化工学报 ›› 2025, Vol. 76 ›› Issue (5): 1997-2010.DOI: 10.11949/0438-1157.20241011

茅雨洁1( ), 路晓飞1,2(

), 路晓飞1,2( ), 锁显1,2, 杨立峰1,2, 崔希利1,2, 邢华斌1,2(

), 锁显1,2, 杨立峰1,2, 崔希利1,2, 邢华斌1,2( )

)

收稿日期:2024-09-09

修回日期:2024-10-25

出版日期:2025-05-25

发布日期:2025-06-13

通讯作者:

路晓飞,邢华斌

作者简介:茅雨洁(2001—),女,硕士研究生,22328056@zju.edu.cn

基金资助:

Yujie MAO1( ), Xiaofei LU1,2(

), Xiaofei LU1,2( ), Xian SUO1,2, Lifeng YANG1,2, Xili CUI1,2, Huabin XING1,2(

), Xian SUO1,2, Lifeng YANG1,2, Xili CUI1,2, Huabin XING1,2( )

)

Received:2024-09-09

Revised:2024-10-25

Online:2025-05-25

Published:2025-06-13

Contact:

Xiaofei LU, Huabin XING

摘要:

在工业气体脱氧技术中,催化脱氧法因其高效性和脱除深度被广泛应用,开发低成本、高活性、高选择性、耐久性强的催化剂是催化脱氧技术的关键。综述了气体脱氧催化剂的研究现状,阐述不同场景下催化脱氧机理,从催化剂结构设计角度总结活性组分、助剂和载体对催化脱氧性能的影响规律。低温活性、抗毒化性能和长周期稳定性是脱氧催化剂开发的重要目标,总结了构筑高活性、高稳定性脱氧催化剂的策略,主要包括空间限域的物理方法以及活性中心合金化、金属-载体强相互作用等化学方法。最后综合气体脱氧剂的研发和应用现状,指出非贵金属脱氧剂、(水)热稳定性单原子脱氧剂、多功能型脱氧催化剂是未来脱氧催化剂发展的重要趋势。

中图分类号:

茅雨洁, 路晓飞, 锁显, 杨立峰, 崔希利, 邢华斌. 工业气体中微量氧深度脱除催化剂研究进展[J]. 化工学报, 2025, 76(5): 1997-2010.

Yujie MAO, Xiaofei LU, Xian SUO, Lifeng YANG, Xili CUI, Huabin XING. Advances in research on catalysts for deep removal of trace oxygen in industrial gases[J]. CIESC Journal, 2025, 76(5): 1997-2010.

| 活性组分 | 助剂 | 载体 | 应用场景 | 反应条件 | 脱氧效果 | 文献 |

|---|---|---|---|---|---|---|

| Pd、Pt、Ru、Rh、Ir 单原子 | — | 氧化铝、氧化锰、氧化钛等 | 含氧氢气 | 25~300℃,0.1~2 MPa, 3000~15000 h-1 | <1 μl/L | [ |

| Pd | — | TiO2-Al2O3 | 含氧氢气,含氧惰性气体 | -10~70℃,9000~18000 ml/(h·g) | <0.1 μl/L | [ |

| Cu、Cr、Zn、Fe | K | 活性炭 | 含氧氢气,含氧惰性气体 | 200~400℃,1~1.5 MPa, 2000~6000 h-1 | <1 μl/L | [ |

| CuO/CeO2 | — | TiO2 | 含氧煤层气 | 400~800℃ | <0.25%(体积) | [ |

| Cu、Mn、Co | — | 活性炭 | 含氧高浓度CO,合成气 | 110~150℃,1000~2000 h-1 | <1 μl/L | [ |

| Co | Mn、Fe、Zn、Cu | 多孔载体 | 含氧煤层气 | 300~650℃,1000~6000 h-1 | <0.5%(体积) | [ |

| Cu 、Pd | Co、Zn、Fe | Al2O3、MgO、SiO2 | 含氧合成气,含氧焦炉气 | 80~120℃,2000~15000 h-1 | <1 μl/L | [ |

| Pd、Ag | — | 稀土氧化物改性的γ-Al2O3 | 含氧富乙烯气 | 110~180℃,1 MPa, 3000~5000 h-1 | <1 μl/L | [ |

