化工学报 ›› 2022, Vol. 73 ›› Issue (2): 634-642.DOI: 10.11949/0438-1157.20211297

收稿日期:2021-09-07

修回日期:2021-11-09

出版日期:2022-02-05

发布日期:2022-02-18

通讯作者:

王兵兵

作者简介:王兵兵(1987—),男,博士,副教授,基金资助:

Bingbing WANG( ),Chao WANG,Zhiming XU

),Chao WANG,Zhiming XU

Received:2021-09-07

Revised:2021-11-09

Online:2022-02-05

Published:2022-02-18

Contact:

Bingbing WANG

摘要:

将一圆筒柱面电极布置在换热器入口管道处,并与高压电源正极连接,研究圆筒电极形成的非匀强电场对实验段换热表面CaCO3污垢沉积的影响。作为对比,同时分析了平行板电极(匀强电场)作用下CaCO3污垢沉积行为。结果表明,施加平行电极与圆筒电极均可抑制换热表面CaCO3污垢的沉积,抑垢率随施加电压(0~5000 V)的增加呈现先升高后降低的变化趋势。当施加平行电极时,最佳抑垢电压值为1000 V,最佳抑垢率为 73.27%。当施加圆筒电极时,最佳抑垢电压为500 V,最佳抑垢率为83%。因此,施加圆筒电极具有更好的抑垢效果,同时最佳抑垢电压更低,可降低电的消耗。此外,在无电场作用时,换热表面CaCO3晶体主要为树枝状文石结构,当施加圆筒或平行电极时,CaCO3晶体主要为块状方解石结构。

中图分类号:

王兵兵, 王超, 徐志明. 圆筒电极抑制换热表面CaCO3污垢沉积特性研究[J]. 化工学报, 2022, 73(2): 634-642.

Bingbing WANG, Chao WANG, Zhiming XU. Characteristics of CaCO3 fouling deposition on heat exchange surface under the action of cylinder electrode[J]. CIESC Journal, 2022, 73(2): 634-642.

| 参数 | 最大相对误差 |

|---|---|

| 流量 | ±0.48% |

| 温度 | ±0.58% |

| 直流电压 | ±0.50% |

| 直流电流 | ±0.50% |

| 线路电阻 | ±0.05% |

表1 相关参数误差

Table 1 Maximum relative error for parameters

| 参数 | 最大相对误差 |

|---|---|

| 流量 | ±0.48% |

| 温度 | ±0.58% |

| 直流电压 | ±0.50% |

| 直流电流 | ±0.50% |

| 线路电阻 | ±0.05% |

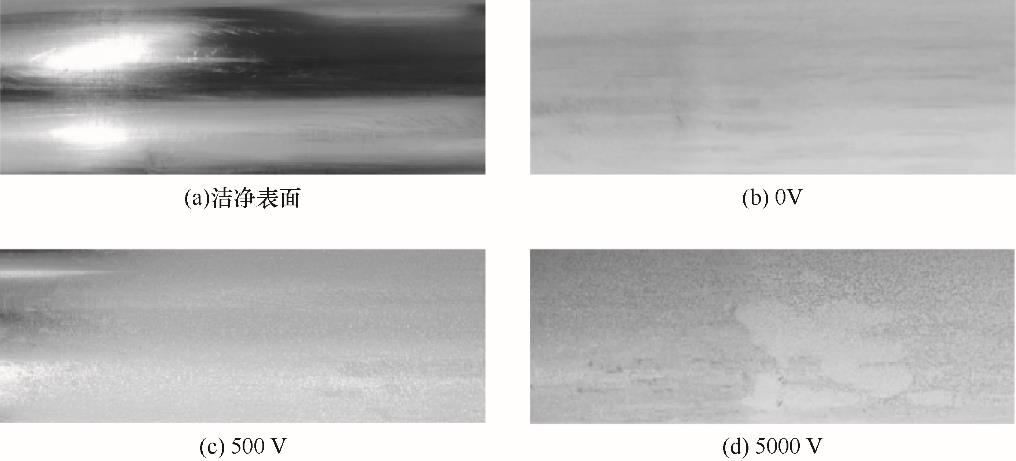

图6 圆筒电极不同施加电压时换热表面上CaCO3污垢层宏观形貌

Fig.6 Macroscopic morphology of CaCO3 fouling layer on heat transfer surface under various voltages of the cylinder electrode

