化工学报 ›› 2024, Vol. 75 ›› Issue (4): 1370-1381.DOI: 10.11949/0438-1157.20231381

收稿日期:2023-12-27

修回日期:2024-01-31

出版日期:2024-04-25

发布日期:2024-06-06

通讯作者:

刘大欢

作者简介:文一如(1999—),女,硕士研究生,18810335112@163.com

Yiru WEN1( ), Jia FU1, Dahuan LIU1,2(

), Jia FU1, Dahuan LIU1,2( )

)

Received:2023-12-27

Revised:2024-01-31

Online:2024-04-25

Published:2024-06-06

Contact:

Dahuan LIU

摘要:

金属有机框架(MOFs)由于其高孔隙率和超高的比表面积在气体吸附和分离领域受到广泛关注,金属有机框架数据库也因此丰富。使用高通量计算筛选方法可以提供丰富的结构性质和性能数据,有利于从大量的金属有机框架材料中筛选具有高性能的材料。为了充分挖掘数据内的信息,将机器学习用作辅助工具,可以揭示隐含的金属有机框架结构和性能关系;能够对金属有机框架材料在不同应用中的性能趋势有更多的理解。特别是在气体储存和分离方面,机器学习方法也被广泛应用。从适用于机器学习工作的金属有机框架的描述符,利用机器学习方法筛选及预测材料性质等方面综述了机器学习预测和设计应用于可燃气体吸附分离的金属有机框架材料的最新研究进展,加快金属有机框架的设计和开发步伐,指引材料的合成方向和规律,降低了人力物力成本。

中图分类号:

文一如, 付佳, 刘大欢. 基于机器学习的MOFs材料研究进展:能源气体吸附分离[J]. 化工学报, 2024, 75(4): 1370-1381.

Yiru WEN, Jia FU, Dahuan LIU. Advances in machine learning-based materials research for MOFs: energy gas adsorption separation[J]. CIESC Journal, 2024, 75(4): 1370-1381.

