化工学报 ›› 2025, Vol. 76 ›› Issue (10): 5262-5276.DOI: 10.11949/0438-1157.20250455

收稿日期:2025-04-28

修回日期:2025-05-31

出版日期:2025-10-25

发布日期:2025-11-25

通讯作者:

周池楼

作者简介:周池楼(1987—),男,博士,副教授,mezcl@scut.edu.cn

基金资助:

Chilou ZHOU( ), Zhiyu LI, Yiran ZHENG

), Zhiyu LI, Yiran ZHENG

Received:2025-04-28

Revised:2025-05-31

Online:2025-10-25

Published:2025-11-25

Contact:

Chilou ZHOU

摘要:

氢致鼓泡断裂是高压氢气快速减压过程中橡胶内部发生的一种损伤现象。针对常用的密封件材料丁腈橡胶(nitrile butadiene rubber,NBR),建立NBR氢致鼓泡有限元模型,研究了单次氢暴露和氢循环暴露工况下橡胶内部损伤演化机制,并探究了填料、氢渗透特性、服役工况参数和空穴参量对NBR氢致鼓泡的影响。结果表明,在单次氢暴露中,泄压结束时刻是NBR最有可能发生鼓泡断裂的时间点;氢循环暴露会扩大空穴损伤,加剧鼓泡断裂风险。填料的加入可提高NBR的抗氢致鼓泡断裂。氢溶解度的增大、氢扩散系数的减小会提高鼓泡断裂的可能。减小氢气压力和泄压速率可以降低鼓泡断裂风险。较大的空穴半径、较小的空穴间距以及较大的空穴数量会带来较大的鼓泡断裂风险。

中图分类号:

周池楼, 李治宇, 郑益然. 高压氢环境下丁腈橡胶密封件氢致鼓泡断裂研究[J]. 化工学报, 2025, 76(10): 5262-5276.

Chilou ZHOU, Zhiyu LI, Yiran ZHENG. Study on hydrogen-induced blister fracture of nitrile butadiene rubber seals servicing in high-pressure hydrogen environments[J]. CIESC Journal, 2025, 76(10): 5262-5276.

