化工学报 ›› 2021, Vol. 72 ›› Issue (8): 4104-4110.DOI: 10.11949/0438-1157.20210164

收稿日期:2021-01-25

修回日期:2021-04-27

出版日期:2021-08-05

发布日期:2021-08-05

通讯作者:

龚剑洪

作者简介:王景效(1995—),男,硕士研究生,

Jingxiao WANG1( ),Xiangyu HE2,Jianhong GONG1(

),Xiangyu HE2,Jianhong GONG1( ),Jianliang XU2,Haifeng LIU2

),Jianliang XU2,Haifeng LIU2

Received:2021-01-25

Revised:2021-04-27

Online:2021-08-05

Published:2021-08-05

Contact:

Jianhong GONG

摘要:

催化裂解反应器是石油深度加工的重要反应器,采用实验方法对新型快速床催化裂解反应器内气固两相流动特性进行了研究,测量了床层内颗粒浓度分布,考察了气体流量对床层轴向和径向上颗粒浓度分布的影响。实验结果表明,床层轴向上颗粒浓度呈现下部稠密上部稀疏的分布规律;当气体流量较低时轴向颗粒浓度呈S形分布,高气量下呈现指数函数形分布,即反应器上部区域的颗粒浓度分布影响较小;床层径向颗粒浓度分布呈现中心稀、边壁浓的特征,且增大空气流量,径向分布趋于均匀。在一定操作条件下,与传统提升管相比,新型快速床颗粒浓度显著提高。

中图分类号:

王景效, 贺翔宇, 龚剑洪, 许建良, 刘海峰. 新型催化裂解快速流化床内颗粒浓度分布实验研究[J]. 化工学报, 2021, 72(8): 4104-4110.

Jingxiao WANG, Xiangyu HE, Jianhong GONG, Jianliang XU, Haifeng LIU. Experimental study on solids concentration in novel fast fluidized bed for catalytic cracking[J]. CIESC Journal, 2021, 72(8): 4104-4110.

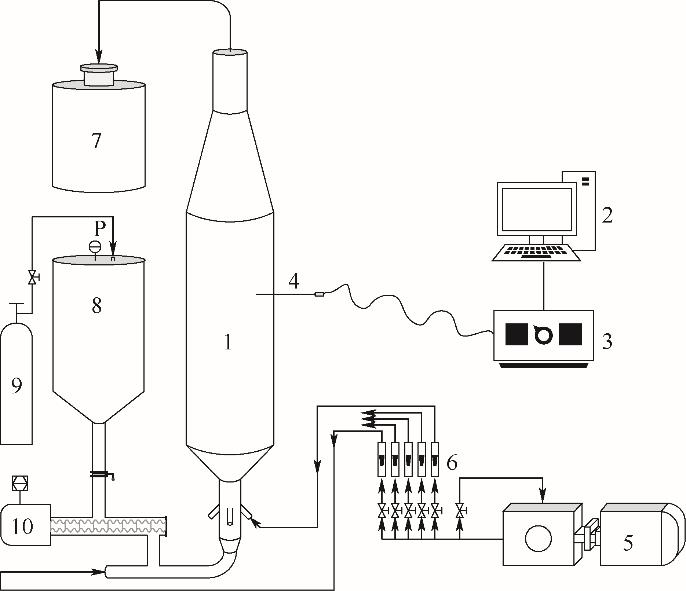

图2 实验流程1—reactor; 2—computer; 3—fiber optic measuring instrument; 4—fiber optic probe; 5—roots fan; 6—rotor flow meter; 7—bag filter; 8—solid storage vessel; 9—compressed air cylinder; 10—feeder

Fig.2 Flow chart of experiment

| 颗粒流量Gs/(kg/h) | 进气量Gg/(m3/h) | ||

|---|---|---|---|

| inlet 1 | 总进气量 | inlet 1 | inlet 2 |

| 1000 | 340 | 36 | 4×76 |

| 392 | 40 | 4×88 | |

| 444 | 44 | 4×100 | |

表1 实验工况

Table 1 Experimental conditions

| 颗粒流量Gs/(kg/h) | 进气量Gg/(m3/h) | ||

|---|---|---|---|

| inlet 1 | 总进气量 | inlet 1 | inlet 2 |

| 1000 | 340 | 36 | 4×76 |

| 392 | 40 | 4×88 | |

| 444 | 44 | 4×100 | |

图4 颗粒浓度轴向截面平均分布(a)、轴线分布(b)和近壁面分布(c)

