化工学报 ›› 2025, Vol. 76 ›› Issue (4): 1863-1874.DOI: 10.11949/0438-1157.20240935

收稿日期:2024-08-19

修回日期:2024-09-28

出版日期:2025-04-25

发布日期:2025-05-12

通讯作者:

曾文慧

作者简介:范佳媛(1998—),女,硕士研究生,工程师,fjyuan818@163.com

基金资助:

Jiayuan FAN( ), Wenhui ZENG(

), Wenhui ZENG( ), Zhichao REN, Wentao ZHANG, Shuang LYU

), Zhichao REN, Wentao ZHANG, Shuang LYU

Received:2024-08-19

Revised:2024-09-28

Online:2025-04-25

Published:2025-05-12

Contact:

Wenhui ZENG

摘要:

相变乳液是一种潜热型功能热流体,既能保持常规传热流体的流动性,还具有相变材料的潜热蓄热能力,可以强化流体传热速率拓展其应用潜力。选用两种有机相变材料并制备多熔点相变乳液,并对其传热进行强化。实验结果表明,所制备相变乳液常温下为平均粒径为129.3~204.4 nm的乳白色胶体体系,具有优良的流动性及稳定性。相变过程出现多个相变控温点,相变潜热为27.49~34.54 J/kg。另外,固态比热容为2.98~3.83 J/(g·K),液态比热容为2.26~2.93 J/(g·K)。相变乳液的热导率为0.42~0.47 W/(m·K),0.5%(质量分数)的纳米Si3N4可以将乳液热导率提高6.0%~13.5%。导热强化后的相变乳液可以作为优良的换热工质应用于降温领域。

中图分类号:

范佳媛, 曾文慧, 任志超, 张文涛, 吕霜. 多熔点相变乳液的制备及性能强化研究[J]. 化工学报, 2025, 76(4): 1863-1874.

Jiayuan FAN, Wenhui ZENG, Zhichao REN, Wentao ZHANG, Shuang LYU. Preparation and heat transfer enhancement of phase change slurry with multi-phase change temperature[J]. CIESC Journal, 2025, 76(4): 1863-1874.

