化工学报 ›› 2022, Vol. 73 ›› Issue (8): 3597-3607.DOI: 10.11949/0438-1157.20220258

侯跃辉1,2( ), 刘璇1,2, 廉应江1, 韩梅1, 尧超群1(

), 刘璇1,2, 廉应江1, 韩梅1, 尧超群1( ), 陈光文1(

), 陈光文1( )

)

收稿日期:2022-02-24

修回日期:2022-06-09

出版日期:2022-08-05

发布日期:2022-09-06

通讯作者:

尧超群,陈光文

作者简介:侯跃辉(1998—),女,硕士研究生,houyuehui@dicp.ac.cn

基金资助:

Yuehui HOU1,2( ), Xuan LIU1,2, Yingjiang LIAN1, Mei HAN1, Chaoqun YAO1(

), Xuan LIU1,2, Yingjiang LIAN1, Mei HAN1, Chaoqun YAO1( ), Guangwen CHEN1(

), Guangwen CHEN1( )

)

Received:2022-02-24

Revised:2022-06-09

Online:2022-08-05

Published:2022-09-06

Contact:

Chaoqun YAO, Guangwen CHEN

摘要:

三硝基间苯三酚(TNPG)是重要的医药中间体,通常以间苯三酚(PG)为原料,在间歇反应釜中经硝化合成。该工艺存在反应时间长、能耗高、安全性差等问题,亟需开展新型连续合成工艺研究。在超声微反应器中开展了PG混酸硝化过程研究,通过引入超声解决微通道中高黏流体混合差和固体产物易造成通道堵塞的难题,实现TNPG连续合成并大幅缩短了反应时间。此外,基于对原料和产物的质谱等分析,初步探讨了反应路径和行为特征。在优化工艺条件下(PG浓度:1.0 mol/L;硝酸与PG摩尔比:4;反应温度:40℃;停留时间6~10 min),TNPG收率可达80%,固体纯度大于98%。

中图分类号:

侯跃辉, 刘璇, 廉应江, 韩梅, 尧超群, 陈光文. 超声微反应器内三硝基间苯三酚合成工艺研究[J]. 化工学报, 2022, 73(8): 3597-3607.

Yuehui HOU, Xuan LIU, Yingjiang LIAN, Mei HAN, Chaoqun YAO, Guangwen CHEN. Synthesis process of trinitrophloroglucinol in an ultrasonic microreactor[J]. CIESC Journal, 2022, 73(8): 3597-3607.

| Sample No. | 设定浓度/(mol/L) | 外标法测定浓度/(mol/L) | ||||

|---|---|---|---|---|---|---|

| PG | TNPG | PG | PG-S | PG总量 | TNPG | |

| 1 | 0.0412 | 0.0061 | 0.0105 | 0.0332 | 0.0437 | 0.0061 |

| 2 | 0.0212 | 0.0047 | 0.0059 | 0.0181 | 0.0240 | 0.0047 |

| 3 | 0.0419 | 0.0049 | 0.0106 | 0.0313 | 0.0419 | 0.0048 |

表1 外标法测定值与设定值比较

Table 1 Comparison between measurement by external standard method and set values