Fig.4 Axial profiles of cross-sectional averaged solids concentration(a), center solids concentration (b) and near wall solids concentration (c)

图6 不同高度截面颗粒浓度径向分布不均匀指数(a)和标准差的轴向分布(b)

Fig.6 Axial profiles of radial non-uniformity index (a) and standard deviation of solids concentration at different heights (b)

| 12 | 陈岱琳, 钟文琪, 邵应娟, 等. 快速流化床气固流动结构及其转变[J]. 工程热物理学报, 2015, 36(11): 2402-2406. |

| Chen D L, Zhong W Q, Shao Y J, et al. The flow pattern and transition of a fast fluidized bed[J]. Journal of Engineering Thermophysics, 2015, 36(11): 2402-2406. | |

| 13 | 王巍, 谢朝钢. 催化裂解(DCC)新技术的开发与应用[J]. 石油化工技术经济, 2005, 21(1): 8-13. |

| Wang W, Xie C G. Development and application of DCC new technology[J]. Techno-Economics in Petrochemicals, 2005, 21(1): 8-13. | |

| 14 | Wang G, Xu C M, Gao J S. Study of cracking FCC naphtha in a secondary riser of the FCC unit for maximum propylene production[J]. Fuel Processing Technology, 2008, 89(9): 864-873. |

| 15 | Zhu X L, Li C Y, Yang C H, et al. Gas-solids flow structure and prediction of solids concentration distribution inside a novel multi-regime riser[J]. Chemical Engineering Journal, 2013, 232: 290-301. |

| 1 | Torres H M, de Jong K P. Catalysts for production of lower olefins from synthesis gas: a review[J]. ACS Catalysis, 2013, 3(9): 2130-2149. |

| 2 | Rahimi N, Karimzadeh R. Catalytic cracking of hydrocarbons over modified ZSM-5 zeolites to produce light olefins: a review[J]. Applied Catalysis A: General, 2011, 398(1/2): 1-17. |

| 16 | Deng R S, Liu H E, Wei F, et al. Axial flow structure at the varying superficial gas velocity in a downer reactor[J]. Chemical Engineering Journal, 2004, 99(1): 5-14. |

| 17 | Wang X H, Gao S Q, Xu Y H, et al. Gas-solids flow patterns in a novel dual-loop FCC riser[J]. Powder Technology, 2005, 152(1/2/3): 90-99. |

| 18 | Lu B N, Wang W, Li J H, et al. Multi-scale CFD simulation of gas-solid flow in MIP reactors with a structure-dependent drag model[J]. Chemical Engineering Science, 2007, 62(18/19/20): 5487-5494. |

| 3 | Ren T, Patel M, Blok K. Olefins from conventional and heavy feedstocks: energy use in steam cracking and alternative processes[J]. Energy, 2006, 31(4): 425-451. |

| 4 | 张络明, 许春芳, 马通, 等. La改性ZSM-5分子筛及其在催化裂解反应中的应用[J]. 化工学报, 2016, 67(8): 3408-3414. |

| Zhang L M, Xu C F, Ma T, et al. Synthesis of La-modified ZSM-5 zeolite and performance for catalytic cracking reaction[J]. CIESC Journal, 2016, 67(8): 3408-3414. | |

| 19 | Chen Y M. Recent advances in FCC technology[J]. Powder Technology, 2006, 163(1/2): 2-8. |

| 20 | Jiang T F. Method and system of converting waste plastics into hydrocarbon oil: US6774271[P]. 2004-08-10. |

| 21 | Yan A J, Ball J, Zhu J. Scale-up effect of riser reactors (3) axial and radial solids flux distribution and flow development[J]. Chemical Engineering Journal, 2005, 109(1/2/3): 97-106. |

| 22 | 白丁荣, 金涌, 俞芷青. 循环流态化(Ⅱ): 气-固流动规律[J]. 化学反应工程与工艺, 1991, 7(3): 303-317. |

| Bai D R, Jin Y, Yu Z Q. Circulating fluidization(Ⅱ): Gas-solids flow pattern [J]. Chemical Reaction Engineering and Technology, 1991, 7(3): 303-317. | |

