化工学报 ›› 2025, Vol. 76 ›› Issue (10): 5176-5189.DOI: 10.11949/0438-1157.20250130

王士成1( ), 张新儒1,2, 王永洪1,2(

), 张新儒1,2, 王永洪1,2( ), 李晋平1,2

), 李晋平1,2

收稿日期:2025-02-13

修回日期:2025-03-21

出版日期:2025-10-25

发布日期:2025-11-25

通讯作者:

王永洪

作者简介:王士成(1999—),男,硕士研究生,wangshicheng319720@163.com

基金资助:

Shicheng WANG1( ), Xinru ZHANG1,2, Yonghong WANG1,2(

), Xinru ZHANG1,2, Yonghong WANG1,2( ), Jinping LI1,2

), Jinping LI1,2

Received:2025-02-13

Revised:2025-03-21

Online:2025-10-25

Published:2025-11-25

Contact:

Yonghong WANG

摘要:

混合基质膜结合了聚合物和无机材料的优点,性能可超过聚合物膜,在气体分离方面具有广泛的应用前景。为了获得高性能的CO2/N2分离膜,利用丙烯基-1,3-磺酸内酯(BS)的环氧基团与CAU-1的伯胺基团开环反应制备磺化CAU-1(CAU-1@BS)。然后,将CAU-1@BS添加到聚乙烯胺(PVAm)中制备制膜液,将其涂覆在亲水性改性聚砜超滤膜上制备得到混合基质复合膜。借助XPS、FTIR和BET表征了CAU-1@BS的化学结构和孔隙结构,并通过SEM表征了膜的形貌结构。此外,还研究了混合基质复合膜的制备条件和测试条件对气体分离性能的影响。研究结果表明,当CAU-1@BS的含量为7%(质量分数)时,制备的混合基质复合膜表现出优异的分离性能,其CO2渗透速率为505 GPU(1 GPU=3.38×10-10 mol·m-2·S-1·Pa-1),CO2/N2选择性为67,与纯PVAm膜(CO2渗透速率为296 GPU;CO2/N2选择性为39)相比,分别提高了70.6%和71.8%。一方面,这是因为通过开环反应引入的磺酸基团不仅可以作为Lewis碱性位点与CO2发生酸碱相互作用,而且能够吸附水分子从而增强CO2在膜中的促进传递效果。另一方面,PVAm中的氨基与CAU-1@BS的多孔结构协同作用提高膜的气体分离性能。此外,在以CO2/N2混合气为原料气的条件下,制备的混合基质复合膜在长达360 h的时间内保持了良好的稳定性,其平均CO2渗透速率和CO2/N2选择性分别为527 GPU和70,这表明该膜具有较好的应用前景。

中图分类号:

王士成, 张新儒, 王永洪, 李晋平. 磺化CAU-1强化聚乙烯胺促进传递膜的CO2/N2分离性能[J]. 化工学报, 2025, 76(10): 5176-5189.

Shicheng WANG, Xinru ZHANG, Yonghong WANG, Jinping LI. Enhancing the CO2/N2 separation performance of PVAm facilitated transport membrane by sulfonated CAU-1[J]. CIESC Journal, 2025, 76(10): 5176-5189.

| Samples | BET surface area/ (m2·g-1) | Total pore volume/ (cm3·g-1) | H-K micropore volume / (cm3·g-1) | Average pore diameter/nm |

|---|---|---|---|---|

| CAU-1 | 755.33 | 1.069 | 0.332 | 6.34 |

| CAU-1@BS | 426.91 | 0.515 | 0.187 | 5.31 |

表1 材料的孔结构参数

Table 1 Porous structure parameters of materials

| Samples | BET surface area/ (m2·g-1) | Total pore volume/ (cm3·g-1) | H-K micropore volume / (cm3·g-1) | Average pore diameter/nm |