| Sample No. | 设定浓度/(mol/L) | 外标法测定浓度/(mol/L) | ||||

|---|---|---|---|---|---|---|

| PG | TNPG | PG | PG-S | PG总量 | TNPG | |

| 1 | 0.0412 | 0.0061 | 0.0105 | 0.0332 | 0.0437 | 0.0061 |

| 2 | 0.0212 | 0.0047 | 0.0059 | 0.0181 | 0.0240 | 0.0047 |

| 3 | 0.0419 | 0.0049 | 0.0106 | 0.0313 | 0.0419 | 0.0048 |

| 温度/℃ | 黏度/(mPa·s) | ||

|---|---|---|---|

| 98%硫酸[ | PG溶液 (1 mol/L) | 硝硫混酸 (硝硫比1/3.9) | |

| 10 | 35.1 | 134.1 | 62.6 |

| 20 | 25.8 | 87.1 | 50.8 |

| 30 | 17.1 | 57.5 | 31.3 |

| 40 | 12.9 | 31.3 | 22.7 |

表2 不同温度下反应物黏度

Table 2 Reactant viscosity at different temperatures

| 温度/℃ | 黏度/(mPa·s) | ||

|---|---|---|---|

| 98%硫酸[ | PG溶液 (1 mol/L) | 硝硫混酸 (硝硫比1/3.9) | |

| 10 | 35.1 | 134.1 | 62.6 |

| 20 | 25.8 | 87.1 | 50.8 |

| 30 | 17.1 | 57.5 | 31.3 |

| 40 | 12.9 | 31.3 | 22.7 |

| 溶液/%(质量) | 黏度/(mPa∙s) |

|---|---|

| 甘油/水 | |

| 80 | 69.6 |

| 85 | 135.9 |

| 甘油/乙醇 | |

| 20 | 2.82 |

| 65 | 47.8 |

表3 室温(18℃)下甘油-水溶液和甘油-乙醇溶液黏度

Table 3 Viscosities of glycerol-water mixture and glycerol-ethanol mixtures at room temperature (18℃)

| 溶液/%(质量) | 黏度/(mPa∙s) |

|---|---|

| 甘油/水 | |

| 80 | 69.6 |

| 85 | 135.9 |

| 甘油/乙醇 | |

| 20 | 2.82 |

| 65 | 47.8 |

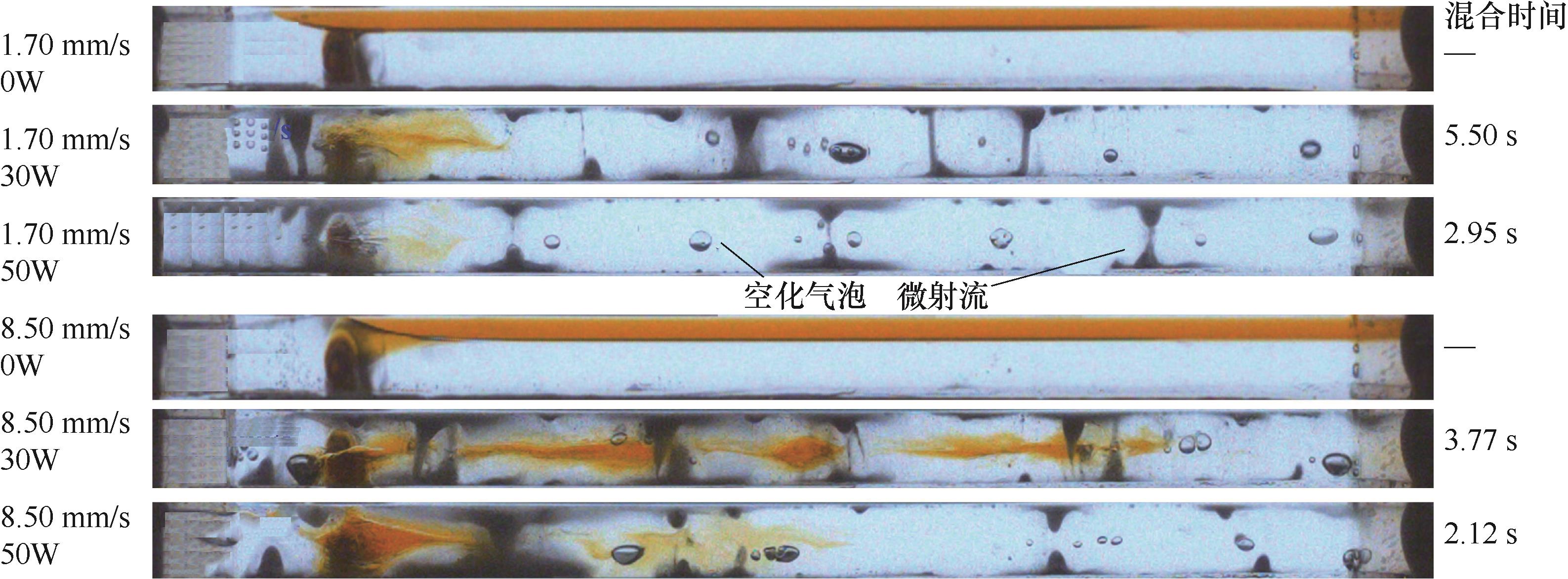

图4 超声功率对超声空化与混合的影响(80%甘油/水-20%甘油/乙醇)

Fig.4 The effect of ultrasonic power on the cavitation and mixing in the channel (80% glycerol/water-20% glycerol/ethanol)

图5 流速对超声空化与混合的影响(85%甘油/水-20%甘油/乙醇,50 W)