| 样品 | PW/g | C18/g | 复合乳化剂/g | 正丁醇/g | 去离子水/g |

|---|---|---|---|---|---|

| PCS-1 | 20 | 0 | 8 | 1.2 | 70.8 |

| PCS-2 | 15 | 5 | |||

| PCS-3 | 10 | 10 | |||

| PCS-4 | 5 | 15 | |||

| PCS-5 | 0 | 20 |

表1 样品含量配比

Table 1 Content and proportion of the sample

| 样品 | PW/g | C18/g | 复合乳化剂/g | 正丁醇/g | 去离子水/g |

|---|---|---|---|---|---|

| PCS-1 | 20 | 0 | 8 | 1.2 | 70.8 |

| PCS-2 | 15 | 5 | |||

| PCS-3 | 10 | 10 | |||

| PCS-4 | 5 | 15 | |||

| PCS-5 | 0 | 20 |

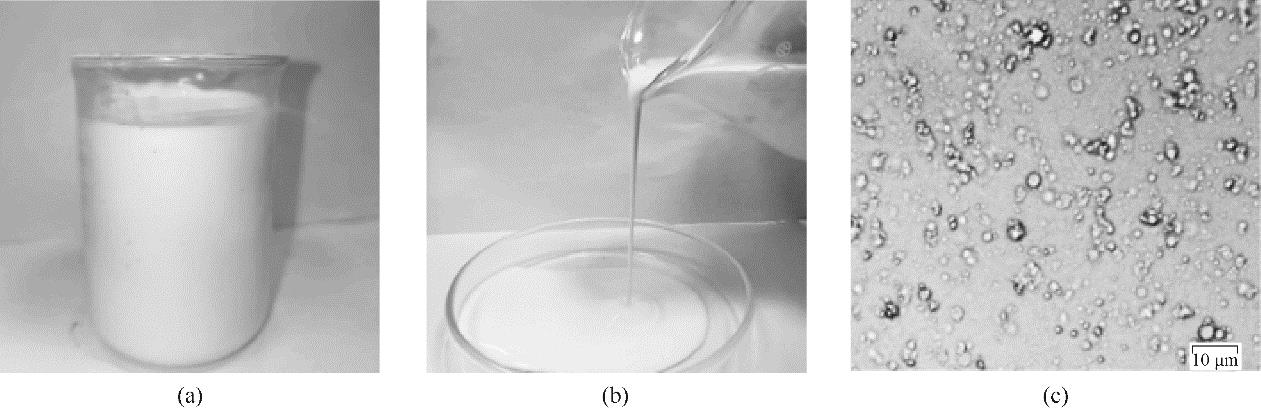

图2 相变乳液的宏观形态及微观结构:(a)静态形貌;(b)动态形貌;(c)×400下微观结构

Fig.2 Macro state and microstructure of phase change slurry: (a) static topography; (b) dynamic topography; (c) microstructure at ×400

