化工学报 ›› 2025, Vol. 76 ›› Issue (7): 3259-3273.DOI: 10.11949/0438-1157.20241502

收稿日期:2024-12-25

修回日期:2025-02-10

出版日期:2025-07-25

发布日期:2025-08-13

通讯作者:

戴贵龙

作者简介:王孝宇(2000—),男,硕士研究生,1476473619@qq.com

基金资助:

Xiaoyu WANG1( ), Guilong DAI1,2(

), Guilong DAI1,2( ), Shukun DENG1, Lingzhu GONG2

), Shukun DENG1, Lingzhu GONG2

Received:2024-12-25

Revised:2025-02-10

Online:2025-07-25

Published:2025-08-13

Contact:

Guilong DAI

摘要:

为提高泡沫多孔介质的流动-传热综合性能,基于Laguerre-Voronoi镶嵌(LVT)算法,建立了具有人工可控孔隙结构的LV开孔泡沫模型。采用经实验验证的孔隙尺度方法,对比分析了边界无封闭骨架(O-LV)和边界有封闭骨架(E-LV)两类LV泡沫的流动、传热及综合性能,并提炼了压降和传热的关联式。结果表明,当径、轴向元胞数大于等于5层时,数值结果满足元胞独立性要求;相比传统陶瓷及L-K泡沫,LV泡沫具有更好的综合性能;在表观流速为0.1~5.0 m/s时,增设封闭骨架能够有效改善壁面效应,且综合性能最大可提升6.0%~9.3%;两类LV泡沫关联式均具有良好的预测精度(R2≥0.98,MAPE≤27%),其孔隙率和Reynolds数的适用范围分别为0.529<ϕ<0.967,14<Reh<3835和0.614<ϕ<0.970,15<Reh<4487。在此基础上推导出了LV泡沫综合性能表达式,由孔隙率和Reynolds数即可预测其综合性能,为高效吸热器及反应器的进一步设计提供了参考。

中图分类号:

王孝宇, 戴贵龙, 邓树坤, 龚凌诸. Laguerre-Voronoi开孔泡沫流动-传热综合性能孔隙尺度模拟[J]. 化工学报, 2025, 76(7): 3259-3273.

Xiaoyu WANG, Guilong DAI, Shukun DENG, Lingzhu GONG. Pore-scale simulation of heat transfer and pressure drop performance in Laguerre-Voronoi open-cell foams[J]. CIESC Journal, 2025, 76(7): 3259-3273.

| dc/m | ds/dc | ϕO-LV | ϕE-LV | asf, O-LV/m-1 | asf, E-LV/m-1 | dh, O-LV/m | dh, E-LV/m |