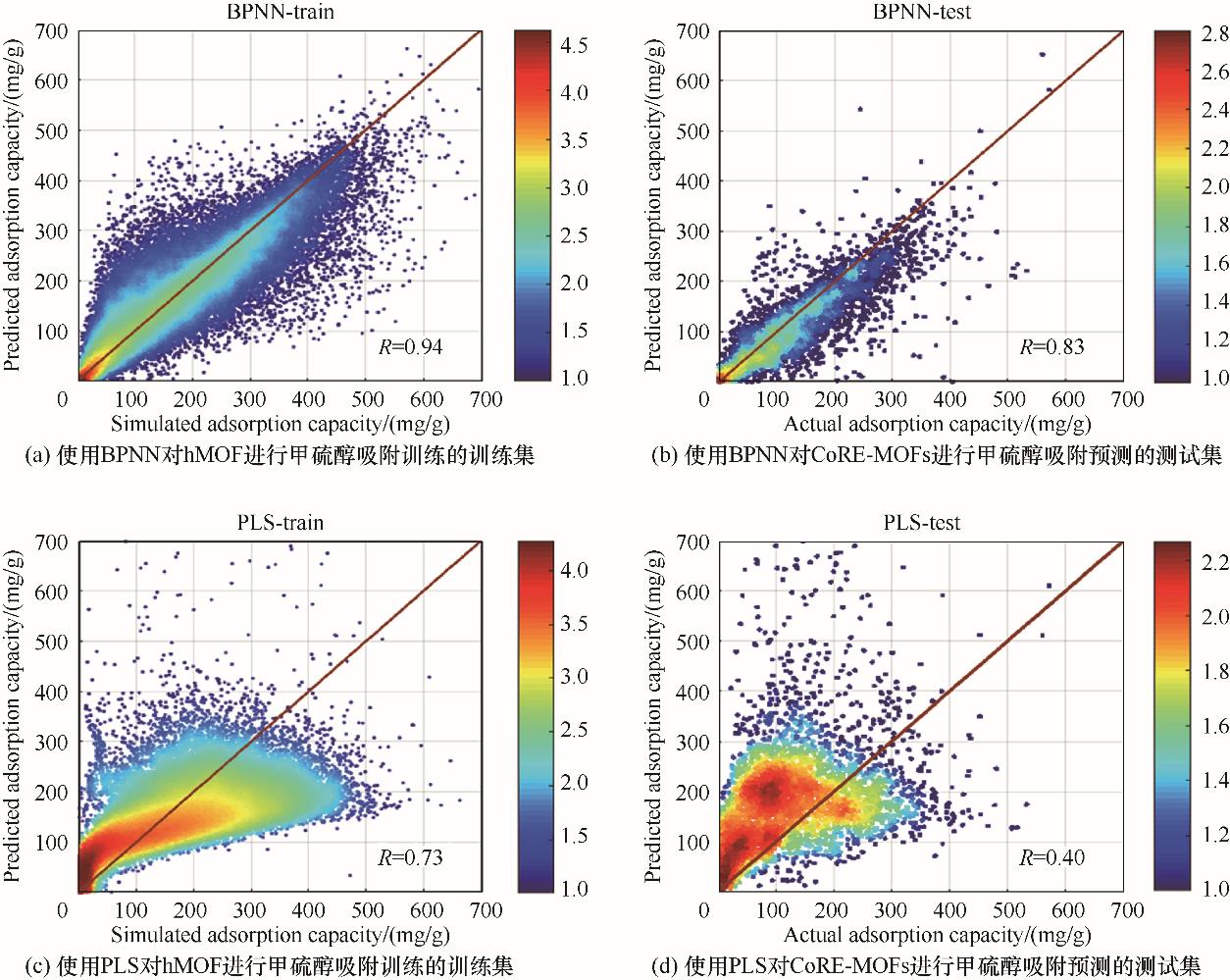

图2 等量描述符的两种机器学习模型对甲硫醇的吸附容量的预测情况对比[49](点的颜色表示MOFs数的密度等值线,密度标度的单位是MOFs数的以10为底的对数)

Fig.2 Comparison of the prediction of adsorption capacity of CH3SH by two machine learning models using the identical descriptor[49]

| 1 | 刘增欣, 王依军, 郝春莲, 等. Zn/Cu单晶转换MOF材料的CO2/CH4分离性能研究[J]. 化工学报, 2021, 72(S1): 546-553. |

| Liu Z X, Wang Y J, Hao C L, et al. Metal-organic frameworks: metathesis of zinc(Ⅱ) with copper(Ⅱ) for efficient CO2/CH4 separation[J]. CIESC Journal, 2021, 72(S1): 546-553. | |

| 2 | 裴仁花, 王永洪, 张新儒, 等. 碳纳米管/环糊精金属有机骨架协同强化混合基质膜的CO2分离[J]. 化工学报, 2022, 73(9): 3904-3914. |

| Pei R H, Wang Y H, Zhang X R, et al. Synergistic of carbon nanotube/cyclodextrin metal organic framework for enhancing CO2 separation of mixed matrix membranes[J]. CIESC Journal, 2022, 73(9): 3904-3914. | |

| 3 | 张后虎, 吴晓莉, 陈冲冲, 等. CD-MOF二维层状膜制备及混合溶剂精准分离研究[J]. 化工学报, 2022, 73(10): 4539-4550. |

| Zhang H H, Wu X L, Chen C C, et al. Preparation of 2D lamellar CD-MOF membranes for accurate separation of mixed solvents[J]. CIESC Journal, 2022, 73(10): 4539-4550. | |

