化工学报 ›› 2025, Vol. 76 ›› Issue (8): 3990-4003.DOI: 10.11949/0438-1157.20250129

张伟1( ), 武齐永1, 孙华中2, 胡适2, 朱小龙2(

), 武齐永1, 孙华中2, 胡适2, 朱小龙2( ), 孔帅3

), 孔帅3

收稿日期:2025-02-12

修回日期:2025-03-24

出版日期:2025-08-25

发布日期:2025-09-17

通讯作者:

朱小龙

作者简介:张伟(1976—),男,博士,高级工程师,13552985272@163.com

基金资助:

Wei ZHANG1( ), Qiyong WU1, Huazhong SUN2, Shi HU2, Xiaolong ZHU2(

), Qiyong WU1, Huazhong SUN2, Shi HU2, Xiaolong ZHU2( ), Shuai KONG3

), Shuai KONG3

Received:2025-02-12

Revised:2025-03-24

Online:2025-08-25

Published:2025-09-17

Contact:

Xiaolong ZHU

摘要:

细水雾除尘技术因具有环保、安全、经济等优势被广泛应用,但尘-雾碰撞时的反弹现象导致降尘效果不佳,且目前对其反弹动力学机制认识不足,缺乏理论指导。本研究针对生产性粉尘及大颗粒烟尘(直径1~125 μm),通过数值模拟分析其与相近直径雾滴碰撞时的反弹行为,并构建了考虑接触角、液滴-颗粒直径比、碰撞速度、液滴黏度、表面张力等多因素的反弹预测模型,得出了反弹临界条件。结果表明,反弹现象主要发生在液滴低速碰撞疏水颗粒时,且雾滴粒径越小,反弹临界速度越大;降低接触角可有效抑制反弹,当接触角小于90°时,反弹现象消失。本研究揭示了影响反弹行为的多重因素,可定量预测尘-雾碰撞反弹行为,为水雾降尘系统的设计优化提供理论依据。

中图分类号:

张伟, 武齐永, 孙华中, 胡适, 朱小龙, 孔帅. 微米尺度液滴与尘粒作用后反弹行为特性研究[J]. 化工学报, 2025, 76(8): 3990-4003.

Wei ZHANG, Qiyong WU, Huazhong SUN, Shi HU, Xiaolong ZHU, Shuai KONG. Study on rebound behavior characteristics of droplets and dust particles at micron-scale[J]. CIESC Journal, 2025, 76(8): 3990-4003.

| 雾化方法 | 水压/MPa | 气压/ MPa | 索特尔平均 粒径/μm | 射程/m | 速度/ (m·s-1) |

|---|---|---|---|---|---|

| 单相高压雾化[ | 6~10 | 无 | 30~80 | < 3 | 12~30 |

| 两相雾化[ | < 0.5 | < 0.6 | < 30 | < 1 | < 10 |

| 超声雾化[ | < 0.5 | < 0.5 | < 30 | 1.5~2 | 4~11 |

| 超音速气流雾化[ | < 0.5 | < 0.5 | 5~20 | 4.9~7 | < 600 |

表1 不同雾化方法产生的雾场特性典型参数

Table 1 Typical parameters of fog field characteristics generated by different atomization methods

| 雾化方法 | 水压/MPa | 气压/ MPa | 索特尔平均 粒径/μm | 射程/m | 速度/ (m·s-1) |

|---|---|---|---|---|---|

| 单相高压雾化[ | 6~10 | 无 | 30~80 | < 3 | 12~30 |

| 两相雾化[ | < 0.5 | < 0.6 | < 30 | < 1 | < 10 |

| 超声雾化[ | < 0.5 | < 0.5 | < 30 | 1.5~2 | 4~11 |

| 超音速气流雾化[ | < 0.5 | < 0.5 | 5~20 | 4.9~7 | < 600 |

| 液滴理化特性改善方法 | 表面张力/(mN·m-1) |

|---|---|

| 磁化水[ | 69~72 |

| 多组分水雾[ | 29~40 |

| 磁化+多组分水雾[ | 26~32 |

| 荷电水雾[ | 12~20 |

表2 不同理化特性改善方法处理后雾滴的表面张力

Table 2 Surface tension of fog droplets treated with different physicochemical properties improvement methods