| 样品 | 尺寸d/nm | 强度/% | Z-平均d/nm | |

|---|---|---|---|---|

| PCS-1 | Peak1 | 673.8 | 52.3 | 204.4 |

| Peak2 | 135.2 | 47.7 | ||

| PCS-2 | Peak1 | 573.0 | 55.3 | 185.6 |

| Peak2 | 113.2 | 44.7 | ||

| PCS-3 | Peak1 | 119.4 | 53.2 | 163.1 |

| Peak2 | 523.5 | 46.8 | ||

| PCS-4 | Peak1 | 156.3 | 83.1 | 141.1 |

| Peak2 | 867.7 | 16.9 | ||

| PCS-5 | Peak1 | 673.8 | 52.3 | 129.3 |

| Peak2 | 135.2 | 47.7 | ||

表2 相变乳液的粒径

Table 2 particle size of phase change slurry

| 样品 | 尺寸d/nm | 强度/% | Z-平均d/nm | |

|---|---|---|---|---|

| PCS-1 | Peak1 | 673.8 | 52.3 | 204.4 |

| Peak2 | 135.2 | 47.7 | ||

| PCS-2 | Peak1 | 573.0 | 55.3 | 185.6 |

| Peak2 | 113.2 | 44.7 | ||

| PCS-3 | Peak1 | 119.4 | 53.2 | 163.1 |

| Peak2 | 523.5 | 46.8 | ||

| PCS-4 | Peak1 | 156.3 | 83.1 | 141.1 |

| Peak2 | 867.7 | 16.9 | ||

| PCS-5 | Peak1 | 673.8 | 52.3 | 129.3 |

| Peak2 | 135.2 | 47.7 | ||

| 样品 | 熔化峰值 温度/℃ | 熔化潜热/(J/g) | 凝固峰值 温度/℃ | 凝固潜热/(J/g) |

|---|---|---|---|---|

| PCS-1 | 42.60 | 35.74 | 25.84 | 35.55 |

| PCS-2 | Peak1:25.58 | Peak1:1.93 | Peak1:10.57 | Peak1:4.16 |

| Peak2:40.65 | Peak2:16.71 | Peak2:24.97 | Peak2:30.38 | |

