化工学报 ›› 2024, Vol. 75 ›› Issue (11): 4095-4119.DOI: 10.11949/0438-1157.20240598

董正亚1,2,3( ), 朱晓晶1,3, 贾竞夫1,3, 张杰1,3, 郑卓韬1,3, 刘晓霖3, 武志林1,2

), 朱晓晶1,3, 贾竞夫1,3, 张杰1,3, 郑卓韬1,3, 刘晓霖3, 武志林1,2

收稿日期:2024-05-31

修回日期:2024-07-29

出版日期:2024-11-25

发布日期:2024-12-26

通讯作者:

董正亚

作者简介:董正亚(1987—),男,博士,教授,zhydong@stu.edu.cn

基金资助:

Zhengya DONG1,2,3( ), Xiaojing ZHU1,3, Jingfu JIA1,3, Jie ZHANG1,3, Zhuotao ZHENG1,3, Xiaolin LIU3, Zhilin WU1,2

), Xiaojing ZHU1,3, Jingfu JIA1,3, Jie ZHANG1,3, Zhuotao ZHENG1,3, Xiaolin LIU3, Zhilin WU1,2

Received:2024-05-31

Revised:2024-07-29

Online:2024-11-25

Published:2024-12-26

Contact:

Zhengya DONG

摘要:

将超声波与微反应器结合能解决常规微反应器易被固体颗粒堵塞、操作弹性欠佳、放大困难等问题,使超声微反应器(USMR)成为新一代微反应器技术,广泛应用于涉及固体堵塞和混合传质受限的反应过程,特别是纳米材料的合成。虽然目前有不少关于USMR的研究报道,但大多局限于实验室用的小型反应器,鲜有关于USMR放大的研究。系统地介绍了USMR系统的结构组成以及各组成部件之间的谐振匹配和放大策略。一般来说,USMR系统包括超声波电源、超声波换能器、微通道反应器、通道中的流体四部分,超声波能量由电源产生并经换能器、微通道传输到流体中。要保证该系统较高的能量传输效率,需要这四个部分对应的谐振频率保持一致、阻抗实现匹配。将USMR系统的放大分成超声波电源放大、反应器辐射面放大、微通道尺寸放大三个方面,系统阐述每个方面放大遇到的核心关键问题和解决思路。最后重点介绍了USMR在纳米材料合成领域的应用,并根据合成过程的机理将其分为反应成核生长控制、分子自组装控制、乳液及界面限域控制三种纳米材料合成类型。综合结果表明,USMR在控制纳米材料尺寸形貌均一性方面展现了巨大的优势。

中图分类号:

董正亚, 朱晓晶, 贾竞夫, 张杰, 郑卓韬, 刘晓霖, 武志林. 超声微反应器系统的放大及其在纳米材料制备中的应用[J]. 化工学报, 2024, 75(11): 4095-4119.

Zhengya DONG, Xiaojing ZHU, Jingfu JIA, Jie ZHANG, Zhuotao ZHENG, Xiaolin LIU, Zhilin WU. Scale-up of ultrasonic microreactor systems and their applications in the preparation of nanomaterials[J]. CIESC Journal, 2024, 75(11): 4095-4119.

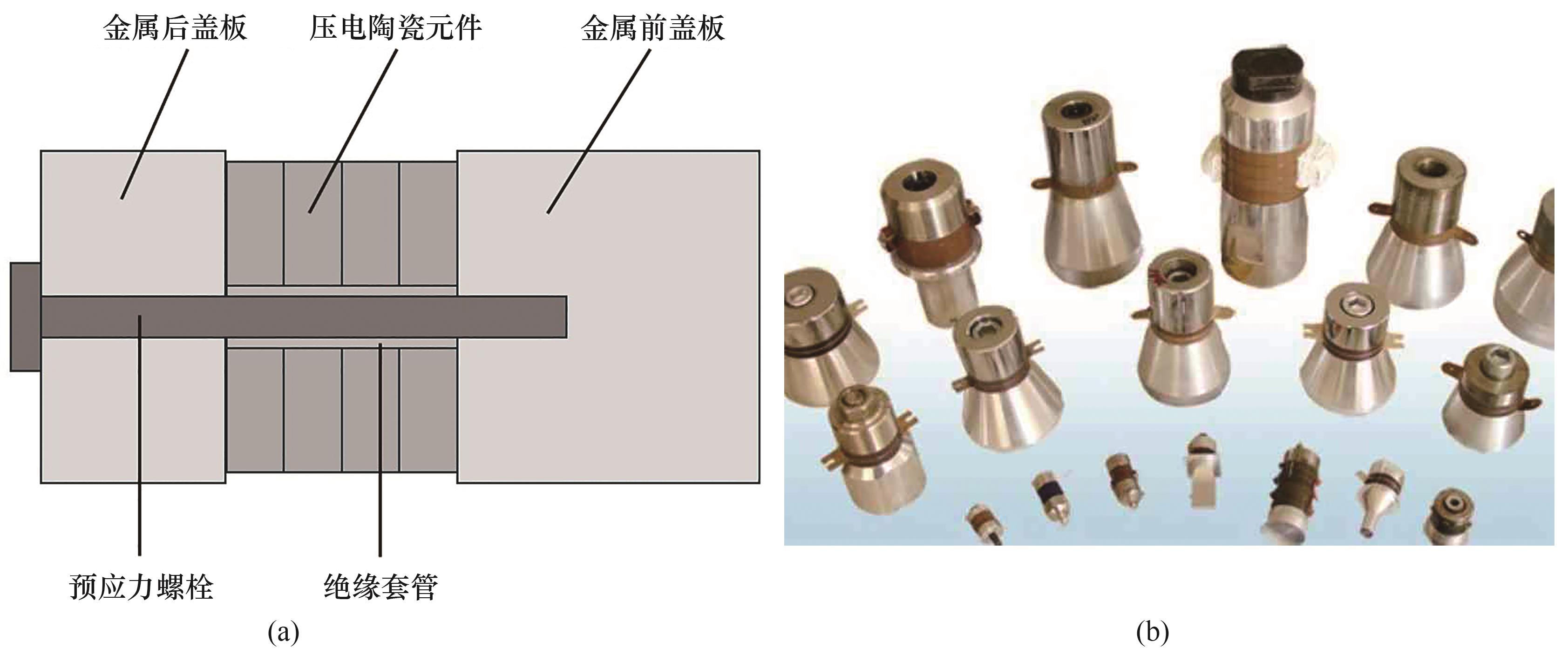

图2 (a)夹心式压电陶瓷超声换能器的结构示意图;(b)各种结构超声换能器的实物图[27]

Fig.2 (a) Schematic diagram of the structure of the sandwich piezoelectric ceramic ultrasonic transducer; (b) Physical diagram of the ultrasonic transducer of various structures[27]

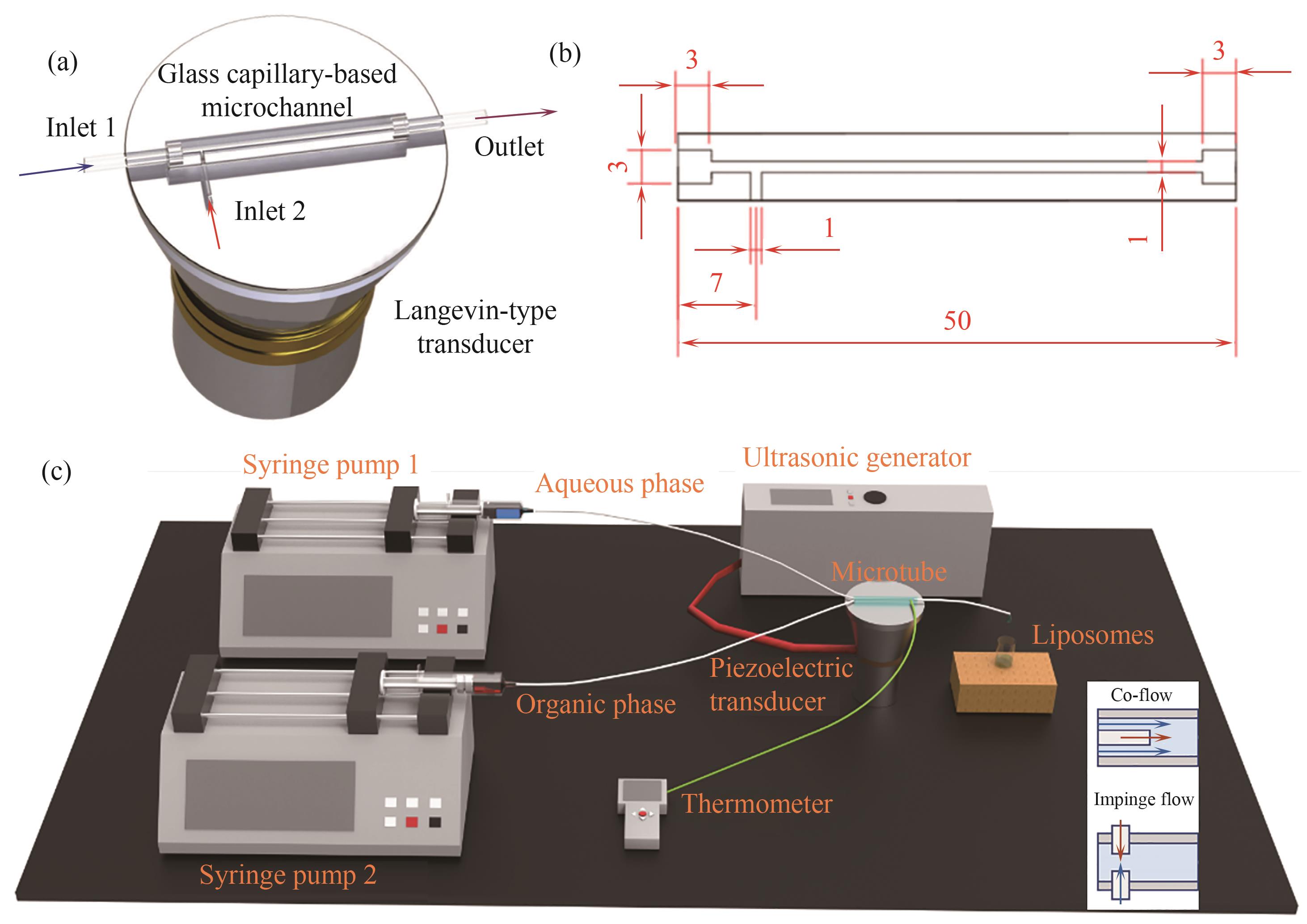

图4 (a)基于USMR的结构示意图;(b)玻璃毛细管微通道的尺寸规格;(c)同轴和对撞型微反应器的装置示意图

Fig.4 (a) Schematic of the ultrasonic cavitation-based micromixer design; (b) Geometric information of the glass capillary-based microchannel; (c) Schematic of the ultrasonic setup using co-flow and impinge flow microchannel