| 种类 | 参数 | |||||

|---|---|---|---|---|---|---|

| μ1 | μ2 | μ3 | α1 | α2 | α3 | |

| NBR-NF | -1.11867425 | 0.55769888 | 2.22428450 | 3.95182467 | 4.29235510 | -5.95262505 |

| NBR-CB60 | -1.03881682 | 0.04061428 | 3.42857186 | 3.25216863 | 4.47136825 | -6.19905068 |

| NBR-SC40 | -2.69313709 | 0.00685580 | 5.37184092 | 0.76680401 | 5.66714773 | -3.78859558 |

| NBR-SC60 | -12.83982220 | 0.38383626 | 15.57560000 | -0.81938224 | 3.49021679 | -1.84497194 |

| NBR-SC80 | -1.21929769 | -5.31274737 | 15.08764880 | -1.99373914 | 3.35181852 | -6.40709787 |

表1 NBR材料模型参数

Table 1 Material model parameters for NBR

| 种类 | 参数 | |||||

|---|---|---|---|---|---|---|

| μ1 | μ2 | μ3 | α1 | α2 | α3 | |

| NBR-NF | -1.11867425 | 0.55769888 | 2.22428450 | 3.95182467 | 4.29235510 | -5.95262505 |

| NBR-CB60 | -1.03881682 | 0.04061428 | 3.42857186 | 3.25216863 | 4.47136825 | -6.19905068 |

| NBR-SC40 | -2.69313709 | 0.00685580 | 5.37184092 | 0.76680401 | 5.66714773 | -3.78859558 |

| NBR-SC60 | -12.83982220 | 0.38383626 | 15.57560000 | -0.81938224 | 3.49021679 | -1.84497194 |

| NBR-SC80 | -1.21929769 | -5.31274737 | 15.08764880 | -1.99373914 | 3.35181852 | -6.40709787 |

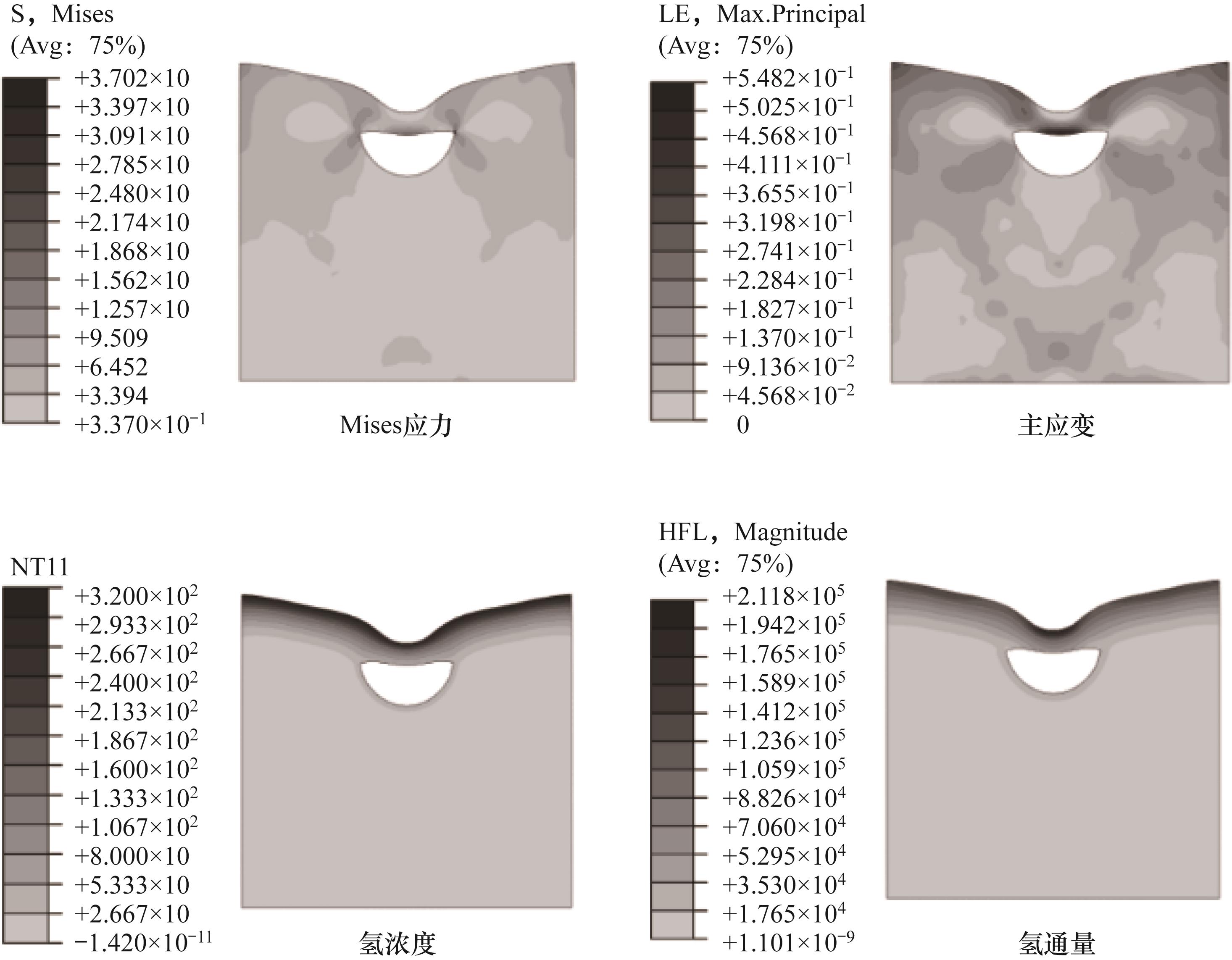

图6 氢气加压结束时NBR样品的Mises应力、主应变、氢浓度和氢通量云图

Fig.6 Mises stress, principal strain, hydrogen concentration, and hydrogen flux across the NBR sample at the end of pressurization

