化工学报 ›› 2025, Vol. 76 ›› Issue (3): 1029-1039.DOI: 10.11949/0438-1157.20241002

张静1,2( ), 杨光1, 菅爱博1, 程思淼1, 王绍哲1, 龚斌1(

), 杨光1, 菅爱博1, 程思淼1, 王绍哲1, 龚斌1( )

)

收稿日期:2024-09-05

修回日期:2024-10-05

出版日期:2025-03-25

发布日期:2025-03-28

通讯作者:

龚斌

作者简介:张静(1971—),女,硕士,教授,2501474185@qq.com

基金资助:

Jing ZHANG1,2( ), Guang YANG1, Aibo JIAN1, Simiao CHENG1, Shaozhe WANG1, Bin GONG1(

), Guang YANG1, Aibo JIAN1, Simiao CHENG1, Shaozhe WANG1, Bin GONG1( )

)

Received:2024-09-05

Revised:2024-10-05

Online:2025-03-25

Published:2025-03-28

Contact:

Bin GONG

摘要:

利用CLSVOF模型和动态自适应网格数值模拟了静水中双油滴撞击凹壁面及聚并过程。结果表明,双油滴撞击水下疏油凹壁面滚动下滑过程中碰撞产生聚并行为,水下亲油表面上双油滴撞壁后铺展边缘接触产生聚并行为。对凹壁面上油滴铺展直径d、近端点距离δ和最大铺展因子β研究表明:β≤3.1聚并形成单液桥;β>3.1,δ/d<3,右侧油滴撞击凹壁面形成空心环,内边缘存在较高压力,导致油滴铺展面积扩张,促使形成双液桥;当β>3.1,δ/d≥3时形成环孔单液桥,但聚并后油滴与凹壁面的润湿面积存在波动。双油滴聚并形成的单液桥无量纲流通面积较大,稳定性优于双液桥,但双液桥缩短了撞壁-聚并的时长。研究可为深入理解旋流器近壁面非均相聚并机理提供理论支持。

中图分类号:

张静, 杨光, 菅爱博, 程思淼, 王绍哲, 龚斌. 基于水下凹壁面上双油滴撞壁-聚并过程分析[J]. 化工学报, 2025, 76(3): 1029-1039.

Jing ZHANG, Guang YANG, Aibo JIAN, Simiao CHENG, Shaozhe WANG, Bin GONG. Analysis of double droplets impact-coalescence process based on underwater concave-wall[J]. CIESC Journal, 2025, 76(3): 1029-1039.