| Pd | 过渡金属盐 | γ-Al2O3 | 含氧液相丙烯 | 40℃,2500 h-1 | <1 μl/L | [ |

| Ni、Mn | Ca、Mg、Sr | Al2O3 | 含氧氮气 | 250~300℃,1000 h-1 | <1 μl/L | [ |

表1 脱氧催化剂研究现状及使用场景举例

Table 1 Research status and application examples of deoxidation catalysts

| 活性组分 | 助剂 | 载体 | 应用场景 | 反应条件 | 脱氧效果 | 文献 |

|---|---|---|---|---|---|---|

| Pd、Pt、Ru、Rh、Ir 单原子 | — | 氧化铝、氧化锰、氧化钛等 | 含氧氢气 | 25~300℃,0.1~2 MPa, 3000~15000 h-1 | <1 μl/L | [ |

| Pd | — | TiO2-Al2O3 | 含氧氢气,含氧惰性气体 | -10~70℃,9000~18000 ml/(h·g) | <0.1 μl/L | [ |

| Cu、Cr、Zn、Fe | K | 活性炭 | 含氧氢气,含氧惰性气体 | 200~400℃,1~1.5 MPa, 2000~6000 h-1 | <1 μl/L | [ |

| CuO/CeO2 | — | TiO2 | 含氧煤层气 | 400~800℃ | <0.25%(体积) | [ |

| Cu、Mn、Co | — | 活性炭 | 含氧高浓度CO,合成气 | 110~150℃,1000~2000 h-1 | <1 μl/L | [ |

| Co | Mn、Fe、Zn、Cu | 多孔载体 | 含氧煤层气 | 300~650℃,1000~6000 h-1 | <0.5%(体积) | [ |

| Cu 、Pd | Co、Zn、Fe | Al2O3、MgO、SiO2 | 含氧合成气,含氧焦炉气 | 80~120℃,2000~15000 h-1 | <1 μl/L | [ |

| Pd、Ag | — | 稀土氧化物改性的γ-Al2O3 | 含氧富乙烯气 | 110~180℃,1 MPa, 3000~5000 h-1 | <1 μl/L | [ |

| Pd | 过渡金属盐 | γ-Al2O3 | 含氧液相丙烯 | 40℃,2500 h-1 | <1 μl/L | [ |

| Ni、Mn | Ca、Mg、Sr | Al2O3 | 含氧氮气 | 250~300℃,1000 h-1 | <1 μl/L | [ |

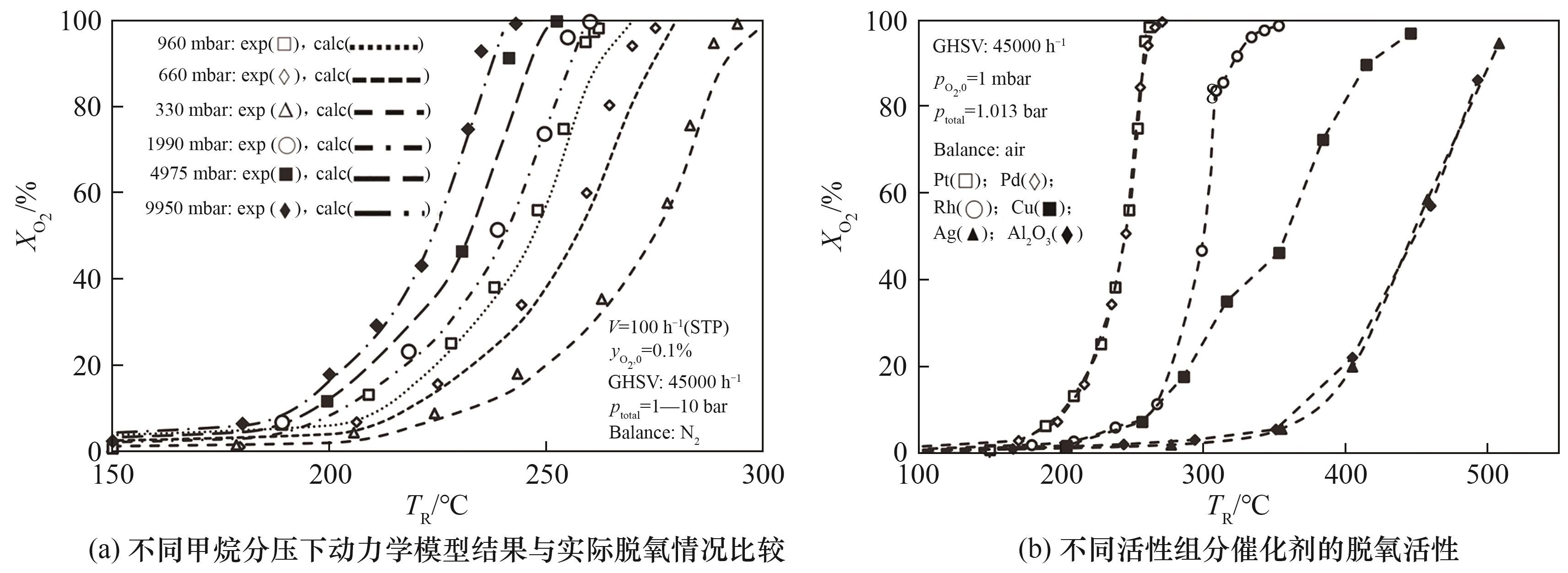

图1 Pt/γ-Al2O3催化剂的脱氧动力学以及脱氧活性对比[19](1 bar=0.1 MPa)