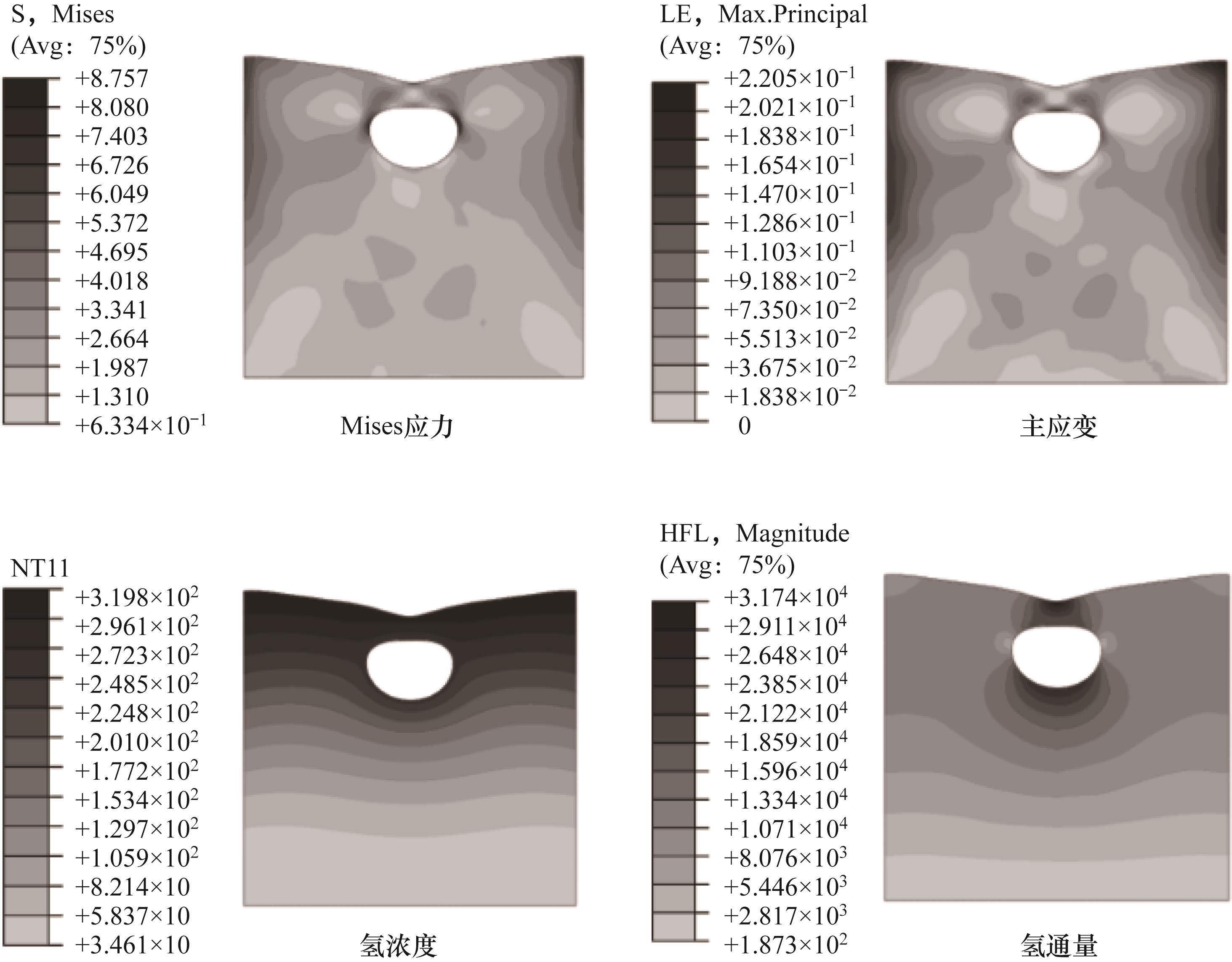

图7 氢气保压结束时NBR样品的Mises应力、主应变、氢浓度和氢通量云图

Fig.7 Mises stress, principal strain, hydrogen concentration, and hydrogen flux across the NBR sample at the end of pressure maintenance