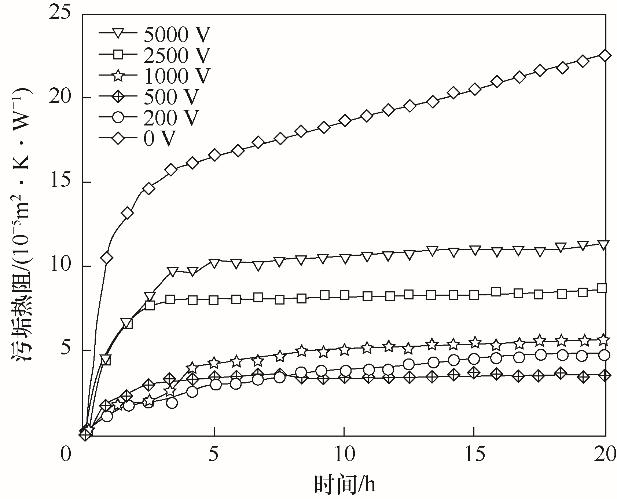

图7 圆筒电极施加不同电压时换热表面上CaCO3污垢热阻变化曲线

Fig.7 Curves of CaCO3 fouling thermal resistance on heat exchange surface under various voltages of the cylinder electrode

| 1 | 陈永东, 陈学东. 我国大型换热器的技术进展[J]. 机械工程学报, 2013, 49(10): 134-143. |

| Chen Y D, Chen X D. Technology development of large-scale heat exchanger in China[J]. Journal of Mechanical Engineering, 2013, 49(10): 134-143. | |

| 2 | Zhao J D, Liu Z A, Zhao E J. Combined effect of constant high voltage electrostatic field and variable frequency pulsed electromagnetic field on the morphology of calcium carbonate scale in circulating cooling water systems[J]. Water Science and Technology, 2014, 70(6): 1074-1082. |

| 3 | 安慧凤. 高压静电场影响循环冷却水CaCO3结晶行为及动力学研究[D]. 呼和浩特: 内蒙古工业大学, 2015. |

| An H F. Effect of the high-voltage electrostatic field on crystallization behavior of CaCO3 and dynamics study about circulating cooling water[D]. Hohhot: Inner Mongolia University of Tehchnology, 2015. | |

| 4 | Boumagoura M, Ghizellaoui S, Rhouati S, et al. Calcium carbonate scaling prevention by a green chemical inhibitor, Gallic acid[J]. Water and Environment Journal, 2021, 35(3): 998-1006. |

| 5 | 赵宇. 羧甲基纤维素钠阻垢特性的研究[D]. 吉林: 东北电力大学, 2020. |

| Zhao Y. Investigation on the fouling inhibition characteristics of sodium carboxymethyl cellulose[D]. Jilin: Northeast Dianli University, 2020. | |

| 6 | Xu Z M, Zhao Y, He J J, et al. Fouling characterization of calcium carbonate on heat transfer surfaces with sodium carboxymethyl cellulose as an inhibitor[J]. International Journal of Thermal Sciences, 2021, 162: 106790. |

| 7 | 窦照英. 磁场电场的防垢技术[J]. 环境保护, 1994, 22(4): 12-14. |

| Dou Z Y. Anti-fouling technology of magnetic field and electric field [J]. Environmental Protection, 1994, 22(4): 12-14. | |

| 8 | 周柏青, 胡梦莎. 工业循环冷却水系统降耗减排综述[J]. 工业水处理, 2017, 37(3): 16-20. |

| Zhou B Q, Hu M S. Review on the consumption lowering and emission reduction of industrial circulating cooling water systems[J]. Industrial Water Treatment, 2017, 37(3): 16-20. | |

| 9 | 曾祥松. 汽轮机凝汽器超声波在线除垢技术应用[J]. 冶金动力, 2019, 38(8): 47-50. |

| Zeng X S. Application of ultrasonic online descaling technology for steam turbine condenser[J]. Metallurgical Power, 2019, 38(8): 47-50. | |

| 10 | 丘泰球, 刘石生, 黄运贤, 等. 物理场防除积垢节能技术[J]. 物理, 2002, 31(3): 162-166. |

| Qiu T Q, Liu S S, Huang Y X, et al. A technique to save energy in scale control by physical fields[J]. Physics, 2002, 31(3): 162-166. | |

| 11 | Alimbekova S R, Bakhtizin R N, Dokichev V A. Electromagnetic prevention of scaling in oil production[J]. IOP Conference Series: Earth and Environmental Science, 2020, 459: 052054. |