|---|---|---|---|---|---|---|---|

| 0.003 | 0.10 | 0.970 | 0.967 | 365.1 | 399.4 | 0.0106 | 0.0097 |

| 0.25 | 0.843 | 0.833 | 710.4 | 796.5 | 0.0047 | 0.0042 | |

| 0.30 | 0.802 | 0.782 | 784.3 | 890.2 | 0.0041 | 0.0035 | |

| 0.36 | 0.736 | 0.704 | 842.1 | 955.4 | 0.0035 | 0.0029 | |

| 0.45 | 0.616 | 0.581 | 903.0 | 1031.1 | 0.0027 | 0.0023 | |

| 0.004 | 0.10 | 0.969 | 0.967 | 302.3 | 333.2 | 0.0128 | 0.0116 |

| 0.25 | 0.839 | 0.808 | 597.1 | 649.2 | 0.0056 | 0.0050 | |

| 0.30 | 0.797 | 0.755 | 670.9 | 727.9 | 0.0048 | 0.0042 | |

| 0.36 | 0.732 | 0.671 | 715.6 | 781.1 | 0.0041 | 0.0034 | |

| 0.45 | 0.614 | 0.538 | 762.0 | 841.3 | 0.0032 | 0.0026 | |

| 0.005 | 0.10 | 0.968 | 0.965 | 246.3 | 274.7 | 0.0157 | 0.0141 |

| 0.25 | 0.838 | 0.807 | 475.1 | 521.3 | 0.0071 | 0.0062 | |

| 0.30 | 0.793 | 0.754 | 524.5 | 588.1 | 0.0060 | 0.0051 | |

| 0.36 | 0.731 | 0.664 | 566.9 | 635.6 | 0.0052 | 0.0042 | |

| 0.45 | 0.617 | 0.529 | 600.0 | 675.1 | 0.0041 | 0.0031 |

表1 LV泡沫结构参数

Table 1 Structural parameters of the LV foams

| dc/m | ds/dc | ϕO-LV | ϕE-LV | asf, O-LV/m-1 | asf, E-LV/m-1 | dh, O-LV/m | dh, E-LV/m |