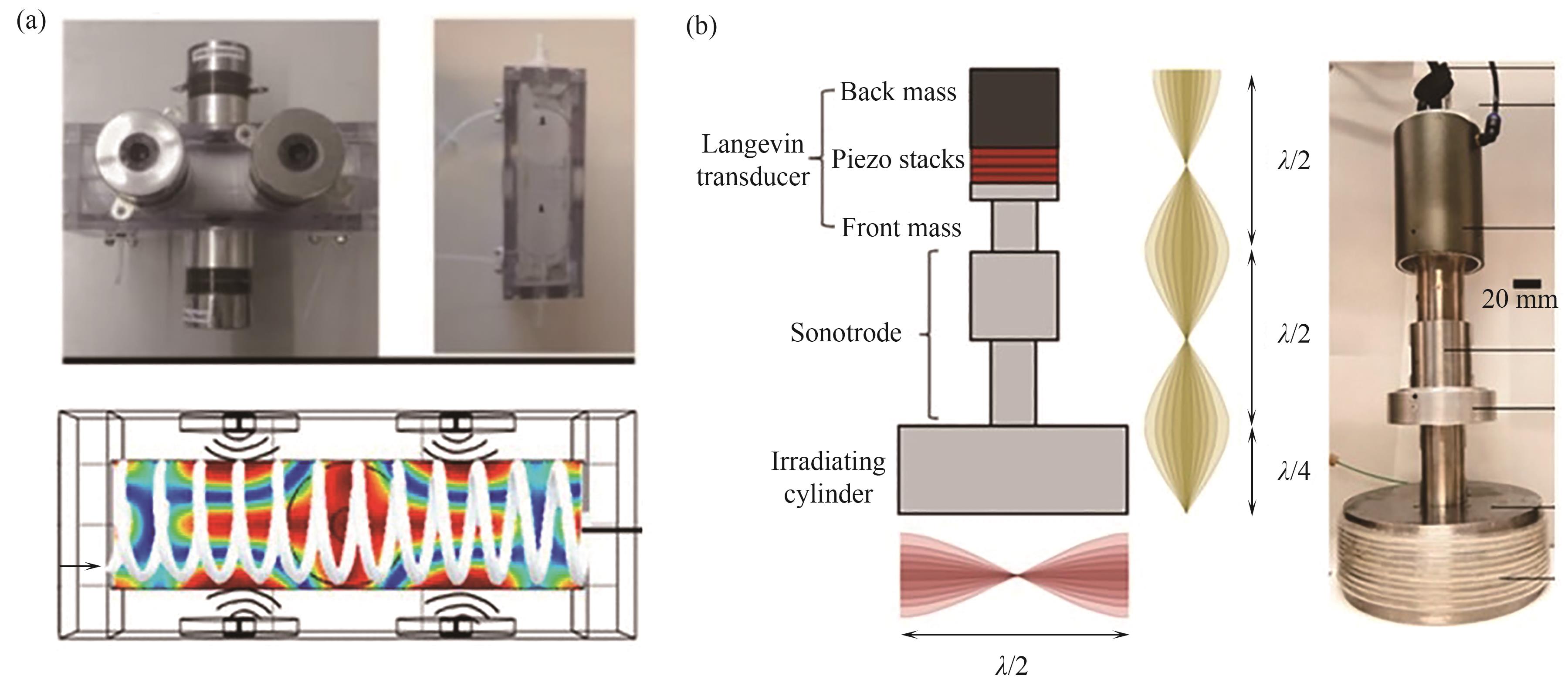

图6 (a)毛细管微反应器构成的振动系统;(b)圆柱体变幅杆与夹心式换能器构成的振动系统

Fig.6 (a) Vibration system consisting of a capillary microreactor; (b) Vibration system consisting of a cylindrical luffing rod and a sandwich transducer

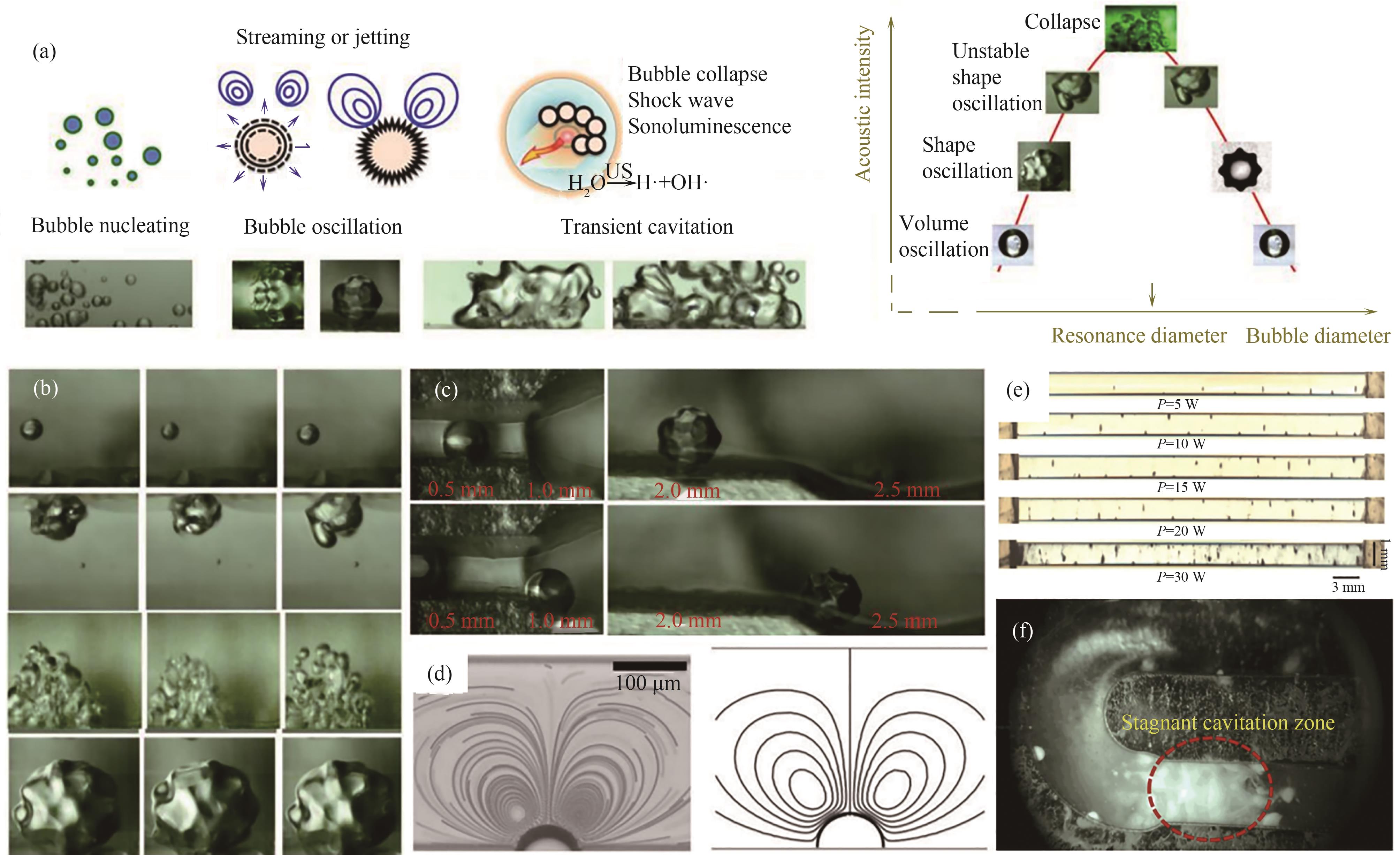

图7 (a)超声作用下的声空化现象[41];微尺度下自由气泡的空化行为:(b)振动行为,(c)限域效应[38];(d)振动产生的声流[42];在USMR中观察到的两个重要的空化气泡振荡现象: (e)直通道中气泡阵列(或气泡簇阵列)与(f)弯曲通道中的强烈振荡气泡云[43]

Fig.7 (a) Acoustic cavitation under ultrasound[41]; Cavitation behavior of free bubbles at the microscale: (b) vibrational behavior,(c) confinement effect[38]; (d) Acoustic flow from vibration[42]; Two important cavitation bubble oscillation phenomena observed in ultrasonic microreactor: (e) bubble arrays (or bubble cluster arrays) in straight channels and (f) strongly oscillating bubble clouds in curved channels[43]

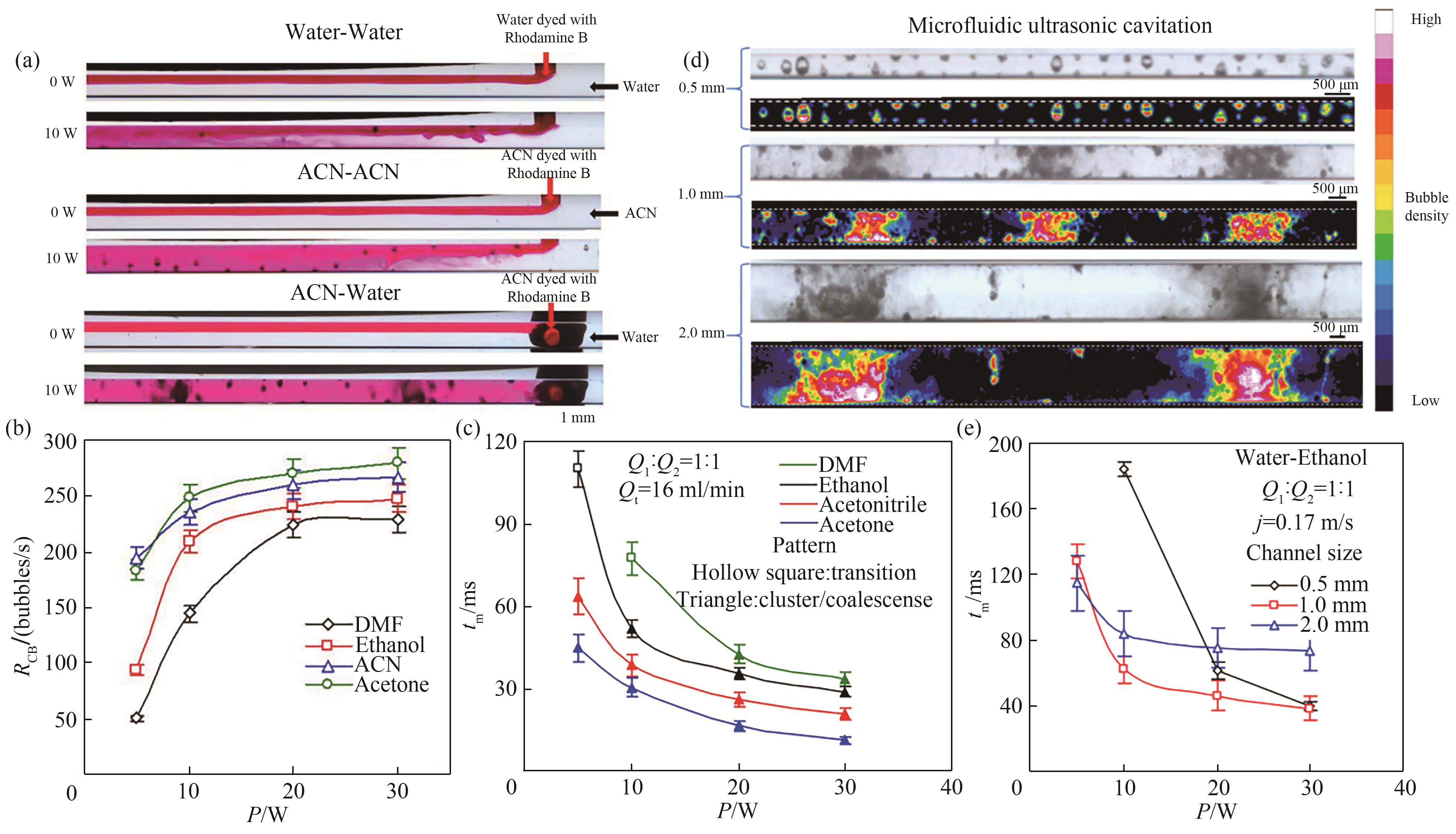

图8 (a) 不同溶剂体系下的超声对空化气泡生成数量的影响与混合表现[22];超声功率对空化气泡生成速率(b)与混合性能(c)的影响; (d) 不同通道尺寸的超声反应器内空化行为与气泡分布[57]; (e) 0.5~2.0 mm微通道中,不同超声功率对混合时间的影响[22]

