化工学报 ›› 2019, Vol. 70 ›› Issue (7): 2636-2644.DOI: 10.11949/0438-1157.20181312

姜自超1( ),方建华1(

),方建华1( ),江泽琦2,王鑫1,冯彦寒1,丁建华1

),江泽琦2,王鑫1,冯彦寒1,丁建华1

收稿日期:2018-11-12

修回日期:2019-04-13

出版日期:2019-07-05

发布日期:2019-07-05

通讯作者:

方建华

作者简介:姜自超(1990—),男,博士研究生,<email>614327919@qq.com</email>

基金资助:

Zichao JIANG1( ),Jianhua FANG1(

),Jianhua FANG1( ),Zeqi JIANG2,Xin WANG1,Yanhan FENG1,Jianhua DING1

),Zeqi JIANG2,Xin WANG1,Yanhan FENG1,Jianhua DING1

Received:2018-11-12

Revised:2019-04-13

Online:2019-07-05

Published:2019-07-05

Contact:

Jianhua FANG

摘要:

在四球摩擦磨损实验机摩擦区域添加了直流磁场发生装置,研究了添加经修饰的纳米WS2润滑油在直流磁场作用下的摩擦磨损性能,用扫描电镜(SEM)配合能谱仪(EDS)及X射线光电子能谱仪(XPS)对钢球磨斑区域表面形貌和典型元素的含量及化学状态进行了分析,并探讨了相关的摩擦学机理。实验结果表明:经修饰后的纳米WS2在150SN基础油中稳定性良好,含纳米WS2的润滑油体现出更好的润滑性能,在纳米WS2含量相同时,直流磁场下的润滑油抗磨减摩效果更好。直流磁场对纳米WS2有一定的聚集效应,并会提高摩擦化学反应发生的概率。

中图分类号:

姜自超, 方建华, 江泽琦, 王鑫, 冯彦寒, 丁建华. 纳米WS2润滑油添加剂在直流磁场下的摩擦磨损特性[J]. 化工学报, 2019, 70(7): 2636-2644.

Zichao JIANG, Jianhua FANG, Zeqi JIANG, Xin WANG, Yanhan FENG, Jianhua DING. Tribological properties ofnano-WS2 lubricating oil additives under DC magnetic field[J]. CIESC Journal, 2019, 70(7): 2636-2644.

图8 有、无磁场条件下基础油和含2.0%纳米WS2润滑油中磨斑表面SEM图和EDS分析结果

Fig.8 SEM micrographs and EDS analysis results of worn surfaces lubricated with oil doped 2.0% nano-WS2 under magnetic or non-magnetic field