| 12 | 徐志明, 常宏亮, 王兵兵, 等. 电场作用下CaCO3污垢特性的实验研究[J]. 中国电机工程学报, 2018, 38(21): 6346-6352, 6496. |

| Xu Z M, Chang H L, Wang B B, et al. Experimental study on CaCO3 fouling characteristics under electric field[J]. Proceedings of the CSEE, 2018, 38(21): 6346-6352, 6496. | |

| 13 | Xu J, Zhao J D, Jia Y, et al. Effect of fouling resistance in heat exchanger and the crystal form of CaCO3 in hard circulating cooling water with electrostatic field and alternating current electric field[J]. Water Science and Technology, 2021, 84(7): 1608-1622. |

| 14 | Geng S H, Chen Y C, Zhao Y, et al. Experimental study on antifouling performance of ultrasonic/electronic compound treatment in heat transfer[J]. Experimental Heat Transfer, 2021, 34(7): 605-619. |

| 15 | 王建国, 李雨通, 邓丽娟. 缠绕式变频电磁水处理器电磁频率对抑垢效果的影响[J]. 化工学报, 2015, 66(3): 972-978. |

| Wang J G, Li Y T, Deng L J. Influence of electromagnetic frequency on scale inhibition for spiral winding variable frequency electromagnetic water processor[J]. CIESC Journal, 2015, 66(3): 972-978. | |

| 16 | Wang J G, Liang Y D. Anti-fouling effect of axial alternating electromagnetic field on calcium carbonate fouling in U-shaped circulating cooling water heat exchange tube[J]. International Journal of Heat and Mass Transfer, 2017, 115: 774-781. |

| 17 | 张一龙, 周满满, 曲宸熙, 等. 电磁场抑制换热面析晶污垢的形成[J]. 农业工程学报, 2020, 36(8): 206-211. |

| Zhang Y L, Zhou M M, Qu C X, et al. Inhibition of the formation of crystallization fouling on heat transfer surface by electromagnetic field[J]. Transactions of the Chinese Society of Agricultural Engineering, 2020, 36(8): 206-211. | |

| 18 | Kim J O, Choi S P, Yoon H, et al. Fouling and scaling reduction by pulsed electric field treatment as pretreatment for desalination[J]. Desalination and Water Treatment, 2012, 43(1/2/3): 118-123. |

| 19 | Tijing L D, Lee D H, Kim D W, et al. Effect of high-frequency electric fields on calcium carbonate scaling[J]. Desalination, 2011, 279(1/2/3): 47-53. |

| 20 | 常宏亮. 电场作用下CaCO3污垢特性的实验研究[D]. 吉林: 东北电力大学, 2018. |

| Chang H L. Experimental study on CaCO3 fouling characteristics under electric field[D]. Jilin: Northeast Dianli University, 2018. | |

| 21 | 王大放. 用分子动力学方法模拟高压电场对碳酸钙结晶过程的影响[D]. 青岛: 中国石油大学, 2010. |

| Wang D F. Molecular dynamics simulation on the impact of high voltage electrostatic field on crystallization of calcium carbonate aqueous solution[D]. Qingdao: China University of Petroleum, 2010. | |

| 22 | 田裕鑫. 静电场对碳酸钙溶液结晶影响的分子动力学研究[D]. 青岛: 中国石油大学, 2008. |

| Tian Y X. Molecular dynamics study on the impact of electrostatic field on crystallization of calcium carbonate liquor[D]. Qingdao: China University of Petroleum, 2008. | |

| 23 | 赵亮. 外部条件对碳酸钙析晶污垢影响实验研究[D]. 济南: 山东大学, 2010. |

| Zhao L. Experimental study of the external conditions on crystallization of calcium carbonate fouling[D]. Jinan: Shandong University, 2010. | |

| 24 | Kline S, McClintock F. Describing uncertainties in single-sample experiments[J]. Mechanical Engineering, 1953, 75: 3-8. |

| 25 | 王佩琼. 高频电磁场防垢技术在循环水中的应用机理初探[J]. 电力建设, 2001, 22(9): 43-45, 48. |

| Wang P Q. Primary inquire into application mechanism of high-frequency electromagnetic field anti-scaling technique in circulating water system[J]. Electric Power Construction, 2001, 22(9): 43-45, 48. | |

| 26 | 张瑜. 电场对CaCO3与CaSO4污垢热阻影响规律研究[D]. 吉林: 东北电力大学, 2019. |

| Zhang Y. Study on the influence of thermal resistance of CaCO3 and CaSO4 fouling under the action of electric field[D]. Jilin: Northeast Dianli University, 2019. | |