Fig.8 (a) The number of cavitation bubbles and mixing behavior under different solvent systems[22]; The effect of ultrasonic power on cavitation bubble formation rate (b) and mixing performance under different solvent systems (c); (d) Cavitation behavior and bubble distribution in the ultrasonic reactor with different channel sizes[57]; (e) Mixing time as a function of ultrasonic power for 0.5—2.0 mm channel sizes[22]

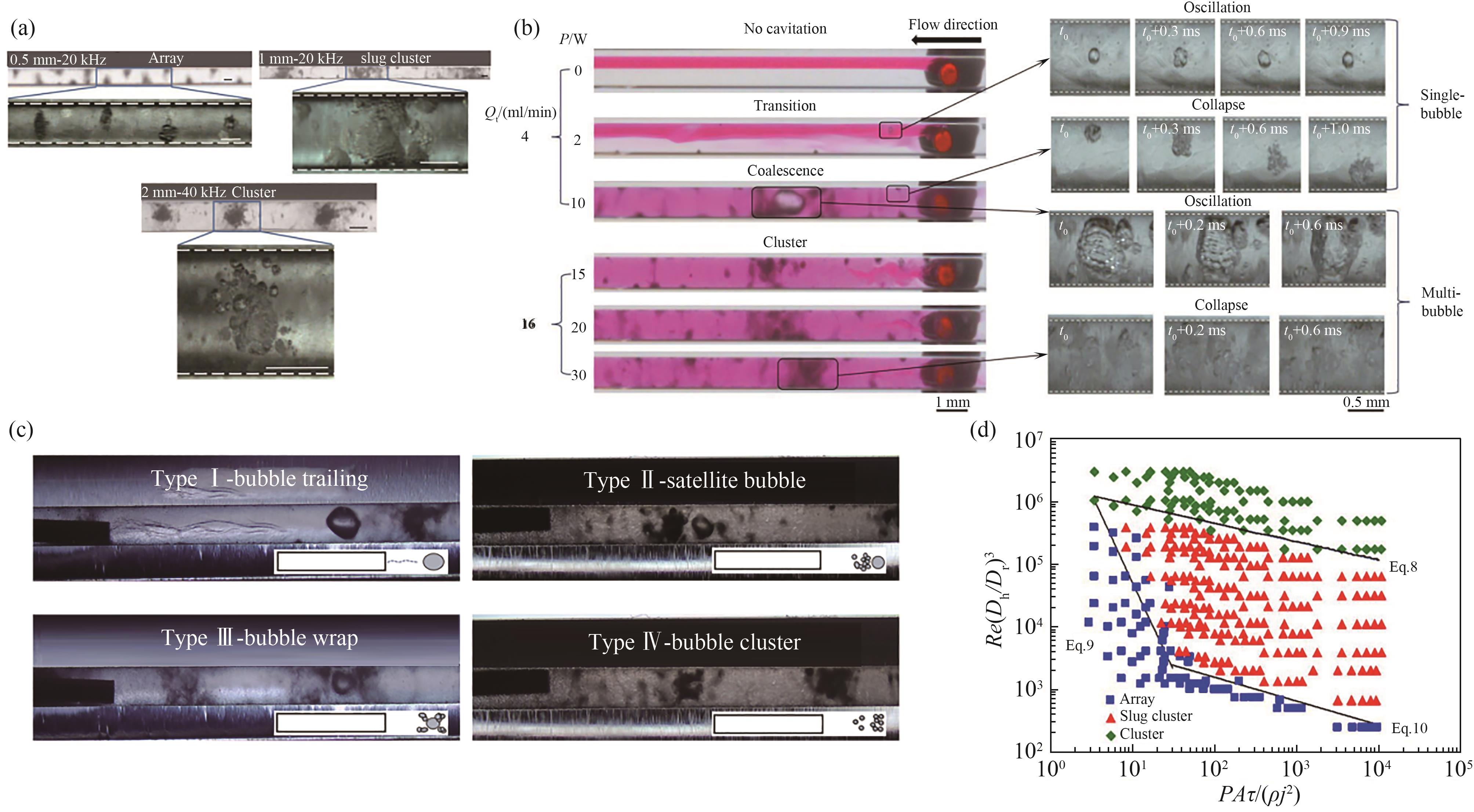

图9 典型的空化模式:(a)不同通道尺寸与频率下的空化模式:阵列模式、弹状团簇模式与团簇模式;(b)不同超声功率和流量下的空化模式与微观空化行为;(c)不同同轴套管与通道相对位置下的空化模式:气泡拖尾型、卫星型、环绕型与团簇型;(d)超声微反应器内的空化模式图[57]

Fig.9 Typical cavitation modes: (a) cavitation modes at different channel sizes and frequencies: array mode, elastic cluster mode and cluster mode; (b) Under different ultrasonic powers and flows: cavitation modes and microscopic cavitation behaviors; (c) Cavitation modes under different relative positions of coaxial casings and channels: bubble tailing, satellite, surround and cluster; (d) Cavitation pattern diagram in the ultrasonic microreactor[57]

