.52 mm,翅片类型波纹片 |

| 参数 | 测量仪表 | 量程 | 精度 |

|---|---|---|---|

| 直冷板温度/℃ | K型热电偶 | -200~260 | ± 0.5% |

| 制冷剂温度/℃ | Pt100热电阻 | -50~200 | ± 0.5℃ |

| 环境温度/℃ | Pt100热电阻 | -50~200 | ± 0.5℃ |

| 低压侧压力/MPa | MIK-P300 | -0.1~2.5 | ± 0.5% |

| 高压侧压力/MPa | MIK-P300 | -0.1~10.0 | ± 0.5% |

| 压缩机功率/W | DDSU666 | 0~99999 | ± 1.0% |

表2 测试仪器与对应参数

Table 2 Parameters of test instrumentation

| 参数 | 测量仪表 | 量程 | 精度 |

|---|---|---|---|

| 直冷板温度/℃ | K型热电偶 | -200~260 | ± 0.5% |

| 制冷剂温度/℃ | Pt100热电阻 | -50~200 | ± 0.5℃ |

| 环境温度/℃ | Pt100热电阻 | -50~200 | ± 0.5℃ |

| 低压侧压力/MPa | MIK-P300 | -0.1~2.5 | ± 0.5% |

| 高压侧压力/MPa | MIK-P300 | -0.1~10.0 | ± 0.5% |

| 压缩机功率/W | DDSU666 | 0~99999 | ± 1.0% |

图3 500 W、40 Hz工况下系统中冷板的最大温差和测点温度分布

Fig.3 Maximum temperature difference of cold plates and temperature distribution of measuring points under 500 W, 40 Hz