|---|---|---|---|---|

| CAU-1 | 755.33 | 1.069 | 0.332 | 6.34 |

| CAU-1@BS | 426.91 | 0.515 | 0.187 | 5.31 |

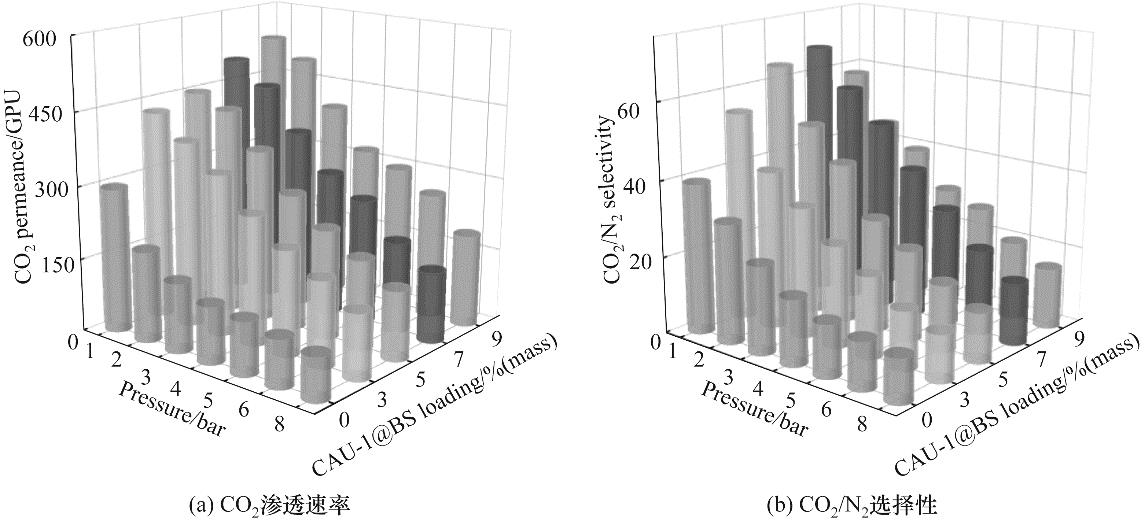

图7 (a) CAU-1与BS的质量比和(b) CAU-1@BS的含量对膜气体分离性能的影响;湿涂层厚度对膜(c) CO2渗透速率和(d) CO2/N2选择性的影响

Fig.7 Effect of (a) the mass ratio of CAU-1to BS and (b) CAU-1@BS loading on the gas separation performance of the membranes; Effect of the wet coating thickness on (c) CO2 permeance and (d) CO2/N2 selectivity of membranes