Fig.1 Deoxidation dynamics of Pt/γ-Al2O3 catalyst and comparison of its deoxidation performance with other catalysts[19]

| 1 | Ligen Y, Vrubel H, Girault H. Energy efficient hydrogen drying and purification for fuel cell vehicles[J]. International Journal of Hydrogen Energy, 2020, 45(18): 10639-10647. |

| 2 | Xiong M, Gao Z, Qin Y. Spillover in heterogeneous catalysis: new insights and opportunities[J]. ACS Catalysis, 2021, 11(5): 3159-3172. |

| 3 | Boucly A, Artiglia L, Roger M, et al. Water inhibition and role of palladium adatoms on Pd/Al2O3 catalysts during methane oxidation[J]. Applied Surface Science, 2022, 606: 154927. |

| 4 | 王军威, 田志坚, 徐金光, 等. 甲烷高温燃烧催化剂研究进展[J]. 化学进展, 2003, 15(3): 242-248. |

| Wang J W, Tian Z J, Xu J G, et al. Progress in research of the catalysts for high temperature combustion of methane[J]. Progress in Chemistry, 2003, 15(3): 242-248. | |

| 5 | Laberty C, Marquez-Alvarez C, Drouet C, et al. CO oxidation over nonstoichiometric nickel manganite spinels[J]. Journal of Catalysis, 2001, 198(2): 266-276. |

| 6 | Pu T C, Tian H J, Ford M E, et al. Overview of selective oxidation of ethylene to ethylene oxide by Ag catalysts[J]. ACS Catalysis, 2019, 9(12): 10727-10750. |

| 7 | 乔波涛, 郎睿, 郑明远, 等. 一种负载型铂族金属单原子催化剂的制备及其在脱氧反应中的应用: 111215060A[P]. 2020-06-02. |

| Qiao B T, Lang R, Zheng M Y, et al. Preparation of supported platinum group metal monatomic catalyst, and applications of supported platinum group metal monatomic catalyst in deoxidation reaction: 111215060A[P]. 2020-06-02. | |

| 8 | 朱月香, 谢有畅, 李峰, 等. 一种氧化钛-氧化铝复合物为载体的钯催化剂及其制法和用途: 1088622C[P]. 2002-08-07. |

| Zhu Y X, Xie Y C, Li F, et al. Palladium catalyst with carrier of titanium oxide-alumina compound, and its preparing process and application: 1088622C[P]. 2002-08-07. | |

| 9 | 李玉柱, 王川平, 张立功, 等. 一种多功能催化剂及其制法和用途: 1233528[P]. 1999-11-03. |

| Li Y Z, Wang C P, Zhang L G, et al. Multi-functional catalyst, prepn. method and use thereof: 1233528[P]. 1999-11-03. | |

| 10 | 王建国, 令狐建设, 吴志伟, 等. 一种具有核壳结构的脱氧催化剂、制备方法及应用: 106362720A[P]. 2017-02-01. |

| Wang J G, Linghu J S, Wu Z W, et al. Deoxidating catalyst with core-shell structure, and preparation method and application of deoxidating catalyst: 106362720A[P]. 2017-02-01. | |

| 11 | 任杰, 孙予罕, 刘东艳, 等. 高浓度一氧化碳合成气脱氧催化剂: 1069688C[P]. 2001-08-15. |

| Ren J, Sun Y H, Liu D Y, et al. High concentration carbon monoxide synthetic gas deoxidizing catalyst: 1069688C[P]. 2001-08-15. | |

| 12 | 廖炯, 陈耀壮, 胡善霖, 等. 一种含氧煤层气脱氧催化剂及其制备方法及应用: 101322942B[P]. 2010-09-29. |

| Liao J, Chen Y Z, Hu S L, et al. Oxygen-containing coal bed gas deoxidation catalyst and preparation thereof as well as applications: 101322942B[P]. 2010-09-29. | |