| 液滴理化特性改善方法 | 表面张力/(mN·m-1) |

|---|---|

| 磁化水[ | 69~72 |

| 多组分水雾[ | 29~40 |

| 磁化+多组分水雾[ | 26~32 |

| 荷电水雾[ | 12~20 |

| 固体类型 | 液体类型 | 接触角 | 液体表面张力σ/(mN·m-1) | 液体黏度μ/(mPa·s) | 来源 |

|---|---|---|---|---|---|

| ST1:聚硅烷处理的二氧化硅(高度疏水) | 蒸馏水 | α = 168.4°,β = 91.4° | 72.3 | 1.04 | 实测 |

| 浓度为1 mmol·L-1的CTAB溶液 | α = 151.2°,β = 15.2° | 34.2 | 1.04 | 实测 | |

| ST2:石墨(中度疏水) | 蒸馏水 | α = 90.0°,β = 23.0° | 72.0 | 1.04 | 文献[ |

| 浓度为1 mmol·L-1的CTAB溶液 | α = 62.0°,β = 17.0° | 34.2 | 1.04 | 文献[ | |

| ST3:二氧化硅(亲水) | 蒸馏水 | α = 25.0°,β = 7.5° | 72.0 | 1.04 | 文献[ |

表3 不同类型液体与固体的湿润特性

Table 3 Wetting characteristics of different types of liquids and solids

| 固体类型 | 液体类型 | 接触角 | 液体表面张力σ/(mN·m-1) | 液体黏度μ/(mPa·s) | 来源 |

|---|---|---|---|---|---|

| ST1:聚硅烷处理的二氧化硅(高度疏水) | 蒸馏水 | α = 168.4°,β = 91.4° | 72.3 | 1.04 | 实测 |

| 浓度为1 mmol·L-1的CTAB溶液 | α = 151.2°,β = 15.2° | 34.2 | 1.04 | 实测 | |