|---|---|---|---|---|---|---|---|

| 0.003 | 0.10 | 0.970 | 0.967 | 365.1 | 399.4 | 0.0106 | 0.0097 |

| 0.25 | 0.843 | 0.833 | 710.4 | 796.5 | 0.0047 | 0.0042 | |

| 0.30 | 0.802 | 0.782 | 784.3 | 890.2 | 0.0041 | 0.0035 | |

| 0.36 | 0.736 | 0.704 | 842.1 | 955.4 | 0.0035 | 0.0029 | |

| 0.45 | 0.616 | 0.581 | 903.0 | 1031.1 | 0.0027 | 0.0023 | |

| 0.004 | 0.10 | 0.969 | 0.967 | 302.3 | 333.2 | 0.0128 | 0.0116 |

| 0.25 | 0.839 | 0.808 | 597.1 | 649.2 | 0.0056 | 0.0050 | |

| 0.30 | 0.797 | 0.755 | 670.9 | 727.9 | 0.0048 | 0.0042 | |

| 0.36 | 0.732 | 0.671 | 715.6 | 781.1 | 0.0041 | 0.0034 | |

| 0.45 | 0.614 | 0.538 | 762.0 | 841.3 | 0.0032 | 0.0026 | |

| 0.005 | 0.10 | 0.968 | 0.965 | 246.3 | 274.7 | 0.0157 | 0.0141 |

| 0.25 | 0.838 | 0.807 | 475.1 | 521.3 | 0.0071 | 0.0062 | |

| 0.30 | 0.793 | 0.754 | 524.5 | 588.1 | 0.0060 | 0.0051 | |

| 0.36 | 0.731 | 0.664 | 566.9 | 635.6 | 0.0052 | 0.0042 | |

| 0.45 | 0.617 | 0.529 | 600.0 | 675.1 | 0.0041 | 0.0031 |

| 样品类型 | D/mm | L/mm | ϕ | ds/dc | dc/mm |

|---|---|---|---|---|---|

| E-LV | 25 | 40 | 0.629 | 0.41 | 4.0 |

| O-LV | 25 | 40 | 0.566 | 0.41 | 4.0 |

表2 实验样品的几何参数

Table 2 Geometric parameters of experimental samples

| 样品类型 | D/mm | L/mm | ϕ | ds/dc | dc/mm |

|---|---|---|---|---|---|

| E-LV | 25 | 40 | 0.629 | 0.41 | 4.0 |

| O-LV | 25 | 40 | 0.566 | 0.41 | 4.0 |

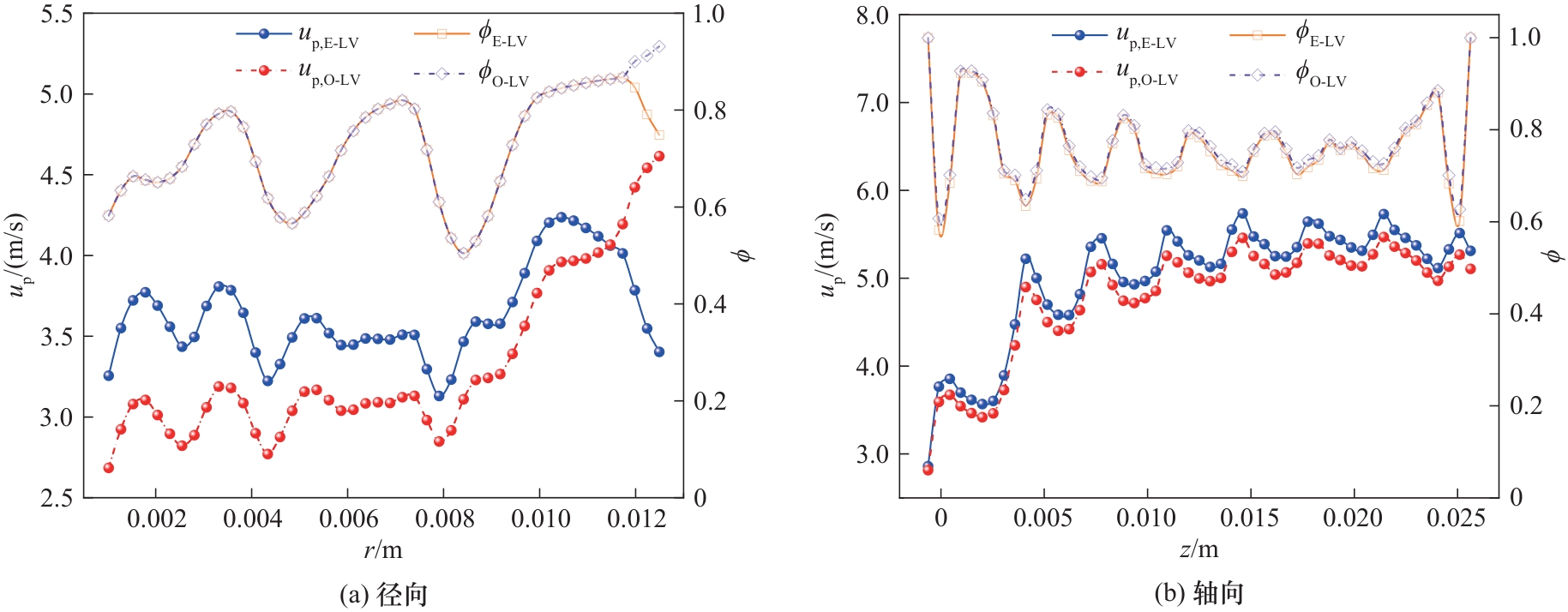

图9 平均流速及孔隙率分布(dc=4 mm,ds/dc=0.30,U=2.0 m/s)

Fig.9 Distribution of average velocity and porosity in O-LV and E-LV foams (dc=4 mm, ds/dc=0.30, U=2.0 m/s)

| 模型 | 经验关联式 | 评价指标 | |

|---|---|---|---|

| R2 | MAPE | ||

| E-LV | 0.99 | 20.6% | |

| 0.98 | 26.5% | ||

| O-LV | 0.99 | 20.4% | |

| 0.98 | 27.0% | ||

表3 传热和压降经验关联式及评价指标

Table 3 Empirical correlations and evaluation indicators of the heat transfer and pressure drop

| 模型 | 经验关联式 | 评价指标 | |

|---|---|---|---|

| R2 | MAPE | ||

| E-LV | 0.99 | 20.6% | |

| 0.98 | 26.5% | ||

| O-LV | 0.99 | 20.4% | |

| 0.98 | 27.0% | ||

| [1] | Chowdhury S, Nugraha A S, O'May R, et al. Bimetallic metal-organic framework-derived porous one-dimensional carbon materials for electrochemical sensing of dopamine[J]. Chemical Engineering Journal, 2024, 492: 152124. |

| [2] | Radogna C, Serrano I, Fargas G, et al. Chemical etching optimization of 3D printed α-Al2O3 monoliths to enhance the catalytic applications[J]. Journal of the European Ceramic Society, 2024, 44(12): 7189-7200. |