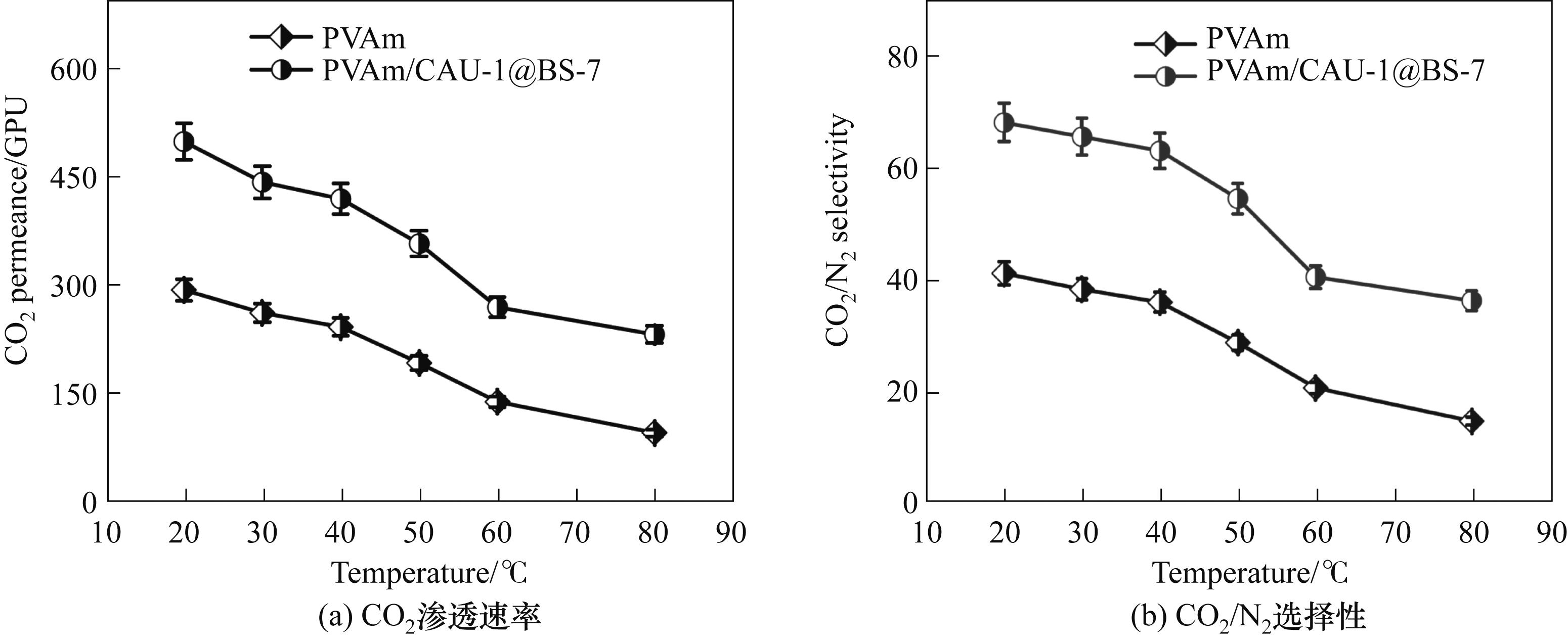

图8 纯PVAm膜和PVAm/CAU-1@BS的(a) CO2渗透速率和(b) CO2/N2选择性与进料气压力的关系

Fig.8 Dependence of (a) CO2 permeance and (b) CO2/N2 selectivity of the pristine PVAm membrane and PVAm/CAU-1@BS on feed gas pressure

图9 纯PVAm膜和PVAm/CAU-1@BS的(a) CO2渗透率和(b) CO2/N2选择性与操作温度的关系

Fig.9 Dependence of (a) CO2 permeance and (b) CO2/N2 selectivity of the pristine PVAm membrane and PVAm/CAU-1@BS membrane as functions of operating temperature

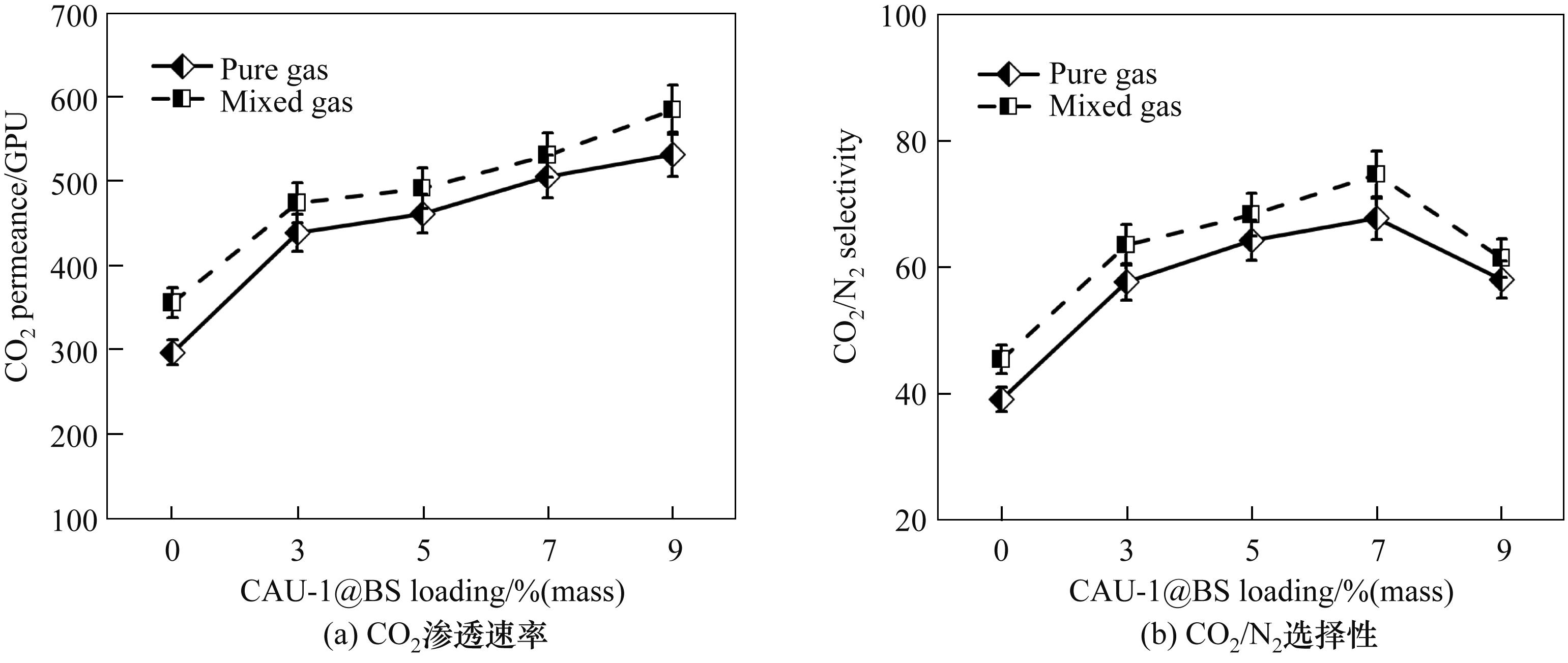

图10 使用混合气体和纯气体测试纯PVAm膜和PVAm/CAU-1@BS的分离性能

Fig.10 Separation performance of the pristine PVAm membrane and PVAm/CAU-1@BS tested using a gas mixture and a pure gas