| ST2:石墨(中度疏水) | 蒸馏水 | α = 90.0°,β = 23.0° | 72.0 | 1.04 | 文献[ |

| 浓度为1 mmol·L-1的CTAB溶液 | α = 62.0°,β = 17.0° | 34.2 | 1.04 | 文献[ | |

| ST3:二氧化硅(亲水) | 蒸馏水 | α = 25.0°,β = 7.5° | 72.0 | 1.04 | 文献[ |

| 颗粒直径/μm | 计算域尺寸/μm |

|---|---|

| 3000 | 21000×6600 |

| 2000 | 14000×4400 |

| 125 | 875×275 |

| 25 | 175×55 |

| 5 | 35×11 |

| 1 | 7×2.2 |

| 0.2 | 1.4×0.44 |

表4 不同颗粒尺寸对应的计算域尺寸

Table 4 Computational domain sizes corresponding to different particle sizes

| 颗粒直径/μm | 计算域尺寸/μm |

|---|---|

| 3000 | 21000×6600 |

| 2000 | 14000×4400 |

| 125 | 875×275 |

| 25 | 175×55 |

| 5 | 35×11 |

| 1 | 7×2.2 |

| 0.2 | 1.4×0.44 |

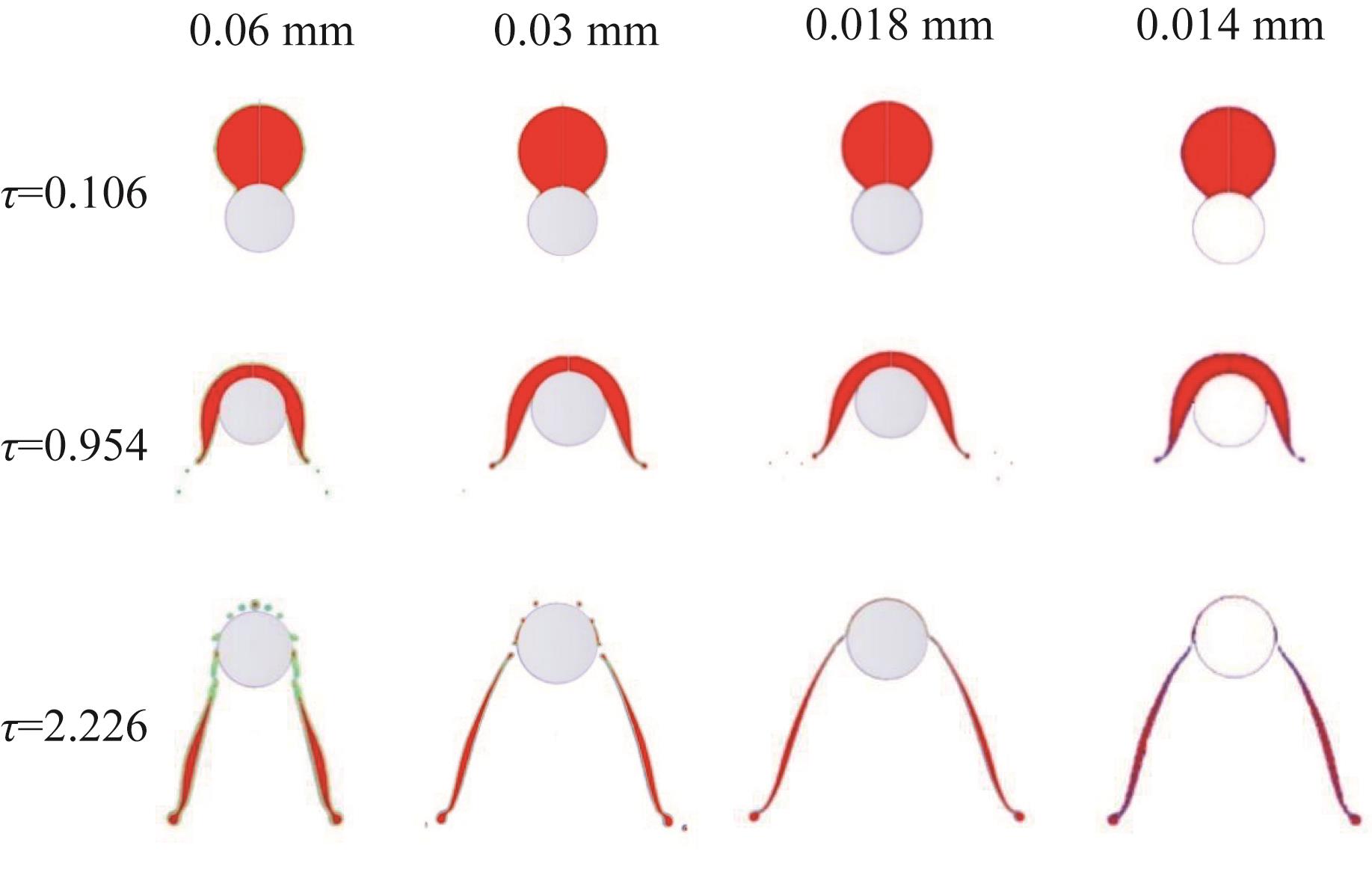

图3 不同网格尺寸条件下液滴形态对比(v0= 4.17 m·s-1,dp= 3 mm,dl = 3.93 mm,α = 168.4°,β = 91.4°)

Fig.3 Comparison of droplet morphology under different grid size conditions

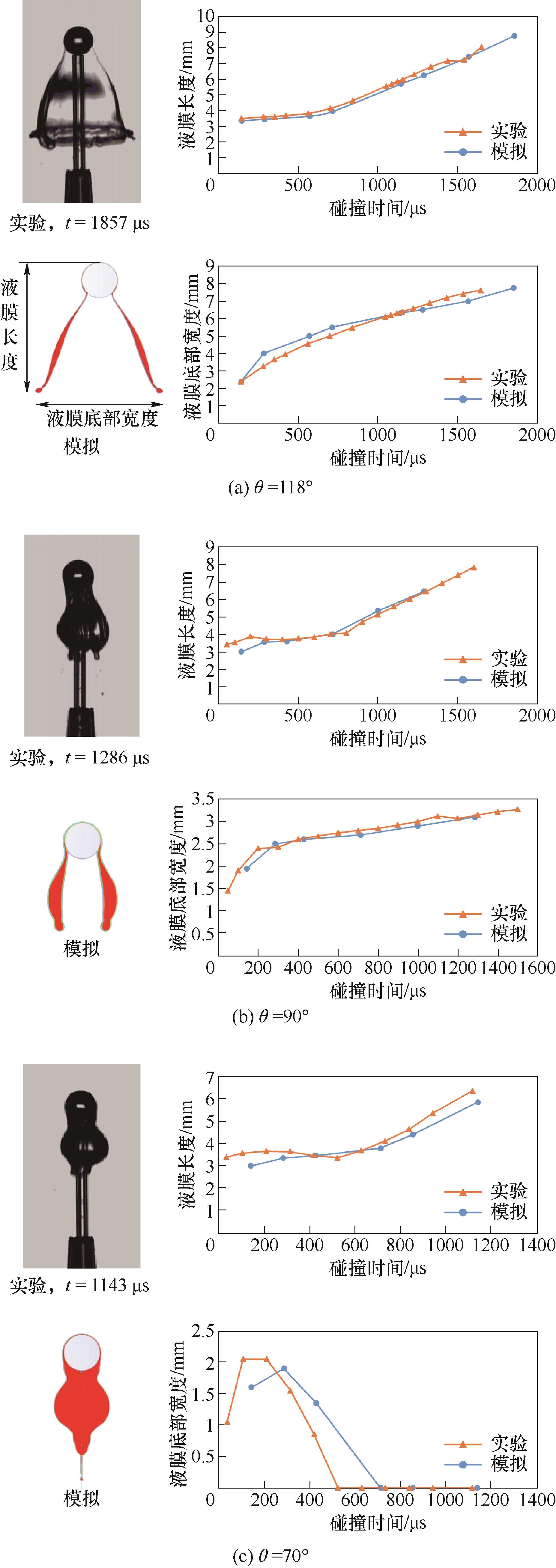

图4 模拟结果与文献[29]中实验记录的液滴形态对比(dp = 2 mm)