| 4 | 王毅, 熊启钊, 陈杨, 等. 锆基金属有机骨架材料用于氨吸附性能的研究[J]. 化工学报, 2022, 73(4): 1772-1780. |

| Wang Y, Xiong Q Z, Chen Y, et al. Research on Zr-based metal-organic frameworks for NH3 adsorption[J]. CIESC Journal, 2022, 73(4): 1772-1780. | |

| 5 | 席国君, 刘子涵, 雷广平. FeTPPs-CuBTC协同强化低浓度煤层气吸附分离[J]. 化工学报, 2022, 73(9): 3940-3949. |

| Xi G J, Liu Z H, Lei G P. Enhanced adsorption and separation of low concentration coalbed methane based on synergistic effect between FeTPPs and CuBTC[J]. CIESC Journal, 2022, 73(9): 3940-3949. | |

| 6 | 张鑫琦, 张宸, 张舵咏, 等. 高选择性PEI@ MOF-808吸附剂在潮湿烟气中的碳捕集性能研究[J]. 化工学报, 2023, 74(10): 4330-4342. |

| Zhang X Q, Zhang C, Zhang D Y, et al. Study on the carbon capture performance of highly selective PEI@MOF-808 adsorbent in humid flue gas[J]. CIESC Journal, 2023, 74(10): 4330-4342. | |

| 7 | 王磊, 蒋勇, 钟达忠, 等. 碳化的MOF用于电催化还原二氧化碳制备乙烯和乙醇[J]. 化工学报, 2022, 73(8): 3576-3585. |

| Wang L, Jiang Y, Zhong D Z, et al. Carbonized metal-organic framework for carbon dioxide reduction to ethylene and ethanol[J]. CIESC Journal, 2022, 73(8): 3576-3585. | |

| 8 | Bernini M C, Fairen-Jimenez D, Pasinetti M, et al. Screening of bio-compatible metal-organic frameworks as potential drug carriers using Monte Carlo simulations[J]. Journal of Materials Chemistry. B, 2014, 2(7): 766-774. |

| 9 | Campbell M G, Liu S F, Swager T M, et al. Chemiresistive sensor arrays from conductive 2D metal-organic frameworks[J]. Journal of the American Chemical Society, 2015, 137(43): 13780-13783. |

| 10 | 王玉杰, 李申辉, 赵之平. M-MOF-74吸附分离H2/He混合物的分子模拟研究[J]. 化工学报, 2022, 73(10): 4507-4517. |

| Wang Y J, Li S H, Zhao Z P. Molecular simulation study on adsorption and separation of H2/He mixtures by M-MOF-74[J]. CIESC Journal, 2022, 73(10): 4507-4517. | |

| 11 | 叶诗洋, 程敏, 吉旭, 等. 高性能COF材料的高通量筛选策略: 己烷异构体分离[J]. 化工学报, 2022, 73(11): 5138-5149. |

| Ye S Y, Cheng M, Ji X, et al. High-throughput computational screening strategy for high-performance COF materials: separation of hexane isomers[J]. CIESC Journal, 2022, 73(11): 5138-5149. | |

| 12 | Yan Y L, Shi Z N, Li H L, et al. Machine learning and in-silico screening of metal-organic frameworks for O2/N2 dynamic adsorption and separation[J]. Chemical Engineering Journal, 2022, 427: 131604. |

| 13 | Hu J B, Suo X, Yang L F, et al. High-throughput computation evaluation of metal-organic frameworks for efficient perfluorocarbons recovery[J]. The Journal of Physical Chemistry C, 2024, 128(2): 941-948. |

| 14 | Gulbalkan H C, Uzun A, Keskin S. Evaluating CH4/N2 separation performances of hundreds of thousands of real and hypothetical MOFs by harnessing molecular modeling and machine learning[J]. ACS Applied Materials & Interfaces, 2024, 128(2): 941-948. |

| 15 | Shi Z N, Yang W Y, Deng X M, et al. Machine-learning-assisted high-throughput computational screening of high performance metal-organic frameworks[J]. Molecular Systems Design & Engineering, 2020, 5(4): 725-742. |