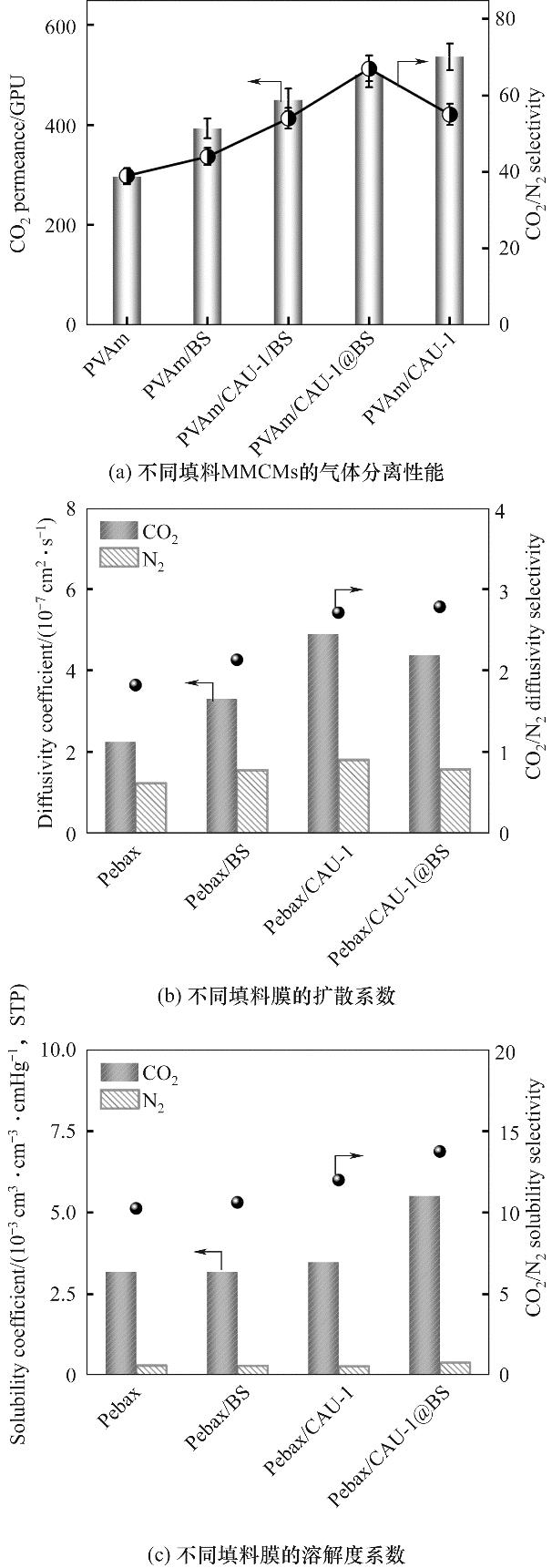

图11 (a)添加了不同填料的MMCMs的气体分离性能;添加了不同填料的Pebax基质膜的(b)扩散系数和(c)溶解度系数

Fig.11 (a) Gas separation performances of MMCMs loaded with different fillers; (b) Diffusion coefficients and (c) solubility coefficients of Pebax-based membranes with different fillers added