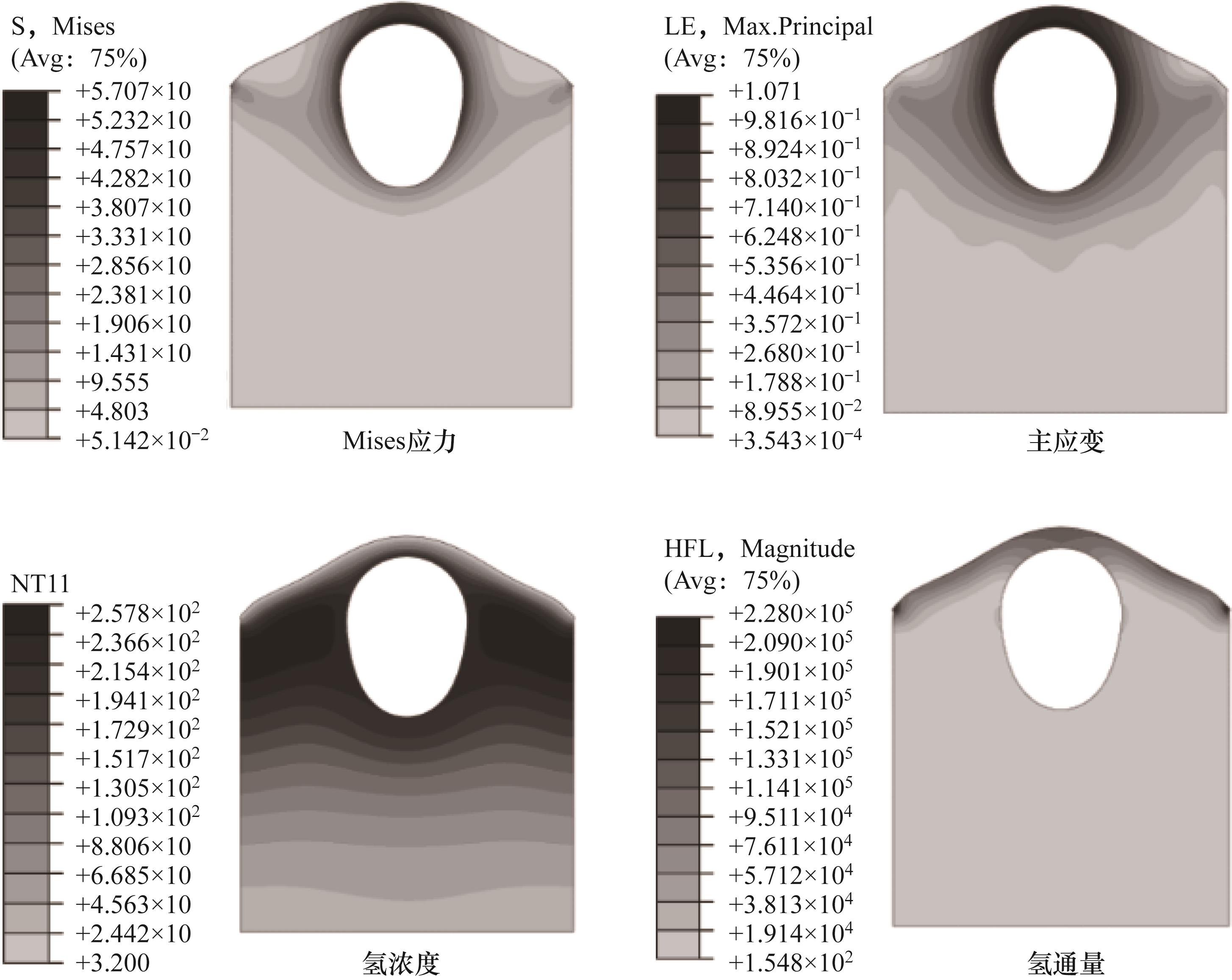

图8 氢气泄压结束时NBR样品的Mises应力、主应变、氢浓度和氢通量云图

Fig.8 Mises stress, principal strain, hydrogen concentration, and hydrogen flux across the NBR sample at the end of depressurization