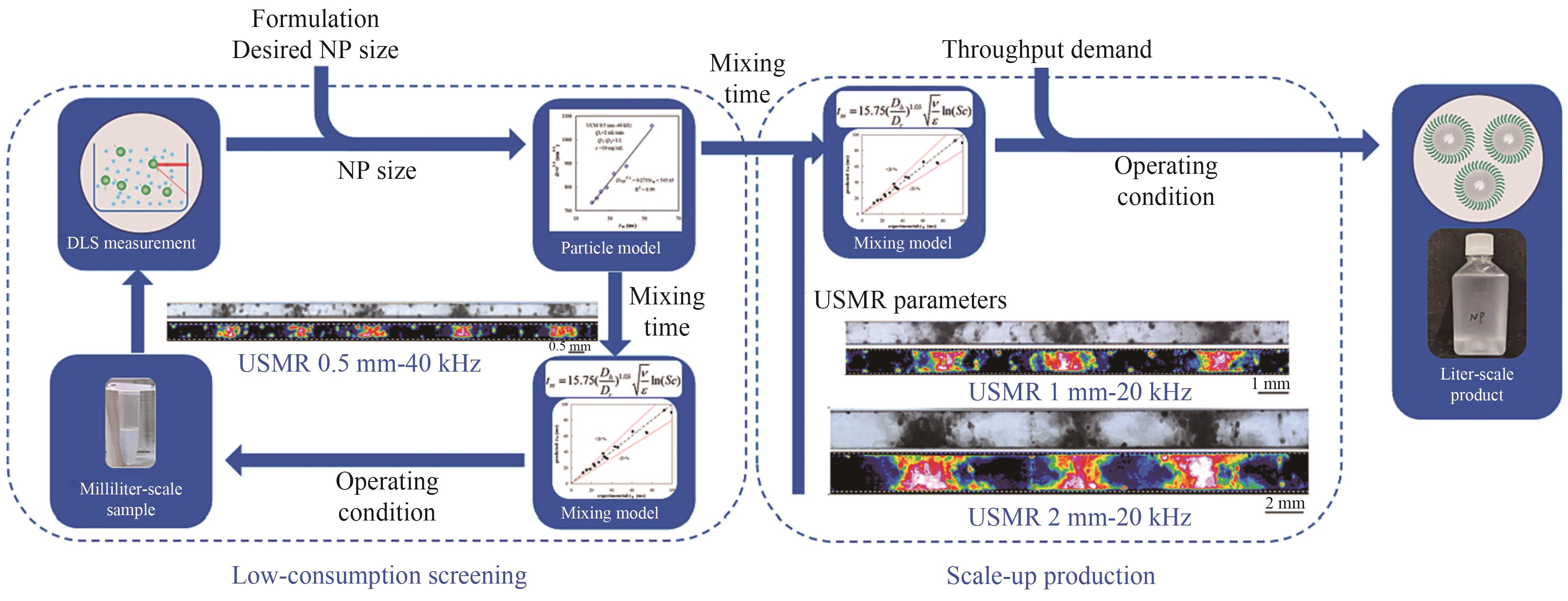

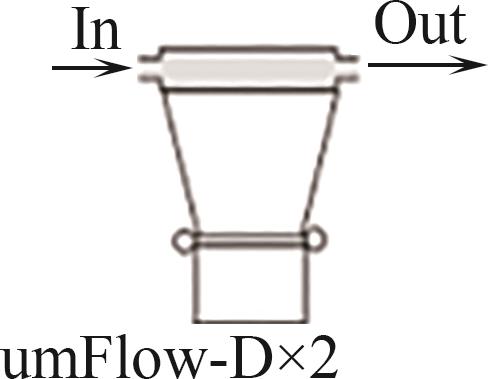

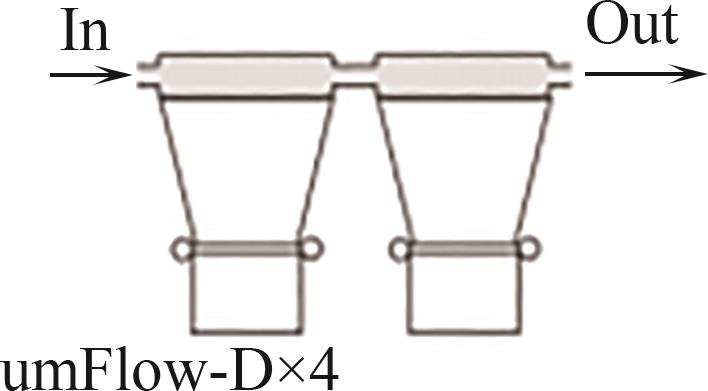

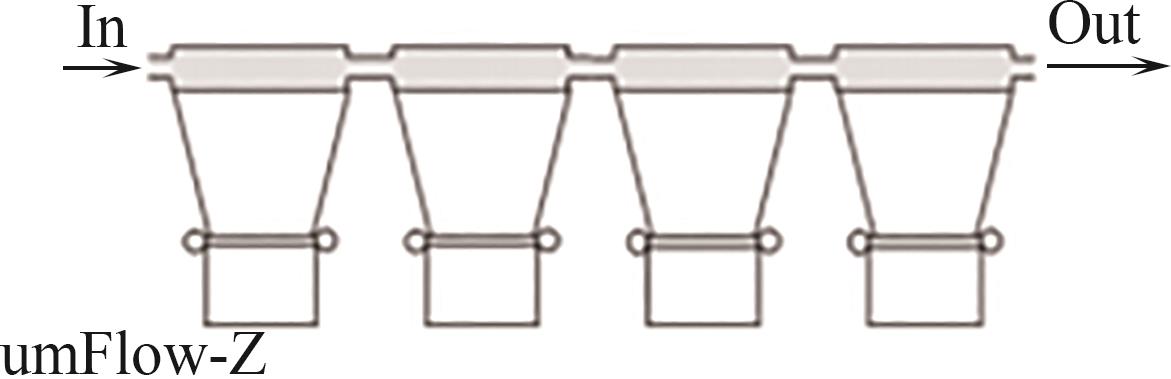

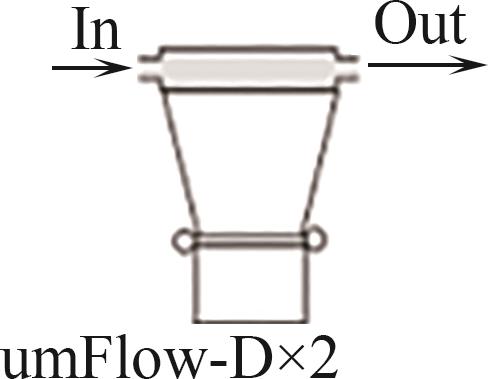

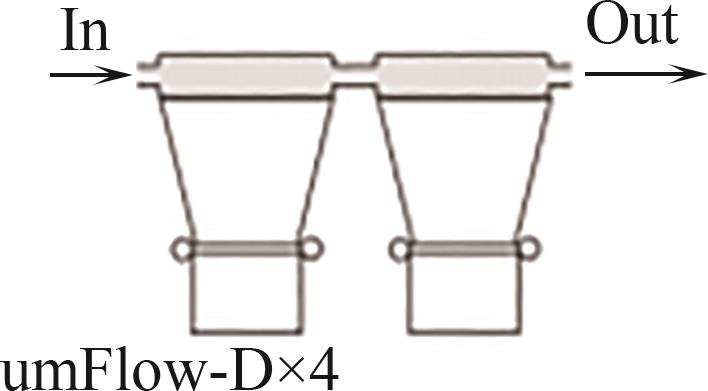

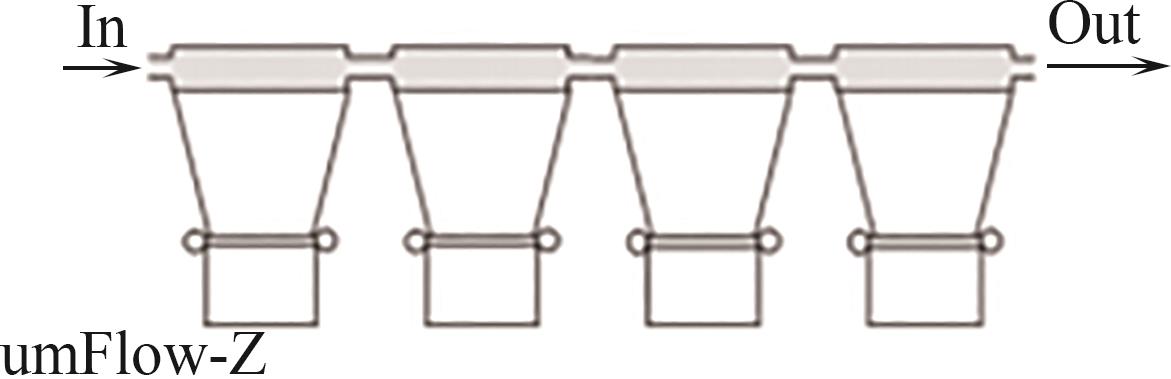

图10 USMR的反溶剂沉淀过程放大策略示意图[57]

Fig.10 Schematic diagram of the scale-up strategy of the antisolvent precipitation process of the ultrasonic microreactor[57]

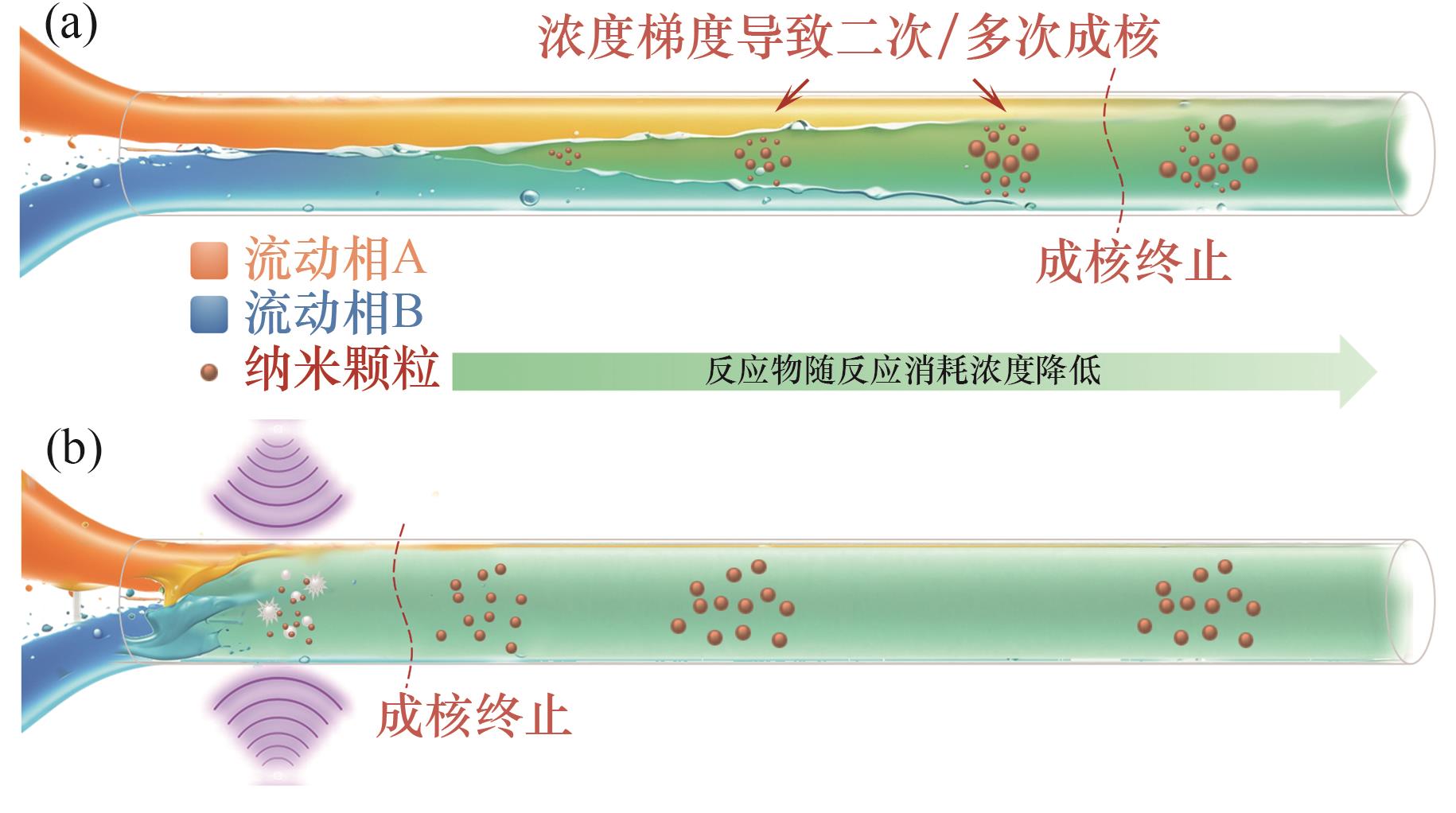

图11 微通道中反应成核生长过程示意图:(a)扩散混合模式下的成核生长;(b)超声强化传质模式下的成核生长

Fig.11 Schematic diagram of the reaction nucleation growth process in the microchannel: (a) Nucleation growth in diffusion mixed mode; (b) Nucleation growth in ultrasound-enhanced mass transfer mode

图12 二氧化硅微球扫描电子显微镜照片:(a)平均粒径155 nm,CV值6.77%;(b)平均粒径300 nm,CV值4.33%;(c)平均粒径409 nm,CV值6.90%;(d)平均粒径550 nm,CV值5.87%;(e)平均粒径730 nm,CV值4.17%;(f)平均粒径840 nm,CV值4.05%

Fig.12 Scanning electron microscopy of silica microspheres: (a) An average particle size of 155 nm and a CV value of 6.77%; (b) An average particle size of 300 nm and a CV value of 4.33%; (c) An average particle size of 409 nm and a CV value of 6.90%; (d) An average particle size of 550 nm and a CV value of 5.87%; (e) An average particle size of 730 nm and a CV value of 4.17%; (f) An average particle size of 840 nm and a CV value of 4.05%

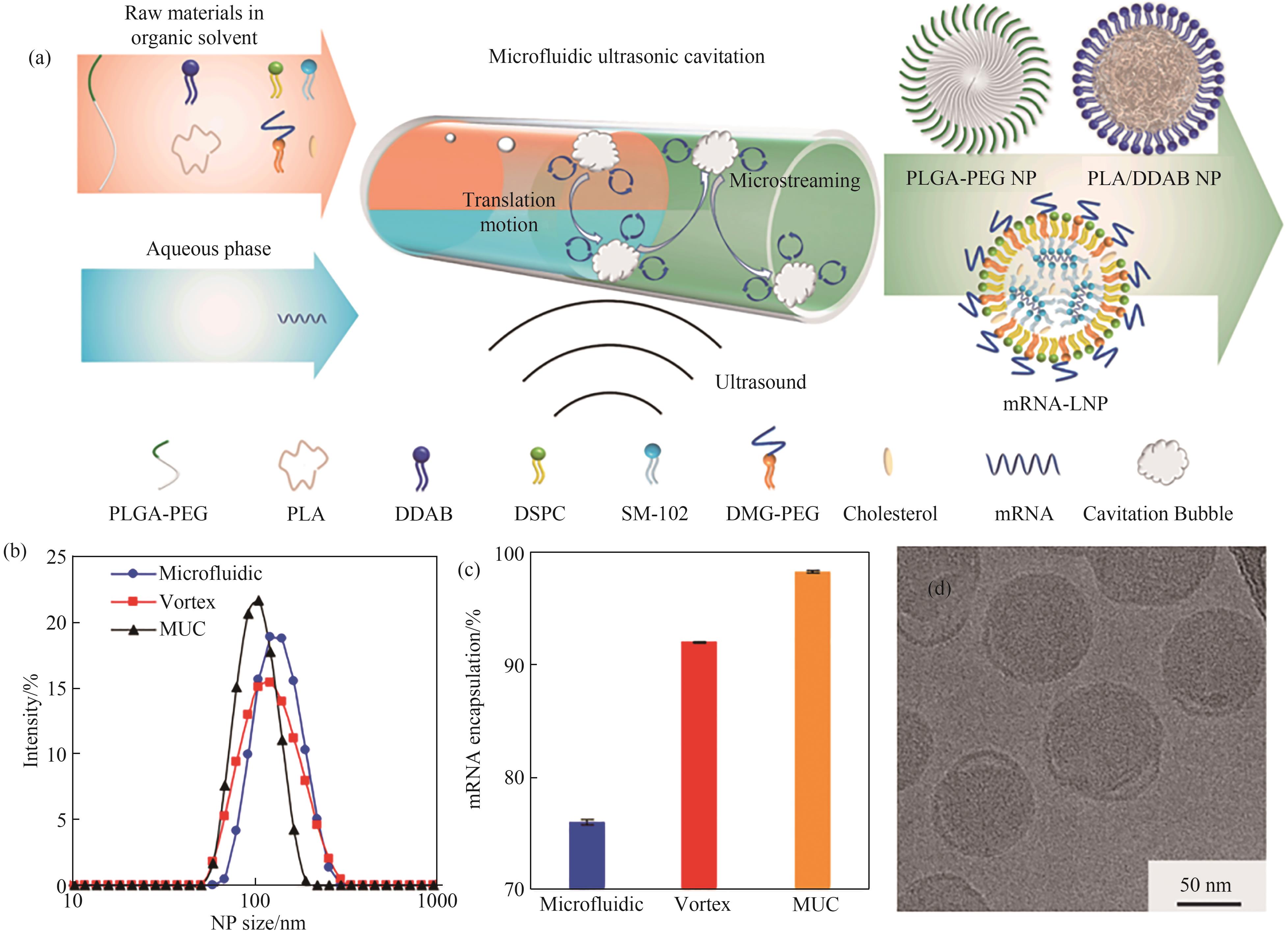

图15 (a) USMR方法合成生物医药NPs示意图;(b)不同方法合成的mRNA-LNPs的大小分布和(c) mRNA封装效率;(d)该方法合成的mRNA-LNP的冷冻透射电镜显微照片[22]