| 27 | 廖立兵, 夏志国. 晶体化学及晶体物理学[M]. 2版. 北京: 科学出版社, 2013. |

| Liao L B, Xia Z G. Crystal Chemistry and Crystal Physics [M]. 2nd ed. Beijing: Science Press, 2013. | |

| 28 | 曹昌年. 水系统探究[J]. 自然杂志, 1998, 20(2): 69-71. |

| Cao C N. Water system research[J]. Nature Magazine, 1998, 20(2): 69-71. | |

| 29 | 邢晓凯, 荆冬锋. CaCO3结垢过程控制机理分析[J]. 热能动力工程, 2007, 22(3): 336-339, 350. |

| Xing X K, Jing D F. An analysis of the mechanism governing the control of CaCO3 scale formation process[J]. Journal of Engineering for Thermal Energy and Power, 2007, 22(3): 336-339, 350. | |

| 30 | 王春明, 全贞花, 陈永昌, 等. 高压静电场抗垢性能的实验研究[J]. 工程热物理学报, 2007, 28(6): 1028-1030. |

| Wang C M, Quan Z H, Chen Y C, et al. Experimental study of anti-fouling capability of the high-voltage electrostatic field[J]. Journal of Engineering Thermophysics, 2007, 28(6): 1028-1030. |

| [1] | 晁京伟, 许嘉兴, 李廷贤. 基于无管束蒸发换热强化策略的吸附热池的供热性能研究[J]. 化工学报, 2023, 74(S1): 302-310. |

| [2] | 何洋, 高森虎, 吴青云, 张明理, 龙涛, 牛佩, 高景辉, 孟颖琪. 析湿工况下平直开缝翅片传热传质特性的数值研究[J]. 化工学报, 2023, 74(3): 1073-1081. |

| [3] | 张舒蕾, 李冰杰, 蒋健, 董新宇, 刘璐. 凸面恒温基底上固着液滴蒸发特性研究[J]. 化工学报, 2022, 73(12): 5537-5546. |

| [4] | 刘坐东, 李斯琪, 邢维维, 徐志明. 板式换热器Ni-P-TiO2复合纳米镀层微生物污垢特性[J]. 化工学报, 2020, 71(8): 3535-3544. |

| [5] | 彭冬根, 徐少华. 蒸发冷却条件下管内LiCl和CaCl2溶液降膜除湿性能对比[J]. 化工学报, 2020, 71(4): 1554-1561. |

| [6] | 张毅,张冠敏,冷学礼,屈晓航,田茂诚. 无霜空气源热泵技术研究进展[J]. 化工学报, 2020, 71(12): 5400-5419. |

| [7] | 丛健,高蓬辉,张东海,周晋鹏,张正函. 超声波对液滴冻结状态及传热的影响[J]. 化工学报, 2020, 71(11): 5117-5128. |

| [8] | 李钰冰, 杨茉, 陆廷康, 戴正华. 具有质热源的方腔内对流传热传质及其非线性特性[J]. 化工学报, 2019, 70(S2): 130-137. |

| [9] | 何洋, 王利民, 唐春丽, 车得福. H型翅片管湿烟气对流冷凝传热的数值模拟研究[J]. 化工学报, 2019, 70(12): 4556-4564. |

| [10] | 牛利娇, 王维, 潘思麒, 张大为, 陈国华. 具有预制孔隙多孔介质冷冻干燥的多相传递模型[J]. 化工学报, 2017, 68(5): 1833-1844. |

| [11] | 张斌, 周孑民, 李茂. 双层配碳烧结过程的传热传质分析[J]. 化工学报, 2017, 68(5): 1811-1822. |

| [12] | 李美军, 路源, 张士杰, 肖云汉. 水平管降膜吸收局部传热传质特性的数值模拟[J]. 化工学报, 2017, 68(4): 1364-1372. |

| [13] | 涂耀东, 葛天舒, 王如竹. 吸附除湿换热:弱关联热质耦合传递过程[J]. 化工学报, 2016, 67(S1): 97-102. |

| [14] | 蔡骥驰, 王瑞祥, 徐荣吉, 张一灏, 丁思源. SDBS对铜-水脉动热管启动及传热性能影响[J]. 化工学报, 2016, 67(5): 1852-1857. |

| [15] | 陈捷超, 李友荣, 于佳佳. 毛细力比为-1时环形液池内双扩散毛细对流数值模拟[J]. 化工学报, 2015, 66(S1): 138-145. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号