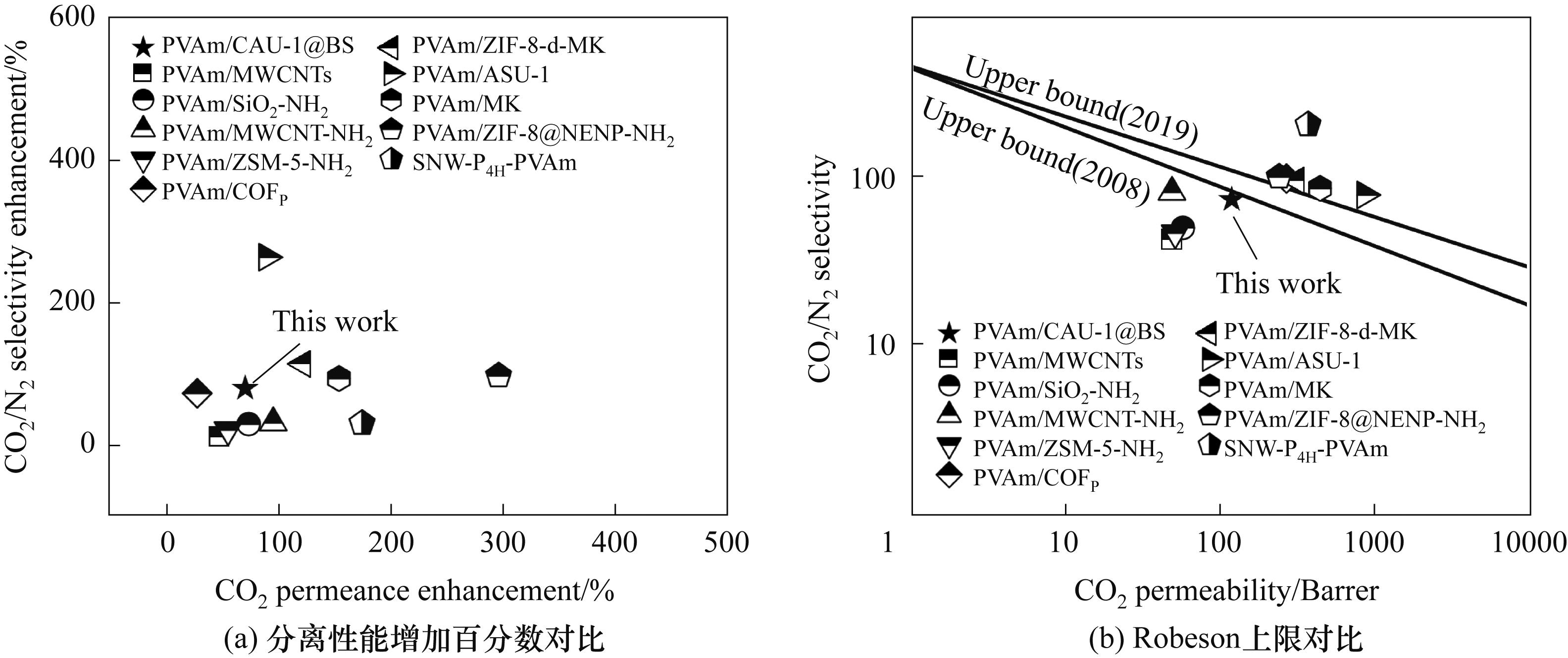

图13 (a) PVAm/CAU-1@BS与其他已报道的基于PVAm的MMCMs的性能增加百分数及其(b)上限对比

Fig.13 (a) Percentage increase in performance of PVAm/CAU-1@BS versus other reported PVAm-based MMCMs and (b) their upper bound

| [1] | Jiang Z P, Qin C, Pan Y W, et al. Multi-decadal coastal acidification in the northern gulf of Mexico driven by climate change and eutrophication[J]. Geophysical Research Letters, 2024, 51(5): e2023GL106300. |

| [2] | Liu C, Shao L Y, Pan C J, et al. Ammonia-based post-combustion CO2 and SO2 integrating capture using multi-stage solvent circulation process[J]. Separation and Purification Technology, 2024, 339: 126611. |

| [3] | Chavaillaz Y, Roy P, Partanen A I, et al. Exposure to excessive heat and impacts on labour productivity linked to cumulative CO2 emissions[J]. Scientific Reports, 2019, 9(1): 13711. |

| [4] | Krótki A, Chwoła T, Więcław-Solny L, et al. Advancements in CO2 hydrogenation—investigating a CNG pilot plant in Poland[J]. Fuel, 2025, 381: 133599. |

| [5] | Yu X H, Xu H Y, Yin J, et al. Achieving China's CO2 reduction targets: insights from a hybrid PPA-PPR forecasting model[J]. Journal of Environmental Management, 2024, 372: 123409. |

| [6] | 谢钰麟, 饶瑞晔, 黄建, 等. 连续ZIF-8膜制备及在氢气分离中的研究进展[J]. 化工进展, 2024, 43(S1): 403-418. |

| Xie Y L, Rao R Y, Huang J, et al. Preparation of continuous ZIF-8 membrane and its progress in hydrogen separation[J]. Chemical Industry and Engineering Progress, 2024, 43(S1): 403-418. | |