| [3] | Fan C, Li Y, Xia X L, et al. Pore-level structural optimization of porous foams for enhancing heat transfer and reducing pressure drop simultaneously[J]. International Communications in Heat and Mass Transfer, 2022, 136: 106215. |

| [4] | 赵长颖, 潘智豪, 王倩, 等. 多孔介质的相变和热化学储热性能[J]. 科学通报, 2016, 61(17): 1897-1915. |

| Zhao C Y, Pan Z H, Wang Q, et al. Heat transfer of phase change materials (PCMs) and thermochemical heat storage in porous materials [J]. Chinese Science Bulletin, 2016, 61(17): 1897-1915. | |

| [5] | Arasteh H, Mashayekhi R, Goodarzi M, et al. Heat and fluid flow analysis of metal foam embedded in a double-layered sinusoidal heat sink under local thermal non-equilibrium condition using nanofluid[J]. Journal of Thermal Analysis and Calorimetry, 2019, 138(2): 1461-1476. |

| [6] | Sheikholeslami M, Rezaeianjouybari B, Darzi M, et al. Application of nano-refrigerant for boiling heat transfer enhancement employing an experimental study[J]. International Journal of Heat and Mass Transfer, 2019, 141: 974-980. |

| [7] | 郑坤灿, 温治, 王占胜, 等. 前沿领域综述多孔介质强制对流换热研究进展[J]. 物理学报, 2012, 61(1): 532-542. |

| Zheng K C, Wen Z, Wang Z S, et al. Review on forced convection heat transfer in porous media[J]. Acta Physica Sinica, 2012, 61(1): 532-542. | |

| [8] | 张承全, 高军, 吕立鹏, 等. 单一尺寸圆柱颗粒填充床的阻力特性[J]. 化工学报, 2019, 70(11): 4181-4190. |

| Zhang C Q, Gao J, Lyu L P, et al. Resistance characteristics of bed packed with mono-size cylindrical particles[J]. CIESC Journal, 2019, 70(11): 4181-4190. | |

| [9] | Wu Z Y, Caliot C, Flamant G, et al. Numerical simulation of convective heat transfer between air flow and ceramic foams to optimise volumetric solar air receiver performances[J]. International Journal of Heat and Mass Transfer, 2011, 54(7/8): 1527-1537. |

| [10] | Dietrich B. Heat transfer coefficients for solid ceramic sponges—experimental results and correlation[J]. International Journal of Heat and Mass Transfer, 2013, 61: 627-637. |

| [11] | Xia X L, Chen X, Sun C, et al. Experiment on the convective heat transfer from airflow to skeleton in open-cell porous foams[J]. International Journal of Heat and Mass Transfer, 2017, 106: 83-90. |

| [12] | Sun M R, Li M, Hu C Z, et al. Comparison of forced convective heat transfer between pillar and real foam structure under high Reynolds number[J]. Applied Thermal Engineering, 2021, 182: 116130. |

| [13] | Moreira A C, Appoloni C R, Rocha W R D, et al. Determination of the porosity and pore size distribution of SiC ceramic foams by nuclear methodologies[J]. Advances in Applied Ceramics, 2010, 109(7): 416-420. |

| [14] | Ghosh I. Heat-transfer analysis of high porosity open-cell metal foam[J]. Journal of Heat Transfer, 2008, 130(3): 034501. |

| [15] | Sun M R, Hu C Z, Zha L G, et al. Pore-scale simulation of forced convection heat transfer under turbulent conditions in open-cell metal foam[J]. Chemical Engineering Journal, 2020, 389: 124427. |

| [16] | Weaire D, Phelan R. A counter-example to Kelvin's conjecture on minimal surfaces[J]. Philosophical Magazine Letters, 1994, 69(2): 107-110. |

| [17] | Cheng Z L, Xu R N, Jiang P X. Morphology, flow and heat transfer in triply periodic minimal surface based porous structures[J]. International Journal of Heat and Mass Transfer, 2021, 170: 120902. |