| 16 | Yan Y L, Zhang L L, Li S H, et al. Adsorption behavior of metal-organic frameworks: from single simulation, high-throughput computational screening to machine learning[J]. Computational Materials Science, 2021, 193: 110383. |

| 17 | Boyd P G, Chidambaram A, García-Díez E, et al. Data-driven design of metal-organic frameworks for wet flue gas CO2 capture[J]. Nature, 2019, 576: 253-256. |

| 18 | Chong S, Lee S, Kim B, et al. Applications of machine learning in metal-organic frameworks[J]. Coordination Chemistry Reviews, 2020, 423: 213487. |

| 19 | Fanourgakis G S, Gkagkas K, Tylianakis E, et al. A universal machine learning algorithm for large-scale screening of materials[J]. Journal of the American Chemical Society, 2020, 142(8): 3814-3822. |

| 20 | Moghadam P Z, Rogge S M J, Li A, et al. Structure-mechanical stability relations of metal-organic frameworks via machine learning[J]. Matter, 2019, 1(1): 219-234. |

| 21 | Zhang L L, Huang Q H, Li L F, et al. Automatic machine learning combined with high-throughput computational screening of hydrophobic metal-organic frameworks for capture of methanol and ethanol from the air[J]. ACS ES&T Engineering, 2024, 4(1): 115-127. |

| 22 | Tsamardinos I, Fanourgakis G S, Greasidou E, et al. An automated machine learning architecture for the accelerated prediction of metal-organic frameworks performance in energy and environmental applications[J]. Microporous and Mesoporous Materials, 2020, 300: 110160. |

| 23 | Fernandez M, Trefiak N R, Woo T K. Atomic property weighted radial distribution functions descriptors of metal-organic frameworks for the prediction of gas uptake capacity[J]. The Journal of Physical Chemistry C, 2013, 117(27): 14095-14105. |

| 24 | Jablonka K M, Ongari D, Moosavi S M, et al. Big-data science in porous materials: materials genomics and machine learning[J]. Chemical Reviews, 2020, 120(16): 8066-8129. |

| 25 | Altintas C, Altundal O F, Keskin S, et al. Machine learning meets with metal organic frameworks for gas storage and separation[J]. Journal of Chemical Information and Modeling, 2021, 61(5): 2131-2146. |

| 26 | Borboudakis G, Stergiannakos T, Frysali M, et al. Chemically intuited, large-scale screening of MOFs by machine learning techniques[J]. NPJ Computational Materials, 2017, 3: 40. |

| 27 | Alpaydin E. Introduction to Machine Learning[M]. MIT Press, 2020. |

| 28 | Gómez-Bombarelli R, Wei J N, Duvenaud D, et al. Automatic chemical design using a data-driven continuous representation of molecules[J]. ACS Central Science, 2018, 4(2): 268-276. |

| 29 | Ward L, Agrawal A, Choudhary A, et al. A general-purpose machine learning framework for predicting properties of inorganic materials[J]. NPJ Computational Materials, 2016, 2: 16028. |

| 30 | Butler K T, Frost J M, Skelton J M, et al. Computational materials design of crystalline solids[J]. Chemical Society Reviews, 2016, 45(22): 6138-6146. |

| 31 | Wang H S, Ji Y J, Li Y Y. Simulation and design of energy materials accelerated by machine learning[J]. WIREs Computational Molecular Science, 2020, 10(1): e1421. |

| 32 | Bénard P, Chahine R. Storage of hydrogen by physisorption on carbon and nanostructured materials[J]. Scripta Materialia, 2007, 56(10): 803-808. |

| 33 | Pardakhti M, Moharreri E, Wanik D, et al. Machine learning using combined structural and chemical descriptors for prediction of methane adsorption performance of metal organic frameworks (MOFs)[J]. ACS Combinatorial Science, 2017, 19(10): 640-645. |