| PCS-3 | Peak1:25.68 | Peak1:6.531 | Peak1:10.32 | Peak1:10.61 |

| Peak2:39.83 | Peak1:10.11 | Peak2:23.99 | Peak2:17.74 | |

| PCS-4 | Peak1:25.77 | Peak1:22.94 | Peak1:10.09 | Peak1:17.77 |

| Peak2:40.96 | Peak2:3.481 | Peak2:25.13 | Peak2:9.72 | |

| PCS-5 | 25.83 | 27.2 | 9.82 | 21.82 |

表3 相变乳液的熔点和潜热

Table 3 Melting point and latent heat of phase change slurry

| 样品 | 熔化峰值 温度/℃ | 熔化潜热/(J/g) | 凝固峰值 温度/℃ | 凝固潜热/(J/g) |

|---|---|---|---|---|

| PCS-1 | 42.60 | 35.74 | 25.84 | 35.55 |

| PCS-2 | Peak1:25.58 | Peak1:1.93 | Peak1:10.57 | Peak1:4.16 |

| Peak2:40.65 | Peak2:16.71 | Peak2:24.97 | Peak2:30.38 | |

| PCS-3 | Peak1:25.68 | Peak1:6.531 | Peak1:10.32 | Peak1:10.61 |

| Peak2:39.83 | Peak1:10.11 | Peak2:23.99 | Peak2:17.74 | |

| PCS-4 | Peak1:25.77 | Peak1:22.94 | Peak1:10.09 | Peak1:17.77 |

| Peak2:40.96 | Peak2:3.481 | Peak2:25.13 | Peak2:9.72 | |

| PCS-5 | 25.83 | 27.2 | 9.82 | 21.82 |

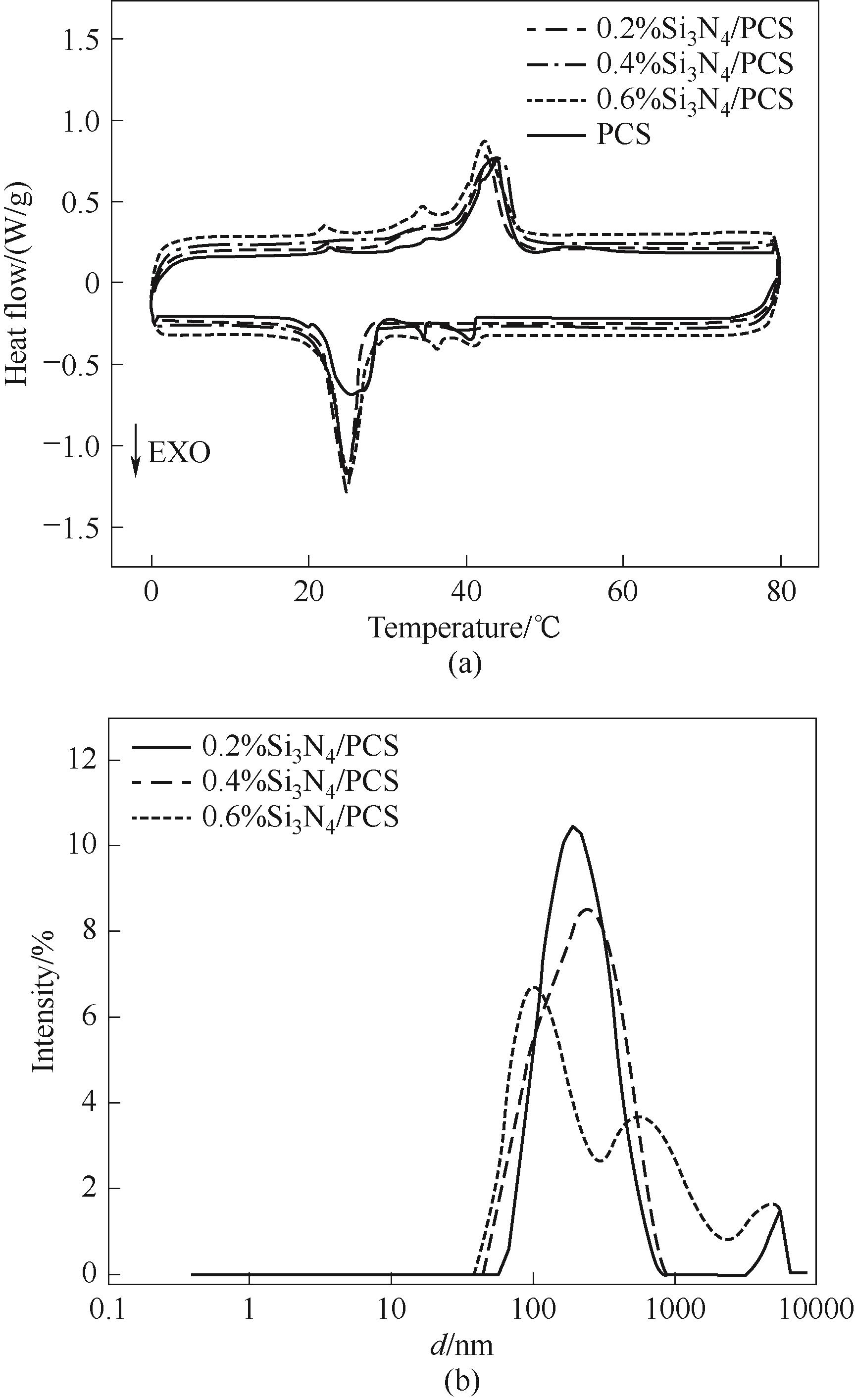

图12 添加不同含量纳米Si3N4相变乳液的DSC曲线(a)和粒径分布(b)

Fig.12 DSC curves (a) and particle size distribution (b) of phase change slurry with different nano-Si3N4 contents

