化工学报 ›› 2025, Vol. 76 ›› Issue (12): 6439-6452.DOI: 10.11949/0438-1157.20250266

魏梦玥1( ), 张新儒1,2(

), 张新儒1,2( ), 王永洪1,2, 李晋平1,2

), 王永洪1,2, 李晋平1,2

收稿日期:2025-03-17

修回日期:2025-05-05

出版日期:2025-12-31

发布日期:2026-01-23

通讯作者:

张新儒

作者简介:魏梦玥(1999—),女,硕士研究生,18234632147@163.com

基金资助:

Mengyue WEI1( ), Xinru ZHANG1,2(

), Xinru ZHANG1,2( ), Yonghong WANG1,2, Jinping LI1,2

), Yonghong WANG1,2, Jinping LI1,2

Received:2025-03-17

Revised:2025-05-05

Online:2025-12-31

Published:2026-01-23

Contact:

Xinru ZHANG

摘要:

由于二维MoS2纳米片表面孔隙率低、层间堆积传质路径长以及在聚合物中相容性差等问题,很难同时提高其混合基质膜的选择性和渗透速率。本工作首先通过离子印迹技术制备得富含空位和缺陷的MoS2(P-MoS2),并使用4-氨基-3-肼基-5-巯基-1,2,4-三唑(AHMT)对P-MoS2改性制备杂化材料(AHMT-MoS2)。然后将AHMT-MoS2添加到聚醚嵌段聚酰胺(Pebax)中制备铸膜液,并涂覆在亲水改性的聚砜(mPSf)支撑体上制备混合基质复合膜(Pebax/AHMT-MoS2)。采用傅里叶变换红外光谱(FTIR)、X-射线衍射(XRD)、扫描电镜(SEM)和N2吸附-脱附表征材料和膜的化学结构、孔隙结构和形态结构。研究了材料的制备条件和测试条件对气体分离的影响。结果表明,Pebax/AHMT-MoS2的CO2渗透速率为818 GPU,CO2/N2选择性为56。这是因为通过离子印迹策略在MoS2表面构建缺陷,增加了CO2亲和位点;其表面孔和层间通道为CO2提供了扩散通道。同时,氨基和肼基的引入,增强了CO2的反应选择性,显著提高分离效果。优异的气体分离性能与低成本,使制备的混合基质复合膜在CO2分离领域极具应用潜力。

中图分类号:

魏梦玥, 张新儒, 王永洪, 李晋平. 利用空位和缺陷工程协同效应提高Pebax膜的CO2分离[J]. 化工学报, 2025, 76(12): 6439-6452.

Mengyue WEI, Xinru ZHANG, Yonghong WANG, Jinping LI. Boosting CO2 separation of Pebax membranes with synergistic effect of vacancies and defects[J]. CIESC Journal, 2025, 76(12): 6439-6452.

| Sample | BET surface area/ (m2·g-1) | Total pore volume/(cm3·g-1) | Average pore diameter/nm |

|---|---|---|---|

| Fe-MoS2 | 0.4226 | 0.0063 | — |

| P-MoS2 | 3.9940 | 0.2658 | 26.6217 |

| AHMT-MoS2 | 6.6226 | 0.0297 | 17.9186 |

表1 材料的孔结构参数

Table 1 Porous structure parameters of materials

| Sample | BET surface area/ (m2·g-1) | Total pore volume/(cm3·g-1) | Average pore diameter/nm |