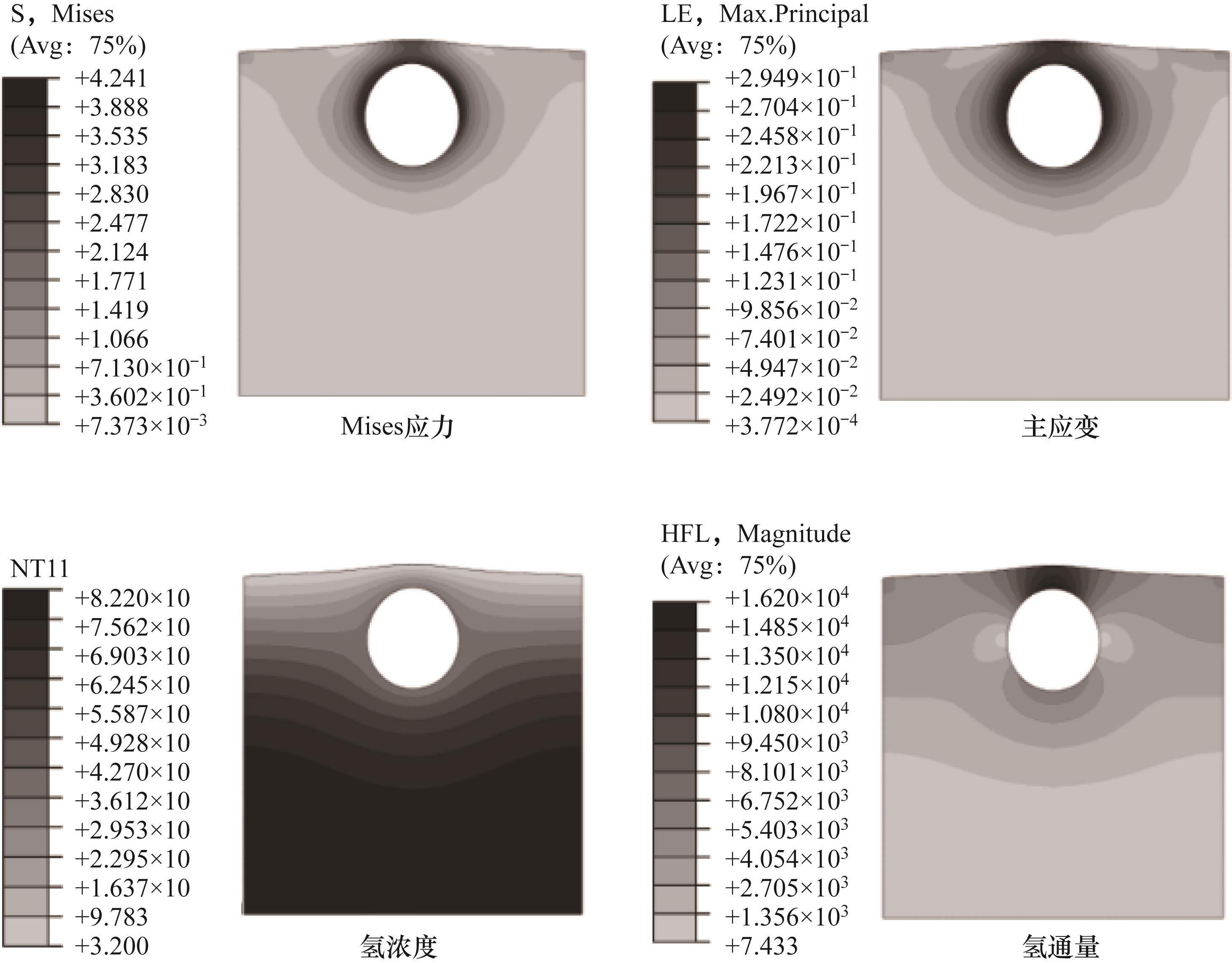

图9 氢气常压结束时NBR样品的Mises应力、主应变、氢浓度和氢通量云图

Fig.9 Mises stress, principal strain, hydrogen concentration, and hydrogen flux across the NBR sample at the end of ambient pressure