| 样品 | 尺寸/nm | 强度/% | Z-平均d/nm | |

|---|---|---|---|---|

| 0.2%Si3N4/PCS | peak1 | 230.2 | 96.8 | 202.2 |

| peak2 | 5006 | 3.2 | ||

| peak3 | 0 | 0 | ||

| 0.4%Si3N4/PCS | peak1 | 244 | 100 | 175.1 |

| peak2 | 0 | 0 | ||

| peak3 | 0 | 0 | ||

| 0.6%Si3N4/PCS | peak1 | 12.4 | 55.7 | 174.6 |

| peak2 | 777.2 | 35.9 | ||

| peak3 | 3997 | 8.5 | ||

表4 添加不同含量纳米Si3N4相变乳液的粒径分布

Table 4 Particle size of phase change slurry with different nano-Si3N4 contents

| 样品 | 尺寸/nm | 强度/% | Z-平均d/nm | |

|---|---|---|---|---|

| 0.2%Si3N4/PCS | peak1 | 230.2 | 96.8 | 202.2 |

| peak2 | 5006 | 3.2 | ||

| peak3 | 0 | 0 | ||

| 0.4%Si3N4/PCS | peak1 | 244 | 100 | 175.1 |

| peak2 | 0 | 0 | ||

| peak3 | 0 | 0 | ||

| 0.6%Si3N4/PCS | peak1 | 12.4 | 55.7 | 174.6 |

| peak2 | 777.2 | 35.9 | ||

| peak3 | 3997 | 8.5 | ||

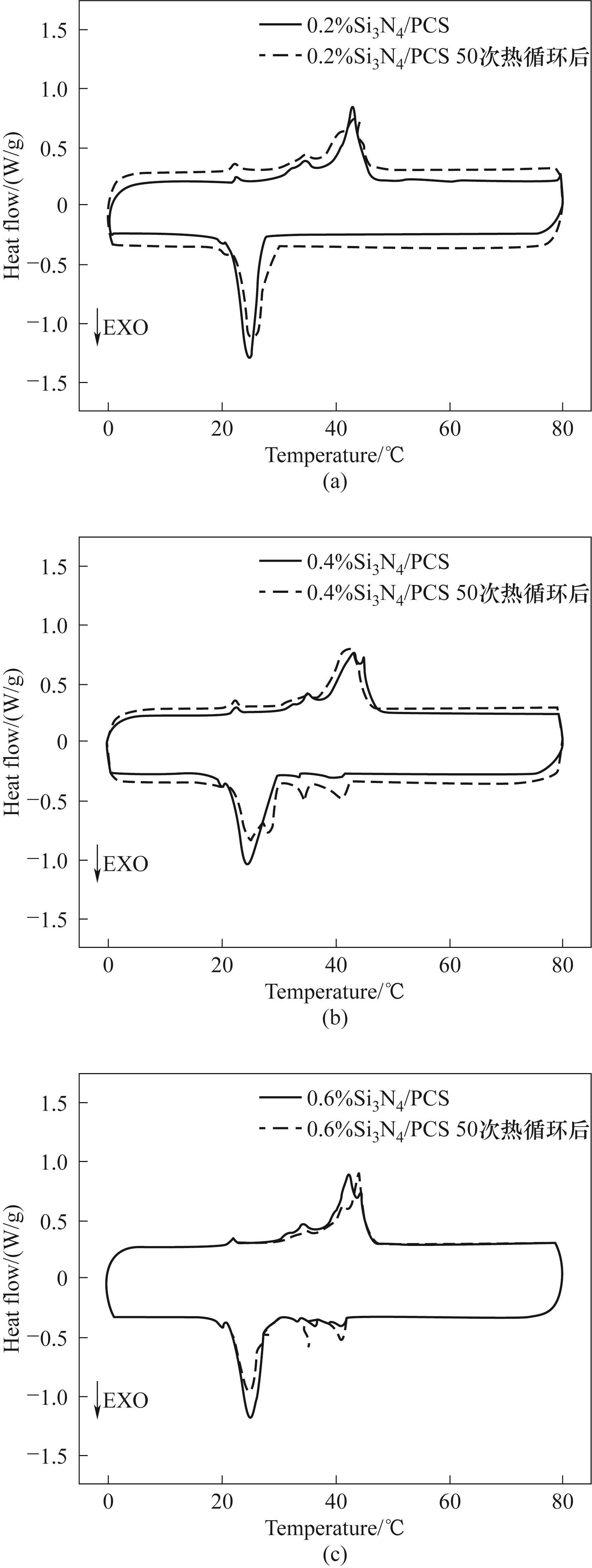

图13 添加不同含量纳米粒子相变乳液熔化/凝固循环前后的DSC曲线

Fig.13 DSC curves of phase change slurry before and after melting/solidification cycle with different nano-Si3N4 contents

| 1 | 冯锦新, 凌子夜, 方晓明, 等. 相变乳液的研究进展[J]. 储能科学与技术, 2022, 11(6): 1968-1979. |

| Feng J X, Ling Z Y, Fang X M, et al. Research progress on phase-change emulsions[J]. Energy Storage Science and Technology, 2022, 11(6): 1968-1979. | |

| 2 | 王兴越, 宋乐春, 陈杰, 等. 用于储能的石蜡相变乳液制备研究[J]. 当代化工, 2022, 51(7): 1610-1614. |

| Wang X Y, Song L C, Chen J, et al. Preparation of paraffin phase change emulsion for energy storage[J]. Contemporary Chemical Industry, 2022, 51(7): 1610-1614. | |

| 3 | Ma F, Zhang P. A review of thermo-fluidic performance and application of shellless phase change slurry(part 1): Preparations, properties and applications[J]. Energy, 2019, 189: 116246. |

| 4 | López-Pedrajas D, Borreguero A M, Ramos F J, et al. Influence of the dispersion characteristics for producing thermoregulating nano phase change slurries[J]. Chemical Engineering Journal, 2023, 452: 139034. |

| 5 | 俞臻杰, 张冠华, 崔国民, 等. 低过冷高导热新型纳米相变乳液制备研究[J]. 热能动力工程, 2020, 35(10): 146-152, 166. |

| Yu Z J, Zhang G H, Cui G M, et al. Fabrication of novel nano phase change emulsion with low supercooling and enhanced thermal conductivity[J]. Journal of Engineering for Thermal Energy and Power, 2020, 35(10): 146-152, 166. | |

| 6 | 周升平, 曾晟. 太阳能建筑用石蜡/CNTs相变乳液的制备及光-热性能研究[J]. 化工新型材料, 2021, 49(3): 113-116, 121. |

| Zhou S P, Zeng S. Preparation and photo-thermal properties of paraffin/CNTs phase change emulsion for solar architecture[J]. New Chemical Materials, 2021, 49(3): 113-116, 121. | |