|---|---|---|---|

| Fe-MoS2 | 0.4226 | 0.0063 | — |

| P-MoS2 | 3.9940 | 0.2658 | 26.6217 |

| AHMT-MoS2 | 6.6226 | 0.0297 | 17.9186 |

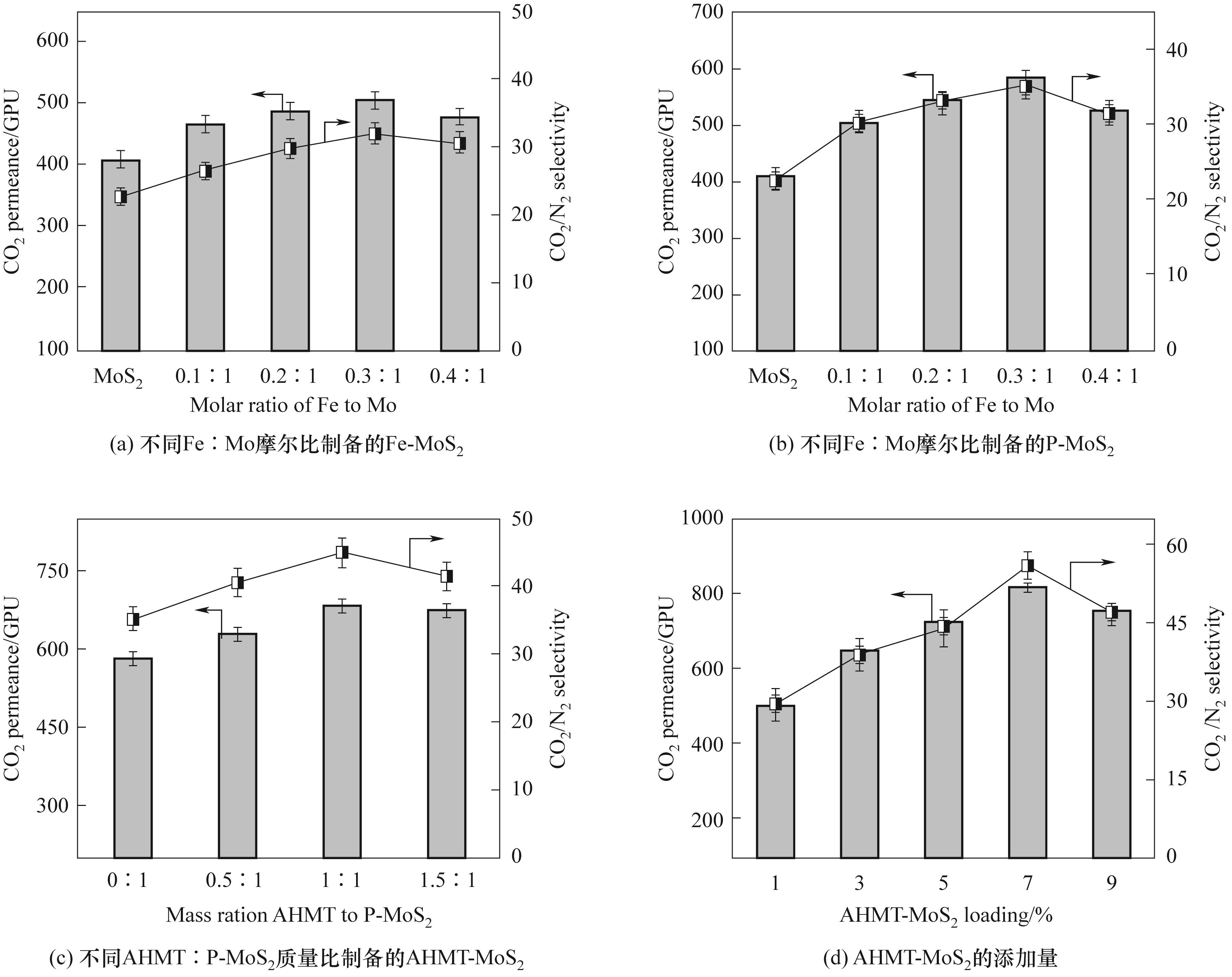

图8 (a)不同Fe∶Mo物质的量比制备的Fe-MoS2;(b)不同Fe∶Mo物质的量比制备的P-MoS2;(c)不同AHMT:P-MoS2质量比制备的AHMT-MoS2和(d)AHMT-MoS2添加量对膜气体分离性能的影响

Fig.8 Effect of (a) Fe to Mo different molar ratios in Fe-MoS2, (b) Fe to Mo different molar ratios in P-MoS2, (c) AHMT to P-MoS2 different the mass ratio in AHMT-MoS2 and (d) AHMT-MoS2 loading on the gas separation performance of the membranes

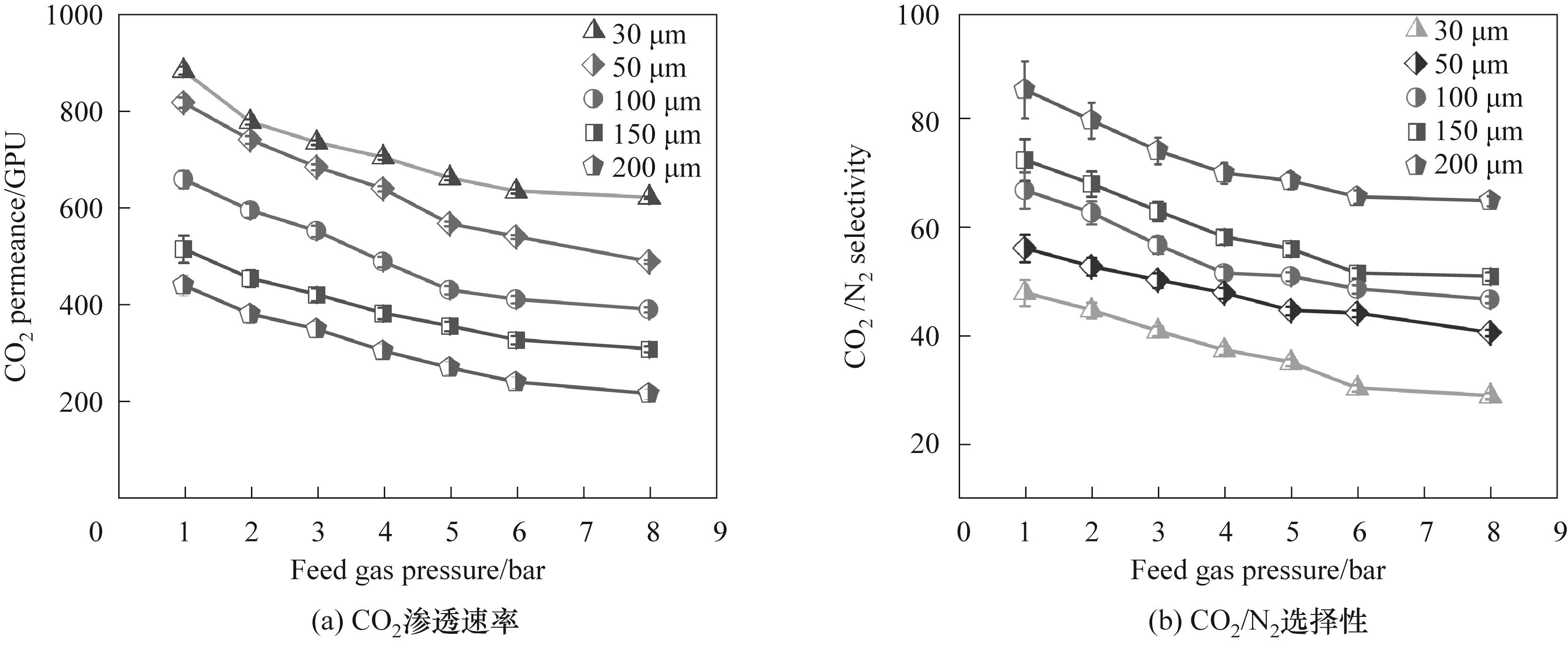

图9 选择性层的湿膜厚度对纯Pebax膜和Pebax/AHMT-MoS2的CO2渗透速率(a)和CO2/N2选择性(b)的影响(1 bar=0.1 MPa)