Fig.4 Comparison between simulation results and experimental droplet morphology recorded in Ref.[29] (dp = 2 mm)

| 常量 | 变量 | ||||

|---|---|---|---|---|---|

| 液滴-颗粒直径比Ω | 液滴表面 张力σ/ (mN·m-1) | 接触角 | 液滴黏度μ/(mPa·s) | 碰撞速度v0/(m·s-1) | 颗粒直径 dp/μm |

| 1.31 | 72 | α= 168.4°,β =91.4° | 1.04 | 1~500 | 1, 5, 25, 125 |

| 5.2 | |||||

表5 研究黏度的影响时设置的条件参数

Table 5 Condition parameters set when studying the influence of viscosity

| 常量 | 变量 | ||||

|---|---|---|---|---|---|

| 液滴-颗粒直径比Ω | 液滴表面 张力σ/ (mN·m-1) | 接触角 | 液滴黏度μ/(mPa·s) | 碰撞速度v0/(m·s-1) | 颗粒直径 dp/μm |

| 1.31 | 72 | α= 168.4°,β =91.4° | 1.04 | 1~500 | 1, 5, 25, 125 |

| 5.2 | |||||

| 常量 | 变量 | ||||

|---|---|---|---|---|---|

| 液滴-颗粒直径比Ω | 液滴黏度μ/(mPa·s) | 碰撞速度v0/(m·s-1) | 颗粒直径dp/μm | 液滴表面张力σ/(mN·m-1) | 接触角 |

| 1.31 | 1.04 | 1~500 | 1, 5, 25, 125 (ST1) | 72 (纯水) | α = 168.4°,β =91.4° |

| 1~500 | 1, 5, 25, 125 (ST1) | 34.2 (CTAB) | α =151.2°,β =15.2° | ||

表6 研究表面张力和接触角影响时的条件参数设置

Table 6 Condition parameter settings when the effects of surface tension and contact angle are investigated

| 常量 | 变量 | ||||

|---|---|---|---|---|---|

| 液滴-颗粒直径比Ω | 液滴黏度μ/(mPa·s) | 碰撞速度v0/(m·s-1) | 颗粒直径dp/μm | 液滴表面张力σ/(mN·m-1) | 接触角 |

| 1.31 | 1.04 | 1~500 | 1, 5, 25, 125 (ST1) | 72 (纯水) | α = 168.4°,β =91.4° |

| 1~500 | 1, 5, 25, 125 (ST1) | 34.2 (CTAB) | α =151.2°,β =15.2° | ||

| 常量 | 变量 | ||||

|---|---|---|---|---|---|

液滴- 颗粒直径比Ω | 液滴表面张力σ/(mN·m-1) | 液滴黏度μ/(mPa·s) | 颗粒 直径dp/μm | 碰撞速度 v0/(m·s-1) | 接触角 |

| 1.31 | 72 | 1.04 | 1, 5, 25, 125 | 1~500 | α = β = 168.4° |

| α = β = 151.2° | |||||

| α = β = 120° | |||||

| α = β = 100° | |||||

| α = β = 90° | |||||

| α = β = 80° | |||||

表7 研究接触角影响反弹临界条件时的条件参数设置

Table 7 The condition parameter setting is studied when the contact angle affects the rebound critical condition

| 常量 | 变量 | ||||

|---|---|---|---|---|---|

液滴- 颗粒直径比Ω | 液滴表面张力σ/(mN·m-1) | 液滴黏度μ/(mPa·s) | 颗粒 直径dp/μm | 碰撞速度 v0/(m·s-1) | 接触角 |