| 参数/mm | 数值 |

|---|---|

| 计算域宽度B | 60 |

| 计算域直边高度H | 75 |

| 凹壁面曲率半径R | 75 |

| 下落高度h0 | 115 |

| 左侧油滴偏心距el | 65 |

| 右侧油滴偏心距er | 33.0~58.5 |

| 油滴初始粒径d0 | 2.2~6.4 |

表1 结构参数和初始油滴参数

Table 1 Structure size and initial droplet parameter

| 参数/mm | 数值 |

|---|---|

| 计算域宽度B | 60 |

| 计算域直边高度H | 75 |

| 凹壁面曲率半径R | 75 |

| 下落高度h0 | 115 |

| 左侧油滴偏心距el | 65 |

| 右侧油滴偏心距er | 33.0~58.5 |

| 油滴初始粒径d0 | 2.2~6.4 |

| 网格方案 | 油水界面 细化阈值 | 流体域 粗化阈值 | 最小网格 尺寸/mm | 最多网格 数量/个 | 网格最大 增量/% |

|---|---|---|---|---|---|

| Plan-0 | 无 | 无 | 1 | 367360 | — |

| Plan-1 | 10-2 | 10-3 | 0.0129 | 528969 | 43.9 |

| Plan-2 | 10-2 | 10-4 | 0.0133 | 532805 | 44.9 |

| Plan-3 | 10-3 | 10-4 | 0.0143 | 531363 | 44.5 |

| Plan-4 | 10-4 | 10-4 | 0.0143 | 591962 | 61.0 |

表2 网格方案

Table 2 Grid plans

| 网格方案 | 油水界面 细化阈值 | 流体域 粗化阈值 | 最小网格 尺寸/mm | 最多网格 数量/个 | 网格最大 增量/% |

|---|---|---|---|---|---|

| Plan-0 | 无 | 无 | 1 | 367360 | — |

| Plan-1 | 10-2 | 10-3 | 0.0129 | 528969 | 43.9 |

| Plan-2 | 10-2 | 10-4 | 0.0133 | 532805 | 44.9 |

| Plan-3 | 10-3 | 10-4 | 0.0143 | 531363 | 44.5 |

| Plan-4 | 10-4 | 10-4 | 0.0143 | 591962 | 61.0 |

| 参数 | 数值 |

|---|---|

| 连续相密度ρc/(kg/m3) | 998.2 |

| 连续相黏度μc/(kg/(m·s)) | 1.003×10-3 |

| 离散相密度ρd/(kg/m3) | 1595.0 |

| 离散相黏度μd/(kg/(m·s)) | 9.69×10-4 |

| 界面张力σ/(N/m) | 4.57×10-2 |

| 重力加速度g/(m/s2) | 9.81 |

表3 连续相和离散相物性参数(293.15 K)