| [18] | Nie Z W, Lin Y Y, Tong Q B. Numerical investigation of pressure drop and heat transfer through open cell foams with 3D Laguerre-Voronoi model[J]. International Journal of Heat and Mass Transfer, 2017, 113: 819-839. |

| [19] | Ferenc J S, Néda Z. On the size distribution of Poisson Voronoi cells[J]. Physica A: Statistical Mechanics and its Applications, 2007, 385(2): 518-526. |

| [20] | Zhang P, Karimpour M, Balint D, et al. A controlled Poisson Voronoi tessellation for grain and cohesive boundary generation applied to crystal plasticity analysis[J]. Computational Materials Science, 2012, 64: 84-89. |

| [21] | Nie Z W, Lin Y Y, Tong Q B. Modeling structures of open cell foams[J]. Computational Materials Science, 2017, 131: 160-169. |

| [22] | Paknahad R, Siavashi M, Hosseini M. Pore-scale fluid flow and conjugate heat transfer study in high porosity Voronoi metal foams using multi-relaxation-time regularized lattice Boltzmann (MRT-RLB) method[J]. International Communications in Heat and Mass Transfer, 2023, 141: 106607. |

| [23] | Xu Q, Wu Y B, Chen Y, et al. Unlocking the thermal efficiency of irregular open-cell metal foams: a computational exploration of flow dynamics and heat transfer phenomena[J]. Energies, 2024, 17(6): 1305. |

| [24] | Skibinski J, Cwieka K, Kowalkowski T, et al. The influence of pore size variation on the pressure drop in open-cell foams[J]. Materials & Design, 2015, 87: 650-655. |

| [25] | Inayat A, Klumpp M, Lämmermann M, et al. Development of a new pressure drop correlation for open-cell foams based completely on theoretical grounds: taking into account strut shape and geometric tortuosity[J]. Chemical Engineering Journal, 2016, 287: 704-719. |

| [26] | Dietrich B, Schabel W, Kind M, et al. Pressure drop measurements of ceramic sponges: determining the hydraulic diameter[J]. Chemical Engineering Science, 2009, 64(16): 3633-3640. |

| [27] | Sepehri E, Siavashi M. Pore-scale direct numerical simulation of fluid dynamics, conduction and convection heat transfer in open-cell Voronoi porous foams[J]. International Communications in Heat and Mass Transfer, 2022, 137: 106274. |

| [28] | Khairullin A, Haibullina A, Sinyavin A, et al. Heat transfer in 3D Laguerre-Voronoi open-cell foams under pulsating flow[J]. Energies, 2022, 15(22): 8660. |

| [29] | Cheng L C, Wong S C. Pore-scale numerical simulation and LTNE analysis for fully-developed forced convective heat transfer in packed beds of mono-sized rough spheres covering near-wall and core regions[J]. International Journal of Heat and Mass Transfer, 2023, 208: 124047. |

| [30] | Du S, Li M J, Ren Q L, et al. Pore-scale numerical simulation of fully coupled heat transfer process in porous volumetric solar receiver[J]. Energy, 2017, 140: 1267-1275. |

| [31] | Du S, Tong ZX, Zhang HH, et al. Tomography-based determination of Nusselt number correlation for the porous volumetric solar receiver with different geometrical parameters[J]. Renewable Energy, 2019, 135: 711-718. |

| [32] | Wu Z Y, Caliot C, Bai F W, et al. Experimental and numerical studies of the pressure drop in ceramic foams for volumetric solar receiver applications[J]. Applied Energy, 2010, 87(2): 504-513. |

| [33] | Yang C, Zhao Y J, Kang L M, et al. High-strength silicon brass manufactured by selective laser melting[J]. Materials Letters, 2018, 210: 169-172. |

| [34] | An J T, Chen C J, Zhang M. Effect of CaCO3 content change on the production of closed-cell aluminum foam by selective laser melting[J]. Optics & Laser Technology, 2021, 141: 107097. |