| 23 | 朱炳辰, 翁惠新, 朱子彬. 催化反应工程[M]. 北京: 中国石化出版社, 2001: 41-59. |

| Zhu B C,Weng H X, Zhu Z B. Catalytic Reaction Engineering[M]. Beijing: China Petrochemical Press, 2001: 41-59. | |

| 24 | Meng X H, Xu C M, Gao J S, et al. Seven-lump kinetic model for catalytic pyrolysis of heavy oil[J]. Catalysis Communications, 2007, 8(8): 1197-1201. |

| 25 | Li X H, Li C Y, Zhang J F, et al. Effects of temperature and catalyst to oil weight ratio on the catalytic conversion of heavy oil to propylene using ZSM-5 and USY catalysts[J]. Journal of Natural Gas Chemistry, 2007, 16(1): 92-99. |

| 26 | 刘清华, 杨朝合, 赵辉, 等. 变径提升管内颗粒流动特性的研究[J]. 石油化工, 2009, 38(1): 40-45. |

| 5 | Zhu X L, Jiang S A, Li C Y, et al. Residue catalytic cracking process for maximum ethylene and propylene production [J]. Industrial & Engineering Chemistry Research, 2013, 52(40): 14366-14375. |

| 6 | Li Z K, Wang G, Gao J S. Effect of retarding components on heavy oil catalytic cracking and their corresponding countermeasures [J]. Energy & Fuels, 2019, 33(11): 10833-10843. |

| 7 | 陈振涛, 徐春明. 重质油在孔道内扩散传质的研究进展 [J]. 化工学报, 2016, 67(1): 165-175. |

| Chen Z T, Xu C M, Progress of research on diffusional transport of heavy oil in pores [J]. CIESC Journal, 2016, 67(01): 165-175. | |

| 8 | 金涌. 流态化工程原理[M]. 北京: 清华大学出版社, 2001: 106-201. |

| Jin Y. Fluidization Engineering Principles[M]. Beijing: Tsinghua University Press, 2001: 106-201. | |

| 9 | 白丁荣, 金涌, 姚文虎. 快速流态化技术进展[J]. 化学工程, 1987, 15(2): 38-46, 30. |

| Bai D R, Jin Y, Yao W H. Progress of fast fluidization technology [J]. Chemical Engineering (China), 1987, 15(2): 38-46, 30. | |

| 10 | 白丁荣, 金涌, 俞芷青. 快速流态化技术[J]. 化工进展, 1988, 7(1): 23-26, 22. |

| Bai D R, Jin Y, Yu Z Q. Fast fluidization technology [J]. Chemical Industry and Engineering Progress, 1988, 7(1): 23-26, 22. | |

| 11 | 李佑楚. 流态化过程工程导论[M]. 北京: 科学出版社, 2008: 534-585. |

| 26 | Liu Q H, Yang C H, Zhao H, et al. Solid flow pattern in changing-diameter riser of a circulating fluidized bed[J]. Petrochemical Technology, 2009, 38(1): 40-45. |

| 27 | Zhu H Y, Zhu J. Gas-solids flow structures in a novel circulating-turbulent fluidized bed[J]. AIChE Journal, 2008, 54(5): 1213-1223. |

| 28 | Geng Q, Zhu X L, Liu Y X, et al. Gas-solid flow behavior and contact efficiency in a circulating-turbulent fluidized bed[J]. Powder Technology, 2013, 245: 134-145. |

| 29 | Li Y Z, Zhai G W, Zhang H T, et al. Experimental and predictive research on solids holdup distribution in a CFB riser[J]. Powder Technology, 2019, 344: 830-841. |

| 30 | 吴诚, 高希, 成有为, 等. 湍动流化床过渡段固含率分布特征的实验及数值模拟[J]. 化工学报, 2013, 64(3): 858-866. |

| Wu C, Gao X, Cheng Y W, et al. Experimental and numerical study of solids concentration distribution in transition section of turbulent fluidized bed[J]. CIESC Journal, 2013, 64(3): 858-866. | |

| 31 | Zhu X L, Yang C H, Li C Y, et al. Comparative study of gas-solids flow patterns inside novel multi-regime riser and conventional riser[J]. Chemical Engineering Journal, 2013, 215/216: 188-201. |

| 32 | Adánez J, Gayán P, García-Labiano F, et al. Axial voidage profiles in fast fluidized beds[J]. Powder Technology, 1994, 81(3): 259-268. |

| 11 | Li Y C. Introduction to Fluidization Process Engineering [M]. Beijing: Science Press, 2008: 534-585. |