| 13 | 郑珩, 陈耀壮, 李洁, 等. 一种用于富CO气脱氧的高活性催化剂及其制备和应用: 102974364A[P]. 2013-03-20. |

| Zheng H, Chen Y Z, Li J, et al. High-activity catalyst for CO gas enrichment type deoxidation as well as preparation and application of high-activity catalyst: 102974364A[P]. 2013-03-20. | |

| 14 | 李洁, 王磊, 陈耀壮, 等. 乙烯气体深度脱氧催化剂性能研究[J]. 低碳化学与化工, 2024, 49(5): 44-49. |

| Li J, Wang L, Chen Y Z, et al. Study on performance of deep deoxidation catalysts for ethylene gas[J]. Low-Carbon Chemistry and Chemical Engineering, 2024, 49(5): 44-49. | |

| 15 | 刘应杰, 王先厚, 孔渝华. 液态丙烯脱氧催化剂的研制[J]. 工业催化, 2016, 24(1): 61-64. |

| Liu Y J, Wang X H, Kong Y H. Development of liquid propylene deoxidation catalyst[J]. Industrial Catalysis, 2016, 24(1): 61-64. | |

| 16 | 徐贤伦, 马军, 汤爱华, 等. 高效脱氧除氢催化剂及制备和应用: 1110249[P]. 1995-10-18. |

| Xu X L, Ma J, Tang A H, et al. High effective desoxydation dehydrogenation catalyst and its preparation and application: 1110249[P]. 1995-10-18. | |

| 17 | 杨学仁, 梁树保, 彭少逸. 纤维状脱氧催化剂的研究[J]. 催化学报, 1980, 1(2): 81-88. |

| Yang X R, Liang S B, Peng S Y. Fibrous catalyst for the removal of oxygen in hydrogen and inert gases[J]. Chinese Journal of Catalysis, 1980, 1(2): 81-88. | |

| 18 | 任作新. 一种高效脱氧催化剂的应用[J]. 冶金动力, 1991, 10(4): 5, 8. |

| Ren Z X. Application of an efficient deoxidation catalyst[J]. Metallurgical Power, 1991, 10(4): 5, 8. | |

| 19 | Ortloff F, Bohnau J, Graf F, et al. removal of oxygen from (bio-) methane via catalytic oxidation of CH4—reaction kinetics for very low O2∶CH4 ratios[J]. Applied Catalysis B: Environmental, 2016, 182: 375-384. |

| 20 | 赵磊, 张玉霞, 文松, 等. 脱氧催化剂及其制备方法和脱除轻质烯烃中氧气的方法: 115707514A[P]. 2023-02-21. |

| Zhao L, Zhang Y X, Wen S, et al. The invention relates to a deoxidation catalyst, a preparation method thereof and a method for removing oxygen from light olefins: 115707514A[P]. 2023-02-21. | |

| 21 | Inceesungvorn B, López-Castro J, Calvino J J, et al. Nano-structural investigation of Ag/Al2O3 catalyst for selective removal of O2 with excess H2 in the presence of C2H4 [J]. Applied Catalysis A: General, 2011, 391(1/2): 187-193. |

| 22 | 王建国, 吴志伟, 朱华青, 等. 负载型非贵金属含氧煤层气脱氧催化剂及其制法和应用: 102872883A[P]. 2013-01-16. |

| Wang J G, Wu Z W, Zhu H Q, et al. Supported non-noble metal oxygen-containing coalbed methane deoxidation catalyst and preparation method and application thereof: 102872883A[P]. 2013-01-16. | |

| 23 | Gan T, Chen X, Chu X F, et al. “Atomic topping” of MnO x on Al2O3 to create electron-rich, aperiodic, lattice oxygens that resemble noble metals for catalytic oxidation[J]. Journal of the American Chemical Society, 2024, 146(24): 16549-16557. |

| 24 | Wang H Y, Wang S, Liu S D, et al. Redox-induced controllable engineering of MnO2-Mn x Co3- x O4 interface to boost catalytic oxidation of ethane[J]. Nature Communications, 2024, 15(1): 4118. |

| 25 | Yu J, Yang Y S, Zhang M, et al. Highly active MnCoO x catalyst toward CO preferential oxidation[J]. ACS Catalysis, 2024, 14(3): 1281-1291. |

| 26 | Wang F, Li K, Li B L, et al. Identification of direct anchoring sites for monoatomic dispersion of precious metals (Pt, Pd, Ag) on CeO2 support[J]. Angewandte Chemie, 2024, 136(11): 2318492. |