| 1.31 | 72 | 1.04 | 1, 5, 25, 125 | 1~500 | α = β = 168.4° |

| α = β = 151.2° | |||||

| α = β = 120° | |||||

| α = β = 100° | |||||

| α = β = 90° | |||||

| α = β = 80° | |||||

| 液滴无量纲参数 | 参数解释 |

|---|---|

| ρl 为液滴密度,dl 为液滴直径,vl 为尘雾相对速度,μl 为液滴动力黏度 | |

| μl 为液滴动力黏度,ρl 为液滴密度,dl 为液滴直径,σ为液滴表面张力 | |

| ρl 为液滴密度,vl 为尘雾相对速度,l为液滴特征长度(在本文中为液滴直径dl ),σ为液滴表面张力 |

表8 无量纲参数解释

Table 8 Dimensionless parameter interpretation

| 液滴无量纲参数 | 参数解释 |

|---|---|

| ρl 为液滴密度,dl 为液滴直径,vl 为尘雾相对速度,μl 为液滴动力黏度 | |

| μl 为液滴动力黏度,ρl 为液滴密度,dl 为液滴直径,σ为液滴表面张力 | |

| ρl 为液滴密度,vl 为尘雾相对速度,l为液滴特征长度(在本文中为液滴直径dl ),σ为液滴表面张力 |

| 条件编号 | 接触角 | 液滴表面张力σ/(mN·m-1) | 反弹边界条件方程 |

|---|---|---|---|

| 1 | 𝛼α = 168.4° β = 91.4° | 72 | 5.807 = 0.00965 ≤ Oh ≤ 0.0483 |

| 2 | 𝛼α = 168.4° β = 168.4° | 72 | 7.301 = 0.00965 ≤ Oh ≤ 0.0483 |

| 3 | 𝛼α = 151.2° β = 151.2° | 72 | 10.034 = 0.00965 ≤ Oh ≤ 0.0483 |

| 4 | 𝛼α = 120.0° β = 120.0° | 72 | 12.491 = 0.00965 ≤ Oh ≤ 0.0483 |

| 5 | 𝛼α = 100.0° β = 100.0° | 72 | 9.077 = 0.00965 ≤ Oh ≤ 0.0483 |

| 6 | 𝛼α = 90.0° β = 90.0° | 72 | 6.663= 0.00965 ≤ Oh ≤ 0.0311 |

| 7 | 𝛼α = 80.0° β = 80.0° | 72 | 当Oh=0.00965,Re = 219.99 当Oh ≥ 0.0193,无反弹现象 |

表9 不同接触角条件下的反弹边界条件方程

Table 9 Bounce-back boundary condition equations for different contact angles

| 条件编号 | 接触角 | 液滴表面张力σ/(mN·m-1) | 反弹边界条件方程 |

|---|---|---|---|

| 1 | 𝛼α = 168.4° β = 91.4° | 72 | 5.807 = 0.00965 ≤ Oh ≤ 0.0483 |

| 2 | 𝛼α = 168.4° β = 168.4° | 72 | 7.301 = 0.00965 ≤ Oh ≤ 0.0483 |

| 3 | 𝛼α = 151.2° β = 151.2° | 72 | 10.034 = 0.00965 ≤ Oh ≤ 0.0483 |

| 4 | 𝛼α = 120.0° β = 120.0° | 72 | 12.491 = 0.00965 ≤ Oh ≤ 0.0483 |

| 5 | 𝛼α = 100.0° β = 100.0° | 72 | 9.077 = 0.00965 ≤ Oh ≤ 0.0483 |

| 6 | 𝛼α = 90.0° β = 90.0° | 72 | 6.663= 0.00965 ≤ Oh ≤ 0.0311 |

| 7 | 𝛼α = 80.0° β = 80.0° | 72 | 当Oh=0.00965,Re = 219.99 当Oh ≥ 0.0193,无反弹现象 |

| α/(°) | β/(°) | Oh | Ω | 式(30)得出的Wecr | 式(31)得出的Wecr | 式(36)得出的Wecr | 前人文献中的Wecr | 来源 |

|---|---|---|---|---|---|---|---|---|

| 90 | 23 | 0.00211 | 0.31 | 128.59 | 115.43 | 62.43 | 63.21 | 文献[ |

| 90 | 23 | 0.00211 | 0.62 | 27.86 | 29.01 | 15.61 | 15.80 | |

| 90 | 23 | 0.00211 | 1.24 | 5.65 | 7.37 | 3.90 | 3.95 | |

| 90 | 23 | 0.00211 | 1.31 | 5.03 | 6.62 | 3.50 | 3.54 | |

| 160 | 23 | 0.00262 | 2.00 | 5.65 | 2.79 | 2.53 | < 3.96 | 文献[ |

| 160 | 23 | 0.00262 | 1.00 | 24.90 | 11.09 | 10.14 | 9.87~30.23 | |

| 160 | 23 | 0.00262 | 0.67 | 51.66 | 50.66 | 12.27 | 70~90 | |

| 160 | 23 | 0.00262 | 0.50 | 95.29 | 89.83 | 21.82 | 130~150 | |

| 160 | 23 | 0.00262 | 0.33 | 222.17 | 201.68 | 49.09 | 130~150 | |

| 125 | 23 | 0.00262 | 2.00 | 7.30 | 4.51 | 1.49 | < 3.96 | |

| 125 | 23 | 0.00262 | 1.00 | 16.82 | 17.96 | 5.95 | 9.87~30.23 | |

| 125 | 23 | 0.00262 | 0.67 | 40.73 | 40.73 | 4.65 | 70~90 | |

| 125 | 23 | 0.00262 | 0.50 | 75.90 | 72.20 | 8.27 | 130~150 | |

| 125 | 23 | 0.00262 | 0.33 | 178.60 | 162.06 | 18.60 | 130~150 | |

| 90 | 23 | 0.00262 | 2.00 | 2.46 | 2.78 | 1.40 | < 3.96 | |

| 90 | 23 | 0.00262 | 1.00 | 9.17 | 11.07 | 5.60 | 3.96~9.87 | |

| 90 | 23 | 0.00262 | 0.67 | 23.61 | 25.16 | 6.78 | 70~90 | |

| 90 | 23 | 0.00262 | 0.50 | 45.50 | 44.57 | 12.05 | 130~150 | |

| 90 | 23 | 0.00262 | 0.33 | 110.29 | 99.96 | 27.11 | 130~150 |

表10 前人研究中的Wecr 与本研究的结果对比

Table 10 Comparison of Wecr in previous studies with the results of this study

| α/(°) | β/(°) | Oh | Ω | 式(30)得出的Wecr | 式(31)得出的Wecr | 式(36)得出的Wecr | 前人文献中的Wecr | 来源 |