| 34 | Bucior B J, Bobbitt N S, Islamoglu T, et al. Energy-based descriptors to rapidly predict hydrogen storage in metal-organic frameworks[J]. Molecular Systems Design & Engineering, 2019, 4(1): 162-174. |

| 35 | Yuan X Y, Li L F, Shi Z N, et al. Molecular-fingerprint machine-learning-assisted design and prediction for high-performance MOFs for capture of NMHCs from air[J]. Advanced Powder Materials, 2022, 1(3): 100026. |

| 36 | Lee Y J, Barthel S D, Dłotko P, et al. Quantifying similarity of pore-geometry in nanoporous materials[J]. Nature Communications, 2017, 8: 15396. |

| 37 | Shekhar S, Chowdhury C. Topological data analysis enhanced prediction of hydrogen storage in metal-organic frameworks (MOFs)[J]. Materials Advances, 2024, 5(2): 820-830. |

| 38 | Jordan M I, Mitchell T M. Machine learning: trends, perspectives, and prospects[J]. Science, 2015, 349(6245): 255-260. |

| 39 | Butler K T, Davies D W, Cartwright H, et al. Machine learning for molecular and materials science[J]. Nature, 2018, 559: 547-555. |

| 40 | 任嘉辉, 刘豫, 刘朝, 等. 基于分子指纹和拓扑指数的工质临界温度理论预测[J]. 化工学报, 2022, 73(4): 1493-1500. |

| Ren J H, Liu Y, Liu C, et al. Critical temperature prediction of working fluids using molecular fingerprints and topological indices[J]. CIESC Journal, 2022, 73(4): 1493-1500. | |

| 41 | Orhan I B, Daglar H, Keskin S, et al. Prediction of O2/N2 selectivity in metal-organic frameworks via high-throughput computational screening and machine learning[J]. ACS Applied Materials & Interfaces, 2022, 14(1): 736-749. |

| 42 | Moosavi S M, Chidambaram A, Talirz L, et al. Capturing chemical intuition in synthesis of metal-organic frameworks[J]. Nature Communications, 2019, 10: 539. |

| 43 | Yan T A, Bi Z Y, Liu D H, et al. A self-evolutionary methodology for reverse design of novel MOFs[J]. The Journal of Physical Chemistry. A, 2022, 126(45): 8476-8486. |

| 44 | de Luna P, Wei J, Bengio Y, et al. Use machine learning to find energy materials[J]. Nature, 2017, 552: 23-27. |

| 45 | Yang P S, Zhang H, Lai X, et al. Accelerating the selection of covalent organic frameworks with automated machine learning[J]. ACS Omega, 2021, 6(27): 17149-17161. |

| 46 | Gülsoy Z, Sezginel K B, Uzun A, et al. Analysis of CH4 uptake over metal-organic frameworks using data-mining tools[J]. ACS Combinatorial Science, 2019, 21(4): 257-268. |

| 47 | Wang Z H, Zhou Y G, Zhou T, et al. Identification of optimal metal-organic frameworks by machine learning: structure decomposition, feature integration, and predictive modeling[J]. Computers & Chemical Engineering, 2022, 160: 107739. |

| 48 | Fanourgakis G S, Gkagkas K, Tylianakis E, et al. Fast screening of large databases for top performing nanomaterials using a self-consistent, machine learning based approach[J]. The Journal of Physical Chemistry C, 2020, 124(36): 19639-19648. |

| 49 | Liang H, Yang W Y, Peng F, et al. Combining large-scale screening and machine learning to predict the metal-organic frameworks for organosulfurs removal from high-sour natural gas[J]. APL Materials, 2019, 7(9): 091101. |

| 50 | Luo Y, Bag S, Zaremba O, et al. MOF synthesis prediction enabled by automatic data mining and machine learning[J]. Angewandte Chemie (International Ed. in English), 2022, 61(19): e202200242. |