| 27 | Kim M Y, Kyriakidou E A, Choi J S, et al. Enhancing low-temperature activity and durability of Pd-based diesel oxidation catalysts using ZrO2 supports[J]. Applied Catalysis B: Environmental, 2016, 187: 181-194. |

| 28 | Reddy B M, Khan A. Recent advances on TiO2-ZrO2 mixed oxides as catalysts and catalyst supports[J]. Catalysis Reviews, 2005, 47(2): 257-296. |

| 29 | 邢华斌, 孙毯毯, 崔希利, 等. 兼具高活性和高烯烃选择性的镍基选择性加氢催化剂及其制备和应用: 115582129A[P]. 2023-01-10. |

| Xing H B, Sun T T, Cui X L, et al. The present invention relates to a nickel-base selective hydrogenation catalyst with high activity and high olefine selectivity, its preparation and application: 115582129A[P]. 2023-01-10. | |

| 30 | Kim H K, Lee C W, Kim M, et al. Preparation of CoMo/Al2O3, CoMo/CeO2, CoMo/TiO2 catalysts using ultrasonic spray pyrolysis for the hydro-desulfurization of 4,6-dimethyldibenzothiophene for fuel cell applications[J]. International Journal of Hydrogen Energy, 2016, 41(41): 18846-18857. |

| 31 | 郑珩, 李洁, 陈耀壮, 等. 一种烯烃气体脱氧催化剂及其制备方法和应用: 103157471A[P]. 2013-06-19. |

| Zheng H, Li J, Chen Y Z, et al. Deoxidation catalyst for olefin gas, preparation method and application thereof: 103157471A[P]. 2013-06-19. | |

| 32 | 王树东, 袁中山, 王胜, 等. 一种煤层气脱氧催化剂、其制备方法及应用: 101664679[P]. 2010-03-10. |

| Wang S D, Yuan Z S, Wang S, et al. Coal bed gas deoxidation catalyst as well as preparation method and application thereof: 101664679[P]. 2010-03-10. | |

| 33 | 吕顺丰, 秦燕璜, 黄凤兴, 等. 一种锰系脱氧剂及其制备方法和应用: 1955150[P]. 2007-05-02. |

| Lyu S F, Qin Y H, Huang F X, et al. Manganese deoxidier and its preparation method and application: 1955150[P]. 2007-05-02. | |

| 34 | Zhao J C, Jiang J, Wen S, et al. Research on alkali metal-modified Pd catalyst for oxygen removal from propylene[J]. Frontiers in Chemistry, 2022, 10: 987556. |

| 35 | Lu F X, Han Y, Jiang J, et al. Unraveling the role of sodium in removing oxygen from propylene over Fe-based catalysts[J]. Catalysis Letters, 2024, 154(4): 1674-1682. |

| 36 | Lu H, Schideman L, Ye Q, et al. High-efficiency catalytic reduction of residual oxygen for purification of carbon dioxide streams from high-pressure oxy-combustion systems[J]. Reaction Chemistry & Engineering, 2021, 6(7): 1220-1229. |

| 37 | Lu H, Jiang Y, Abiodun O, et al. Catalytic removal of oxygen impurities from pressurized oxy-combustion flue gas for the production of high-purity carbon dioxide[J]. Energy & Fuels, 2022, 36(5): 2701-2711. |

| 38 | Xue Y X, Gu J N, Yu C W, et al. High-efficient removal of oxygen(O2) impurity from H2 flow on nickel-manganese oxide: regulating the exposed crystal plane, structure-activity relationship and determination of active sites[J]. Applied Surface Science, 2024, 648: 159054. |

| 39 | Carrillo C, DeLaRiva A, Xiong H F, et al. Regenerative trapping: how Pd improves the durability of Pt diesel oxidation catalysts[J]. Applied Catalysis B: Environmental, 2017, 218: 581-590. |

| 40 | Wang L X, Wang L, Meng X J, et al. New strategies for the preparation of sinter-resistant metal-nanoparticle-based catalysts[J]. Advanced Materials, 2019, 31(50): e1901905. |

| 41 | Cargnello M, Wieder N L, Montini T, et al. Synthesis of dispersible Pd@CeO2 core-shell nanostructures by self-assembly[J]. Journal of the American Chemical Society, 2010, 132(4): 1402-1409. |

| 42 | Cargnello M, Delgado Jaén J J, Hernández Garrido J C, et al. Exceptional activity for methane combustion over modular Pd@CeO2 subunits on functionalized Al2O3 [J]. Science, 2012, 337(6095): 713-717. |