|---|---|---|---|---|---|---|---|---|

| 90 | 23 | 0.00211 | 0.31 | 128.59 | 115.43 | 62.43 | 63.21 | 文献[ |

| 90 | 23 | 0.00211 | 0.62 | 27.86 | 29.01 | 15.61 | 15.80 | |

| 90 | 23 | 0.00211 | 1.24 | 5.65 | 7.37 | 3.90 | 3.95 | |

| 90 | 23 | 0.00211 | 1.31 | 5.03 | 6.62 | 3.50 | 3.54 | |

| 160 | 23 | 0.00262 | 2.00 | 5.65 | 2.79 | 2.53 | < 3.96 | 文献[ |

| 160 | 23 | 0.00262 | 1.00 | 24.90 | 11.09 | 10.14 | 9.87~30.23 | |

| 160 | 23 | 0.00262 | 0.67 | 51.66 | 50.66 | 12.27 | 70~90 | |

| 160 | 23 | 0.00262 | 0.50 | 95.29 | 89.83 | 21.82 | 130~150 | |

| 160 | 23 | 0.00262 | 0.33 | 222.17 | 201.68 | 49.09 | 130~150 | |

| 125 | 23 | 0.00262 | 2.00 | 7.30 | 4.51 | 1.49 | < 3.96 | |

| 125 | 23 | 0.00262 | 1.00 | 16.82 | 17.96 | 5.95 | 9.87~30.23 | |

| 125 | 23 | 0.00262 | 0.67 | 40.73 | 40.73 | 4.65 | 70~90 | |

| 125 | 23 | 0.00262 | 0.50 | 75.90 | 72.20 | 8.27 | 130~150 | |

| 125 | 23 | 0.00262 | 0.33 | 178.60 | 162.06 | 18.60 | 130~150 | |

| 90 | 23 | 0.00262 | 2.00 | 2.46 | 2.78 | 1.40 | < 3.96 | |

| 90 | 23 | 0.00262 | 1.00 | 9.17 | 11.07 | 5.60 | 3.96~9.87 | |

| 90 | 23 | 0.00262 | 0.67 | 23.61 | 25.16 | 6.78 | 70~90 | |

| 90 | 23 | 0.00262 | 0.50 | 45.50 | 44.57 | 12.05 | 130~150 | |

| 90 | 23 | 0.00262 | 0.33 | 110.29 | 99.96 | 27.11 | 130~150 |

| [1] | 谢文博, 魏婉笛. 李珏: 职防路上 我看到繁星满天[R/OL]. (2023-04-28). . |

| Xie W B, Wei W D. Li Jue: I saw a starry sky on the way to work defense[R/OL]. (2023-04-28). . | |

| [2] | 袁亮. 煤矿粉尘防控与职业安全健康科学构想[J]. 煤炭学报, 2020, 45(1): 1-7. |

| Yuan L. Scientific conception of coal mine dust control and occupational safety[J]. Journal of China Coal Society, 2020, 45(1): 1-7. | |

| [3] | 王运敏, 李刚, 刘建国, 等. 我国非煤矿山职业健康防控技术研究现状、挑战及展望[J]. 金属矿山, 2024(9): 1-12. |

| Wang Y M, Li G, Liu J G, et al. Current status, challenges and prospects of occupational health control technology in China's non-coal mines[J]. Metal Mine, 2024(9): 1-12. | |

| [4] | 天津市消防救援总队. 已发32起!致235死, 475伤![R/OL]. (2023). . |

| Tianjin Fire rescue Corps. 32 cases have been sent! 235 dead, 475 wounded![R/OL]. (2023). . | |

| [5] | 王国法, 庞义辉, 任怀伟, 等. 矿山智能化建设的挑战与思考[J]. 智能矿山, 2022, 3(10): 2-15. |

| Wang G F, Pang Y H, Ren H W, et al. Challenges and thinking of mine intelligent construction[J]. Journal of Intelligent Mine, 2022, 3(10): 2-15. | |

| [6] | 马素平, 寇子明. 喷雾降尘机理的研究[J]. 煤炭学报, 2005, 30(3): 297-300. |

| Ma S P, Kou Z M. Study on mechanism of reducing dust by spray[J]. Journal of China Coal Society, 2005, 30(3): 297-300. | |

| [7] | 蒋仲安, 王亚朋, 许峰. 金属矿山气-水喷头雾化特性及降尘能力实验研究[J]. 中南大学学报(自然科学版), 2020, 51(1): 184-192. |

| Jiang Z A, Wang Y P, Xu F. Experimental study on atomization characteristics and dust reduction capacity of gas-water nozzles in metal mines[J]. Journal of Central South University (Science and Technology), 2020, 51(1): 184-192. | |

| [8] | 李刚, 吴超. 超声干雾抑尘机理及其技术参数优化研究[J]. 中国安全科学学报, 2015, 25(3): 108-113. |

| Li G, Wu C. Research on mechanism and parameters optimization of ultrasonic atomization technique for dust removal[J]. China Safety Science Journal, 2015, 25(3): 108-113. | |

| [9] | 张天. 超音速汲水式气动雾化细观动力学特性及捕尘机理研究[D]. 阜新: 辽宁工程技术大学, 2021. |

| Zhang T. Study on meso-dynamic characteristics and dust catching mechanism of supersonic pumping pneumatic atomization[D]. Fuxin: Liaoning Technical University, 2021. | |