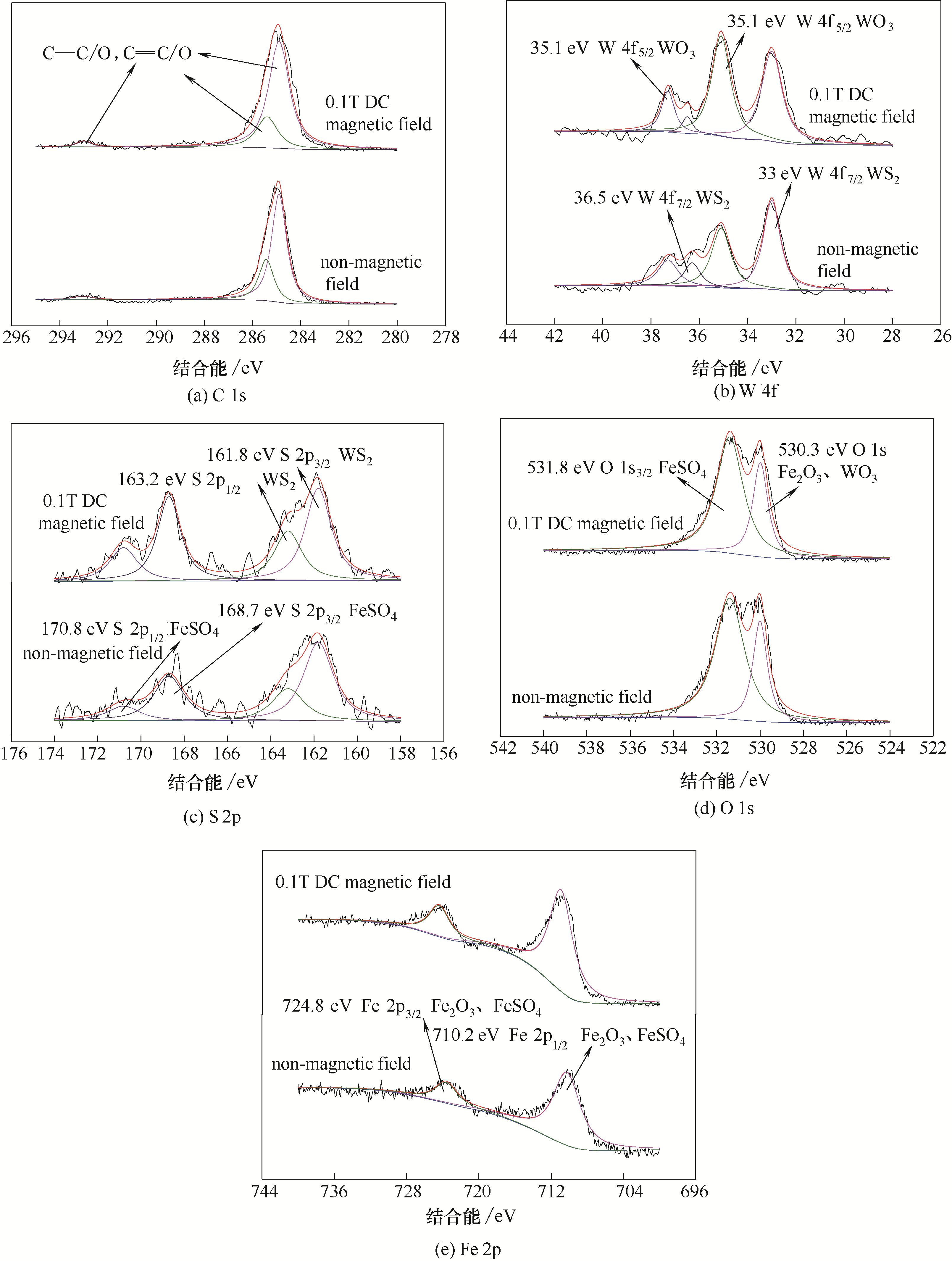

图9 有、无磁场条件下含2.0%纳米WS2润滑油中磨斑表面典型元素的XPS谱图

Fig.9 XPS spectra of typical elements on worn surfaces lubricated with oil doped with 2.0% of WS2 nanoparticles under magnetic or non-magnetic field

| 1 | RemskarM, VirsekM, JesihA. WS2 nanobuds as a new hybrid nanomaterial[J]. Nano Letters, 2008, 8(1): 76-80. |

| 2 | LinJ Y, ZhangR X, YeW Y, et al. Nano-WS2 embedded PES membrane with improved fouling and permselectivity[J]. Journal of Colloid & Interface Science, 2013, 396(6): 120-128. |

| 3 | DuanJ J, ChenS, ChambersB A, et al. 3D WS2 nanolayers@heteroatom‐doped graphene films as hydrogen evolution catalyst electrodes[J]. Advanced Materials, 2015, 27(28): 4234-4241. |

| 4 | ZhouL Y, YanS C, PanL J, et al. A scalable sulfuration of WS2 to improve cyclability and capability of lithium-ion batteries[J]. Nano Research, 2016, 9(3): 857-865. |

| 5 | MaT, ZhangT, GaoP G, et al. Synthesis and properties of ultrahigh molecular weight polyethylene/WS₂ nanoparticle fiber for bullet-proof materials[J]. Chinese Science Bulletin, 2013, 58(8): 945-948. |

| 6 | WuN, HuN N, ZhouG B, et al. Tribological properties of lubricating oil with micro/nano-scale WS2 particles[J]. Journal of Experimental Nanoscience, 2018, 13(1): 1-12. |

| 7 | ZhengD, WuY P, LiZ Y, et al. Tribological properties of WS2/graphene nanocomposites as lubricating oil additives[J]. RSC Advances, 2017, 7(23): 14060-14068. |

| 8 | 杨士钊, 胡建强, 谢凤, 等. 低纳米二硫化钨含量润滑油抗磨性能[J]. 石油学报: 石油加工, 2017, 33(3): 543-548. |

| YangS Z, HuJ Q, XieF, et al. Anti-wear properties of low nano-WS2 content lubricant [J]. Acta Petrolei Sinica(Petroleum Processing Section), 2017, 33(3): 543-548. | |

| 9 | 李长生, 于云, 刘艳清, 等. WS2纳米颗粒的合成及摩擦学性能研究[J]. 无机化学学报, 2008, 24(2): 275-279. |

| LiC S, YuY, LiuY Q, et al. Synthesis and tribological properties of WS2 nanoparticles[J]. Chinese Journal of Inorganic Chemistry, 2008, 24(2): 275-279. | |