| 43 | Kuhn A N, Ma Y L, Zhang C, et al. Selective reduction of oxygen on non-noble metal copper nanocatalysts[J]. Energy Technology, 2020, 8(3): 1901213. |

| 44 | Aitbekova A, Zhou C S, Stone M L, et al. Templated encapsulation of platinum-based catalysts promotes high-temperature stability to 1100℃[J]. Nature Materials, 2022, 21(11): 1290-1297. |

| 45 | Peng H G, Dong T, Yang S Y, et al. Intra-crystalline mesoporous zeolite encapsulation-derived thermally robust metal nanocatalyst in deep oxidation of light alkanes[J]. Nature Communications, 2022, 13(1): 295. |

| 46 | Gao M Y, Gong Z M, Weng X F, et al. Methane combustion over palladium catalyst within the confined space of MFI zeolite[J]. Chinese Journal of Catalysis, 2021, 42(10): 1689-1699. |

| 47 | Bruix A, Rodriguez J A, Ramírez P J, et al. A new type of strong metal-support interaction and the production of H2 through the transformation of water on Pt/CeO2(111) and Pt/CeO( x)/TiO2(110) catalysts[J]. Journal of the American Chemical Society, 2012, 134(21): 8968-8974. |

| 48 | Murata K, Kosuge D, Ohyama J, et al. Exploiting metal-support interactions to tune the redox properties of supported Pd catalysts for methane combustion[J]. ACS Catalysis, 2020, 10(2): 1381-1387. |

| 49 | Zhang J, Wang H, Wang L, et al. Wet-chemistry strong metal-support interactions in titania-supported Au catalysts[J]. Journal of the American Chemical Society, 2019, 141(7): 2975-2983. |

| 50 | Liu X Y, Liu M H, Luo Y C, et al. Strong metal-support interactions between gold nanoparticles and ZnO nanorods in CO oxidation[J]. Journal of the American Chemical Society, 2012, 134(24): 10251-10258. |

| 51 | Wang H, Wang L, Lin D, et al. Strong metal-support interactions on gold nanoparticle catalysts achieved through Le Chatelier’s principle[J]. Nature Catalysis, 2021, 4: 418-424. |

| 52 | 宋兴福, 万江, 汪瑾, 等. Co-Mo/γ-Al2O3非贵金属高效脱氧催化剂的研究[J]. 工业催化, 2004, 12(8): 46-49. |

| Song X F, Wan J, Wang J, et al. Development of a high-efficient non-noble metal Co-Mo/γ-Al2O3 deoxidation catalyst[J]. Industrial Catalysis, 2004, 12(8): 46-49. | |

| 53 | 纵秋云, 余汉涛, 郭建学, 等. 一种高强度耐硫变换脱氧剂及其制备方法: 1464037[P]. 2003-12-31. |

| Zong Q Y, Yu H T, Guo J X, et al. Low cost sulfur transformation resistant deoxidizing agent and process for preparing the same: 1464037[P]. 2003-12-31. | |

| 54 | Wiesmann T, Youn Suh S, Kaluza S, et al. Catalytic oxygen removal from synthetic coke oven gas: a comparison of sulfided CoMo/γ-Al2O3 and NiMo/γ-Al2O3 catalysts with Pt/γ-Al2O3 as benchmark catalyst[J]. Chemie Ingenieur Technik, 2020, 92(10): 1533-1541. |

| 55 | 孙倩, 张新堂, 赵国明, 等. TiO2改性的Co-Mo耐硫变换脱氧催化剂常压性能研究[J]. 应用化工, 2020, 49(12): 2986-2993. |

| Sun Q, Zhang X T, Zhao G M, et al. Study on the atmospheric performance of TiO2 modified Co-Mo sulfur-tolerant shift deoxygenation catalyst[J]. Applied Chemical Industry, 2020, 49(12): 2986-2993. | |

| 56 | Xu L X, Pan Y, Li H M, et al. Highly active and water-resistant lanthanum-doped platinum-cobalt oxide catalysts for CO oxidation[J]. Applied Catalysis B: Environmental, 2023, 331: 122678. |

| 57 | Bae J, Shin D, Jeong H, et al. Highly water-resistant La-doped Co3O4 catalyst for CO oxidation[J]. ACS Catalysis, 2019, 9(11): 10093-10100. |

| 58 | Wang Y H, Wang S F, Bai J Y, et al. Structural evolution in LaCoO3 by polyol treatment: highly active and resistant Co3O4/La2O2CO3/LaCoO3 heterostructure catalysts for CH4 oxidation[J]. Applied Catalysis B: Environmental, 2023, 338: 123079. |