| [10] | 金龙哲, 刘建国, 林清侠, 等. 矿山喷雾降尘技术研究与应用现状综述[J]. 金属矿山, 2023(7): 2-17. |

| Jin L Z, Liu J G, Lin Q X, et al. Review on the research and application of water spray dust-reduction technology in mines[J]. Metal Mine, 2023(7): 2-17. | |

| [11] | 田畅. X型旋流压力喷嘴雾化参数及降尘效率预测模型[D]. 湘潭: 湖南科技大学, 2019. |

| Tian C. Prediction model of atomization parameters and dust removal efficiency of X-type swirl pressure nozzle[D]. Xiangtan: Hunan University of Science and Technology, 2019. | |

| [12] | 徐翠翠. 喷嘴内外流场雾化特性及尘雾耦合降尘试验研究[D]. 青岛: 山东科技大学, 2018. |

| Xu C C. Experimental study on atomization characteristics of flow field inside and outside nozzle and dust suppression coupled with dust and fog[D]. Qingdao: Shandong University of Science and Technology, 2018. | |

| [13] | 房雪明. 综采面气液两相喷射微细水雾降尘技术及应用[D]. 淮南: 安徽理工大学, 2022. |

| Fang X M. Dust suppression technology and application of gas-liquid two-phase jet micro-water mist in fully mechanized mining face[D]. Huainan: Anhui University of Science & Technology, 2022. | |

| [14] | 宋皓然. 内混式空气雾化喷嘴结构优化与实验研究[D]. 淮南: 安徽理工大学, 2022. |

| Song H R. Structure optimization and experimental study of internal mixing air atomization nozzle[D]. Huainan: Anhui University of Science & Technology, 2022. | |

| [15] | 江丙友, 张琦, 朱志辉, 等. 湿式除尘器中气水喷雾降尘效果试验研究[J]. 金属矿山, 2023(7): 82-90. |

| Jiang B Y, Zhang Q, Zhu Z H, et al. Experimental study on dust reduction effect of air-water spray in wet dust collector[J]. Metal Mine, 2023(7): 82-90. | |

| [16] | 邬高高, 王鹏飞, 刘荣华, 等. 供气压力对流体型超声喷嘴雾化特性及降尘效率的影响[J]. 煤炭学报, 2021, 46(6): 1898-1906. |

| Wu G G, Wang P F, Liu R H, et al. Impact of air supply pressure on the atomization characteristics and dust removal efficiency of fluid ultrasonic nozzle[J]. Journal of China Coal Society, 2021, 46(6): 1898-1906. | |

| [17] | 李刚, 吴将有, 金龙哲, 等. 我国金属矿山粉尘防治技术研究现状及展望[J]. 金属矿山, 2021(1): 154-167. |

| Li G, Wu J Y, Jin L Z, et al. Study status and prospect of dust control technology for metal mines in China[J]. Metal Mine, 2021(1): 154-167. | |

| [18] | 李哲, 葛少成, 孙丽英, 等. 磁化荷电水雾最佳降尘参数确定实验研究[J]. 中国安全生产科学技术, 2022, 18(11): 77-84. |

| Li Z, Ge S C, Sun L Y, et al. Experimental study on determination of optimal dust reduction parameters of magnetized charged water mist[J]. Journal of Safety Science and Technology, 2022, 18(11): 77-84. | |

| [19] | 王晓楠. 表面活性剂复配对煤尘润湿性的协同效应研究[D]. 淮南: 安徽理工大学, 2020. |

| Wang X N. Study on synergistic effect of surfactant combination on coal dust wettability[D]. Huainan: Anhui University of Science & Technology, 2020. | |

| [20] | 李国春, 齐国栋, 孔帅, 等. 环保型泡沫灭火剂在变压器油表面的铺展特性研究[J]. 山东电力技术, 2024, 51(8): 67-77. |

| Li G C, Qi G D, Kong S, et al. Study on the spreading characteristics of environmentally friendly foam fire extinguishing agent on transformer oil surface [J]. Shandong Electric Power Technology, 2024, 51(8): 67-77. | |

| [21] | 周群. 煤矿井下活性磁化水降尘机制及技术研究[D]. 徐州: 中国矿业大学, 2019. |

| Zhou Q. Study on dust suppression mechanism and technology of active magnetized water in coal mine[D]. Xuzhou: China University of Mining and Technology, 2019. | |

| [22] | Mitra S, Doroodchi E, Pareek V, et al. Collision behaviour of a smaller particle into a larger stationary droplet[J]. Advanced Powder Technology, 2015, 26(1): 280-295. |

| [23] | Malgarinos I, Nikolopoulos N, Gavaises M. A numerical study on droplet-particle collision dynamics[J]. International Journal of Heat and Fluid Flow, 2016, 61: 499-509. |

| [24] | 韩方伟, 张金宜, 赵月, 等. 液滴在球形粉尘表面的动力润湿特性[J]. 煤炭学报, 2021, 46(8): 2614-2622. |

| Han F W, Zhang J Y, Zhao Y, et al. Kinetic wetting characteristics of droplet on the surface of spherical dust[J]. Journal of China Coal Society, 2021, 46(8): 2614-2622. | |