Fig.5 The effect of flow velocity on the cavitation and mixing in the channel (85% glycerol/water-20% glycerol/ethanol, 50 W)

| 工艺 | PG反应液 | 硝化试剂 | 整体 | 两相流量比 (混酸/PG) | |

|---|---|---|---|---|---|

| CPG/(mol/L) | N/S | S/PG | N/PG | ||

| 本工艺 | 1.0 | 1/3.9 | 34.1/1 | 4/1 | 1 |

| Cantillo等[ | 1.0 | 1/12.3 | 54.6/1 | 3/1 | 2 |

| 釜式[ | 1.14 | 1/1.25 | 20.8/1 | 4/1 | — |

表4 不同工艺中硫酸用量对比

Table 4 Comparison of sulfuric acid usage between different process conditions

| 工艺 | PG反应液 | 硝化试剂 | 整体 | 两相流量比 (混酸/PG) | |

|---|---|---|---|---|---|

| CPG/(mol/L) | N/S | S/PG | N/PG | ||

| 本工艺 | 1.0 | 1/3.9 | 34.1/1 | 4/1 | 1 |

| Cantillo等[ | 1.0 | 1/12.3 | 54.6/1 | 3/1 | 2 |

| 釜式[ | 1.14 | 1/1.25 | 20.8/1 | 4/1 | — |

图A3 溶解24 h的间苯三酚浓硫酸溶液质谱图因为脱去了两个质子使质荷比变化,图A3中分子量为141.9648和181.9429的质谱峰对应的是二磺化间苯三酚和三磺化间苯三酚的半峰

Fig.A3 Mass spectrogram of composition of sulfuric acid solution of phloroglucinol dissolved more than 24 h

| 1 | Hegetschweiler K, Erni I, Schneider W, et al. Preparation, characterisation, and structure of N-methylated derivatives of 1,3,5-triamino-1,3,5-trideoxy-cis-inositol: polyalcohols with unusual acidity[J]. Helvetica Chimica Acta, 1990, 73(1): 97-105. |

| 2 | Crisponi G, Nurchi V M, Crespo-Alonso M, et al. Chelating agents for metal intoxication[J]. Current Medicinal Chemistry, 2012, 19(17): 2794-2815. |

| 3 | Ramadan A M, Calatayud S J M, Parac-Vogt T N. Trinuclear rare earth metal complexes based on 1,3,5-triamino-1,3,5-trideoxy-cis-inositol as catalysts for the hydrolysis of phosphodiesters[J]. Dalton Transactions (Cambridge, England: 2003), 2011, 40(6): 1230-1232. |

| 4 | 黄靖伦, 张丽媛, 马卿, 等. 无氯TATB的合成工艺改进[J]. 含能材料, 2012, 20(5): 551-554. |

| Huang J L, Zhang L Y, Ma Q, et al. Improvement of synthesis technology of TATB free from chloride[J]. Chinese Journal of Energetic Materials, 2012, 20(5): 551-554. | |

| 5 | 李明豪. 高品质无氯TATB的绿色合成研究[D]. 南京: 南京理工大学, 2013. |

| Li M H. Studies on green synthesis of high quality TATB free from chloride[D]. Nanjing: Nanjing University of Science and Technology, 2013. | |

| 6 | 高鸿宾. 有机化学[M]. 4版. 北京: 高等教育出版社, 2005:5. |

| Gao H B. Organic Chemistry[M]. 4th ed. Beijing: Higher Education Press,2005: 5. | |

| 7 | 杨学斌. TATB合成工艺研究[D]. 北京: 北京理工大学, 2016. |

| Yang X B. Study on synthesis technology of TATB[D]. Beijing: Beijing Institute of Technology, 2016. | |

| 8 | 常婷. 无氯TATB合成工艺及其应用研究[D]. 南京: 南京理工大学, 2018. |

| Chang T. Study on synthesis technogy of TATB without chlorine and its application[D]. Nanjing: Nanjing University of Science and Technology, 2018. | |

| 9 | 陈光文. 微化工技术研究进展[J]. 现代化工, 2007, 27(10): 8-13. |

| Chen G W. Advance and prospect of microchemical engineering and technology[J]. Modern Chemical Industry, 2007, 27(10): 8-13. | |

| 10 | Yu W F, Wei Z Y, Xu R J, et al. Explosive synthesis: novel intrinsically safe method and application with micro-channel reactor[J]. Journal of Physics: Conference Series, 2020, 1507(2): 022030. |