| 59 | Chen C H, Njagi E C, Sun S P, et al. Hydrophobic polymer-coated metal oxide catalysts for effective low-temperature oxidation of CO under moisture-rich conditions[J]. Chemistry of Materials, 2010, 22(11): 3313-3315. |

| 60 | 张俊香, 李景芝, 梁艳萍, 等. 一种钯/氧化锰脱氧剂: 1030895C[P]. 1996-02-07. |

| Zhang J X, Li J Z, Liang Y P, et al. Deoxidiser of palladium/manganese oxide: 1030895C[P]. 1996-02-07. | |

| 61 | 吕顺丰, 黄凤兴, 秦燕璜, 等. MnO-Ag/CaAl2O4乙烯脱氧剂性能[J]. 化工进展, 2008, 27(9): 1442-1445, 1452. |

| Lyu S F, Huang F X, Qin Y H, et al. Performance of MnO-Ag/CaAl2O4 oxygen scavenger for ethylene[J]. Chemical Industry and Engineering Progress, 2008, 27(9): 1442-1445, 1452. | |

| 62 | Kuhn A N, Chen Z T, Lu Y Q, et al. Sequential oxygen reduction and adsorption for carbon dioxide purification for flue gas applications[J]. Energy Technology, 2019, 7(4): 1980311. |

| 63 | Cheng N C, Zhang L, Doyle-Davis K, et al. Single-atom catalysts: from design to application[J]. Electrochemical Energy Reviews, 2019, 2(4): 539-573. |

| 64 | Xiong H F, Datye A K, Wang Y. Thermally stable single-atom heterogeneous catalysts[J]. Advanced Materials, 2021, 33(50): e2004319. |

| 65 | Lv H W, Guo W X, Chen M, et al. Rational construction of thermally stable single atom catalysts: from atomic structure to practical applications[J]. Chinese Journal of Catalysis, 2022, 43(1): 71-91. |

| 66 | Yang Y T, Xiao Y, Jiang L, et al. Ultrahigh single Au atoms loaded porous aromatic frameworks for enhanced photocatalytic hydrogen evolution[J]. Advanced Materials, 2024, 36(41): e2404791. |

| 67 | Hou Z Q, Lu Y, Liu Y X, et al. A general dual-metal nanocrystal dissociation strategy to generate robust high-temperature-stable alumina-supported single-atom catalysts[J]. Journal of the American Chemical Society, 2023, 145(29): 15869-15878. |

| 68 | Liu S X, Wang Y, Lyu K F, et al. A one-pot strategy for anchoring single Pt atoms in MOFs with diverse coordination environments[J]. Nature Synthesis, 2024, 3: 1158-1167. |

| 69 | Li X, Pereira-Hernández X I, Chen Y Z, et al. Functional CeO x nanoglues for robust atomically dispersed catalysts[J]. Nature, 2022, 611(7935): 284-288. |

| 70 | Jones J, Xiong H F, DeLaRiva A T, et al. Thermally stable single-atom platinum-on-ceria catalysts via atom trapping[J]. Science, 2016, 353(6295): 150-154. |

| 71 | Zhang Z H, Tian J S, Lu Y B, et al. Memory-dictated dynamics of single-atom Pt on CeO2 for CO oxidation[J]. Nature Communications, 2023, 14(1): 2664. |

| 72 | Xu J, Wang Y, Wang K, et al. Single-atom Rh on high-index CeO2 facet for highly enhanced catalytic CO oxidation[J]. Angewandte Chemie International Edition, 2023, 62(28): e202302877. |

| 73 | Xie S H, Liu L P, Lu Y, et al. Pt atomic single-layer catalyst embedded in defect-enriched ceria for efficient CO oxidation[J]. Journal of the American Chemical Society, 2022, 144(46): 21255-21266. |

| 74 | Jiang D, Yao Y G, Li T Y, et al. Tailoring the local environment of platinum in single-atom Pt1/CeO2 catalysts for robust low-temperature CO oxidation[J]. Angewandte Chemie, 2021, 133(50): 26258-26266. |

| 75 | Nie L, Mei D H, Xiong H F, et al. Activation of surface lattice oxygen in single-atom Pt/CeO2 for low-temperature CO oxidation[J]. Science, 2017, 358(6369): 1419-1423. |

| 76 | Muravev V, Spezzati G, Su Y Q, et al. Interface dynamics of Pd-CeO2 single-atom catalysts during CO oxidation[J]. Nature Catalysis, 2021, 4(6): 469-478. |