| [7] | Wang K F, Chen D L, Tang J L, et al. PIM-1-based membranes mediated with CO2-philic MXene nanosheets for superior CO2/N2 separation[J]. Chemical Engineering Journal, 2024, 483: 149305. |

| [8] | He W, Wang X Z, Guan J, et al. Membranes with molecular gatekeepers for efficient CO2 capture and H2 purification[J]. ACS Applied Materials & Interfaces, 2024, 16(16): 21222-21232. |

| [9] | Sreenath S, Sam A A. Hybrid membrane-cryogenic CO2 capture technologies: a mini-review[J]. Frontiers in Energy Research, 2023, 11: 1167024. |

| [10] | Zheng W J, Yu J B, Hu Z Y, et al. 3D hollow CoNi-LDH nanocages based MMMs with low resistance and CO2-philic transport channel to boost CO2 capture[J]. Journal of Membrane Science, 2022, 653: 120542. |

| [11] | Mohsenpour Tehrani M, Chehrazi E. Metal-organic-frameworks based mixed-matrix membranes for CO2 separation: an applicable-conceptual approach[J]. ACS Applied Materials & Interfaces, 2024, 16(26): 32906-32929. |

| [12] | Gan L, Andres-Garcia E, Mínguez Espallargas G, et al. Adsorptive separation of CO2 by a hydrophobic carborane-based metal-organic framework under humid conditions[J]. ACS Applied Materials & Interfaces, 2023, 15(4): 5309-5316. |

| [13] | Yahia M, Lozano L A, Zamaro J M, et al. Microwave-assisted synthesis of metal-organic frameworks UiO-66 and MOF-808 for enhanced CO2/CH4 separation in PIM-1 mixed matrix membranes[J]. Separation and Purification Technology, 2024, 330: 125558. |

| [14] | 张文焱, 刘浩, 宋伟龙, 等. 不同粒径UiO-66混掺改性TFN-FO膜的构建及性能评价[J]. 化工学报, 2024, 75(5): 1920-1928. |

| Zhang W Y, Liu H, Song W L, et al. Construction and performance evaluation of TFN-FO membranes incorporated with UiO-66 nanoparticles of different sizes[J]. CIESC Journal, 2024, 75(5): 1920-1928. | |

| [15] | Carja I D, Tavares S R, Shekhah O, et al. Insights into the enhancement of MOF/polymer adhesion in mixed-matrix membranes via polymer functionalization[J]. ACS Applied Materials & Interfaces, 2021, 13(24): 29041-29047. |

| [16] | Jiang Y Z, Liu C Y, Caro J, et al. A new UiO-66-NH2 based mixed-matrix membranes with high CO2/CH4 separation performance[J]. Microporous and Mesoporous Materials, 2019, 274: 203-211. |

| [17] | Katare A, Mandal B. Surface engineering of Zr BDC nanoparticles via conjugation with lysine to enhance the CO2/N2 separation performance of chitosan mixed matrix membranes under dry and humid conditions[J]. ACS Applied Nano Materials, 2023, 6(6): 4821-4833. |

| [18] | Wang B, Qiao Z H, Xu J Y, et al. Unobstructed ultrathin gas transport channels in composite membranes by interfacial self-assembly[J]. Advanced Materials, 2020, 32(22): 1907701. |

| [19] | Xiao S J, Huo X W, Tong Y X, et al. Improvement of thin-film nanocomposite(TFN) membrane performance by CAU-1 with low charge and small size[J]. Separation and Purification Technology, 2021, 274: 118467. |

| [20] | Wang Y H, Li L, Zhang X R, et al. Polyvinylamine/amorphous metakaolin mixed-matrix composite membranes with facilitated transport carriers for highly efficient CO2/N2 separation[J]. Journal of Membrane Science, 2020, 599: 117828. |

| [21] | Wang Y H, Hu F N, Zhang X R, et al. Enhancing CO2-facilitated transport in PVAm membranes through the synergistic effect of porous molybdenum disulfide and mobilizable sulfonic groups[J]. Journal of Materials Chemistry A, 2025, 13(4): 3132-3145. |

| [22] | Ahnfeldt T, Dr N G, Gunzelmann D, et al. [Al4(OH)2(OCH3)4(H2N-bdc)3]⋅xH2O: a 12-connected porous metal-organic framework with an unprecedented aluminum-containing brick[J]. Angewandte Chemie International Edition, 2009, 48(28): 5163-5166. |