| 7 | 陈薇, 刘攀, 肖一啸, 等. 石蜡相变乳液的热稳定性及换热性能研究[J]. 化工新型材料, 2023, 51(S2): 532-537. |

| Chen W, Liu P, Xiao Y X, et al. Study on thermal stability and heat transfer properties of paraffin phase change emulsions[J]. New Chemical Materials, 2023, 51(S2): 532-537. | |

| 8 | 黄莉. 石蜡/水相变乳液的稳定性能和储能容量[J]. 材料研究学报, 2017, 31(10): 789-795. |

| Huang L. Stability and heat storage capacity of phase change emulsion paraffin/water[J]. Chinese Journal of Materials Research, 2017, 31(10): 789-795. | |

| 9 | Chinnasamy V, Heo J, Lee H, et al. Development of highly stable n-heptadecane/water-based phase change emulsion with mixed surfactant for thermal management applications[J]. Journal of Molecular Liquids, 2024, 393: 123695. |

| 10 | Liu L, Zhang X Y, Liang H B, et al. Cooling storage performance of a novel phase change material nano-emulsion for room air-conditioning in a self-designed pilot thermal storage unit[J]. Applied Energy, 2022, 308: 118405. |

| 11 | Ho C J, Lin K H, Yang T F, et al. Efficacy of turbulent convective heat transfer in a circular tube with water-based nanoemulsion of n-eicosan—an experimental study[J]. International Journal of Heat and Mass Transfer, 2022, 183: 122062. |

| 12 | Shao J J, Darkwa J, Kokogiannakis G. Development of a novel phase change material emulsion for cooling systems[J]. Renewable Energy, 2016, 87: 509-516. |

| 13 | Farid M M, Al-hallajs, et al. Microchannel heat exchanger with micro-encapsulated phase change material for high flux cooling: US8109324[P]. 2012-02-07. |

| 14 | Wang X C, Niu J L. Performance of cooled-ceiling operating with MPCM slurry[J]. Energy Conversion and Management, 2009, 50(3): 583-591. |

| 15 | Griffiths P W, Eames P C. Performance of chilled ceiling panels using phase change material slurries as the heat transport medium[J]. Applied Thermal Engineering, 2007, 27(10): 1756-1760. |

| 16 | Huang L, Doetsch C, Pollerberg C. Low temperature paraffin phase change emulsions[J]. International Journal of Refrigeration, 2010, 33(8): 1583-1589. |

| 17 | 邹得球, 宋文吉, 肖睿, 等. 石蜡乳状液储热技术研究进展与应用前景[J]. 现代化工, 2008, 28(7): 12-15. |

| Zou D Q, Song W J, Xiao R, et al. Study progress in wax emulsion as heat storage media and its application[J]. Modern Chemical Industry, 2008, 28(7): 12-15. | |

| 18 | 刘小诗, 邹得球, 贺瑞军, 等. 氧化石墨烯/石蜡复合相变乳液的制备及对流传热特性[J]. 化工学报, 2019, 70(3): 1188-1197. |

| Liu X S, Zou D Q, He R J, et al. Preparation and heat transfer characteristics of GO/paraffin composite phase change emulsions[J]. CIESC Journal, 2019, 70(3): 1188-1197. | |

| 19 | Huang L, Petermann M, Doetsch C. Evaluation of paraffin/water emulsion as a phase change slurry for cooling applications[J]. Energy, 2009, 34(9): 1145-1155. |

| 20 | Dai H, Liu Y W. Analysis and optimization of thermo-hydraulic characteristics of phase change slurry in wavy MCHS with porous fins based on RSM and desirability methods[J]. International Journal of Heat and Mass Transfer, 2023, 216: 124638. |

| 21 | Zhu W H, Lei F, Zhong H, et al. Latent heat recovery of composite PCM for hybrid BTMSs based on micro-encapsulated phase change slurry[J]. Journal of Energy Storage, 2023, 72: 108330. |