| 10 | MaharajD, BhushanB. Effect of MoS2, and WS2, nanotubes on nanofriction and wear reduction in dry and liquid environments[J]. Tribology Letters, 2013, 49(2): 323-339. |

| 11 | RatoiM, NisteV B, WslkerJ, et al. Mechanism of action of WS2, lubricant nanoadditives in high-pressure contacts[J]. Tribology Letters, 2013, 52(1): 81-91. |

| 12 | LiS P, DengJ X, YanG Y, et al. Microstructure, mechanical properties and tribological performance of TiSiN–WS2, hard-lubricant coatings[J]. Applied Surface Science, 2014, 309(4): 209-217. |

| 13 | ChenC B, MaoD H, ShiC, et al. Experimental study on the tribological characteristics of nanometer WS2 lubricating oil additive based on engine oil[J]. Advanced Materials Research, 2011, 328/329/330: 203-208. |

| 14 | AldanaP U, DassenoyF, VacherB, et al. WS2 nanoparticles anti-wear and friction reducing properties on rough surfaces in the presence of ZDDP additive[J]. Tribology International, 2016, 102: 213-221. |

| 15 | AldanaP U, Vacher, Béatrice, Le MogneT, et al. Action mechanism of WS2 nanoparticles with ZDDP additive in boundary lubrication regime[J]. Tribology Letters, 2014, 56(2): 249-258. |

| 16 | MujuM K, RadhakrishnaA. Wear of non-magnetic materials in the presence of a magnetic field[J]. Wear, 1980, 58(1): 49-58. |

| 17 | SenouciA, ZaidiH, FreneJ, et al. Damage of surfaces in sliding electrical contact copper/steel[J]. Applied Surface Science, 1999, 144/145(98): 287-291. |

| 18 | 魏永辉, 张永振, 陈跃. 磁场干涉对不同磁属性材料干摩擦学特性的影响[J].机械工程学报, 2012, (12): 102-109. |

| WeiY H, ZhangZ Y, ChenY. Influence of magnetic field interfering on dry-sliding tribological characteristics of materials with different magnetic properties [J]. Journal of Mechanical Engineering, 2012, (12): 102-109. | |

| 19 | 张敏, 凤仪. 电流对碳纳米管-银-石墨复合材料摩擦磨损性能的影响[J]. 摩擦学学报, 2005, 25(4): 328-332. |

| ZhangM, FengY. Effect of electric current on the friction and wear behavior of carbon nanotubes-silver-graphite composite[J].Tribology, 2005, 25(4): 328-332. | |

| 20 | JiangZ Q, FangJ H, ChenB S, et al. Effect of magnetic field on tribological properties of lubricating oils with and without tricresyl phosphate[J]. China Petroleum Processing & Petrochemical Technology, 2016, 18(3): 119-124. |

| 21 | JiangZ Q, FangJ H, ChenB S, et al. Improvement of magnetic field on tribological properties of lubricating oils with zinc butyloctyl dithiophosphate[J]. China Petroleum Processing & Petrochemical Technology, 2016, 18(4): 92-98. |

| 22 | 石琛, 毛大恒, 毛向辉. 纳米二硫化钨颗粒的分散稳定性[J]. 中南大学学报(自然科学版), 2010, 41(2): 476-482. |

| ShiC, MaoD H, MaoX H. Dispersion stability of nano-tungsten disulfide particulates[J]. Journal of Central South University(Science and Technology), 2010, 41(2): 476-482. | |

| 23 | 陈汉林, 陈国需, 杜鹏飞, 等. 二硫化钨纳米粉体作为锂基润滑脂添加剂的摩擦学研究[J]. 摩擦学学报, 2015, 35(6): 651-657. |

| ChenH L, ChenG X, DuP F, et al. Tribology of nano-tungsten disulfide powder as an lubricating additive for lithium grease[J]. Tribology, 2015, 35(6): 651-657. | |

| 24 | ZhangR C, QaioD, LiuX Q, et al. A facile and effective method to improve the dispersibility of WS2 nanosheets in PAO8 for the tribological performances[J]. Tribology International, 2018, 118: 60-70. |

| 25 | 解挺, 闫照明, 杨婷婷, 等. 外加磁场对摩擦副摩擦学性能影响的研究进展[J]. 合肥工业大学学报(自然科学版), 2012, 35(12): 1601-1604. |

| XieT, YanZ M, YangT T, et al. Study progress of the effect of external magnetic field on tribological properties of friction pair[J]. Journal of Hefei University of Technology(Natural Science), 2012, 35(12): 1601-1604. | |