Table 3 Parameters of continuous-phase and discrete-phase at293.15 K

| 参数 | 数值 |

|---|---|

| 连续相密度ρc/(kg/m3) | 998.2 |

| 连续相黏度μc/(kg/(m·s)) | 1.003×10-3 |

| 离散相密度ρd/(kg/m3) | 1595.0 |

| 离散相黏度μd/(kg/(m·s)) | 9.69×10-4 |

| 界面张力σ/(N/m) | 4.57×10-2 |

| 重力加速度g/(m/s2) | 9.81 |

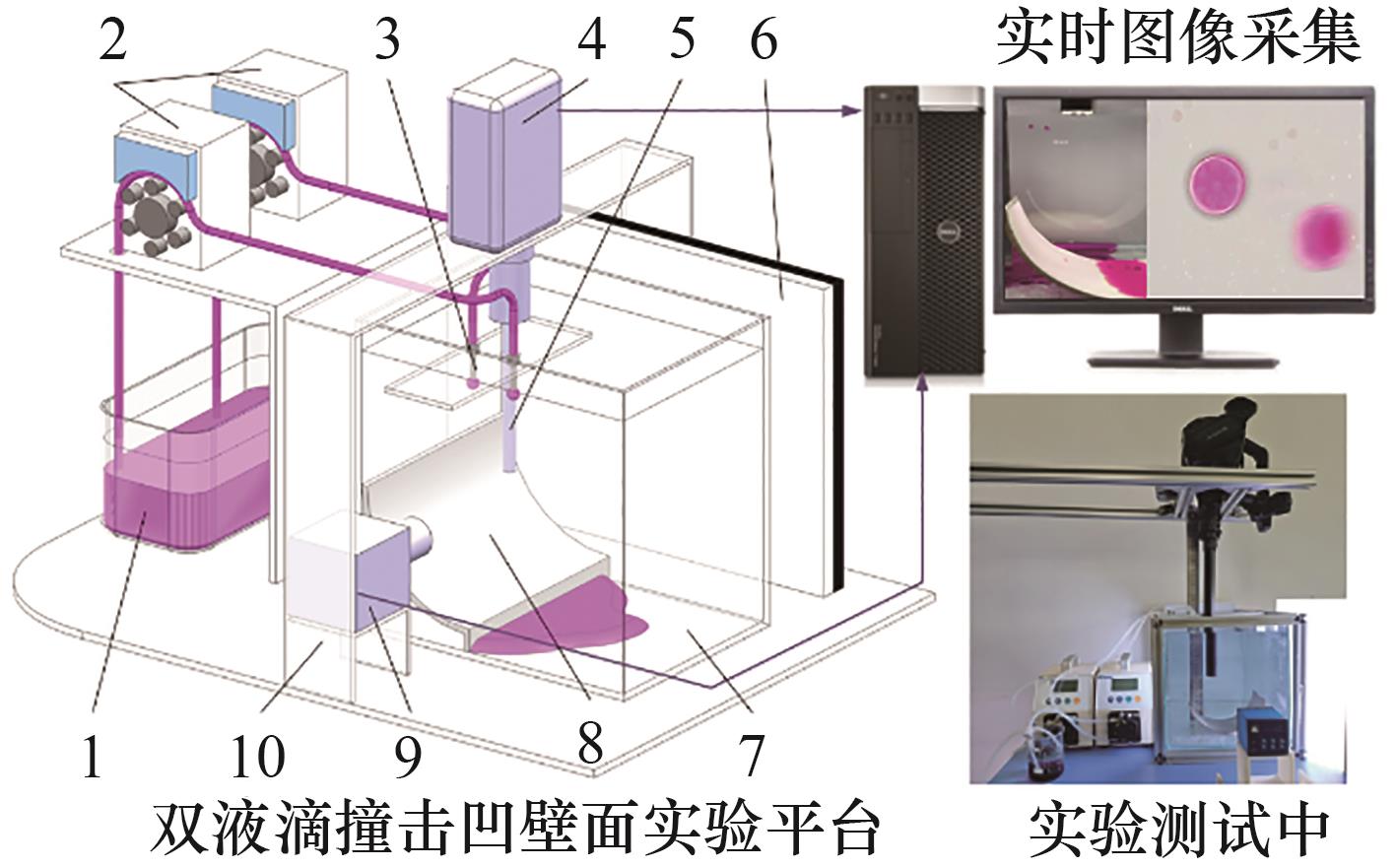

图4 双油滴撞击凹壁面实验装置1—水封四氯化碳;2—蠕动泵;3—针头;4—摄像机;5—微距镜头;6—灯板;7—水箱;8—凹壁面;9—CCD相机;10—相机支架

Fig.4 Experimental setup for double droplets impact on concave-wall1—water-sealed CCl4; 2—peristaltic pump; 3—needle; 4—camera; 5—macro lens; 6—lamp plate; 7—tank; 8—concave-wall; 9—CCD camera; 10—camera bracket

| 1 | Zang D Y, Yu Y K, Chen Z, et al. Acoustic levitation of liquid drops: dynamics, manipulation and phase transitions[J]. Advances in Colloid and Interface Science, 2017, 243: 77-85. |

| 2 | Borcia R, Bestehorn M. On the coalescence of sessile drops with miscible liquids[J]. The European Physical Journal. E, Soft Matter, 2011, 34(8): 81. |

| 3 | 邢雷, 苗春雨, 蒋明虎, 等. 多级螺旋分离器结构优化设计与性能分析[J]. 化工学报, 2023, 74(11): 4587-4599. |

| Xing L, Miao C Y, Jiang M H, et al. Optimal design and performance analysis of multi-stage spiral separator[J]. CIESC Journal, 2023, 74(11): 4587-4599. | |

| 4 | 武秋敏, 苏昕, 崔忻羽. 喷墨印刷液滴的铺展特性研究[J]. 包装工程, 2023, 44(11): 227-234. |

| Wu Q M, Su X, Cui X Y. Spreading characteristics of inkjet printing droplets[J]. Packaging Engineering, 2023, 44(11): 227-234. | |

| 5 | Rioboo R, Tropea C, Marengo M. Outcomes from a drop impact on solid surfaces[J]. Atomization and Sprays, 2001, 11(2): 155-165. |