| 51 | Zheng Z L, Zhang O F, Nguyen H L, et al. ChatGPT research group for optimizing the crystallinity of MOFs and COFs[J]. ACS Central Science, 2023, 9(11): 2161-2170. |

| 52 | Moghadam P Z, Fairen-Jimenez D, Snurr R Q. Efficient identification of hydrophobic MOFs: application in the capture of toxic industrial chemicals[J]. Journal of Materials Chemistry A, 2016, 4(2): 529-536. |

| 53 | Deng F, Qin X Z, Chai K G, et al. Adsorption and removal of industrial dyes by water-stabilized aluminum-based metal-organic frameworks[J]. ACS Applied Nano Materials, 2023, 6(10): 8675-8684. |

| 54 | Batra R, Chen C, Evans T G, et al. Prediction of water stability of metal-organic frameworks using machine learning[J]. Nature Machine Intelligence, 2020, 2: 704-710. |

| 55 | Loughran Ryan P, Tara H, Andrzej G, et al. CO2 capture from wet flue gas using a water-stable and cost-effective metal-organic framework[J]. Cell Reports Physical Science, 2023, 4(7): 101470. |

| 56 | Burtch N C, Jasuja H, Walton K S. Water stability and adsorption in metal-organic frameworks[J]. Chemical Reviews, 2014, 114(20): 10575-10612. |

| 57 | Qadir N U, Said S A, Bahaidarah H M. Structural stability of metal organic frameworks in aqueous media—controlling factors and methods to improve hydrostability and hydrothermal cyclic stability[J]. Microporous and Mesoporous Materials, 2015, 201: 61-90. |

| 58 | Ge Z W, Feng S, Ma C C, et al. Quantifying and comparing the effects of key chemical descriptors on metal-organic frameworks water stability with CatBoost and SHAP[J]. Microchemical Journal, 2024, 196: 109625. |

| 59 | Tsamardinos I, Charonyktakis P, Papoutsoglou G, et al. Just Add Data: automated predictive modeling for knowledge discovery and feature selection[J]. NPJ Precision Oncology, 2022, 6: 38. |

| 60 | Xia W, Yang Y S, Sheng L Z, et al. Temperature-dependent molecular sieving of fluorinated propane/propylene mixtures by a flexible-robust metal-organic framework[J]. Science Advances, 2024, 10(3): eadj6473. |

| 61 | Xiong X H, Song L, Wang W, et al. Capture fluorocarbon and chlorofluorocarbon from air using DUT-67 for safety and semi-quantitative analysis[J]. Advanced Science, 2024: e2308123. |

| 62 | Xiong G Z, Zhang J, Lin B, et al. A stable paddle-wheel Co-MOF (FNU-2) for the efficient separation of light hydrocarbons[J]. Microporous and Mesoporous Materials, 2024, 366: 112970. |

| 63 | Zhao D, Yu K L, Han X, et al. Recent progress on porous MOFs for process-efficient hydrocarbon separation, luminescent sensing, and information encryption[J]. Chemical Communications, 2022, 58(6): 747-770. |

| 64 | Zhang L, Song L, Meng L L, et al. Anionic Ni-based metal-organic framework with Li(Ⅰ) cations in the pores for efficient C2H2/CO2 separation[J]. ACS Applied Materials & Interfaces, 2024, 16(1): 847-852. |

| 65 | Suyetin M. The application of machine learning for predicting the methane uptake and working capacity of MOFs[J]. Faraday Discussions, 2021, 231: 224-234. |

| 66 | Lee S, Kim B, Cho H, et al. Computational screening of trillions of metal-organic frameworks for high-performance methane storage[J]. ACS Applied Materials & Interfaces, 2021, 13(20): 23647-23654. |