| 11 | Dong Z Y, Zhao S N, Zhang Y C, et al. Mixing and residence time distribution in ultrasonic microreactors[J]. AIChE Journal, 2017, 63(4): 1404-1418. |

| 12 | Hartman R L, Naber J R, Zaborenko N, et al. Overcoming the challenges of solid bridging and constriction during Pd-catalyzed C-N bond formation in microreactors[J]. Organic Process Research & Development, 2010, 14(6): 1347-1357. |

| 13 | Castro F, Kuhn S, Jensen K, et al. Continuous-flow precipitation of hydroxyapatite in ultrasonic microsystems[J]. Chemical Engineering Journal, 2013, 215/216: 979-987. |

| 14 | Horie T, Sumino M, Tanaka T, et al. Photodimerization of maleic anhydride in a microreactor without clogging[J]. Organic Process Research & Development, 2010, 14(2): 405-410. |

| 15 | Zhao S N, Yao C Q, Dong Z Y, et al. Intensification of liquid-liquid two-phase mass transfer by oscillating bubbles in ultrasonic microreactor[J]. Chemical Engineering Science, 2018, 186: 122-134. |

| 16 | Zhao S N, Yao C Q, Dong Z Y, et al. Role of ultrasonic oscillation in chemical processes in microreactors: a mesoscale issue[J]. Particuology, 2020, 48: 88-99. |

| 17 | Dong Z Y, Yao C Q, Zhang Y C, et al. Hydrodynamics and mass transfer of oscillating gas-liquid flow in ultrasonic microreactors[J]. AIChE Journal, 2016, 62(4): 1294-1307. |

| 18 | Cantillo D, Damm M, Dallinger D, et al. Sequential nitration/hydrogenation protocol for the synthesis of triaminophloroglucinol: safe generation and use of an explosive intermediate under continuous-flow conditions[J]. Organic Process Research & Development, 2014, 18(11): 1360-1366. |

| 19 | Rhodes F H, Barbour C B. The viscosities of mixtures of sulfuric acid and water[J]. Industrial & Engineering Chemistry, 1923, 15(8): 850-852. |

| 20 | 刘光启. 化学化工物性数据手册:无机卷[M]. 北京: 化学工业出版社, 2002: 66. |

| Liu G Q. Handbook of Physical Property Data for Chemistry and Chemical Engineering: Inorganic Volume[M]. Beijing: Chemical Industry Press, 2002: 66. | |

| 21 | Zhao S N, Yao C Q, Zhang Q, et al. Acoustic cavitation and ultrasound-assisted nitration process in ultrasonic microreactors: the effects of channel dimension, solvent properties and temperature[J]. Chemical Engineering Journal, 2019, 374: 68-78. |

| 22 | Zhao S N, Dong Z Y, Yao C Q, et al. Liquid-liquid two-phase flow in ultrasonic microreactors: cavitation, emulsification, and mass transfer enhancement[J]. AIChE Journal, 2018, 64(4): 1412-1423. |

| 23 | Guo C, Liu J, Li X H, et al. Effect of cavitation bubble on the dispersion of magnetorheological polishing fluid under ultrasonic preparation[J]. Ultrasonics Sonochemistry, 2021, 79: 105782. |

| 24 | Ozcelik A, Ahmed D, Xie Y L, et al. An acoustofluidic micromixer via bubble inception and cavitation from microchannel sidewalls[J]. Analytical Chemistry, 2014, 86(10): 5083-5088. |

| 25 | Wu W Q, Feng W, Lin Q H, et al. Synthesis and thermal decomposition of TNPG[J]. Thermochimica Acta, 2020, 683: 178396. |

| 26 | Cho J K, Kim Y T, Kim Y G, et al. Practical neutral aromatic nitration with nitrogen dioxide in the presence of heterogeneous catalysts under moderate oxygen pressure[J]. Research on Chemical Intermediates, 2006, 32(8): 759-766. |

| 27 | Ross D S, Kuhlmann K F, Malhotra R. Studies in aromatic nitration. 2. Nitrogen-14 NMR study of the nitric acid/nitronium ion equilibrium in aqueous sulfuric-acid[J]. Journal of the American Chemical Society, 1983, 105(13): 4299-4302. |

| 28 | Wen Z H, Yang M, Zhao S N, et al. Kinetics study of heterogeneous continuous-flow nitration of trifluoromethoxybenzene[J]. Reaction Chemistry & Engineering, 2018, 3(3): 379-387. |