Fig.15 (a) Schematic illustration of USMR approach for synthesis biomedical organic NPs; (b) Size distribution and (c) mRNA encapsulation efficiency of mRNA-LNPs synthesized by different approaches; (d) Cryo-TEM micrographs of mRNA-LNP synthesized via this approach[22]

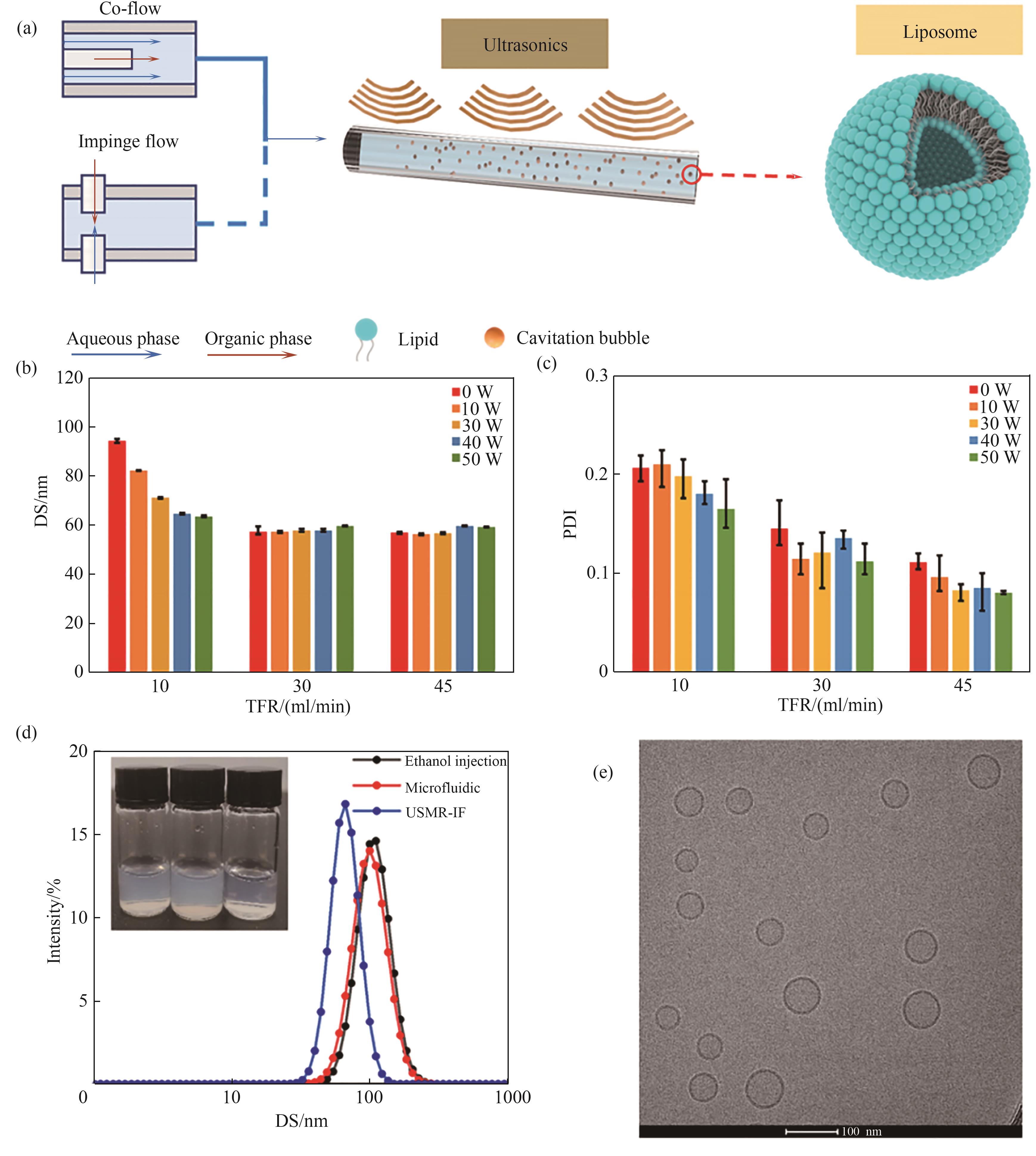

图16 (a)在不同流动模式下用USMR制备脂质体;(b),(c)超声功率对USMR-IF制备脂质体DS和PDI的影响;(d)不同方法制备的脂质体的比较;(e)在最佳条件下用USMR-IF制备的脂质体的冷冻透射电镜图像[25]

Fig.16 (a) Preparation of liposomes by USMR with different flow patterns; (b),(c) Effect of ultrasonic power on DS and PDI of liposomes prepared with USMR-IF; (d) Comparison of liposomes prepared by different methods; (e) Cryo-TEM image of liposomes prepared with USMR-IF under the optimal condition[25]

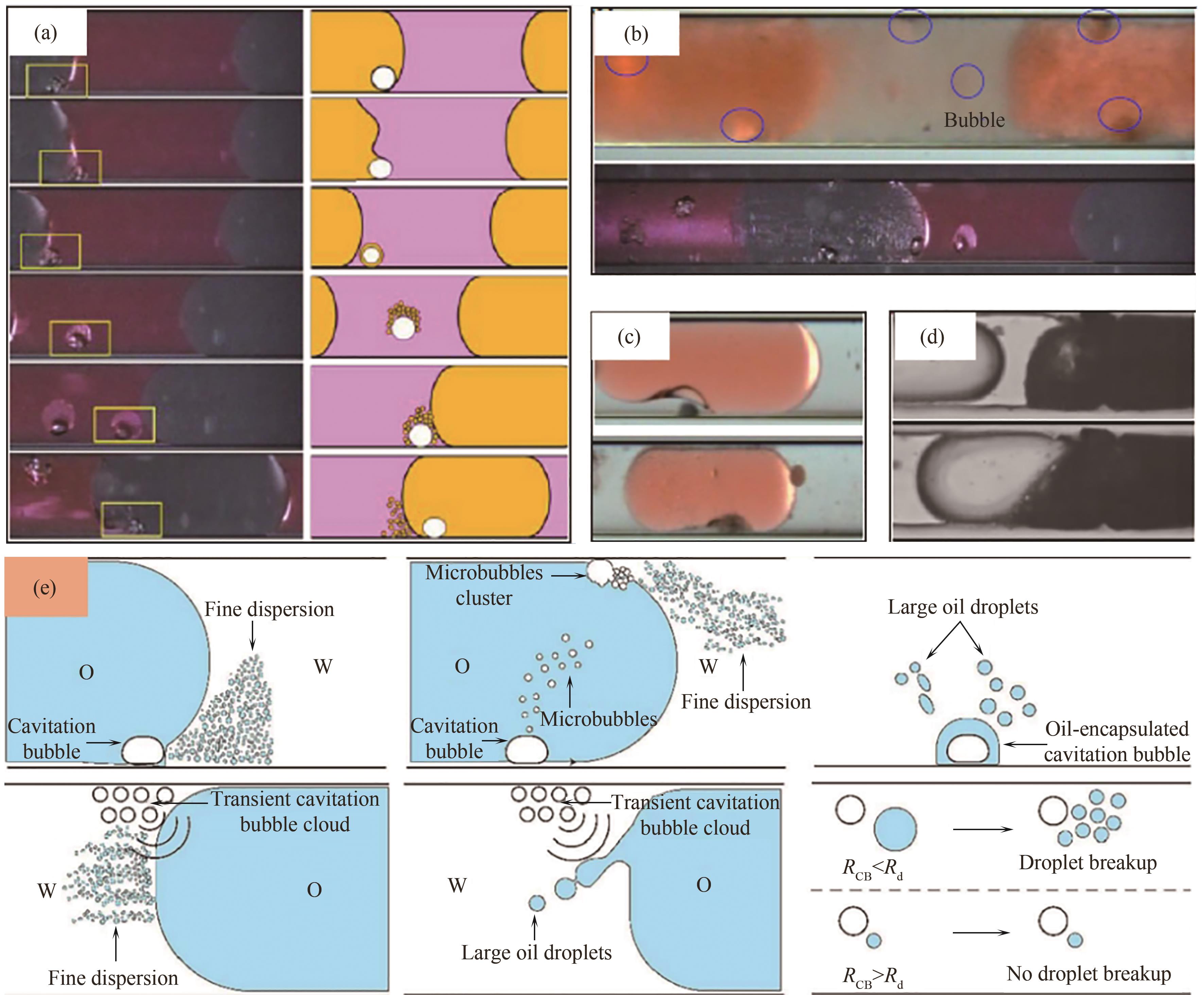

图17 USMR中观察到的超声乳化现象:(a)气泡穿梭乳化[110],(b)两相乳化[41],(c)气泡振荡诱导界面变形和乳化,(d)冲击波诱导乳化[112];(e)不同空化行为对乳液尺寸分布的影响[114]

Fig.17 Emulsification observed in ultrasonic microreactor: (a) bubble shuttle emulsification[110], (b) two-phase emulsification[41],(c) bubble oscillation-induced interface deformation and emulsification, (d) shockwave-induced emulsification[112]; (e) Effect of different cavitation behaviors on emulsion size distribution[114]

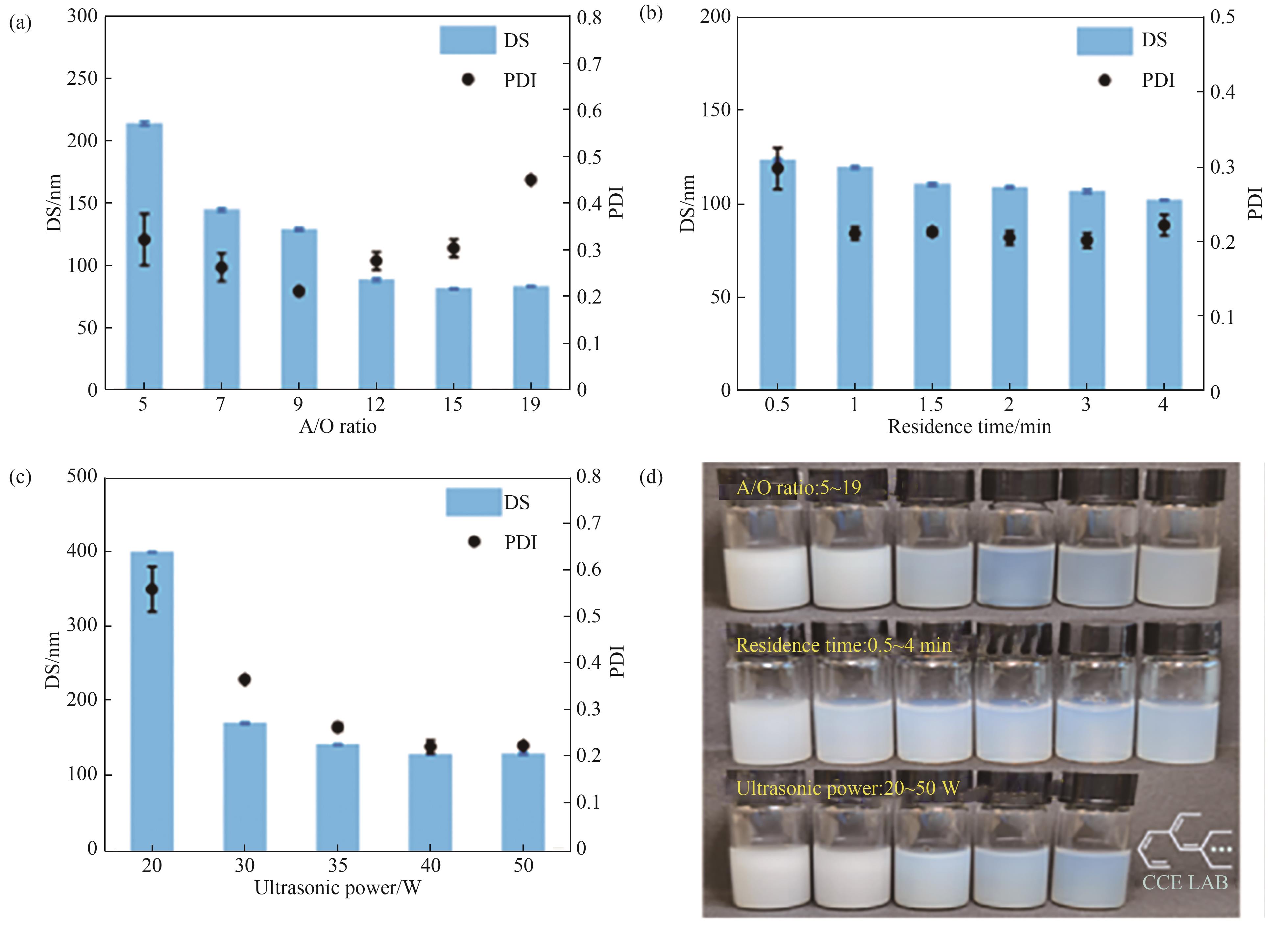

图18 主要因素对于乳液粒径和PDI的影响:(a)水相与大豆油比例,(b)物料停留时间,(c)超声功率;(d)乳液样品照片[26]