| 67 | 赖欣, 卢罡, 王磊, 等. 基于ANN的新型MOFs性能预测[J]. 计算机系统应用, 2021, 30(9): 1-11. |

| Lai X, Lu G, Wang L, et al. ANN-based prediction about performance of novel MOFs[J]. Computer Systems & Applications, 2021, 30(9): 1-11. | |

| 68 | Glasby L T, Moghadam P Z. Hydrogen storage in MOFs: machine learning for finding a needle in a haystack[J]. Patterns, 2021, 2(7): 100305. |

| 69 | García-Holley P, Schweitzer B, Islamoglu T, et al. Benchmark study of hydrogen storage in metal-organic frameworks under temperature and pressure swing conditions[J]. ACS Energy Letters, 2018, 3(3): 748-754. |

| 70 | Zhang X, Lin R B, Wang J, et al. Optimization of the pore structures of MOFs for record high hydrogen volumetric working capacity[J]. Advanced Materials, 2020, 32(17): e1907995. |

| 71 | Ahmed A, Siegel D J. Predicting hydrogen storage in MOFs via machine learning[J]. Patterns, 2021, 2(7): 100291. |

| 72 | Goldsmith J, Wong-Foy A G, Cafarella M J, et al. Theoretical limits of hydrogen storage in metal-organic frameworks: opportunities and trade-offs[J]. Chemistry of Materials, 2013, 25(16): 3373-3382. |

| 73 | Ahmed A, Liu Y Y, Purewal J, et al. Balancing gravimetric and volumetric hydrogen density in MOFs[J]. Energy & Environmental Science, 2017, 10(11): 2459-2471. |

| 74 | Gómez-Gualdrón D A, Wang T C, García-Holley P, et al. Understanding volumetric and gravimetric hydrogen adsorption trade-off in metal-organic frameworks[J]. ACS Applied Materials & Interfaces, 2017, 9(39): 33419-33428. |

| 75 | Geurts P, Ernst D, Wehenkel L. Extremely randomized trees[J]. Machine Learning, 2006, 63(1): 3-42. |

| 76 | Shekhar S, Chowdhury C. Prediction of hydrogen storage in metal-organic frameworks: a neural network based approach[J]. Results in Surfaces and Interfaces, 2024, 14: 100166. |

| 77 | Zhang X, Zhang X, Johnson J A, et al. Highly porous zirconium metal-organic frameworks with β-UH3-like topology based on elongated tetrahedral linkers[J]. Journal of the American Chemical Society, 2016, 138(27): 8380-8383. |

| 78 | Wang T, Lin E, Peng Y L, et al. Rational design and synthesis of ultramicroporous metal-organic frameworks for gas separation[J]. Coordination Chemistry Reviews, 2020, 423: 213485. |

| 79 | Shi Y S, Xie Y, Cui H, et al. Highly selective adsorption of carbon dioxide over acetylene in an ultramicroporous metal-organic framework[J]. Advanced Materials, 2021, 33(45): e2105880. |

| 80 | 蔡铖智, 李丽凤, 邓小梅, 等. 基于机器学习和高通量计算筛选金属有机框架的甲烷/乙烷/丙烷分离性能[J]. 化学学报, 2020, 78(5): 427-436. |

| Cai C Z, Li L F, Deng X M, et al. Machine learning and high-throughput computational screening of metal-organic framework for separation of methane/ethane/propane[J]. Acta Chimica Sinica, 2020, 78(5): 427-436. | |

| 81 | Yang L F, Qian S H, Wang X B, et al. Energy-efficient separation alternatives: metal-organic frameworks and membranes for hydrocarbon separation[J]. Chemical Society Reviews, 2020, 49(15): 5359-5406. |

| 82 | Adil K, Belmabkhout Y, Pillai R S, et al. Gas/vapour separation using ultra-microporous metal-organic frameworks: insights into the structure/separation relationship[J]. Chemical Society Reviews, 2017, 46(11): 3402-3430. |