| 6 | 梁超, 王宏, 朱恂, 等. 液滴撞击不同浸润性壁面动态过程的数值模拟[J]. 化工学报, 2013, 64(8): 2745-2751. |

| Liang C, Wang H, Zhu X, et al. Numerical simulation of droplet impact on surfaces with different wettabilities[J]. CIESC Journal, 2013, 64(8): 2745-2751. | |

| 7 | 周超, 魏超政. 单液滴冲击超疏水壁面的压力特性研究[J]. 工程热物理学报, 2021, 42(12): 3238-3248. |

| Zhou C, Wei C Z. Study on the pressure characteristics of single droplet impact super-hydrophobic wall surface[J]. Journal of Engineering Thermophysics, 2021, 42(12): 3238-3248. | |

| 8 | Zhang R, Hao P F, He F. Drop impact on oblique superhydrophobic surfaces with two-tier roughness[J]. Langmuir, 2017, 33(14): 3556-3567. |

| 9 | Wang H, Liu C, Zhan H Y, et al. Droplet asymmetric bouncing on inclined superhydrophobic surfaces[J]. ACS Omega, 2019, 4(7): 12238-12243. |

| 10 | Antonini C, Villa F, Marengo M. Oblique impacts of water drops onto hydrophobic and superhydrophobic surfaces: outcomes, timing, and rebound maps[J]. Experiments in Fluids, 2014, 55(4): 1713. |

| 11 | Shen C Q, Yu C, Chen Y P. Spreading dynamics of droplet on an inclined surface[J]. Theoretical and Computational Fluid Dynamics, 2016, 30(3): 237-252. |

| 12 | Chen W Y, Yang F, Yan Y H, et al. Lattice Boltzmann simulation of the spreading behavior of a droplet impacting on inclined solid wall[J]. Journal of Mechanical Science and Technology, 2018, 32(6): 2637-2649. |

| 13 | Ouyang S, Xiong Z Q, Zhao J Y, et al. Droplet impact on a concave wall in a rotating gas flow field[J]. International Communications in Heat and Mass Transfer, 2022, 135: 106131. |

| 14 | 张静, 张浩, 龚斌, 等. 水下四氯化碳单液滴在凹壁面上的动态特性[J]. 过程工程学报, 2022, 22(12): 1613-1622. |

| Zhang J, Zhang H, Gong B, et al. Dynamic characteristic of single CCl4 droplet underwater on concave-wall[J]. The Chinese Journal of Process Engineering, 2022, 22(12): 1613-1622. | |

| 15 | 李逢超, 付宇, 李超, 等. 铝液滴撞击曲面的流动特性分析[J]. 物理学报, 2022, 71(18): 181-193. |

| Li F C, Fu Y, Li C, et al. Flowing characteristics of aluminum droplets impacting curved surface[J]. Acta Physica Sinica, 2022, 71(18): 181-193. | |

| 16 | Sayyari H, Peiravi M M, Alinejad J. Surveying the effects of concave obstacles with different edge walls on hollow glycerin droplet impacting using the volume of fluid approach[J]. Advances in Mechanical Engineering, 2022, 14(11): 1-11. |

| 17 | 周晓庆, 李春煜, 杨光, 等. 液滴撞击不同曲率过冷波纹面结冰动力学行为及机理研究[J]. 化工学报, 2023, 74(S1): 141-153. |

| Zhou X Q, Li C Y, Yang G, et al. Icing kinetics and mechanism of droplet impinging on supercooled corrugated plates with different curvature[J]. CIESC Journal, 2023, 74(S1): 141-153. | |

| 18 | Wang Y T, Qian L J, Chen Z L, et al. Coalescence of binary droplets in the transformer oil based on small amounts of polymer: effects of initial droplet diameter and collision parameter[J]. Polymers, 2020, 12(9): 2054. |

| 19 | Yuan S X, Dabirian R, Shoham O, et al. Numerical simulation of liquid droplet coalescence and breakup[J]. Journal of Energy Resources Technology, 2020, 142(10): 102101. |