| [23] | Makhtar S N N M, Pauzi M Z M, Peechmani P, et al. The feasibility study of CAU-1 as an adsorbent for Cu, Zn, Pb, As, Fe and endocrine disrupting chemical bisphenol-A (BPA)[J]. Arabian Journal of Chemistry, 2023, 16(9): 105042. |

| [24] | Dhakshinamoorthy A, Heidenreich N, Lenzen D, et al. Knoevenagel condensation reaction catalysed by Al-MOFs with CAU-1 and CAU-10-type structures[J]. CrystEngComm, 2017, 19(29): 4187-4193. |

| [25] | Mukhopadhyay S, Debgupta J, Singh C, et al. Designing UiO-66-based superprotonic conductor with the highest metal-organic framework based proton conductivity[J]. ACS Applied Materials & Interfaces, 2019, 11(14): 13423-13432. |

| [26] | Zhong X, Liang W, Wang H F, et al. Aluminum-based metal-organic frameworks (CAU-1) highly efficient U O 2 2 + and T c O 4 - ions immobilization from aqueous solution[J]. Journal of Hazardous Materials, 2021, 407: 124729. |

| [27] | Wu D P, Lin H, Ren X F, et al. ZIF-8 derived spherical porous carbon as an efficient sustained-release carrier for nitroimidazole drugs[J]. Materials Today Chemistry, 2024, 38: 102057. |

| [28] | Lu J C, Zhong X Y, Lin X M, et al. Nanoconfined carbonization enabling high-density porous carbon for jointly superior gravimetric and volumetric zinc-ion storage[J]. Energy & Environmental Science, 2024, 17(18): 6833-6843. |

| [29] | Wang Y H, Bai X, Zhang X R, et al. Improving CO2 separation performance of PVAm membrane by the addition of polyethylenimine-functionalized halloysite nanotubes[J]. Journal of Membrane Science, 2023, 677: 121609. |

| [30] | 王立维, 王娟娟, 王永洪, 等. 聚乙烯胺/Cu3(BTC)2-MMT-NH2混合基质膜的制备及气体传递性能[J]. 化工学报, 2022, 73(7): 3068-3077. |

| Wang L W, Wang J J, Wang Y H, et al. Gas transport properties of PVAm-based mixed matrix membranes by incorporating with Cu3(BTC)2-MMT-NH2 [J]. CIESC Journal, 2022, 73(7): 3068-3077. | |

| [31] | Wang M, Wang Z, Li N, et al. Relationship between polymer-filler interfaces in separation layers and gas transport properties of mixed matrix composite membranes[J]. Journal of Membrane Science, 2015, 495: 252-268. |

| [32] | Li X H, He S, Jiang Y D, et al. Unraveling bilayer interfacial features and their effects in polar polymer nanocomposites[J]. Nature Communications, 2023, 14(1): 5707. |

| [33] | Zhang N, Peng D D, Wu H, et al. Significantly enhanced CO2 capture properties by synergy of zinc ion and sulfonate in Pebax-pitch hybrid membranes[J]. Journal of Membrane Science, 2018, 549: 670-679. |

| [34] | Liao J Y, Wang Z, Gao C Y, et al. A high performance PVAm-HT membrane containing high-speed facilitated transport channels for CO2 separation[J]. Journal of Materials Chemistry A, 2015, 3(32): 16746-16761. |

| [35] | Li P Y, Wang Z, Liu Y N, et al. A synergistic strategy via the combination of multiple functional groups into membranes towards superior CO2 separation performances[J]. Journal of Membrane Science, 2015, 476: 243-255. |

| [36] | Wang W F, Yuan Y, Shi F, et al. Enhancing dispersibility of nanofiller via polymer-modification for preparation of mixed matrix membrane with high CO2 separation performance[J]. Journal of Membrane Science, 2023, 683: 121791. |

| [37] | Zhao S, Cao X C, Ma Z J, et al. Mixed-matrix membranes for CO2/N2 separation comprising a poly(vinylamine) matrix and metal-organic frameworks[J]. Industrial & Engineering Chemistry Research, 2015, 54(18): 5139-5148. |

| [38] | He Y P, Wang Z, Dong S L, et al. Polymeric composite membrane fabricated by 2-aminoterephthalic acid chemically cross-linked polyvinylamine for CO2 separation under high temperature[J]. Journal of Membrane Science, 2016, 518: 60-71. |

| [39] | Zhang C X, Wang Z, Cai Y, et al. Investigation of gas permeation behavior in facilitated transport membranes: relationship between gas permeance and partial pressure[J]. Chemical Engineering Journal, 2013, 225: 744-751. |