| 26 | WeiY H, ZhangY Z, ChenY, et al. Impact of material permeability on friction and wear properties under the interference of DC steady magnetic field[J]. Tribology International, 2013, 57(4): 162-169. |

| 27 | XieG X, GuoD, LuoJ B. Lubrication under charged conditions[J]. Tribology International, 2015, 84: 22-35. |

| 28 | 杨钊龙. 若干非铁磁材料的低维磁特性研究[D]. 兰州: 兰州大学, 2016. |

| YangZ L. Low-dimensional magnetic characteristics of several non-ferromagnetic materials[D]. Lanzhou: Lanzhou University, 2016. | |

| 29 | HuoN J, LiY, KangJ, et al. Edge-states ferromagnetism of WS2 nanosheets[J]. Applied Physics Letters, 2014, 104(20): 2831-2836. |

| 30 | YangZ L, GaoD Q, ZhangJ, et al. Realization of high Curie temperature ferromagnetism in atomically thin MoS2 and WS2 nanosheets with uniform and flower-like morphology[J]. Nanoscale, 2014, 7(2): 650-658. |

| 31 | LiH P, LiuS, HuangS L, et al. Impurity-induced ferromagnetism and metallicity of WS2 monolayer[J]. Ceramics International, 2015, 42(2): 2364-2369. |

| [1] | 仪显亨, 周骛, 蔡小舒, 蔡天意. 光纤后向动态光散射测量纳米颗粒的浓度适用范围研究[J]. 化工学报, 2023, 74(8): 3320-3328. |

| [2] | 王志龙, 杨烨, 赵真真, 田涛, 赵桐, 崔亚辉. 搅拌时间和混合顺序对锂离子电池正极浆料分散特性的影响[J]. 化工学报, 2023, 74(7): 3127-3138. |

| [3] | 李勇, 高佳琦, 杜超, 赵亚丽, 李伯琼, 申倩倩, 贾虎生, 薛晋波. Ni@C@TiO2核壳双重异质结的构筑及光热催化分解水产氢[J]. 化工学报, 2023, 74(6): 2458-2467. |

| [4] | 黄心童, 耿宇昊, 刘恒源, 陈卓, 徐建鸿. 微流控制备新型功能纳米粒子研究进展[J]. 化工学报, 2023, 74(1): 355-364. |

| [5] | 曲国娟, 江涛, 刘涛, 马骧. 超分子策略调控金纳米团簇的发光行为[J]. 化工学报, 2023, 74(1): 397-407. |

| [6] | 张炜, 李昊阳, 徐纯刚, 李小森. 气体水合物生成微观机理及分析方法研究进展[J]. 化工学报, 2022, 73(9): 3815-3827. |

| [7] | 张鑫, 许蕊, 路馨语, 牛永安. SiO2@BiOCl-Bi24O31Cl10核壳微球的合成及光催化[J]. 化工学报, 2022, 73(8): 3636-3646. |

| [8] | 王江丽, 薛敏, 赵承科, 岳凤霞. 木质素分级对其应用性能的影响[J]. 化工学报, 2022, 73(5): 1894-1907. |

| [9] | 宋伟, 李万佳, 俞树荣, 马荣荣. 热力耦合下TC4合金微动磨损行为影响的研究[J]. 化工学报, 2022, 73(3): 1324-1334. |

| [10] | 张苗, 杨洪海, 尹勇, 徐悦, 沈俊杰, 卢心诚, 施伟刚, 王军. 氧化石墨烯/水脉动热管的启动及传热特性[J]. 化工学报, 2022, 73(3): 1136-1146. |

| [11] | 周楠, 王簪, 邵应娟, 钟文琪. 煤沥青球气固流化磨损特性实验研究[J]. 化工学报, 2022, 73(2): 587-594. |

| [12] | 李文祥, 王钧禾, 郝怡静, 周乐平. 淬火初温影响疏水表面沸腾传热特性的实验研究[J]. 化工学报, 2022, 73(12): 5394-5404. |

| [13] | 张志敏, 丁雪兴, 张兰霞, 力宁, 司佳鑫. 浮环密封端面分形磨损预估模型及数值分析[J]. 化工学报, 2022, 73(12): 5526-5536. |

| [14] | 胡慧慧, 杨亮, 刘道平, 张柯. 低剂量超吸水树脂溶液微滴中甲烷水合物生成动力学[J]. 化工学报, 2022, 73(10): 4659-4667. |

| [15] | 董晓锐, 王凯, 骆广生. 金纳米颗粒的微反应连续合成[J]. 化工学报, 2021, 72(7): 3823-3831. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号