Fig.18 The influence of the main factors on the particle size and PDI of the emulsions: (a) the ratio of aqueous phase to soybean oil, (b) the residence time of the feedstocks, (c) ultrasonic power; (d) Photographs of emulsion samples[26]

| USMR | Residence time/min | Ultrasonic power/W | Total flow rate/(ml/min) | DS/nm | PDI |

|---|---|---|---|---|---|

| umFlow-D×1 | 1 | 40 | 0.66 | 119.8 | 0.211 |

| 1 | 40 | 1.32 | 121.3 | 0.239 |

| 1 | 40 | 2.64 | 119.7 | 0.225 |

| 0.7 | 160 | 20 | 120.5 | 0.219 |

表1 用不同USMR制备的纳米乳液的粒径和PDI(A∶O=9∶1)[26]

Table 1 DS and PDI of nanoemulsions prepared with different USMR(A∶O ratio:9∶1)[26]

| USMR | Residence time/min | Ultrasonic power/W | Total flow rate/(ml/min) | DS/nm | PDI |

|---|---|---|---|---|---|

| umFlow-D×1 | 1 | 40 | 0.66 | 119.8 | 0.211 |

| 1 | 40 | 1.32 | 121.3 | 0.239 |

| 1 | 40 | 2.64 | 119.7 | 0.225 |

| 0.7 | 160 | 20 | 120.5 | 0.219 |

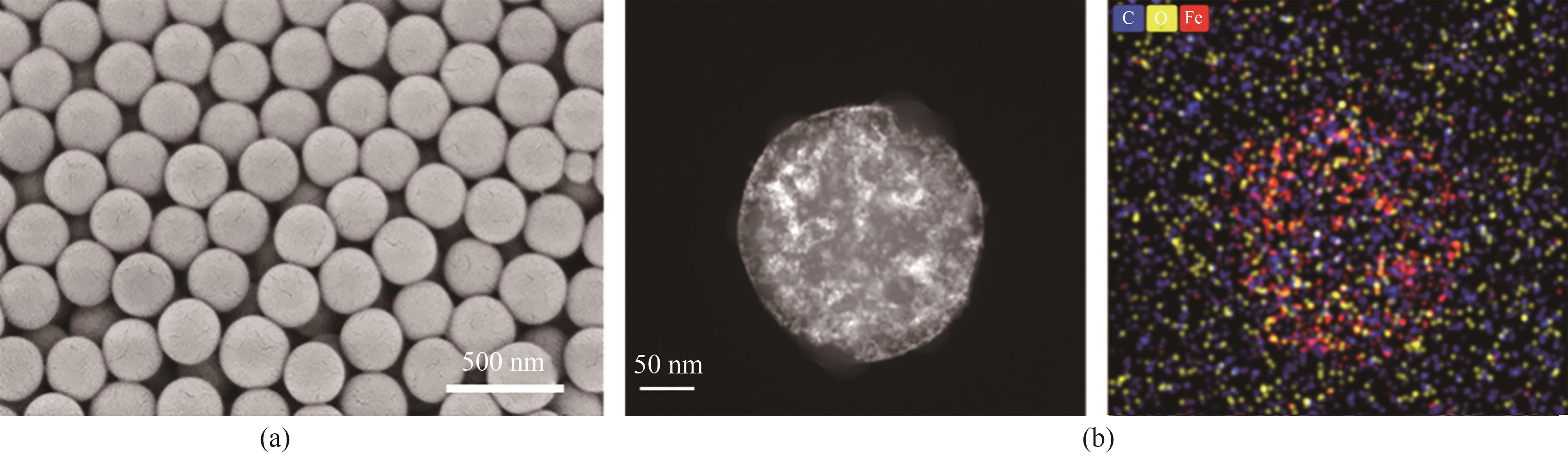

图19 聚合物纳米磁性微球照片:(a)扫描电镜照片;(b)透射电镜照片及EDS

Fig.19 Photographs of magnetic polymer nanosphere: (a) photographs of scanning electron microscope; (b) photographs of transmission electron microscope and EDS

| 1 | Jensen K F. Flow chemistry—microreaction technology comes of age[J]. AIChE Journal, 2017, 63(3): 858-869. |

| 2 | Berton M, de Souza J M, Abdiaj I, et al. Scaling continuous API synthesis from milligram to kilogram: extending the enabling benefits of micro to the plant[J]. Journal of Flow Chemistry, 2020, 10(1): 73-92. |

| 3 | 陈光文, 袁权. 微化工技术[J]. 化工学报, 2003, 54(4): 427-439. |

| Chen G W, Yuan Q. Micro-chemical technology[J]. Journal of Chemical Industry and Engineering (China), 2003, 54(4): 427-439. | |

| 4 | 骆广生, 吕阳成, 王凯, 等. 微化工技术[M]. 北京: 化学工业出版社, 2020. |

| Luo G S, Lyu Y C, Wang K. Micro Chemical Engineering and Technology[M]. Beijing: Chemical Industry Press, 2020. | |

| 5 | 陈光文, 赵玉潮, 乐军, 等. 微化工过程中的传递现象[J]. 化工学报, 2013, 64(1): 63-75. |

| Chen G W, Zhao Y C, Le J, et al. Transport phenomena in micro-chemical engineering[J]. CIESC Journal, 2013, 64(1): 63-75. | |

| 6 | Wu K J, Kuhn S. Strategies for solids handling in microreactors[J]. Chimica Oggi/Chemistry Today, 2014, 32(3): 62-66. |

| 7 | Hartman R L, Naber J R, Zaborenko N, et al. Overcoming the challenges of solid bridging and constriction during Pd-catalyzed C—N bond formation in microreactors[J]. Organic Process Research & Development, 2010, 14(6): 1347-1357. |

| 8 | Hessel V, Löwe H, Schönfeld F. Micromixers—a review on passive and active mixing principles[J]. Chemical Engineering Science, 2005, 60(8/9): 2479-2501. |

| 9 | Kashid M, Renken A, Kiwi-minsker L. Microstructured Devices for Chemical Processing[M]. Hoboken: Wiley‐VCH Verlag GmbH & Co. KGaA, 2014. |

| 10 | Dong Z Y, Wen Z H, Zhao F, et al. Scale-up of micro- and milli-reactors: an overview of strategies, design principles and applications[J]. Chemical Engineering Science: X, 2021, 10: 100097. |

| 11 | Zhang J S, Wang K, Teixeira A R, et al. Design and scaling up of microchemical systems: a review[J]. Annual Review of Chemical and Biomolecular Engineering, 2017, 8: 285-305. |

| 12 | Su Y H, Chen G W, Kenig E Y. An experimental study on the numbering-up of microchannels for liquid mixing[J]. Lab on a Chip, 2015, 15(1): 179-187. |

| 13 | Fernandez Rivas D, Kuhn S. Synergy of microfluidics and ultrasound: process intensification challenges and opportunities[J]. Topics in Current Chemistry (Cham), 2016, 374(5): 70. |

| 14 | 董正亚, 陈光文, 赵帅南, 等. 声化学微反应器——超声和微反应器协同强化[J]. 化工学报, 2018, 69(1): 102-115. |

| Dong Z Y, Chen G W, Zhao S N, et al. Sonochemical microreactor—synergistic intensification of ultrasound and microreactor[J]. CIESC Journal, 2018, 69(1): 102-115. | |

| 15 | Dong Z, Delacour C, Carogher K M, et al. Continuous ultrasonic reactors: design, mechanism and application[J]. Materials, 2020, 13: 344. |

| 16 | Dong Z Y, Zhao S N, Zhang Y C, et al. Mixing and residence time distribution in ultrasonic microreactors[J]. AIChE Journal, 2017, 63(4): 1404-1418. |

| 17 | Delacour C, Lutz C, Kuhn S. Pulsed ultrasound for temperature control and clogging prevention in micro-reactors[J]. Ultrasonics Sonochemistry, 2019, 55: 67-74. |

| 18 | Dong Z Y, Fernandez Rivas D, Kuhn S. Acoustophoretic focusing effects on particle synthesis and clogging in microreactors[J]. Lab on a Chip, 2019, 19(2): 316-327. |

| 19 | Kuhn S, Noël T, Gu L, et al. A Teflon microreactor with integrated piezoelectric actuator to handle solid forming reactions[J]. Lab on a Chip, 2011, 11(15): 2488-2492. |

| 20 | John J J, Kuhn S, Braeken L, et al. Temperature controlled interval contact design for ultrasound assisted liquid-liquid extraction[J]. Chemical Engineering Research and Design, 2017, 125: 146-155. |

| 21 | Dong Z Y, Yao C Q, Zhang Y C, et al. Hydrodynamics and mass transfer of oscillating gas-liquid flow in ultrasonic microreactors[J]. AIChE Journal, 2016, 62(4): 1294-1307. |

| 22 | Liu Z K, Yang M, Dong Z Y, et al. Cavitation behavior and mixing performance of antisolvent precipitation process in an ultrasonic micromixer[J]. AIChE Journal, 2023, 69(7): e18080. |

| 23 | 余杨屏, 杨梅, 李明芝, 等. 微反应器内Stöber法可控制备SiO2微球[J]. 过程工程学报, 2023, 23(6): 908-917. |

| Yu Y B, Yang M, Li M Z, et al. The controllable preparation of SiO2 microspheres by Stöber method in the microreactor[J]. The Chinese Journal of Process Engineering, 2023, 23(6): 908-917. | |

| 24 | Li M Z, Liu Z K, Yao W, et al. Ultrasonic cavitation-enabled microfluidic approach toward the continuous synthesis of cesium lead halide perovskite nanocrystals[J]. Chinese Journal of Chemical Engineering, 2023, 59: 32-41. |

| 25 | Peng C H, Zhu X J, Zhang J, et al. Antisolvent fabrication of monodisperse liposomes using novel ultrasonic microreactors: process optimization, performance comparison and intensification effect[J]. Ultrasonics Sonochemistry, 2024, 103: 106769. |