| 20 | Gebauer F, Villwock J, Kraume M, et al. Detailed analysis of single drop coalescence—influence of ions on film drainage and coalescence time[J]. Chemical Engineering Research and Design, 2016, 115: 282-291. |

| 21 | Kamp J, Villwock J, Kraume M. Drop coalescence in technical liquid/liquid applications: a review on experimental techniques and modeling approaches[J]. Reviews in Chemical Engineering, 2017, 33(1): 1-47. |

| 22 | Roisman I V, Abboud M, Brockmann P, et al. Forced flows in liquid bridges[J]. Current Opinion in Colloid & Interface Science, 2023, 67: 101738. |

| 23 | Shen C Q, Chen Y Y, Yu C, et al. Numerical study on the liquid-liquid interface evolution during droplet coalescence[J]. Microgravity Science and Technology, 2020, 32(4): 737-748. |

| 24 | Peng L Q, Luo Z Y, Zuo Y Y, et al. Pinch-off of liquid bridge during droplet coalescence under constrained condition[J]. Chemical Engineering Science, 2018, 177: 471-480. |

| 25 | Xing L, Li J Y, Jiang M H, et al. Coalescence dynamics of droplets collision on substrates with different contact angles[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2023, 670: 131573. |

| 26 | Huang J X, Wang L, He K. Three-dimensional study of double droplets impact on a wettability-patterned surface[J]. Computers & Fluids, 2022, 248: 105669. |

| 27 | Zhou X, Wang H, Wu J J, et al. Bounce behaviors of double droplets simultaneously impact cold superhydrophobic surface[J]. International Journal of Heat and Mass Transfer, 2023, 208: 124075. |

| 28 | Huang B, Nan X H, Fu C, et al. Probing the coalescence mechanism of oil droplets in fluids produced by oil wells and the microscopic interaction between molecules in oil films[J]. Energies, 2022, 15(12): 4274. |

| 29 | Jiang C Z, Wang Z H, Yang Q W, et al. Numerical investigations of collision modes of double droplets on a spherical surface based on the phase field method[J]. Korean Journal of Chemical Engineering, 2024, 41(6): 1551-1566. |

| 30 | Sussman M, Puckett E G. A coupled level set and volume-of-fluid method for computing 3D and axisymmetric incompressible two-phase flows[J]. Journal of Computational Physics, 2000, 162(2): 301-337. |

| 31 | 周鑫, 马小晶, 胡丽娜, 等. 不同壁面条件下液滴撞击铺展特性的模拟研究[J]. 计算力学学报, 2022, 39(6): 761-767. |

| Zhou X, Ma X J, Hu L N, et al. Simulation study on spreading characteristics of droplet impinging under different wall conditions[J]. Chinese Journal of Computational Mechanics, 2022, 39(6): 761-767. | |

| 32 | Brackbill J U, Kothe D B, Zemach C. A continuum method for modeling surface tension[J]. Journal of Computational Physics, 1992, 100(2): 335-354. |

| 33 | Chen Y L, Guo L, Sun W C, et al. Molecular dynamics simulations of wetting behaviors of droplets on surfaces with different rough structures[J]. International Journal of Multiphase Flow, 2023, 169: 104613. |

| 34 | 张晓林, 黄军杰. 楔形体上复合液滴润湿铺展行为的格子Boltzmann方法研究[J]. 物理学报, 2023, 72(2): 173-183. |

| Zhang X L, Huang J J. Study on wetting and spreading behaviors of compound droplets on wedge by lattice Boltzmann method[J]. Acta Physica Sinica, 2023, 72(2): 173-183. | |

| 35 | Zhang J, Gao Y B, Gong B, et al. Experimental investigation on single-droplet deformation and breakup in a concave-wall jet[J]. Chemical Engineering & Technology, 2021, 44(2): 238-247. |