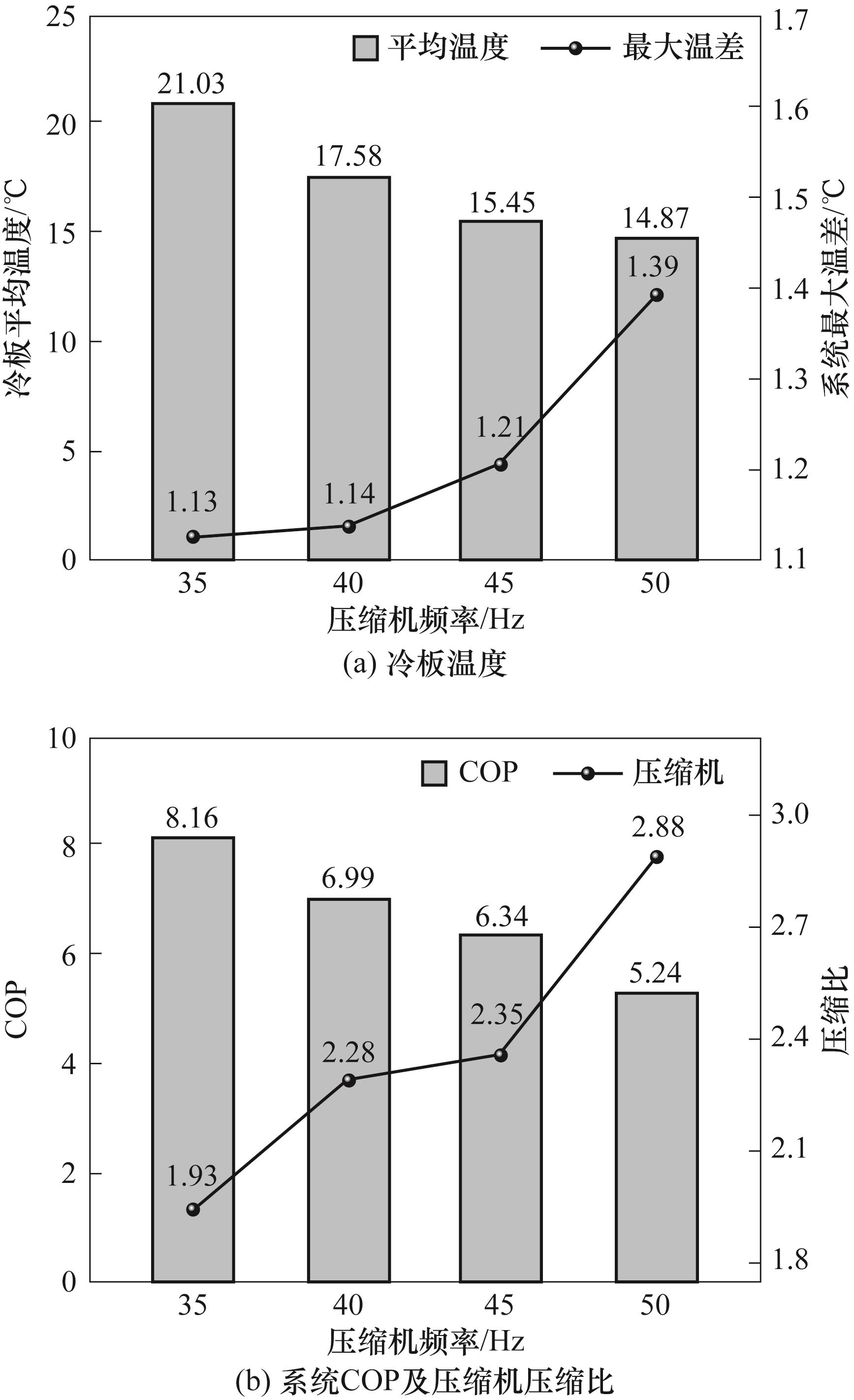

图6 500 W低热载荷下不同压缩机频率对应的冷板温度和系统COP及压缩机压缩比

Fig. 6 Cold plate temperature, system COP and compressor compression ratio corresponding to different compressor frequencies under low heat load of 500 W

| 1 | 梁坤峰, 米国强, 徐红玉, 等. 动力电池双向热管理系统性能分析与优化[J]. 化工学报, 2021, 72(8): 4146-4154. |

| Liang K F, Mi G Q, Xu H Y, et al. Performance analysis and optimization of two-way thermal management system for power battery[J]. CIESC Journal, 2021, 72(8): 4146-4154. | |

| 2 | 李新泽, 张双星, 杨洪海, 等. 基于电池冷却用新型脉动热管性能的实验研究[J]. 化工学报, 2024, 75(6): 2222-2232. |

| Li X Z, Zhang S X, Yang H H, et al. Experimental study on performance of new type of pulsating heat pipe for battery cooling[J]. CIESC Journal, 2024, 75(6): 2222-2232. | |

| 3 | 梅简, 张杰, 刘双宇, 等. 电池储能技术发展现状[J]. 浙江电力, 2020, 39(3): 75-81. |

| Mei J, Zhang J, Liu S Y, et al. Development status of battery energy storage technology[J]. Zhejiang Electric Power, 2020, 39(3): 75-81. | |

| 4 | Wu W X, Wang S F, Wu W, et al. A critical review of battery thermal performance and liquid based battery thermal management[J]. Energy Conversion and Management, 2019, 182: 262-281. |

| 5 | 朱晓庆, 王震坡, WANG Hsin, 等. 锂离子动力电池热失控与安全管理研究综述[J]. 机械工程学报, 2020, 56(14): 91-118. |

| Zhu X Q, Wang Z P, Wang H, et al. Review of thermal runaway and safety management for lithium-ion traction batteries in electric vehicles[J]. Journal of Mechanical Engineering, 2020, 56(14): 91-118. | |

| 6 | Choudhari V G, Dhoble D A S, Sathe T M. A review on effect of heat generation and various thermal management systems for lithium ion battery used for electric vehicle[J]. Journal of Energy Storage, 2020, 32: 101729. |

| 7 | Liu H Q, Wei Z B, He W D, et al. Thermal issues about Li-ion batteries and recent progress in battery thermal management systems: a review[J]. Energy Conversion and Management, 2017, 150: 304-330. |

| 8 | Dai X Y, Ping P, Kong D P, et al. Heat transfer enhanced inorganic phase change material compositing carbon nanotubes for battery thermal management and thermal runaway propagation mitigation[J]. Journal of Energy Chemistry, 2024, 89: 226-238. |

| 9 | 刘业凤, 王君如, 华正豪. 锂离子电池的热分析与仿真设计[J]. 制冷技术, 2022, 42(3): 68-74. |

| Liu Y F, Wang J R, Hua Z H. Thermal analysis and simulation design of lithium-ion battery[J]. Chinese Journal of Refrigeration Technology, 2022, 42(3): 68-74. | |

| 10 | 刘邦金, 汪林威, 吴月月, 等. 锂离子电池热管理研究进展[J]. 化工学报, 2024, 75: 1-26. |

| Liu B J, Wang L W, Wu Y Y, et al. Advances in thermal management of lithium-ion batteries[J]. CIESC Journal, 2024, 75: 1-26. | |