| 26 | Xu J H, Zhu X J, Zhang J, et al. Nanoemulsification of soybean oil using ultrasonic microreactor: process optimization, scale-up and numbering-up in series[J]. Ultrasonics Sonochemistry, 2023, 97: 106451. |

| 27 | 林书玉. 超声换能器的原理及设计[M]. 北京: 科学出版社, 2004. |

| Lin S Y. Principle and Design of Ultrasonic Transducer[M]. Beijing: Science Press, 2004. | |

| 28 | 吕效平, 丁德胜, 张萍. 超声化工过程强化[M]. 北京: 化学工业出版社, 2020. |

| Lv X P, Ding D S, Zhang P. Ultrasonic Chemical Process Intensification[M]. Beijing: Chemical Industry Press, 2020. | |

| 29 | Hübner S, Kressirer S, Kralisch D, et al. Ultrasound and microstructures—a promising combination?[J]. ChemSusChem, 2012, 5(2): 279-288. |

| 30 | Roberge D, Rainone F, Quittmann W, et al. Method for preventing plugging of a continuous-reaction channel-system and micro-reactor for carrying out the method: US10058840B2[P]. 2018-08-28. |

| 31 | Horie T, Sumino M, Tanaka T, et al. Photodimerization of maleic anhydride in a microreactor without clogging[J]. Organic Process Research & Development, 2010, 14(2): 405-410. |

| 32 | Delacour C, Stephens D S, Lutz C, et al. Design and characterization of a scaled-up ultrasonic flow reactor[J]. Organic Process Research & Development, 2020, 24(10): 2085-2093. |

| 33 | Koiranen T, Ekberg B, Häkkinen A, et al. Ultrasound crystallization device and an ultrasound crystallization system: US11141679B2[P]. 2021-10-12. |

| 34 | Dong Z Y, Yao C Q, Zhang X L, et al. A high-power ultrasonic microreactor and its application in gas-liquid mass transfer intensification[J]. Lab on a Chip, 2015, 15(4): 1145-1152. |

| 35 | John J J. Ultrasound assisted liquid-liquid extraction in microchannels[D].Brussels: Katholieke Universiteit Leuven, 2017. |

| 36 | Navarro-Brull F J, Teixeira A R, Giri G, et al. Enabling low power acoustics for capillary sonoreactors[J]. Ultrasonics Sonochemistry, 2019, 56: 105-113. |

| 37 | 董正亚, 陈光文, 袁权. 一种大功率超声波微反应器: 104923468B[P]. 2018-10-23. |

| Dong Z Y, Chen G W, Yuan Q. A high power ultrasonic microreactor: 104923468B[P]. 2018-10-23. | |

| 38 | Zhao S N, Yao C Q, Zhang Q, et al. Acoustic cavitation and ultrasound-assisted nitration process in ultrasonic microreactors: the effects of channel dimension, solvent properties and temperature[J]. Chemical Engineering Journal, 2019, 374: 68-78. |

| 39 | 冯若. 超声手册[M]. 南京: 南京大学出版社, 1999. |

| Feng R. Ultrasonics Handbook[M]. Nanjing: Nanjing University Press, 1999. | |

| 40 | Dong Z Y, Zondag S D A, Schmid M, et al. A meso-scale ultrasonic milli-reactor enables gas-liquid-solid photocatalytic reactions in flow[J]. Chemical Engineering Journal, 2022, 428: 130968. |

| 41 | Yao C Q, Zhao S N, Liu L X, et al. Ultrasonic emulsification: basic characteristics, cavitation, mechanism, devices and application[J]. Frontiers of Chemical Science and Engineering, 2022, 16(11): 1560-1583. |

| 42 | Wang C, Jalikop S V, Hilgenfeldt S. Efficient manipulation of microparticles in bubble streaming flows[J]. Biomicrofluidics, 2012, 6(1): 012801. |

| 43 | Ding L, Zhao S N, Liu L X, et al. Characteristics of emulsion preparation in an ultrasonic microreactor: cavitation, droplet size and energy efficiency[J]. Chemical Engineering Journal, 2024, 484: 149462. |

| 44 | Suslick K S, Eddingsaas N C, Flannigan D J, et al. Extreme conditions during multibubble cavitation: sonoluminescence as a spectroscopic probe[J]. Ultrasonics Sonochemistry, 2011, 18(4): 842-846. |

| 45 | Collis J, Manasseh R, Liovic P, et al. Cavitation microstreaming and stress fields created by microbubbles[J]. Ultrasonics, 2010, 50(2): 273-279. |

| 46 | Orthaber U, Zevnik J, Petkovšek R, et al. Cavitation bubble collapse in a vicinity of a liquid-liquid interface—basic research into emulsification process[J]. Ultrasonics Sonochemistry, 2020, 68: 105224. |

| 47 | Louisnard O. Analytical expressions for primary Bjerknes force on inertial cavitation bubbles[J]. Physical Review E, 2008, 78(3): 036322. |

| 48 | Gonzalez-Avila S R, Klaseboer E, Khoo B C, et al. Cavitation bubble dynamics in a liquid gap of variable height[J]. Journal of Fluid Mechanics, 2011, 682: 241-260. |

| 49 | Zhang Q, Dong Z Y, Zhao S N, et al. Ultrasound-assisted gas-liquid mass transfer process in microreactors: the influence of surfactant, channel size and ultrasound frequency[J]. Chemical Engineering Journal, 2020, 405: 126720. |

| 50 | Zhang Q, Dong Z Y, Liu Z K, et al. Effect of ultrasonic waveforms on gas-liquid mass transfer in microreactors[J]. AIChE Journal, 2022, 68(8): e17689. |

| 51 | Xu F S, Yang L X, Liu Z K, et al. Numerical investigation on the hydrodynamics of Taylor flow in ultrasonically oscillating microreactors[J]. Chemical Engineering Science, 2021, 235: 116477. |

| 52 | Bremond N, Arora M, Ohl C D, et al. Controlled multibubble surface cavitation[J]. Physical Review Letters, 2006, 96(22): 224501. |

| 53 | Li Y L, Tan C J, Yan B, et al. Evaluation of the properties of daughter bubbles generated by inertial cavitation of preformed microbubbles[J]. Ultrasonics Sonochemistry, 2021, 72: 105400. |

| 54 | Zhang X M, Li F, Wang C H, et al. Effects of translational motion on the Bjerknes forces of bubbles activated by strong acoustic waves[J]. Ultrasonics, 2022, 126: 106809. |

| 55 | Tho P, Manasseh R, Ooi A. Cavitation microstreaming patterns in single and multiple bubble systems[J]. Journal of Fluid Mechanics, 2007, 576: 191-233. |

| 56 | Lin J Y, Lin S Y. Two-dimensional ultrasonic plastic welding system based on phononic crystal dislocation theory[J]. Acta Physica Sinica, 2020, 69(18): 184302. |

| 57 | Liu Z K, Yang M, Zhao Q K, et al. Scale-up of antisolvent precipitation process with ultrasonic microreactors: cavitation patterns, mixing characteristics and application in nanoparticle manufacturing[J]. Chemical Engineering Journal, 2023, 475: 146040. |

| 58 | Yang L X, Xu F S, Zhang Q, et al. Gas-liquid hydrodynamics and mass transfer in microreactors under ultrasonic oscillation[J]. Chemical Engineering Journal, 2020, 397: 125411. |

| 59 | 赵玉潮, 陈光文. 微化工系统的并行放大研究进展[J]. 中国科学: 化学, 2015, 45(1): 16-23. |

| Zhao Y C, Chen G W. Progress in research on numbering-up of microchemical system[J]. Science China Chemistry, 2015, 45(1): 16-23. | |

| 60 | 崔永晋, 李严凯, 王凯, 等. 微分散设备数量放大方式研究进展[J]. 化工学报, 2020, 71(10): 4350-4364. |

| Cui Y J, Li Y K, Wang K, et al. Recent advances of numbering-up technology of micro-dispersion devices[J]. CIESC Journal, 2020, 71(10): 4350-4364. | |

| 61 | Nisisako T, Ando T, Hatsuzawa T. High-volume production of single and compound emulsions in a microfluidic parallelization arrangement coupled with coaxial annular world-to-chip interfaces[J]. Lab on a Chip, 2012, 12(18): 3426-3435. |

| 62 | Liu X L, Wu Z L, Manzoli M, et al. Medium-high frequency sonication dominates spherical-SiO2 nanoparticle size[J]. Ultrasonics Sonochemistry, 2022, 90: 106181. |

| 63 | Liu L X, Liu Z K, Zhao S N, et al. The separation and enrichment of molecules with part amphipathy using a novel ultrasonic emulsion-enrichment method[J]. Chemical Engineering Journal, 2022, 444: 136682. |

| 64 | Li W, Leong T S H, Ashokkumar M, et al. A study of the effectiveness and energy efficiency of ultrasonic emulsification[J]. Physical Chemistry Chemical Physics, 2018, 20(1): 86-96. |

| 65 | Sowers K L, Swartz B, Krauss T D. Chemical mechanisms of semiconductor nanocrystal synthesis[J]. Chemistry of Materials, 2013, 25(8): 1351-1362. |

| 66 | Kwon S G, Hyeon T. Formation mechanisms of uniform nanocrystals via hot-injection and heat-up methods[J]. Small, 2011, 7(19): 2685-2702. |

| 67 | Peng X G. An essay on synthetic chemistry of colloidal nanocrystals[J]. Nano Research, 2009, 2(6): 425-447. |

| 68 | LaMer V K, Dinegar R H. Theory, production and mechanism of formation of monodispersed hydrosols[J]. Journal of the American Chemical Society, 1950, 72(11): 4847-4854. |

| 69 | Xie R G, Li Z, Peng X G. Nucleation kinetics vs chemical kinetics in the initial formation of semiconductor nanocrystals[J]. Journal of the American Chemical Society, 2009, 131(42): 15457-15466. |

| 70 | Tao Y T, Wu K J, He C H. Continuous synthesis of boron-doped carbon nitride supported silver nanoparticles in an ultrasound-assisted coiled flow inverter microreactor[J]. Journal of Flow Chemistry, 2024, 14(1): 177-196. |

| 71 | Zhang Z B, Wang K, Xu C B, et al. Ultrasound enhancing the mass transfer of droplet microreactor for the synthesis of AgInS2 nanocrystals[J]. Chemical Engineering Journal, 2022, 435: 134948. |

| 72 | 陈帅帅, 陈鑫超, 凌晨, 等. 微反应器中超声对Cu-ZnO催化剂制备过程的影响[J]. 高校化学工程学报, 2019, 33(5): 1092-1097. |

| Chen S S, Chen X C, Ling C, et al. Effects of ultrasound on the preparation of Cu-ZnO catalysts in a microreactor[J]. Journal of Chemical Engineering of Chinese Universities, 2019, 33(5): 1092-1097. | |

| 73 | Zhao Q K, Yang L X, Yao C Q, et al. Ultrasonic enhanced continuous crystallization: induction time and process control[J]. Industrial & Engineering Chemistry Research, 2023, 62(47): 20083-20095. |

| 74 | Liu Z K, Yang M, Yao W, et al. Microfluidic ultrasonic cavitation enables versatile and scalable synthesis of monodisperse nanoparticles for biomedical application[J]. Chemical Engineering Science, 2023, 280: 119052. |

| 75 | Zhao S N, Zhao Q K, Yao C Q, et al. Investigation of anti-clogging mechanism of ultrasound-driven oscillating slugs/bubbles and its application on continuous crystallization process[J]. Chemical Engineering Science, 2024, 290: 119898. |