| 29 | Shen J N, Zhao Y C, Chen G W, et al. Investigation of nitration processes of iso-octanol with mixed acid in a microreactor[J]. Chinese Journal of Chemical Engineering, 2009, 17(3): 412-418. |

| 30 | Song J, Cui Y J, Luo G S, et al. Kinetic study of o-nitrotoluene nitration in a homogeneously continuous microflow[J]. Reaction Chemistry & Engineering, 2022, 7(1): 111-122. |

| 31 | Zaldivar J M, Barcons C, Hernandez H, et al. Modelling and optimization of semibatch toluene mononitration with mixed acid from performance and safety viewpoints[J]. Chemical Engineering Science, 1992, 47(9/10/11): 2517-2522. |

| 32 | Andreozzi R, Canterino M, Caprio V, et al. Salicylic acid nitration by means of nitric acid/acetic acid system: chemical and kinetic characterization[J]. Organic Process Research & Development, 2006, 10(6): 1199-1204. |

| 33 | Quadros P A, Oliveira N M C, Baptista C M S G. Continuous adiabatic industrial benzene nitration with mixed acid at a pilot plant scale[J]. Chemical Engineering Journal, 2005, 108(1/2): 1-11. |

| [1] | 陈爱强, 代艳奇, 刘悦, 刘斌, 吴翰铭. 基板温度对HFE7100液滴蒸发过程的影响研究[J]. 化工学报, 2023, 74(S1): 191-197. |

| [2] | 谈莹莹, 刘晓庆, 王林, 黄鲤生, 李修真, 王占伟. R1150/R600a自复叠制冷循环开机动态特性实验研究[J]. 化工学报, 2023, 74(S1): 213-222. |

| [3] | 江河, 袁俊飞, 王林, 邢谷雨. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244. |

| [4] | 程小松, 殷勇高, 车春文. 不同工质在溶液除湿真空再生系统中的性能对比[J]. 化工学报, 2023, 74(8): 3494-3501. |

| [5] | 刘文竹, 云和明, 王宝雪, 胡明哲, 仲崇龙. 基于场协同和 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. |

| [6] | 汪尔奇, 彭书舟, 杨震, 段远源. 含HFO混合体系气液相平衡的理论模型评价[J]. 化工学报, 2023, 74(8): 3216-3225. |

| [7] | 黄可欣, 李彤, 李桉琦, 林梅. 加装旋转叶轮T型通道流场的模态分解[J]. 化工学报, 2023, 74(7): 2848-2857. |

| [8] | 张艳梅, 袁涛, 李江, 刘亚洁, 孙占学. 高效SRB混合菌群构建及其在酸胁迫条件下的性能研究[J]. 化工学报, 2023, 74(6): 2599-2610. |

| [9] | 姚晓宇, 沈俊, 李健, 李振兴, 康慧芳, 唐博, 董学强, 公茂琼. 流体气液临界参数测量方法研究进展[J]. 化工学报, 2023, 74(5): 1847-1861. |

| [10] | 党玉荣, 莫春兰, 史科锐, 方颖聪, 张子杨, 李作顺. 综合评价模型联合遗传算法的混合工质ORC系统性能研究[J]. 化工学报, 2023, 74(5): 1884-1895. |

| [11] | 孙永尧, 高秋英, 曾文广, 王佳铭, 陈艺飞, 周永哲, 贺高红, 阮雪华. 面向含氮油田伴生气提质利用的膜耦合分离工艺设计优化[J]. 化工学报, 2023, 74(5): 2034-2045. |

| [12] | 刘倩, 曹禹, 周琦, 穆景山, 历伟. 孔道结构修饰的Ziegler-Natta催化剂设计与高抗冲低缠结UHMWPE的制备[J]. 化工学报, 2023, 74(3): 1092-1101. |

| [13] | 陈号, 田仪娟, 全学军, 蒋子文, 李纲. 铬铁矿在HCl-HF体系中的分解行为[J]. 化工学报, 2023, 74(3): 1161-1174. |

| [14] | 贾露凡, 王艺颖, 董钰漫, 李沁园, 谢鑫, 苑昊, 孟涛. 微流控双水相贴壁液滴流动强化酶促反应研究[J]. 化工学报, 2023, 74(3): 1239-1246. |

| [15] | 张雪婷, 胡激江, 赵晶, 李伯耿. 高分子量聚丙二醇在微通道反应器中的制备[J]. 化工学报, 2023, 74(3): 1343-1351. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号