| 11 | Zhang X H, Li Z, Luo L G, et al. A review on thermal management of lithium-ion batteries for electric vehicles[J]. Energy, 2022, 238: 121652. |

| 12 | Ma S, Jiang M D, Tao P, et al. Temperature effect and thermal impact in lithium-ion batteries: a review[J]. Progress in Natural Science: Materials International, 2018, 28(6): 653-666. |

| 13 | Wang Q, Jiang B, Li B, et al. A critical review of thermal management models and solutions of lithium-ion batteries for the development of pure electric vehicles[J]. Renewable and Sustainable Energy Reviews, 2016, 64: 106-128. |

| 14 | Amba Prasad Rao G, Shravan Kumar S. A review of integrated battery thermal management systems for lithium-ion batteries of electric vehicles[J]. e-Prime - Advances in Electrical Engineering, Electronics and Energy, 2024, 8: 100526. |

| 15 | 李康靖, 谭晓军, 褚燕燕, 等. 风冷式车用锂离子动力电池包热管理研究[J]. 电源技术, 2019, 43(12): 1975-1978, 2035. |

| Li K J, Tan X J, Chu Y Y, et al. A research on the air cooling thermal management system of lithium-ion traction battery pack in electric vehicles[J]. Chinese Journal of Power Sources, 2019, 43(12): 1975-1978, 2035. | |

| 16 | 孙港国, 魏名山, 郑思宇, 等. 纯电动汽车空调与电池综合热管理仿真研究[J]. 制冷技术, 2022, 42(2): 12-18. |

| Sun G G, Wei M S, Zheng S Y, et al. Simulation research on integrated thermal management of air-conditioning and battery for electric vehicles[J]. Chinese Journal of Refrigeration Technology, 2022, 42(2): 12-18. | |

| 17 | Akbarzadeh M, Jaguemont J, Kalogiannis T, et al. A novel liquid cooling plate concept for thermal management of lithium-ion batteries in electric vehicles[J]. Energy Conversion and Management, 2021, 231: 113862. |

| 18 | Xu J, Guo Z C, Xu Z M, et al. A systematic review and comparison of liquid-based cooling system for lithium-ion batteries[J]. eTransportation, 2023, 17: 100242. |

| 19 | 李潇, 陈江英, 李翔晟. 基于新型流道液冷板的动力电池热管理性能[J]. 电源技术, 2020, 44(10): 1438-1442. |

| Li X, Chen J Y, Li X S. Study on thermal management performance of power batteries based on new flow passage liquid cooling plate[J]. Chinese Journal of Power Sources, 2020, 44(10): 1438-1442. | |

| 20 | 徐海峰, 苏林, 盛雷. 液冷板电池组散热性能仿真及优化[J]. 制冷技术, 2019, 39(2): 23-28, 39. |

| Xu H F, Su L, Sheng L. Simulation and optimization of heat dissipation performance of liquid cooled panel battery pack[J]. Chinese Journal of Refrigeration Technology, 2019, 39(2): 23-28, 39. | |

| 21 | 赵洪波, 刘杰, 马彪, 等. 水冷PEMFC热管理系统控制策略及仿真研究[J]. 化工学报, 2020, 71(5): 2139-2150. |

| Zhao H B, Liu J, Ma B, et al. Control strategy and simulation research of water-cooled PEMFC thermal management system[J]. CIESC Journal, 2020, 71(5): 2139-2150. | |

| 22 | Lu M Y, Zhang X L, Ji J, et al. Research progress on power battery cooling technology for electric vehicles[J]. Journal of Energy Storage, 2020, 27: 101155. |

| 23 | Zhao L Y, Li W, Wang G Y, et al. A novel thermal management system for lithium-ion battery modules combining direct liquid-cooling with forced air-cooling[J]. Applied Thermal Engineering, 2023, 232: 120992. |

| 24 | 赖艳红, 罗立晟, 陈镜如, 等. 刀片电池直冷冷却热管理系统设计与优化[J]. 制冷技术, 2023, 43(2): 72-77. |

| Lai Y H, Luo L S, Chen J R, et al. Design and optimization of thermal management system for blade battery direct cooling[J]. Chinese Journal of Refrigeration Technology, 2023, 43(2): 72-77. | |

| 25 | 聂磊, 王敏弛, 赵耀, 等. 纯电动汽车冷媒直冷电池热管理系统的实验研究[J]. 制冷学报, 2020, 41(4): 52-58. |

| Nie L, Wang M C, Zhao Y, et al. Experimental study on direct refrigerant battery cooling system for electric vehicle[J]. Journal of Refrigeration, 2020, 41(4): 52-58. | |