| 22 | Ran F M, Zhang H, Xu C L, et al. Thermal performances evaluation of a flat-plate solar collector using microencapsulated phase-change slurry as heat transfer medium[J]. International Journal of Energy Research, 2022, 46(10): 14044-14059. |

| 23 | Huang L, Piontek U, Chen M B, et al. Thermal performance of cold plate based on phase change emulsion for Li-ion battery[J]. Energy, 2023, 282: 128743. |

| 24 | Abdeali G, Bahramian A R. A comprehensive review on rheological behavior of phase change materials fluids (slurry and emulsion): the way toward energy efficiency[J]. Journal of Energy Storage, 2022, 55: 105549. |

| [1] | 孙睿, 王军锋, 许浩洁, 李步发, 徐雅弦. 喷雾冷却技术及其强化传热机制研究进展[J]. 化工学报, 2025, 76(4): 1404-1421. |

| [2] | 刘萍, 邱雨生, 李世婧, 孙瑞奇, 申晨. 微通道内纳米流体传热流动特性[J]. 化工学报, 2025, 76(1): 184-197. |

| [3] | 张双星, 刘舫辰, 张义飞, 杜文静. R-134a脉动热管相变蓄放热实验研究[J]. 化工学报, 2023, 74(S1): 165-171. |

| [4] | 张贲, 王松柏, 魏子亚, 郝婷婷, 马学虎, 温荣福. 超亲水多孔金属结构驱动的毛细液膜冷凝及传热强化[J]. 化工学报, 2023, 74(7): 2824-2835. |

| [5] | 王海, 林宏, 王晨, 许浩洁, 左磊, 王军锋. 高压静电场强化多孔介质表面沸腾传热特性研究[J]. 化工学报, 2023, 74(7): 2869-2879. |

| [6] | 刘润竹, 储甜甜, 张孝阿, 王成忠, 张军营. α,ω-端羟基亚苯基氟硅聚合物的合成及性能[J]. 化工学报, 2023, 74(3): 1360-1369. |

| [7] | 林志敏, 王崇兆, 强国智, 刘树山, 王良璧. 润滑油在内插同轴交叉翼型涡产生器管内流动与传热特性分析[J]. 化工学报, 2022, 73(11): 4957-4973. |

| [8] | 林伟翔, 苏港川, 陈强, 文键, 王斯民. 基于超声技术的沉浸式换热器强化传热研究[J]. 化工学报, 2021, 72(8): 4055-4063. |

| [9] | 魏小兰, 谢佩, 王维龙, 陆建峰, 丁静. 含钙三元氯化物体系相图计算与熔盐热稳定性[J]. 化工学报, 2021, 72(6): 3074-3083. |

| [10] | 高剑晨, 赵炳晨, 何峰, 李廷贤. 六水硝酸镁相变储热复合材料改性制备及储/放热性能研究[J]. 化工学报, 2021, 72(6): 3328-3337. |

| [11] | 忻睦迪, 邢恩会. 三甲基膦和金属氧化物复合改性ZSM-5分子筛及其裂解性能研究[J]. 化工学报, 2021, 72(5): 2657-2668. |

| [12] | 张锐, 邵琦, 张华宇, 金泽龙, 张小亮. 硼掺杂二氧化硅杂化膜的制备及渗透汽化脱盐性能[J]. 化工学报, 2021, 72(4): 2317-2327. |

| [13] | 张文波, 凌子夜, 方晓明, 张正国. 新型六水氯化镁-六水硝酸镁/石墨相氮化碳复合相变材料的制备及其热性能研究[J]. 化工学报, 2021, 72(12): 6399-6406. |

| [14] | 高峰, 陈永昌, 赵金龙, 马重芳. 磁场对熔盐射流冲击传热的影响[J]. 化工学报, 2020, 71(S2): 92-97. |

| [15] | 郎中敏, 吴刚强, 赫文秀, 韩晓星, 苟延梦, 李双莹. 二氧化铈/水基纳米流体核沸腾传热特性[J]. 化工学报, 2020, 71(5): 2061-2068. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号