| [40] | Xin Q P, Liu T Y, Li Z, et al. Mixed matrix membranes composed of sulfonated poly(ether ether ketone) and a sulfonated metal-organic framework for gas separation[J]. Journal of Membrane Science, 2015, 488: 67-78. |

| [41] | Zhang B B, Fu J W, Zhang Q F, et al. Study on CO2 facilitated separation of mixed matrix membranes containing surface modified MWCNTs[J]. Journal of Applied Polymer Science, 2019, 136(33): 47848. |

| [42] | Janakiram S, Yu X Y, Ansaloni L, et al. Manipulation of fibril surfaces in nanocellulose-based facilitated transport membranes for enhanced CO2 capture[J]. ACS Applied Materials & Interfaces, 2019, 11(36): 33302-33313. |

| [43] | Cao X C, Wang Z, Qiao Z H, et al. Penetrated COF channels: amino environment and suitable size for CO2 preferential adsorption and transport in mixed matrix membranes[J]. ACS Applied Materials & Interfaces, 2019, 11(5): 5306-5315. |

| [1] | 臧子晴, 李修真, 谈莹莹, 刘晓庆. 分凝器对两级分离自复叠制冷循环特性影响研究[J]. 化工学报, 2025, 76(S1): 17-25. |

| [2] | 裴星亮, 叶翠平, 裴赢丽, 李文英. 碱改性MIL-53(Cr)选择性吸附分离二甲苯异构体[J]. 化工学报, 2025, 76(S1): 258-267. |

| [3] | 李银龙, 刘国强, 晏刚. 分馏与闪蒸分离耦合自复叠制冷循环性能分析[J]. 化工学报, 2025, 76(S1): 26-35. |

| [4] | 张建民, 何美贵, 贾万鑫, 赵静, 金万勤. 聚氧化乙烯/冠醚共混膜及其二氧化碳分离性能[J]. 化工学报, 2025, 76(9): 4862-4871. |

| [5] | 郭旭, 贾继宁, 姚克俭. 基于优化CNN-BiLSTM神经网络的间歇精馏过程建模[J]. 化工学报, 2025, 76(9): 4613-4629. |

| [6] | 王杰, 林渠成, 张先明. 基于分解算法的混合气体多级膜分离系统全局优化[J]. 化工学报, 2025, 76(9): 4670-4682. |

| [7] | 李文龙, 常程, 吴小林, 姬忠礼. 油水聚结过滤材料中的液体分布特性及过程压降演化研究[J]. 化工学报, 2025, 76(9): 4850-4861. |

| [8] | 张荟钦, 赵泓竣, 付正军, 庄力, 董凯, 贾添智, 曹雪丽, 孙世鹏. 纳滤膜在离子型稀土浸出液提浓中的应用研究[J]. 化工学报, 2025, 76(8): 4095-4107. |

| [9] | 陈治宏, 吴佳伟, 楼小玲, 贠军贤. 化学品生物制造过程机器学习的研究进展[J]. 化工学报, 2025, 76(8): 3789-3804. |

| [10] | 蒋明虎, 汪帆, 邢雷, 赵立新, 李新亚, 陈丁玮. 井下含气对油水分离管柱流场特性及性能影响[J]. 化工学报, 2025, 76(7): 3361-3372. |

| [11] | 刘沁雯, 叶恒冰, 张逸伟, 朱法华, 钟文琪. 煤与禽类粪便混合燃料的加压富氧燃烧特性研究[J]. 化工学报, 2025, 76(7): 3487-3497. |

| [12] | 高照, 吴熙, 夏丹, 张霖宙. 石油加工分子管理平台热力学及分离单元模块开发[J]. 化工学报, 2025, 76(7): 3212-3225. |

| [13] | 梁碧麟, 余倩, 贾思琦, 李芳, 李其明. Ni-MOF-74金属有机框架膜的结构调变及气体分离性能研究[J]. 化工学报, 2025, 76(6): 2714-2721. |

| [14] | 茅雨洁, 路晓飞, 锁显, 杨立峰, 崔希利, 邢华斌. 工业气体中微量氧深度脱除催化剂研究进展[J]. 化工学报, 2025, 76(5): 1997-2010. |

| [15] | 时任泽, 丁秋燕, 袁振军, 那健, 刘见华, 郭树虎, 赵雄, 李洪, 高鑫. 4N电子级二乙氧基甲基硅烷的纯化技术研究[J]. 化工学报, 2025, 76(5): 2186-2197. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号