| 76 | Tenchov R, Bird R, Curtze A E, et al. Lipid nanoparticles─from liposomes to mRNA vaccine delivery, a landscape of research diversity and advancement[J]. ACS Nano, 2021, 15(11): 16982-17015. |

| 77 | Hu M D, Li X Y, You Z, et al. Physiological barriers and strategies of lipid-based nanoparticles for nucleic acid drug delivery[J]. Advanced Materials, 2024, 36(22): 2303266. |

| 78 | Xu M Z, Qi Y M, Liu G S, et al. Size-dependent in vivo transport of nanoparticles: implications for delivery, targeting, and clearance[J]. ACS Nano, 2023, 17(21): 20825-20849. |

| 79 | Kon E, Ad-El N, Hazan-Halevy I, et al. Targeting cancer with mRNA-lipid nanoparticles: key considerations and future prospects[J]. Nature Reviews Clinical Oncology, 2023, 20(11): 739-754. |

| 80 | Hong S C, Park K M, Hong C R, et al. Microfluidic assembly of liposomes dual-loaded with catechin and curcumin for enhancing bioavailability[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2020, 594: 124670. |

| 81 | Boyd-Moss M, Baratchi S, Di Venere M, et al. Self-contained microfluidic systems: a review[J]. Lab on a Chip, 2016, 16(17): 3177-3192. |

| 82 | Homayouni A, Sohrabi M, Amini M, et al. Effect of high pressure homogenization on physicochemical properties of curcumin nanoparticles prepared by antisolvent crystallization using HPMC or PVP[J]. Materials Science & Engineering C, Materials for Biological Applications, 2019, 98: 185-196. |

| 83 | Zhou S, Li J B, Yu J, et al. Unique flower-like cur-metal complexes loaded liposomes for primary and metastatic breast cancer therapy[J]. Materials Science and Engineering C, 2021, 121: 111835. |

| 84 | Sala M, Miladi K, Agusti G, et al. Preparation of liposomes: a comparative study between the double solvent displacement and the conventional ethanol injection—from laboratory scale to large scale[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2017, 524: 71-78. |

| 85 | Johnson B K, Prud'homme R K. Mechanism for rapid self-assembly of block copolymer nanoparticles[J]. Physical Review Letters, 2003, 91(11): 118302. |

| 86 | Liu L X, Yao C Q, Zhao S N, et al. Enhanced antisolvent processes in an ultrasonic capillary microreactor: cavitation, mixing and application in mini-emulsion preparation[J]. Chemical Engineering Journal, 2023, 466: 143426. |

| 87 | Riewe J, Erfle P, Melzig S, et al. Antisolvent precipitation of lipid nanoparticles in microfluidic systems—a comparative study[J]. International Journal of Pharmaceutics, 2020, 579: 119167. |

| 88 | Zhigaltsev I V, Tam Y K, Leung A K K, et al. Production of limit size nanoliposomal systems with potential utility as ultra-small drug delivery agents[J]. Journal of Liposome Research, 2015, 26(2): 96-102. |

| 89 | Carvalho B G, Ceccato B T, Michelon M, et al. Advanced microfluidic technologies for lipid nano-microsystems from synthesis to biological application[J]. Pharmaceutics, 2022, 14(1): 141. |

| 90 | Wu K, Choi A, Koch M, et al. Variant SARS-CoV-2 mRNA vaccines confer broad neutralization as primary or booster series in mice[J]. Vaccine, 2021, 39(51): 7394-7400. |

| 91 | Chaudhary N, Weissman D, Whitehead K A. mRNA vaccines for infectious diseases: principles, delivery and clinical translation[J]. Nature Reviews. Drug Discovery, 2021, 20(11): 817-838. |

| 92 | Zhang N N, Li X F, Deng Y Q, et al. A thermostable mRNA vaccine against COVID-19[J]. Cell, 2020, 182(5): 1271-1283. |

| 93 | Yao W, Liu Z K, Guo L T, et al. Continuous synthesis of monodisperse polymer nanoparticles: new insights into the effects of experimental variables under controlled mixing conditions[J]. Chemical Engineering Science, 2024, 288: 119846. |

| 94 | Huang H, du Toit H, Panariello L, et al. Continuous synthesis of gold nanoparticles in micro- and millifluidic systems[J]. Physical Sciences Reviews, 2021, 6(3): 119-158. |

| 95 | Bolze H, Riewe J, Bunjes H, et al. Continuous production of lipid nanoparticles by ultrasound-assisted microfluidic antisolvent precipitation[J]. Chemical Engineering & Technology, 2021, 44(9): 1641-1650. |

| 96 | Huang P H, Zhao S G, Bachman H, et al. Acoustofluidic synthesis of particulate nanomaterials[J]. Advanced Science, 2019, 6(19): 1900913. |

| 97 | Zhao S N, Yao C Q, Dong Z Y, et al. Role of ultrasonic oscillation in chemical processes in microreactors: a mesoscale issue[J]. Particuology, 2020, 48: 88-99. |

| 98 | Daniel S, Kis Z, Kontoravdi C, et al. Quality by design for enabling RNA platform production processes[J]. Trends in Biotechnology, 2022, 40(10): 1213-1228. |

| 99 | Fryd M M, Mason T G. Advanced nanoemulsions[J]. Annual Review of Physical Chemistry, 2012, 63: 493-518. |

| 100 | Boonme P, Junyaprasert V B, Suksawad N, et al. Microemulsions and nanoemulsions: novel vehicles for whitening cosmeceuticals[J]. Journal of Biomedical Nanotechnology, 2009, 5(4): 373-383. |

| 101 | Sheth T, Seshadri S, Prileszky T, et al. Multiple nanoemulsions[J]. Nature Reviews Materials, 2020, 5(3): 214-228. |

| 102 | Jaiswal M, Dudhe R, Sharma P K. Nanoemulsion: an advanced mode of drug delivery system[J]. 3 Biotech, 2015, 5(2): 123-127. |

| 103 | Solans C, Izquierdo P, Nolla J, et al. Nano-emulsions[J]. Current Opinion in Colloid & Interface Science, 2005, 10(3/4): 102-110. |

| 104 | Ashaolu T J. Nanoemulsions for health, food, and cosmetics: a review[J]. Environmental Chemistry Letters, 2021, 19(4): 3381-3395. |

| 105 | Le N M N, Zsák S, Le-Vinh B, et al. Charge-converting nanoemulsions as promising retinal drug and gene delivery systems[J]. ACS Applied Materials & Interfaces, 2022, 14(39): 44981-44991. |

| 106 | Wilson R J, Li Y, Yang G Z, et al. Nanoemulsions for drug delivery[J]. Particuology, 2022, 64: 85-97. |

| 107 | Li G T, Zhang Z Y, Liu H F, et al. Nanoemulsion-based delivery approaches for nutraceuticals: fabrication, application, characterization, biological fate, potential toxicity and future trends[J]. Food & Function, 2021, 12(5): 1933-1953. |

| 108 | McClements D J. Edible nanoemulsions: fabrication, properties, and functional performance[J]. Soft Matter, 2011, 7(6): 2297-2316. |

| 109 | Modarres-Gheisari S M M, Gavagsaz-Ghoachani R, Malaki M, et al. Ultrasonic nano-emulsification—a review[J]. Ultrasonics Sonochemistry, 2019, 52: 88-105. |

| 110 | Zhao S N, Dong Z Y, Yao C Q, et al. Liquid-liquid two-phase flow in ultrasonic microreactors: cavitation, emulsification, and mass transfer enhancement[J]. AIChE Journal, 2018, 64(4): 1412-1423. |

| 111 | Zhao S N, Yao C Q, Liu L X, et al. Ultrasound emulsification in microreactors: effects of channel material, surfactant nature, and ultrasound parameters[J]. Industrial & Engineering Chemistry Research, 2023, 62(12): 5170-5180. |

| 112 | Nieves E, Vite G, Kozina A, et al. Ultrasound-assisted production and optimization of mini-emulsions in a microfluidic chip in continuous-flow[J]. Ultrasonics Sonochemistry, 2021, 74: 105556. |

| 113 | Wu W H, Eskin D G, Priyadarshi A, et al. New insights into the mechanisms of ultrasonic emulsification in the oil-water system and the role of gas bubbles[J]. Ultrasonics Sonochemistry, 2021, 73: 105501. |

| 114 | Udepurkar A P, Clasen C, Kuhn S. Emulsification mechanism in an ultrasonic microreactor: influence of surface roughness and ultrasound frequency[J]. Ultrasonics Sonochemistry, 2023, 94: 106323. |

| 115 | Tiong T J, Chu J K, Lim L Y, et al. A computational and experimental study on acoustic pressure for ultrasonically formed oil-in-water emulsion[J]. Ultrasonics Sonochemistry, 2019, 56: 46-54. |

| [1] | 阮见, 李双, 温正慧. 自动化与智能化在流动化学中的应用[J]. 化工学报, 2024, 75(11): 4120-4140. |

| [2] | 郑雨婷, 方冠东, 张梦波, 张浩淼, 王靖岱, 阳永荣. 微化工精馏分离技术研究进展[J]. 化工学报, 2024, 75(1): 47-59. |

| [3] | 张梦波, 楼琳瑾, 冯艺荣, 郑雨婷, 张浩淼, 王靖岱, 阳永荣. 烷基铝氧烷合成技术研究进展[J]. 化工学报, 2023, 74(2): 525-534. |

| [4] | 侯跃辉, 刘璇, 廉应江, 韩梅, 尧超群, 陈光文. 超声微反应器内三硝基间苯三酚合成工艺研究[J]. 化工学报, 2022, 73(8): 3597-3607. |

| [5] | 董晓锐, 王凯, 骆广生. 金纳米颗粒的微反应连续合成[J]. 化工学报, 2021, 72(7): 3823-3831. |

| [6] | 李光晓,刘塞尔,苏远海. 微尺度内液-液传质及反应过程强化的研究进展[J]. 化工学报, 2021, 72(1): 452-467. |

| [7] | 黄晋培, 黄丹, 王法军, 徐建鸿. 霍夫曼重排反应过程的研究进展[J]. 化工学报, 2021, 72(1): 158-166. |

| [8] | 李志康, 商鲁伟, 聂苗苗, 邓文生, 谭璟. G/O/W微分散体系实现甲酸/三辛胺-正辛醇体系萃取分离[J]. 化工学报, 2020, 71(9): 4219-4227. |

| [9] | 王凯, 吕阳成, 秦康, 骆广生. 双T型微通道内气液液三相分散规律[J]. 化工学报, 2013, 64(2): 470-475. |

| [10] | 骆广生, 王凯, 吕阳成, 王玉军, 徐建鸿. 微尺度下非均相反应的研究进展[J]. 化工学报, 2013, 64(1): 165-172. |

| [11] | 陈光文, 赵玉潮, 乐军, 董正亚, 曹海山, 袁权. 微化工过程中的传递现象[J]. 化工学报, 2013, 64(1): 63-75. |

| [12] | 骆广生,王 凯,王玉军,吕阳成,徐建鸿. 微化工系统的原理和应用 [J]. CIESC Journal, 2011, 30(8): 1637-. |

| [13] | 李宏亮,文振中,林 莹,解 楠,于新海,栾伟玲,涂善东. 我国在化工、生物与热动力微系统领域的研究进展 [J]. CIESC Journal, 2011, 30(1): 26-. |

| [14] | 孙宏伟1,陈建峰2. 我国化工过程强化技术理论与应用研究进展 [J]. CIESC Journal, 2011, 30(1): 1-. |

| [15] | 陈光文;赵玉潮;袁权. 微尺度下液-液流动与传质特性的研究进展 [J]. CIESC Journal, 2010, 61(7): 1627-1635. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号