| 33 | Li J H, Tung Y, Kwauk M. Axial voidage profiles of fast fluidized beds in different operating regions[M]//Circulating Fluidized Bed Technology. Amsterdam: Elsevier, 1988: 193-203. |

| 34 | 毛晓阳, 王成秀, 蓝兴英, 等. 入口结构对18 m气固循环流化床提升管内颗粒流动特性的影响[J]. 化工学报, 2018, 69(5): 1931-1937. |

| Mao X Y, Wang C X, Lan X Y, et al. Effects of inlet distributor on particle flow characteristics in 18 m circulating fluidized bed riser[J]. CIESC Journal, 2018, 69(5): 1931-1937. | |

| 35 | Zhu J X, Manyele S V. Radial nonuniformity index (RNI) in fluidized beds and other multiphase flow systems[J]. The Canadian Journal of Chemical Engineering, 2001, 79(2): 203-213. |

| [1] | 涂玉明, 邵高燕, 陈健杰, 刘凤, 田世超, 周智勇, 任钟旗. 钙基催化剂的设计合成及应用研究进展[J]. 化工学报, 2023, 74(7): 2717-2734. |

| [2] | 白宇恩, 张彬瑞, 刘东阳, 赵亮, 高金森, 徐春明. ZSM-5分子筛酸性能和孔结构的协同作用对C5烯烃催化裂解性能的影响[J]. 化工学报, 2023, 74(1): 438-448. |

| [3] | 张玉明, 纪德馨, 朱翰文, 万利锋, 张炜, 温宏炎, 岳君容. 微型流化床中萘裂解生成小分子气体的反应动力学研究[J]. 化工学报, 2021, 72(5): 2604-2615. |

| [4] | 忻睦迪, 邢恩会. 三甲基膦和金属氧化物复合改性ZSM-5分子筛及其裂解性能研究[J]. 化工学报, 2021, 72(5): 2657-2668. |

| [5] | 刘美佳,王刚,张忠东,许顺年,王皓,党法璐,何盛宝. 碳五烷烃裂解制低碳烯烃反应性能的分析[J]. 化工学报, 2021, 72(10): 5172-5182. |

| [6] | 孙先亮, 李健, 韩哲哲, 许传龙. 基于数据驱动的卷积神经网络电容层析成像图像重建[J]. 化工学报, 2020, 71(5): 2004-2016. |

| [7] | 金铭, 胡定华, 李强, 范德松. Al2O3纳米流体液滴蒸发特性的数值模拟研究[J]. 化工学报, 2019, 70(11): 4199-4206. |

| [8] | 孙子文, 陈岱琳, 钟文琪, Aibing Yu. 快速流化床颗粒团絮特征的MP-PIC数值模拟[J]. 化工学报, 2018, 69(8): 3443-3451. |

| [9] | 王平, 赵辉, 杨朝合. 面向过程控制的两段提升管重油催化裂解动态建模[J]. 化工学报, 2016, 67(8): 3499-3506. |

| [10] | 王平, 赵辉, 杨朝合. 基于多目标优化的两段提升管重油催化裂解自优化控制[J]. 化工学报, 2016, 67(8): 3491-3498. |

| [11] | 孙丽媛, 张亚飞, 巩雁军. ZSM-5/EU-1共生分子筛的可控合成及催化裂解性能[J]. 化工学报, 2016, 67(8): 3436-3445. |

| [12] | 张络明, 许春芳, 马通, 巩雁军. La改性ZSM-5分子筛及其在催化裂解反应中的应用[J]. 化工学报, 2016, 67(8): 3408-3414. |

| [13] | 赵丹, 袁美华, 张耀远, 姜桂元, 赵震, 刘佳, 韩善磊, 孙华倩. Cr掺杂ZSM-5双功能催化剂的制备及其催化裂解正丁烷[J]. 化工学报, 2016, 67(8): 3400-3407. |

| [14] | 马通, 耿祖豹, 李冰, 赵琦, 巩雁军. 不同模板制备ZSM-5分子筛的酸性特征及催化裂解性能差异[J]. 化工学报, 2016, 67(8): 3374-3379. |

| [15] | 王成秀, 祝京旭, 蓝兴英, 高金森. 下行床内提高颗粒浓度及改善颗粒分布研究进展[J]. 化工学报, 2015, 66(8): 2810-2816. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号