| 26 | Yang S C, Zhou S D, Zhou X N, et al. Essential technologies on the direct cooling thermal management system for electric vehicles[J]. International Journal of Energy Research, 2021, 45(10): 14436-14464. |

| 27 | Guo J, Jiang F M. A novel electric vehicle thermal management system based on cooling and heating of batteries by refrigerant[J]. Energy Conversion and Management, 2021, 237: 114145. |

| 28 | Wang Z K, Wang Y N, Xie Z F, et al. Parametric investigation on the performance of a direct evaporation cooling battery thermal management system[J]. International Journal of Heat and Mass Transfer, 2022, 189: 122685. |

| 29 | 李鑫盛, 贾腾, 赵耀, 等. 多箱电池包直冷热管理系统的实验研究[J]. 制冷学报, 2024, 45: 1-8. |

| Li X S, Jia T, Zhao Y, et al. Experimental research on direct cooling thermal management system for multi-box battery packs[J]. Journal of Refrigeration, 2024, 45: 1-8. | |

| 30 | Moffat R J. Describing the uncertainties in experimental results[J]. Experimental Thermal and Fluid Science, 1988, 1(1): 3-17. |

| [1] | 沙鑫权, 胡然, 丁磊, 蒋珍华, 吴亦农. 空间用单机两级有阀线性压缩机研制及测试[J]. 化工学报, 2025, 76(S1): 114-122. |

| [2] | 燕子腾, 詹飞龙, 丁国良. 空调用套管式分流器结构设计及分流效果验证[J]. 化工学报, 2025, 76(S1): 152-159. |

| [3] | 袁琳慧, 王瑜. 单服务器浸没射流式液冷系统散热性能[J]. 化工学报, 2025, 76(S1): 160-169. |

| [4] | 赵子祥, 段钟弟, 孙浩然, 薛鸿祥. 大温差两相流动诱导水锤冲击的数值模型[J]. 化工学报, 2025, 76(S1): 170-180. |

| [5] | 黄博, 黄灏, 王文, 贺隆坤. 薄膜型LNG船液货舱温度场计算分析[J]. 化工学报, 2025, 76(S1): 195-204. |

| [6] | 汪思远, 刘国强, 熊通, 晏刚. 窗式空调器轴流风机的风速非均匀分布特性及其对冷凝器流路优化设计的影响规律[J]. 化工学报, 2025, 76(S1): 205-216. |

| [7] | 曹庆泰, 郭松源, 李建强, 蒋赞, 汪彬, 耑锐, 吴静怡, 杨光. 负过载下多孔隔板对液氧贮箱蓄液性能的影响研究[J]. 化工学报, 2025, 76(S1): 217-229. |

| [8] | 孔繁臣, 张硕, 唐明生, 邹慧明, 胡舟航, 田长青. 二氧化碳直线压缩机气体轴承模拟[J]. 化工学报, 2025, 76(S1): 281-288. |

| [9] | 牛宏斌, 邱丽, 杨景轩, 张忠林, 郝晓刚, 赵忠凯, 阿布里提, 官国清. 筒体直径对旋风分离器性能的影响及其流场机制[J]. 化工学报, 2025, 76(5): 2367-2376. |

| [10] | 王光磊, 刘晓玲, 徐震, 李琳. 面向压缩空气储能的气-水直接接触换热特性[J]. 化工学报, 2025, 76(4): 1595-1603. |

| [11] | 齐聪, 岳林菲. 交织网状小通道热沉的传热特性[J]. 化工学报, 2025, 76(4): 1534-1544. |

| [12] | 孙睿, 王军锋, 许浩洁, 李步发, 徐雅弦. 喷雾冷却技术及其强化传热机制研究进展[J]. 化工学报, 2025, 76(4): 1404-1421. |

| [13] | 翟祥瑞, 张伟, 张倩倩, 曲玖哲, 杨绪飞, 邓雅军, 宇波. 基于外场扰动的固液相变储能主动强化换热技术[J]. 化工学报, 2025, 76(4): 1432-1446. |

| [14] | 范佳媛, 曾文慧, 任志超, 张文涛, 吕霜. 多熔点相变乳液的制备及性能强化研究[J]. 化工学报, 2025, 76(4): 1863-1874. |

| [15] | 刘璐, 万开, 王文玥, 王太, 汤建成, 王少恒. 基于氦膨胀制冷的正仲氢转化耦合流动换热研究[J]. 化工学报, 2025, 76(4): 1513-1522. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号