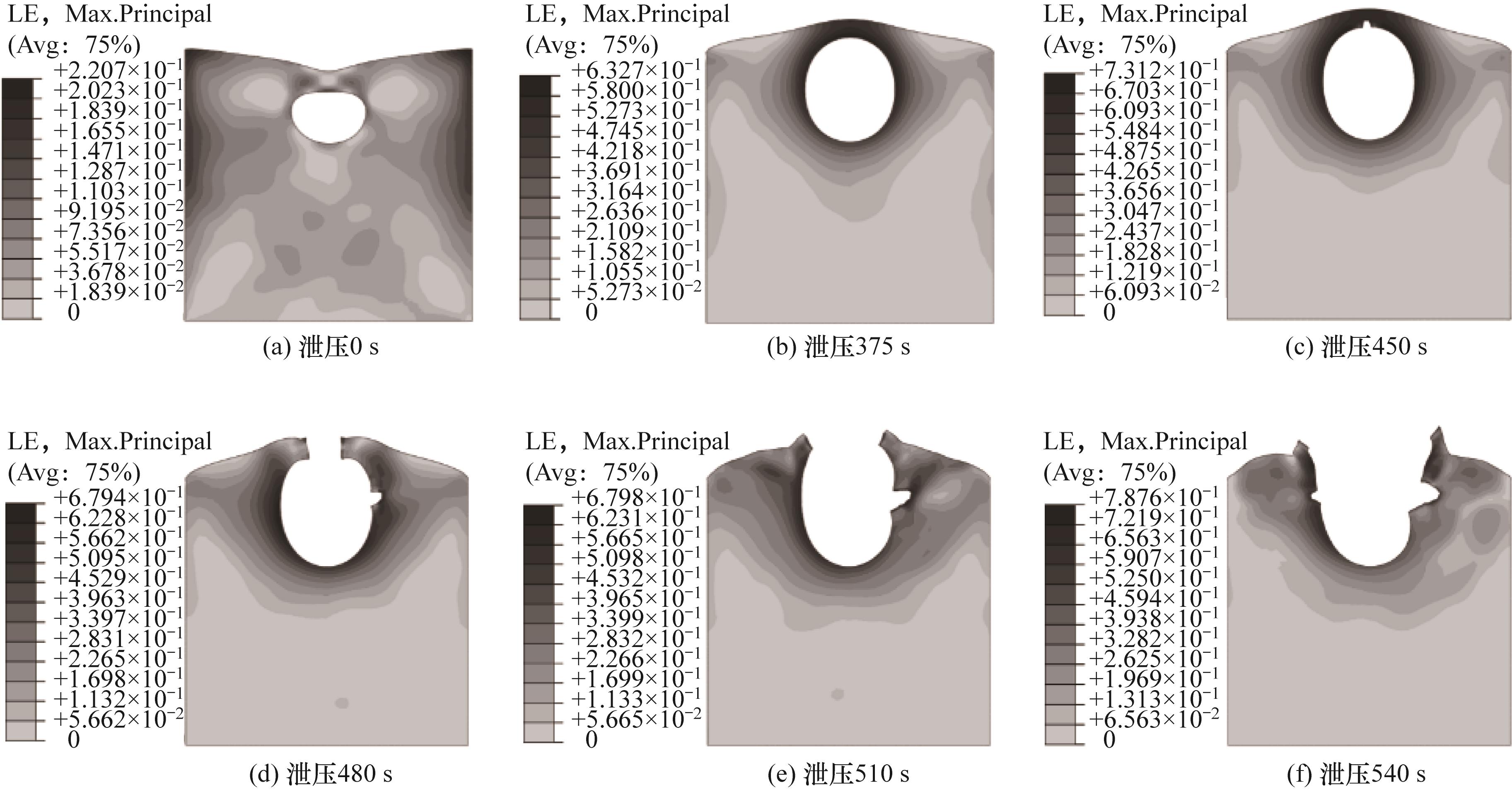

图10 氢气泄压不同时刻NBR样品的主应变云图

Fig.10 Principal strain across the NBR sample with depressurization at (a) 0 s, (b) 375 s, (c) 450 s, (d) 480 s, (e) 510 s, (f) 540 s