| [35] | Moffat R J. Describing the uncertainties in experimental results[J]. Experimental Thermal and Fluid Science, 1988, 1(1): 3-17. |

| [36] | Dybbs A, Edwards R V. A new look at porous media fluid mechanics: darcy to turbulent[M]//Fundamentals of Transport Phenomena in Porous Media. Dordrecht: Springer Netherlands, 1984: 199-256. |

| [37] | Strąk K, Piasecka M. The applicability of heat transfer correlations to flows in minichannels and new correlation for subcooled flow boiling[J]. International Journal of Heat and Mass Transfer, 2020, 158: 119933. |

| [1] | 袁琳慧, 王瑜. 单服务器浸没射流式液冷系统散热性能[J]. 化工学报, 2025, 76(S1): 160-169. |

| [2] | 赵子祥, 段钟弟, 孙浩然, 薛鸿祥. 大温差两相流动诱导水锤冲击的数值模型[J]. 化工学报, 2025, 76(S1): 170-180. |

| [3] | 黄博, 黄灏, 王文, 贺隆坤. 薄膜型LNG船液货舱温度场计算分析[J]. 化工学报, 2025, 76(S1): 195-204. |

| [4] | 汪思远, 刘国强, 熊通, 晏刚. 窗式空调器轴流风机的风速非均匀分布特性及其对冷凝器流路优化设计的影响规律[J]. 化工学报, 2025, 76(S1): 205-216. |

| [5] | 孙云龙, 徐肖肖, 黄永方, 郭纪超, 陈卫卫. 水平光滑管内CO2流动沸腾的非绝热可视化研究[J]. 化工学报, 2025, 76(S1): 230-236. |

| [6] | 郭纪超, 徐肖肖, 孙云龙. 基于植物工厂中的CO2浓度气流模拟及优化研究[J]. 化工学报, 2025, 76(S1): 237-245. |

| [7] | 孔俊龙, 毕扬, 赵耀, 代彦军. 储能电池直冷热管理系统的模拟实验[J]. 化工学报, 2025, 76(S1): 289-296. |

| [8] | 吴梓航, 徐震原, 游锦方, 潘权稳, 王如竹. 基于吸附式储冷技术的深井钻探设备冷却系统[J]. 化工学报, 2025, 76(S1): 309-317. |

| [9] | 于宏鑫, 王宁波, 郭焱华, 邵双全. 动态蓄冰系统的板式换热器流动换热模拟研究[J]. 化工学报, 2025, 76(S1): 106-113. |

| [10] | 吴馨, 龚建英, 李祥宇, 王宇涛, 杨小龙, 蒋震. 超声波激励疏水表面液滴运动的实验研究[J]. 化工学报, 2025, 76(S1): 133-139. |

| [11] | 燕子腾, 詹飞龙, 丁国良. 空调用套管式分流器结构设计及分流效果验证[J]. 化工学报, 2025, 76(S1): 152-159. |

| [12] | 郭松源, 周晓庆, 缪五兵, 汪彬, 耑锐, 曹庆泰, 陈成成, 杨光, 吴静怡. 火箭上升段含多孔板液氧贮箱增压输运数值研究[J]. 化工学报, 2025, 76(S1): 62-74. |

| [13] | 任现超, 谷雅秀, 段少斌, 贾文竹, 李汉林. 翅片式椭圆套管蒸发式冷凝器传热传质性能实验研究[J]. 化工学报, 2025, 76(S1): 75-83. |

| [14] | 王俊鹏, 冯佳琪, 张恩搏, 白博峰. 曲折式与阵列式迷宫阀芯结构内流动与空化特性研究[J]. 化工学报, 2025, 76(S1): 93-105. |

| [15] | 周臣儒, 刘陈伟, 王志远, 綦民辉, 董三宝, 王翔宇, 李明忠. 甲醇和乙二醇对甲烷水合物黏附强度的影响[J]. 化工学报, 2025, 76(7): 3596-3604. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号