Fig.9 Effect of the wet coating thickness of the selective layer on the CO2 permeance (a) and CO2/N2 selectivity (b) of pure Pebax membrane and Pebax/AHMT-MoS2

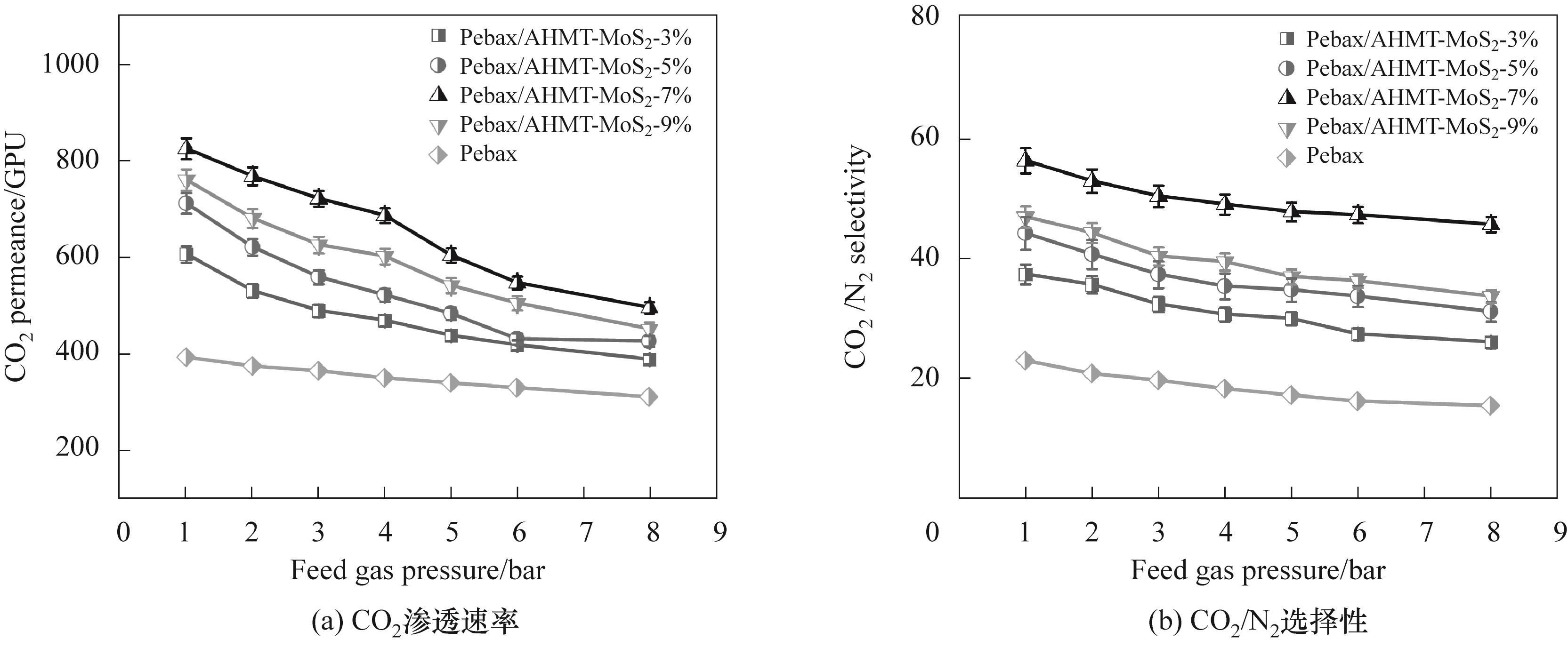

图10 进料气压力对纯Pebax膜和Pebax/AHMT-MoS2的CO2渗透速率(a)和CO2/N2选择性(b)的影响

Fig.10 Effect of the feed gas pressure on the CO2 permeance (a) and CO2/N2 selectivity (b) of the pure Pebax membrane and Pebax/AHMT-MoS2