| 36 | 郝冠球, 刘向东, 陈永平. 电场调控剪切流场内液滴形变特性研究[J]. 工程热物理学报, 2024, 45(1): 129-134. |

| Hao G Q, Liu X D, Chen Y P. Electric-field-controlled droplet deformation in a shear flow field[J]. Journal of Engineering Thermophysics, 2024, 45(1): 129-134. | |

| 37 | He H B, Liu Z, Ji J B, et al. Analysis of interaction and flow pattern of multiple bubbles in shear-thinning viscoelastic fluids[J]. Energies, 2023, 16(14): 5345. |

| [1] | 韩东, 高宁宁, 唐新德, 龚升高, 夏良树. 适用欧拉-拉格朗日方法模拟气液泡状流的气泡破碎模型[J]. 化工学报, 2024, 75(2): 553-565. |

| [2] | 赵文琪, 邓燕君, 朱春英, 付涛涛, 马友光. 纳米粒子稳定的Pickering乳液及其液滴聚并动力学研究进展[J]. 化工学报, 2024, 75(1): 33-46. |

| [3] | 张银宁, 王进卿, 冯致, 詹明秀, 徐旭, 张光学, 池作和. 升温条件下多孔介质内气泡的生长和聚并行为[J]. 化工学报, 2023, 74(4): 1509-1518. |

| [4] | 黄杏梅, 张莹, 王宗勇, 李雅侠, 张丽. 水平均匀电场下盐水中氯气气泡的聚并特性[J]. 化工学报, 2023, 74(12): 4881-4891. |

| [5] | 刘道银, 范志恒, 马吉亮, 陈晓平. 湿颗粒倾斜碰撞恢复系数的直接数值模拟[J]. 化工学报, 2023, 74(10): 4063-4073. |

| [6] | 万景, 张霖, 樊亚超, 刘勰民, 骆培成, 张锋, 张志炳. 基于介尺度PBM模型的生物反应器放大模拟及实验研究[J]. 化工学报, 2022, 73(6): 2698-2707. |

| [7] | 杨蕊, 朱宝锦, 吕超, 张磊, 肖迎松. 脉动条件下旋流场内气液两相流流型及其转变机理[J]. 化工学报, 2022, 73(10): 4389-4398. |

| [8] | 赵峻逸, 薛士东, 韩敬坤, 温荣福, 兰忠, 郝婷婷, 马学虎. 双液滴碰撞行为及调控机制的研究进展[J]. 化工学报, 2021, 72(5): 2354-2372. |

| [9] | 张华海, 王悦琳, 王铁峰. 全浓度范围下醇类表面活性剂对气泡聚并影响的实验研究[J]. 化工学报, 2020, 71(9): 4161-4167. |

| [10] | 张皓, 王凯. 基于显微图像识别的微流控液滴聚并研究[J]. 化工学报, 2020, 71(2): 526-534. |

| [11] | 张静, 王巍, 宋姝宁, 龚斌, 李雅侠, 王学平, 吴剑华. 入口结构对三维凹壁面切向射流作用下离散颗粒行为的影响[J]. 化工学报, 2019, 70(8): 3021-3032. |

| [12] | 张静, 周圆圆, 龚斌, 李雅侠, 刘海良, 吴剑华. 三维凹壁面切向射流流动特性分析[J]. 化工学报, 2019, 70(4): 1340-1348. |

| [13] | 周剑宏, 童宝宏, 王伟, 刘焜, 苏家磊. 含气泡油滴撞击矩形沟槽壁面的数值分析[J]. 化工学报, 2018, 69(12): 5011-5023. |

| [14] | 李阳, 杜乐, 高若梅, 吴偲, 龚亚辉. 微通道中原位分散技术可控制备氧化铜纳米流体及复合薄膜前体[J]. 化工学报, 2018, 69(11): 4918-4928. |

| [15] | 郑建祥, 许帅, 王京阳, 史梦燚, 汪龙. 基于微分代数积分矩量法的聚并器超细颗粒聚团研究[J]. 化工学报, 2017, 68(1): 119-128. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号