| [25] | Zhu X L, Wang D M, Craig V S J. Interaction of particles with surfactant thin films: implications for dust suppression[J]. Langmuir, 2019, 35(24): 7641-7649. |

| [26] | Li X, Dong Z Q, Wang L P, et al. A magnetic field coupling fractional step lattice Boltzmann model for the complex interfacial behavior in magnetic multiphase flows[J]. Applied Mathematical Modelling, 2023, 117: 219-250. |

| [27] | Li X, Dong Z Q, Li Y, et al. A fractional-step lattice Boltzmann method for multiphase flows with complex interfacial behavior and large density contrast[J]. International Journal of Multiphase Flow, 2022, 149: 103982. |

| [28] | Yoon I, Shin S. Direct numerical simulation of droplet collision with stationary spherical particle: a comprehensive map of outcomes[J]. International Journal of Multiphase Flow, 2021, 135: 103503. |

| [29] | Banitabaei S A, Amirfazli A. Droplet impact onto a solid sphere: effect of wettability and impact velocity[J]. Physics of Fluids, 2017, 29(6): 062111. |

| [30] | Banitabaei S A, Amirfazli A. Droplet impact onto a solid sphere in mid-air: effect of viscosity, gas density, and diameter ratio on impact outcomes[J]. Physics of Fluids, 2020, 32(3): 037102. |

| [31] | Pasandideh-Fard M, Chandra S, Mostaghimi J. A three-dimensional model of droplet impact and solidification[J]. International Journal of Heat and Mass Transfer, 2002, 45(11): 2229-2242. |

| [32] | Khojasteh D, Bordbar A, Kamali R, et al. Curvature effect on droplet impacting onto hydrophobic and superhydrophobic spheres[J]. International Journal of Computational Fluid Dynamics, 2017, 31(6/7/8): 310-323. |

| [33] | Liu X H, Zhao Y M, Chen S, et al. Numerical research on the dynamic characteristics of a droplet impacting a hydrophobic tube[J]. Physics of Fluids, 2017, 29(6): 062105. |

| [34] | Mundo C, Sommerfeld M, Tropea C. Droplet-wall collisions: experimental studies of the deformation and breakup process[J]. International Journal of Multiphase Flow, 1995, 21(2): 151-173. |

| [1] | 马晓文, 程扬帆, 李世周, 梁茹萍, 鲍忠奥. 粒径对TiH2粉尘云燃爆特性及温度分布特征的影响[J]. 化工学报, 2025, 76(8): 4341-4349. |

| [2] | 张帅, 喻健良, 丁建飞, 闫兴清. 气流输运工况玉米淀粉爆炸火焰传播与压力特性实验研究[J]. 化工学报, 2024, 75(5): 2072-2080. |

| [3] | 李珍宝, 李超, 王虎, 王绍瑞, 黎泉. MPP抑制铝镁合金粉尘爆炸微观机理研究[J]. 化工学报, 2023, 74(8): 3608-3614. |

| [4] | 蔡骁, 张龙凯, 王金华, 黄佐华. 单颗粒铁粉燃烧特性及产物形貌分析[J]. 化工学报, 2023, 74(11): 4702-4709. |

| [5] | 吴延鹏, 栾珊珊, 苏伟, 邢奕, 钱付平. 钢铁厂原料堆粉尘无组织排放抑制技术进展[J]. 化工学报, 2021, 72(S1): 53-62. |

| [6] | 孟凯, 许建良, 代正华, 刘海峰, 王辅臣, 龚剑洪. 水分子对初始碳烟颗粒形成过程影响的分子动力学模拟[J]. 化工学报, 2019, 70(6): 2237-2243. |

| [7] | 吴延鹏, 郭占闯. 超疏水表面防附尘性能实验分析[J]. 化工学报, 2018, 69(S2): 365-372. |

| [8] | 张斌, 胡恩柱, 刘天霞, 胡献国. 生物质燃油碳烟颗粒的形貌、结构与组分表征[J]. 化工学报, 2015, 66(1): 441-448. |

| [9] | 朱辉, 付海明, 亢燕铭. 荷尘状态单纤维过滤压降数值计算与分析[J]. 化工学报, 2012, 63(12): 3927-3936. |

| [10] | 张星, 姬忠礼, 陈鸿海, 熊至宜. 高压天然气管道内粉尘在线检测方法 [J]. 化工学报, 2010, 61(9): 2334-2339. |

| [11] | 王延吉 ; 胡洁; 薛伟 ;赵新强. 催化反应过程绿色集成系统 [J]. CIESC Journal, 2007, 58(11): 2689-2696. |

| [12] | 刘章现,冯兴华,杨甲文. 炭素厂生产车间粉尘及沥青烟治理工程设计 [J]. CIESC Journal, 2006, 25(7): 837-. |

| [13] | 梁红;叶代启;林维明;付名利;何雄彬 . Sn催化剂对柴油车排气颗粒去除效果 [J]. CIESC Journal, 2004, 55(11): 1869-1873. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号