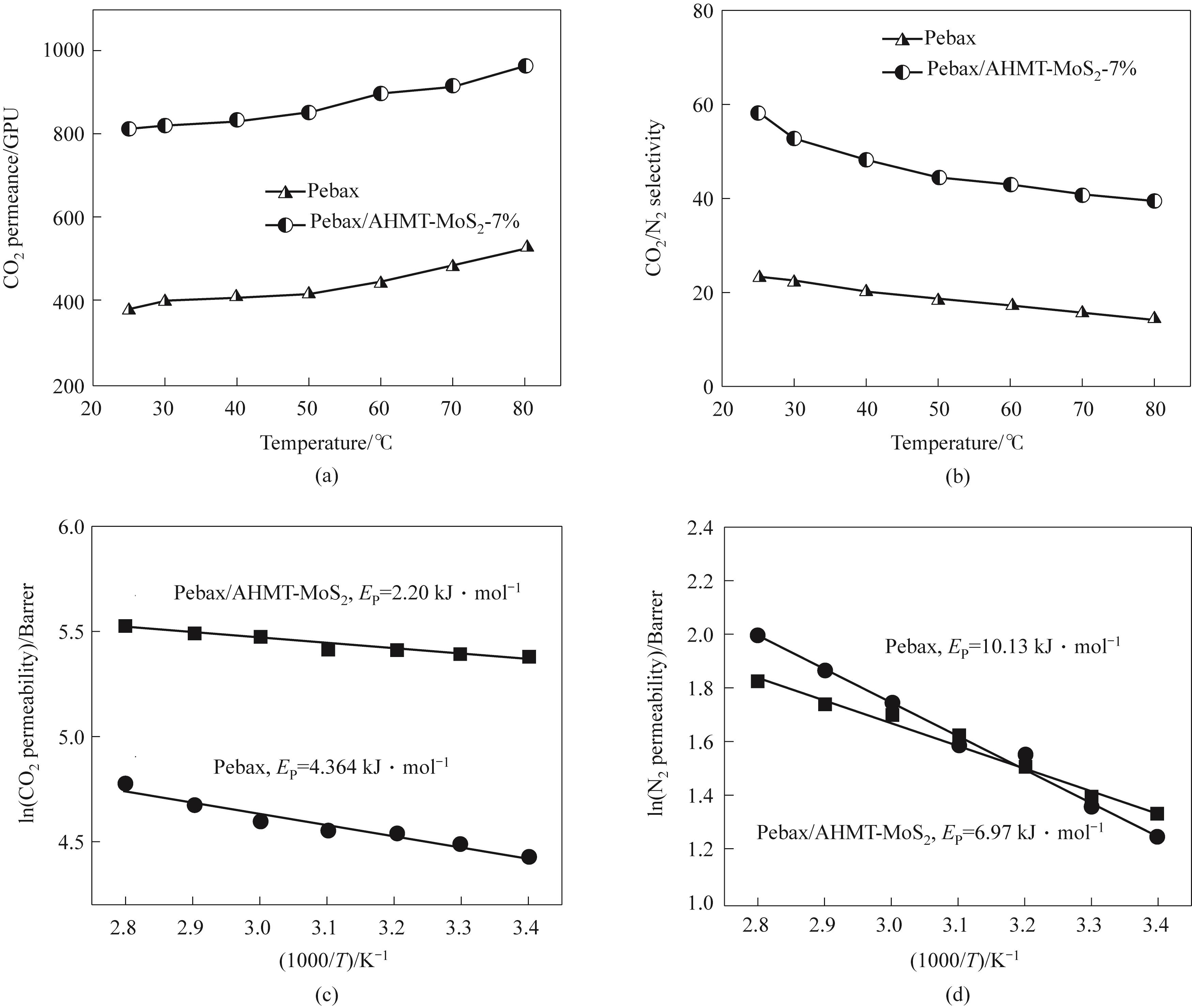

图11 操作温度对纯Pebax膜和Pebax/AHMT-MoS2的CO2渗透速率(a)与CO2/N2选择性(b)的影响;(c)ln (CO2 permeability)和(d)ln (N2 permeability)与1000/T的Arrhenius谱图

Fig.11 Effect of the operating temperature on the CO2 permeance (a) and the CO2/N2 selectivity (b) of the pure Pebax membrane and Pebax/AHMT-MoS2; (c) Arrhenius plot of ln (CO2 permeability) vs 1000/T and (d) Arrhenius plot of ln (N2 permeability) vs 1000/T