| 83 | Halder P, Singh J K. High-throughput screening of metal-organic frameworks for ethane-ethylene separation using the machine learning technique[J]. Energy & Fuels, 2020, 34(11): 14591-14597. |

| [1] | 莫滨宇, 张雅馨, 刘国振, 刘公平, 金万勤. 面向一/二价离子分离的金属有机骨架膜研究进展[J]. 化工学报, 2024, 75(4): 1183-1197. |

| [2] | 李添翼, 武玉泰, 王永胜, 顾佳锐, 宋沂恒, 杨丰铖, 郝广平. 轻同位素分离纯化与催化标记研究进展[J]. 化工学报, 2024, 75(4): 1284-1301. |

| [3] | 张凯博, 沈佳新, 李玉霞, 谈朋, 刘晓勤, 孙林兵. Y沸石中Cu(Ⅰ)的可控构筑及其乙烯/乙烷吸附分离性能研究[J]. 化工学报, 2024, 75(4): 1607-1615. |

| [4] | 孟园, 倪善, 刘亚锋, 王文杰, 赵越, 朱育丹, 杨良嵘. 功能化多孔氮化碳材料对铀的吸附性能研究[J]. 化工学报, 2024, 75(4): 1616-1629. |

| [5] | 张子佳, 仇昕月, 孙翔, 罗志斌, 罗海中, 贺高红, 阮雪华. 聚酰亚胺膜材料分子结构设计强化CO2渗透性研究进展[J]. 化工学报, 2024, 75(4): 1137-1152. |

| [6] | 刘东飞, 张帆, 刘铮, 卢滇楠. 机器学习势及其在分子模拟中的应用综述[J]. 化工学报, 2024, 75(4): 1241-1255. |

| [7] | 李俊, 赵亮, 高金森, 徐春明. 不同馏分油分级分质加工中萃取技术研究进展[J]. 化工学报, 2024, 75(4): 1065-1080. |

| [8] | 吕田田, 原敏, 王江, 高美珍, 杨佳辉, 徐红, 董晋湘, 石琪. ZTIF基疏水微介孔碳的制备及5-羟甲基糠醛吸附分离性能[J]. 化工学报, 2024, 75(4): 1642-1654. |

| [9] | 董霄, 白志山, 杨晓勇, 殷伟, 刘宁普, 于启凡. CHPPO工艺氧化液耦合除杂技术的研究与工业应用[J]. 化工学报, 2024, 75(4): 1630-1641. |

| [10] | 刘莹, 郑芳, 杨启炜, 张治国, 任其龙, 鲍宗必. 二甲苯异构体吸附分离研究进展[J]. 化工学报, 2024, 75(4): 1081-1095. |

| [11] | 曾玉娇, 肖炘, 杨刚, 张意博, 郑光明, 李防, 汪凤玲. 基于机理与数据混合驱动的湿法磷酸生产过程代理建模与优化[J]. 化工学报, 2024, 75(3): 936-944. |

| [12] | 陈宇翔, 刘传磊, 龚子君, 赵起越, 郭冠初, 姜豪, 孙辉, 沈本贤. 机器学习辅助乙硫醇高效吸收溶剂分子设计[J]. 化工学报, 2024, 75(3): 914-923. |

| [13] | 张天永, 张晶怡, 姜爽, 李彬, 吕东军, 陈都民, 陈雪. 弱酸性蓝AS染料排放的废盐制碳基吸附剂及利用[J]. 化工学报, 2024, 75(3): 890-899. |

| [14] | 李宁, 朱朋飞, 张立峰, 卢栋臣. 基于非凸与不可分离正则化算法的电容层析成像图像重建[J]. 化工学报, 2024, 75(3): 836-846. |

| [15] | 邢雷, 关帅, 蒋明虎, 赵立新, 蔡萌, 刘海龙, 陈德海. 高气液比井下气液旋流分离器结构设计与性能分析[J]. 化工学报, 2024, 75(3): 900-913. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号