| 77 | Xiong H F, Kunwar D, Jiang D, et al. Engineering catalyst supports to stabilize PdO x two-dimensional rafts for water-tolerant methane oxidation[J]. Nature Catalysis, 2021, 4(10): 830-839. |

| 78 | Wang Y, Ren P J, Hu J T, et al. Electron penetration triggering interface activity of Pt-graphene for CO oxidation at room temperature[J]. Nature Communications, 2021, 12(1): 5814. |

| 79 | Wang L, Peng H, Shi S L, et al. Metal-organic framework derived hollow CuO/CeO2 nano-sphere: to expose more highly dispersed Cu—O—Ce interface for enhancing preferential CO oxidation[J]. Applied Surface Science, 2022, 573: 151611. |

| 80 | Huang W X, Johnston-Peck A C, Wolter T, et al. Steam-created grain boundaries for methane C—H activation in palladium catalysts[J]. Science, 2021, 373(6562): 1518-1523. |

| [1] | 郭彭涛, 王婷, 薛波, 应允攀, 刘大欢. 用于CH4/N2分离的多吸附位点超微孔MOF[J]. 化工学报, 2025, 76(5): 2304-2312. |

| [2] | 李紫鹃, 谭晓艳, 吴永盛, 杨陈怡, 陈红, 毕小刚, 刘捷, 喻发全. 分子模拟研究三维扭曲催化芳烃-降冰片烯环化聚合物膜的CO2/N2分离机理[J]. 化工学报, 2025, 76(5): 2348-2357. |

| [3] | 花敬贤, 罗宇荣, 顾亚伟, 吴婷婷, 潘宜昌, 邢卫红. 超薄取向ZIF-8膜的制备及乙烯/乙烷高效分离[J]. 化工学报, 2025, 76(5): 2209-2218. |

| [4] | 李艳, 雷美丽, 李鑫钢. 基于分离性能的顺序式模拟移动床结构调控策略[J]. 化工学报, 2025, 76(5): 2219-2229. |

| [5] | 巴雅琪, 吴涛, 邸安頔, 陆安慧. 多孔炭材料用于低碳烃分离的研究进展[J]. 化工学报, 2025, 76(5): 2136-2157. |

| [6] | 谈朋, 李雪梅, 刘晓勤, 孙林兵. 基于柔性MOFs的磁响应复合材料及其丙烯吸附性能研究[J]. 化工学报, 2025, 76(5): 2230-2240. |

| [7] | 向昕辰, 鲁丹, 赵影, 姚之侃, 寇瑞强, 郑丹军, 周志军, 张林. 聚酰胺纳滤膜表面季铵化提高荷正电性及其锂镁分离性能[J]. 化工学报, 2025, 76(5): 2377-2386. |

| [8] | 何燎, 李俊, 高梦舒, 刘东阳, 张宇豪, 赵亮, 高金森, 徐春明. 石油烃中芳烃分离技术研究进展[J]. 化工学报, 2025, 76(5): 1909-1926. |

| [9] | 徐泽海, 刘超, 张国亮. 聚合物基疏水渗透汽化膜及其溶剂回收应用[J]. 化工学报, 2025, 76(5): 2055-2069. |

| [10] | 时任泽, 丁秋燕, 袁振军, 那健, 刘见华, 郭树虎, 赵雄, 李洪, 高鑫. 4N电子级二乙氧基甲基硅烷的纯化技术研究[J]. 化工学报, 2025, 76(5): 2186-2197. |

| [11] | 王金月, 谢恩泽, 马翰泽, 袁晟, 何光伟, 姜忠义. 单原子层分离膜:进展与展望[J]. 化工学报, 2025, 76(5): 1943-1959. |

| [12] | 陆艳秋, 狄扬, 石文博, 殷聪聪, 汪勇. 基于新型有机多孔聚合物的智能响应膜研究进展[J]. 化工学报, 2025, 76(5): 2101-2118. |

| [13] | 陶春珲, 李印辉, 傅钰, 段然, 赵泽一, 唐羽丰, 张罡, 马和平. 不同吸附剂对低浓度Kr气的选择性吸附与纯化[J]. 化工学报, 2025, 76(5): 2358-2366. |

| [14] | 赵浩帆, 任豪杰, 刘宗凯, 董冠英, 张亚涛. MOFs玻璃膜在气体分离领域的研究进展[J]. 化工学报, 2025, 76(5): 2042-2054. |

| [15] | 张越, 刘佳鑫, 马敬, 刘毅. 金属有机骨架膜应用于海水提铀研究进展[J]. 化工学报, 2025, 76(5): 2087-2100. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号