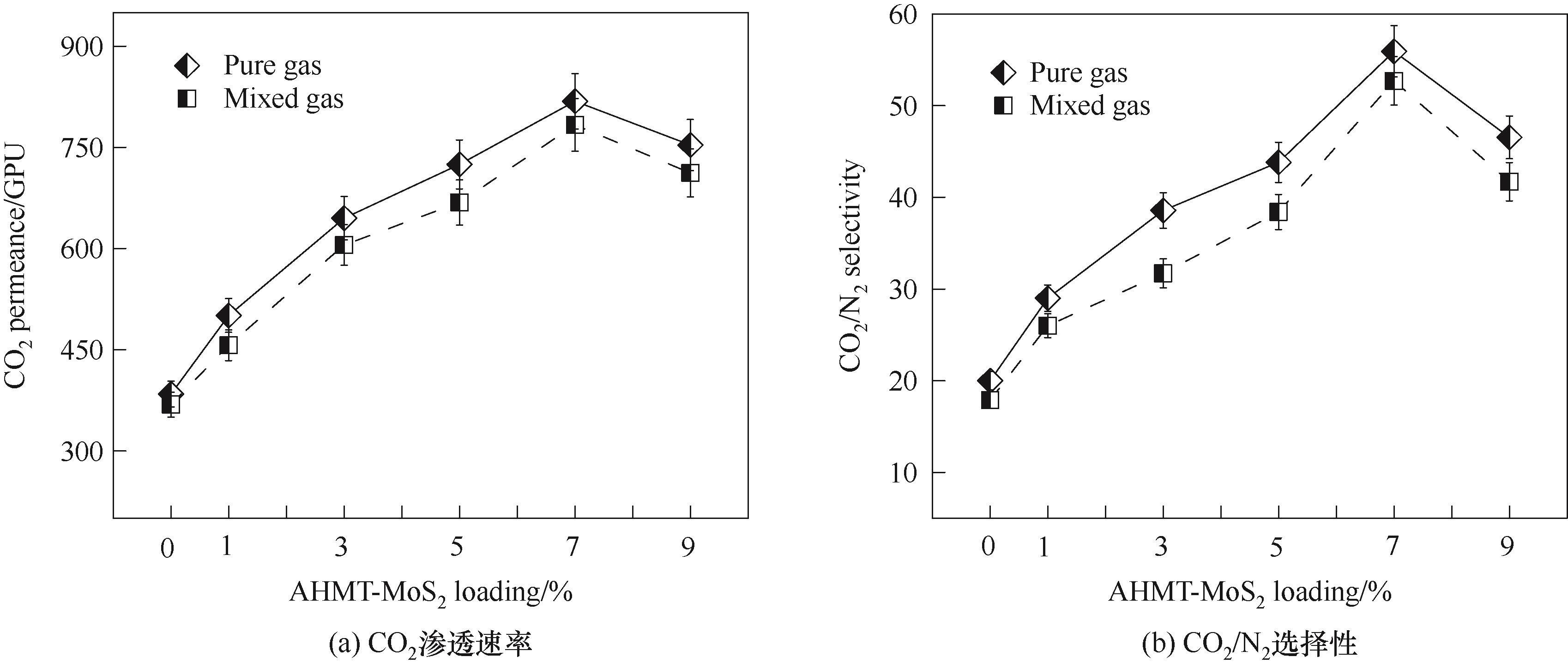

图12 纯Pebax膜和Pebax/AHMT-MoS2在纯气和混合气测试条件下的气体分离性能

Fig.12 Gas separation performance of the pure Pebax membrane and Pebax/AHMT-MoS2 as determined by pure gas and mixed gas testing

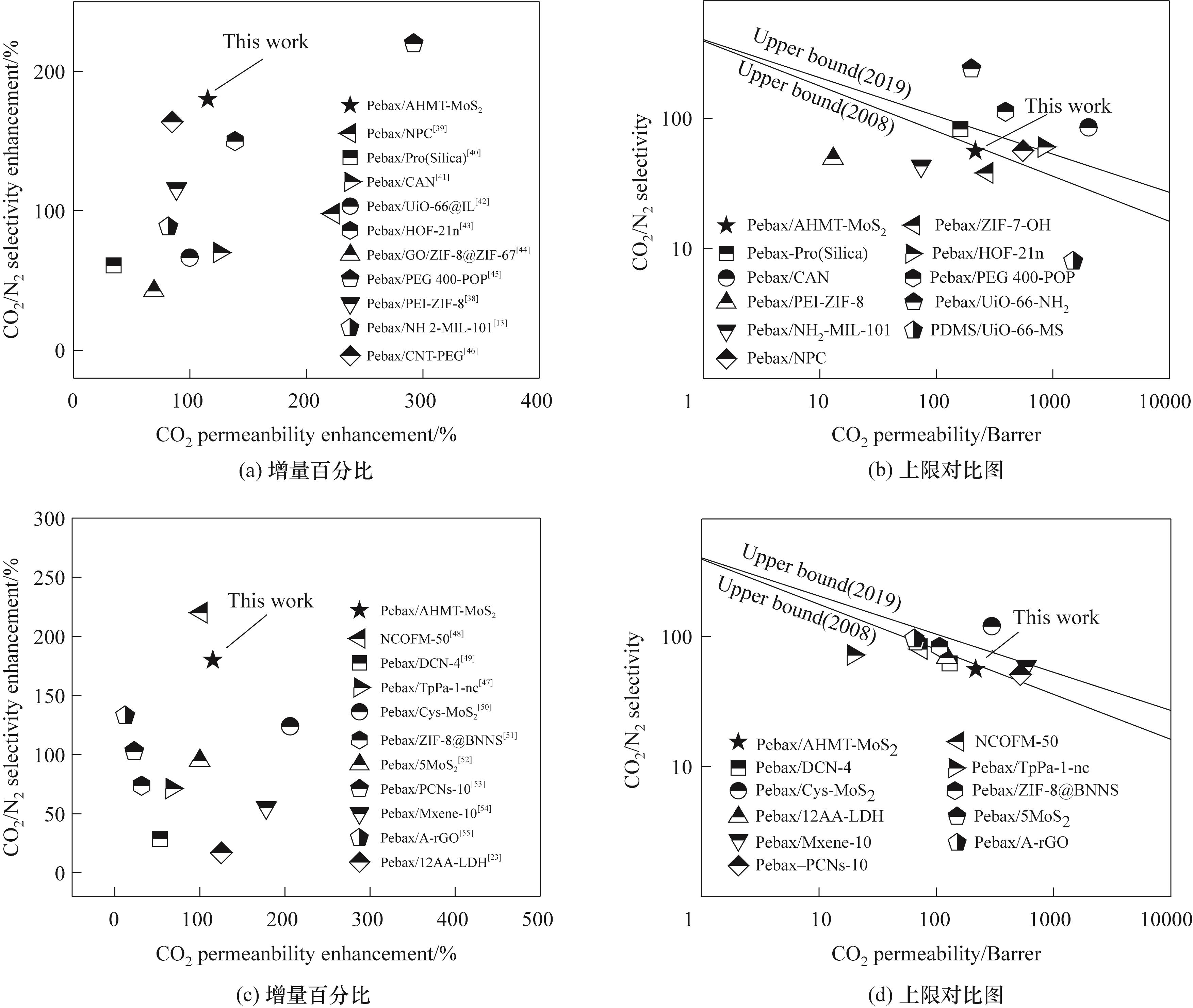

图14 Pebax/AHMT-MoS2气体分离对比:(a)与已报道Pebax基质MMCMs的增量百分比对比和(c)上限对比图;(b)与已报道片层填料MMCMs的增量百分比对比和(d)上限对比

Fig.14 Comparison of Pebax/AHMT-MoS2 gas separation performance: (a) percentage incremental increase vs reported Pebax-based and (c) its upper bound plot; (b) percentage incremental increase vs reported lamellar fillers and (d) its upper bound plot

| [1] | Liu Y L, Rui Z H. A storage-driven CO2 EOR for a net-zero emission target[J]. Engineering, 2022, 18: 79-87. |

| [2] | Zhao X, Ma X W, Chen B Y, et al. Challenges toward carbon neutrality in China: strategies and countermeasures[J]. Resources, Conservation and Recycling, 2022, 176: 105959. |

| [3] | Li W, Zhang S H, Lu C. Exploration of China's net CO2 emissions evolutionary pathways by 2060 in the context of carbon neutrality[J]. Science of the Total Environment, 2022, 831: 154909. |

| [4] | Wang Y T, Jalife S, Robles A, et al. Efficient CO2/CO separation by pressure swing adsorption using an intrinsically nanoporous molecular crystal[J]. ACS Applied Nano Materials, 2022, 5(10): 14021-14026. |

| [5] | Dong S L, Wang Z, Sheng M L, et al. High-performance multi-layer composite membrane with enhanced interlayer compatibility and surface crosslinking for CO2 separation[J]. Journal of Membrane Science, 2020, 610: 118221. |

| [6] | Dong H X, Shi F Y, Yi H J, et al. Selective enhancement mechanism of CO2/N2 separation in Pebax mixed matrix membrane doped with oriented optional magnetic two-dimensional carbon nitride[J]. Journal of Membrane Science, 2025, 719: 123740. |

| [7] | Wang Y H, Jin Z, Zhang X R, et al. Enhancing CO2 separation performance of mixed matrix membranes by incorporation of L-cysteine-functionalized MoS2 [J]. Separation and Purification Technology, 2022, 297: 121560. |

| [8] | Chen D K, Ying W, Guo Y, et al. Enhanced gas separation through nanoconfined ionic liquid in laminated MoS2 membrane[J]. ACS Applied Materials & Interfaces, 2017, 9(50): 44251-44257. |

| [9] | Wang Y H, Hu F N, Zhang X R, et al. Enhancing CO2-facilitated transport in PVAm membranes through the synergistic effect of porous molybdenum disulfide and mobilizable sulfonic groups[J]. Journal of Materials Chemistry A, 2025, 13(4): 3132-3145. |

| [10] | Luo Z Y, Ge J J, Liu C P, et al. Engineering the HER catalytic behavior of heteroatom-doped molybdenum disulfide via versatile partial cation exchange[J]. Journal of Energy Chemistry, 2020, 41: 15-19. |

| [11] | Li Z X, Sun M, Yang J L, et al. High-performance iron-doped molybdenum disulfide photocatalysts enhance peroxymonosulfate activation for water decontamination[J]. Chemical Engineering Journal, 2022, 446: 137380. |

| [12] | Wang Y H, Li L, Zhang X R, et al. Polyvinylamine/graphene oxide/PANI@CNTs mixed matrix composite membranes with enhanced CO2/N2 separation performance[J]. Journal of Membrane Science, 2019, 589: 117246. |

| [13] | Song C F, Li R, Fan Z C, et al. CO2/N2 separation performance of Pebax/MIL-101 and Pebax/NH2-MIL-101 mixed matrix membranes and intensification via sub-ambient operation[J]. Separation and Purification Technology, 2020, 238: 116500. |

| [14] | Yao Z Y, Zhang W, Ren X C, et al. A volume self-regulation MoS2 superstructure cathode for stable and high mass-loaded Zn-ion storage[J]. ACS Nano, 2022, 16(8): 12095-12106. |

| [15] | Li Y, Zhang R P, Zhou W, et al. Hierarchical MoS2 hollow architectures with abundant Mo vacancies for efficient sodium storage[J]. ACS Nano, 2019, 13(5): 5533-5540. |

| [16] | Wang Y H, Zhang L, Zhang X R, et al. Mixed matrix membranes consisting of PDMS and IL@MoS2 for enhancing 2-phenylethanol pervaporation separation[J]. Journal of Membrane Science, 2024, 706: 122947. |

| [17] | Zhou L, He B Z, Yang Y, et al. Facile approach to surface functionalized MoS2 nanosheets[J]. RSC Advances, 2014, 4(61): 32570-32578. |

| [18] | Chou S S, De M, Kim J, et al. Ligand conjugation of chemically exfoliated MoS2 [J]. Journal of the American Chemical Society, 2013, 135(12): 4584-4587. |

| [19] | Pan D X, Zhang J Q, Xue P Q, et al. Mixed matrix membranes with excellent CO2 capture induced by nano-carbon hybrids[J]. ChemNanoMat, 2017, 3(8): 560-568. |

| [20] | Wu Y D, Zhao D, Chen S H, et al. The effect of structure change from polymeric membrane to gel membrane on CO2 separation performance[J]. Separation and Purification Technology, 2021, 261: 118243. |

| [21] | Wang Y H, Ma Z W, Zhang X R, et al. Mixed-matrix membranes consisting of Pebax and novel nitrogen-doped porous carbons for CO2 separation[J]. Journal of Membrane Science, 2022, 644: 120182. |

| [22] | Zhang Q, Zhou M, Liu X F, et al. Pebax/two-dimensional MFI nanosheets mixed-matrix membranes for enhanced CO2 separation[J]. Journal of Membrane Science, 2021, 636: 119612. |

| [23] | Guo H, Lian S H, Li R, et al. Preparation of mixed matrix membranes by layered double hydroxides of amino acid intercalation and Pebax for ameliorated CO2 separation[J]. Journal of Environmental Chemical Engineering, 2023, 11(2): 109399. |

| [24] | Wang Y H, Li L, Zhang X R, et al. Polyvinylamine/amorphous metakaolin mixed-matrix composite membranes with facilitated transport carriers for highly efficient CO2/N2 separation[J]. Journal of Membrane Science, 2020, 599: 117828. |

| [25] | 靳卓, 王永洪, 张新儒, 等. Pebax/a-MoS2/MIP-202混合基质膜的制备及CO2分离性能[J]. 化工学报, 2022, 73(10): 4527-4538. |

| Jin Z, Wang Y H, Zhang X R, et al. Preparation of Pebax/a-MoS2/MIP-202 mixed matrix membranes for CO2 separation[J]. CIESC Journal, 2022, 73(10): 4527-4538. | |

| [26] | Bamonte S, Shubhashish S, Khanna H, et al. Magnetically doped molybdenum disulfide layers for enhanced carbon dioxide capture[J]. ACS Applied Materials & Interfaces, 2022, 14(24): 27799-27813. |

| [27] | Li F F, Yun S S, Gui L P, et al. Hydrazino-containing Zr-MOF for enhanced Lewis acid-base catalysis of CO2 fixation into cyclocarbonate[J]. Journal of Environmental Chemical Engineering, 2024, 12(6): 114311. |

| [28] | Liu Y C, Chen C Y, Lin G S, et al. Characterization and molecular simulation of Pebax-1657-based mixed matrix membranes incorporating MoS2 nanosheets for carbon dioxide capture enhancement[J]. Journal of Membrane Science, 2019, 582: 358-366. |

| [29] | Pan F S, Ding H, Li W D, et al. Constructing facilitated transport pathway in hybrid membranes by incorporating MoS2 nanosheets[J]. Journal of Membrane Science, 2018, 545: 29-37. |

| [30] | Xiang L, Pan Y C, Jiang J L, et al. Thin poly(ether-block-amide)/attapulgite composite membranes with improved CO2 permeance and selectivity for CO2/N2 and CO2/CH4 [J]. Chemical Engineering Science, 2017, 160: 236-244. |

| [31] | Nobakht D, Abedini R. Improved gas separation performance of Pebax®1657 membrane modified by poly-alcoholic compounds[J]. Journal of Environmental Chemical Engineering, 2022, 10(3): 107568. |

| [32] | Liao J Y, Wang Z, Gao C Y, et al. A high performance PVAm–HT membrane containing high-speed facilitated transport channels for CO2 separation[J]. Journal of Materials Chemistry A, 2015, 3(32): 16746-16761. |

| [33] | Ahmadpour E, Shamsabadi A A, Behbahani R M, et al. Study of CO2 separation with PVC/Pebax composite membrane[J]. Journal of Natural Gas Science and Engineering, 2014, 21: 518-523. |

| [34] | Xu S S, Huang H L, Guo X Y, et al. Highly selective gas transport channels in mixed matrix membranes fabricated by using water-stable Cu-BTC[J]. Separation and Purification Technology, 2021, 257: 117979. |

| [35] | Ishaq S, Tamime R, Bilad M R, et al. Mixed matrix membranes comprising of polysulfone and microporous Bio-MOF-1: preparation and gas separation properties[J]. Separation and Purification Technology, 2019, 210: 442-451. |

| [36] | Solimando X, Lherbier C, Babin J, et al. Pseudopeptide bioconjugate additives for CO2 separation membranes[J]. Polymer International, 2016, 65(12): 1464-1473. |

| [37] | Gao J, Mao H Z, Jin H, et al. Functionalized ZIF-7/Pebax® 2533 mixed matrix membranes for CO2/N2 separation[J]. Microporous and Mesoporous Materials, 2020, 297: 110030. |

| [38] | Jiao C L, Li Z D, Li X X, et al. Improved CO2/N2 separation performance of Pebax composite membrane containing polyethyleneimine functionalized ZIF-8[J]. Separation and Purification Technology, 2021, 259: 118190. |

| [39] | Mahdi E K, Amir M N, et al. Pebax/NC-PCL membrane containing well-distributed PCL grafted biodegradable nano-chitosan particles for CO2 separation[J]. Colloids and Surfaces A-Physicochemical and Engineering Aspects, 2025, 701: 135576. |

| [40] | Khalilinejad I, Kargari A, Sanaeepur H, et al. Preparation and characterization of (Pebax 1657 silica nanoparticle)/PVC mixed matrix composite membrane for CO2/N2 separation[J]. Chemistry and Chemical Engineering Quarterly, 2017, 30(4): 567‑582. |

| [41] | Zhang Y H, Tang Y P, Li X Y, et al. Pebax mixed-matrix membrane with highly dispersed ZIF-8@CNTs to enhance CO2/N2 separation[J].ACS Omega, 2021, 6(13):7595-7604. |

| [42] | Tang P H, So P B, Li W H, et al. Carbon dioxide enrichment PEBAX/MOF composite membrane for CO2 separation[J]. Membranes, 2021, 11(6): 404‑04. |

| [43] | Wang Y H, Ren, Y X, Cao Y, et al. Engineering HOF‑based mixed‑matrix membranes for efficient CO2 separation[J]. Nano Research, 2023, 15:50. |

| [44] | Li P L, Ma W Z, Zhong J, et al. Research on triazine‑based nitrogen‑doped porous carbon/Pebax mixed‑matrix membranes for CO2 separation and its gas transport mechanism[J]. Journal of Nanoparticle Research, 2024, 26:108. |

| [45] | Cho E H, Kim K B, Rhim J W, et al. Transport properties of PEBAX blended membranes with PEG and glutaraldehyde for SO2 and other gases[J]. Polymer Korea, 2014, 38: 1‑8. |

| [46] | Habibzare S, Asghari M, Djirsarai A, et al. Nano‑composite PEBAX®/PEG membranes: effect of MWNT filler on CO2/CH4 separation[J]. International Journal of Nanotechnology Development, 2014, 3(6): 45‑58. |

| [47] | Zou C C, Li Q Q, Hua Y Y, et al. Mechanical synthesis of COF nanosheet cluster and its mixed matrix membrane for efficient CO2 removal[J]. ACS Applied Materials and Interfaces, 2017, 9(34): 29093-29100. |

| [48] | Rahman M M, Filiz V, Shishatskiy S, et al. PEBAX® with PEG functionalized POSS as nanocomposite membranes for CO2 separation[J]. Journal of Membrane Science, 2013, 452: 215‑229. |

| [49] | Zhang S, Li L, Wang W, et al. Experimental study on surfactant‑based pressure‑reduction and injection enhancement in a certain oilfield[J]. Petroleum Exploration and Development, 2017, 44(2): 123‑132. |

| [50] | Zhang X, Peng G, Luo W J, et al. Pebax membranes-based on different two-dimensional materials for CO2 capture: a review[J]. Separation and Purification Technology, 2024, 340: 126744. |

| [51] | Guo F, Xiao W, Ma C, et al. Constructing gas transmission pathways in two‑dimensional composite material ZIF‑8@BNNS mixed‑matrix membranes to enhance CO2/N2 separation performance[J]. Membranes, 2023, 13(4): 444. |

| [52] | Liu Y C, Chen C Y, Lin G S, et al. Characterization and molecular simulation of Pebax-1657-based mixed matrix membranes incorporating MoS2 nanosheets for carbon dioxide capture enhancement[J]. Journal of Membrane Science, 2019, 582: 358-366. |

| [53] | Hou J P, Li X Q, Guo R L, et al. Mixed matrix membranes with fast and selective transport pathways for efficient CO2 separation[J]. Nanotechnology, 2018, 29: 1361. |

| [54] | Luo W J, Niu Z H, Mu P, et al. Pebax and CMC@MXene-based mixed matrix membrane with high mechanical strength for the highly efficient capture of CO2 [J]. Macromolecules, 2022, 55(21): 9851-9859. |

| [55] | Casadei R, Baschetti M G, Yoo M J, et al. Pebax® 2533/graphene oxide nanocomposite membranes for carbon capture[J]. Membranes, 2020, 10(8):188. |

| [1] | 臧子晴, 李修真, 谈莹莹, 刘晓庆. 分凝器对两级分离自复叠制冷循环特性影响研究[J]. 化工学报, 2025, 76(S1): 17-25. |

| [2] | 黄灏, 王文, 贺隆坤. LNG船薄膜型液货舱预冷过程模拟与分析[J]. 化工学报, 2025, 76(S1): 187-194. |

| [3] | 黄博, 黄灏, 王文, 贺隆坤. 薄膜型LNG船液货舱温度场计算分析[J]. 化工学报, 2025, 76(S1): 195-204. |

| [4] | 裴星亮, 叶翠平, 裴赢丽, 李文英. 碱改性MIL-53(Cr)选择性吸附分离二甲苯异构体[J]. 化工学报, 2025, 76(S1): 258-267. |

| [5] | 李银龙, 刘国强, 晏刚. 分馏与闪蒸分离耦合自复叠制冷循环性能分析[J]. 化工学报, 2025, 76(S1): 26-35. |

| [6] | 张建民, 何美贵, 贾万鑫, 赵静, 金万勤. 聚氧化乙烯/冠醚共混膜及其二氧化碳分离性能[J]. 化工学报, 2025, 76(9): 4862-4871. |

| [7] | 郭旭, 贾继宁, 姚克俭. 基于优化CNN-BiLSTM神经网络的间歇精馏过程建模[J]. 化工学报, 2025, 76(9): 4613-4629. |

| [8] | 王杰, 林渠成, 张先明. 基于分解算法的混合气体多级膜分离系统全局优化[J]. 化工学报, 2025, 76(9): 4670-4682. |

| [9] | 李文龙, 常程, 吴小林, 姬忠礼. 油水聚结过滤材料中的液体分布特性及过程压降演化研究[J]. 化工学报, 2025, 76(9): 4850-4861. |

| [10] | 王钰, 冯英楠, 王涛, 赵之平. 原位生长构筑纳米复合纳滤膜:膜制备与应用[J]. 化工学报, 2025, 76(9): 4723-4736. |

| [11] | 陈治宏, 吴佳伟, 楼小玲, 贠军贤. 化学品生物制造过程机器学习的研究进展[J]. 化工学报, 2025, 76(8): 3789-3804. |

| [12] | 张荟钦, 赵泓竣, 付正军, 庄力, 董凯, 贾添智, 曹雪丽, 孙世鹏. 纳滤膜在离子型稀土浸出液提浓中的应用研究[J]. 化工学报, 2025, 76(8): 4095-4107. |

| [13] | 刘沁雯, 叶恒冰, 张逸伟, 朱法华, 钟文琪. 煤与禽类粪便混合燃料的加压富氧燃烧特性研究[J]. 化工学报, 2025, 76(7): 3487-3497. |

| [14] | 高照, 吴熙, 夏丹, 张霖宙. 石油加工分子管理平台热力学及分离单元模块开发[J]. 化工学报, 2025, 76(7): 3212-3225. |

| [15] | 丁宏鑫, 干文翔, 赵雍洋, 贾润泽, 康子祺, 赵玉隆, 向勇. X65钢焊接接头在超临界CO2相及富H2O相中的腐蚀机理研究[J]. 化工学报, 2025, 76(7): 3426-3435. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号