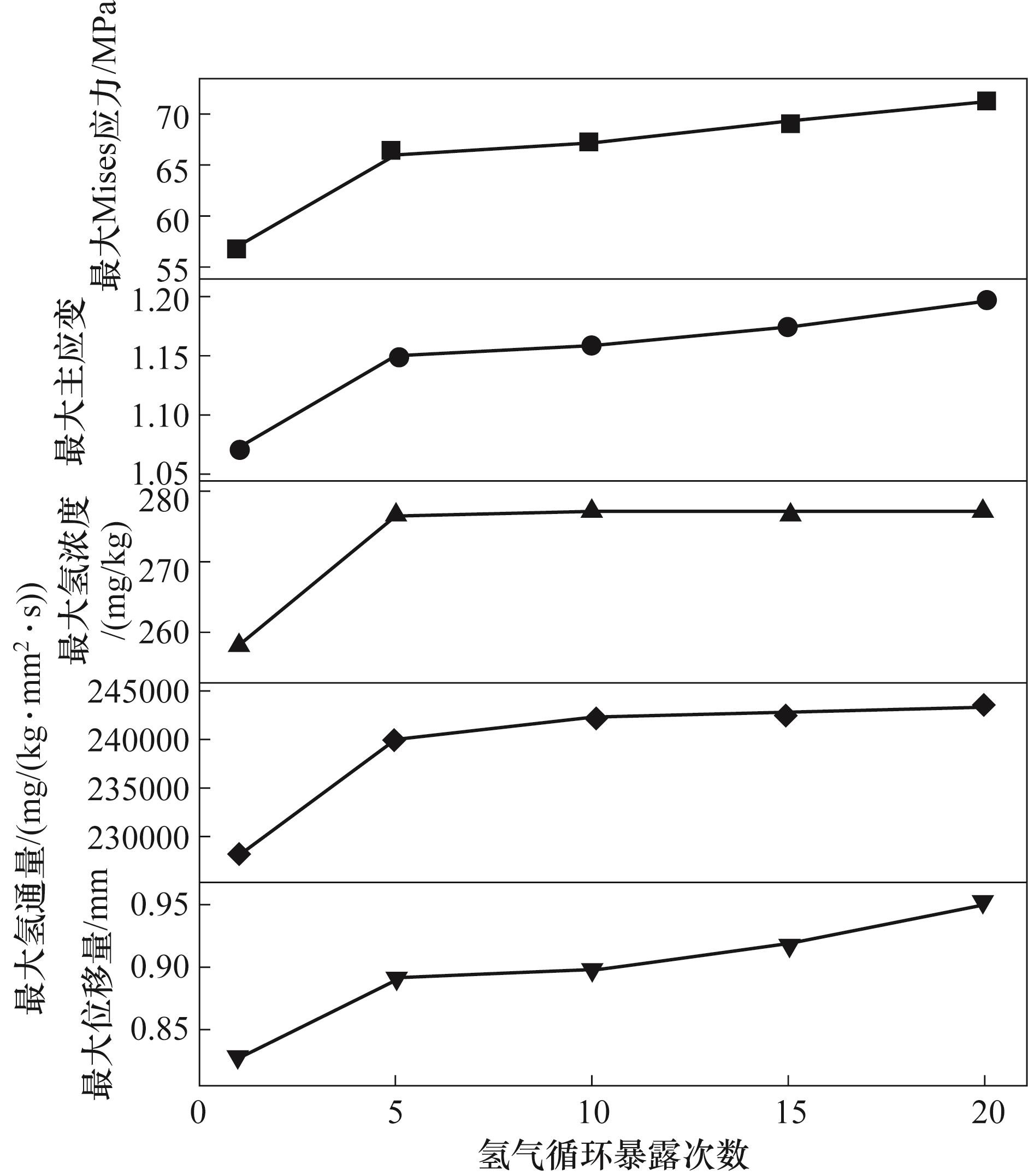

图12 氢循环暴露过程中最大Mises应力、最大主应变、最大氢浓度、最大氢通量、最大位移量的变化

Fig.12 Maximum Mises stress, maximum principal strain, maximum hydrogen concentration, maximum hydrogen flux, and maximum displacement of NBR during hydrogen cycle exposure

| [1] | Yasmin R, Ruhul Amin B M, Shah R, et al. A survey of commercial and industrial demand response flexibility with energy storage systems and renewable energy[J]. Sustainability, 2024, 16(2): 731. |

| [2] | Kabeyi M J B, Olanrewaju O A. Sustainable energy transition for renewable and low carbon grid electricity generation and supply[J]. Frontiers in Energy Research, 2022, 9: 743114. |

| [3] | Laimon M, Yusaf T. Towards energy freedom: exploring sustainable solutions for energy independence and self-sufficiency using integrated renewable energy-driven hydrogen system[J]. Renewable Energy, 2024, 222: 119948. |

| [4] | 周池楼, 刘先晖, 张永君, 等. 钢中夹杂物对氢扩散行为的影响规律[J]. 天然气工业, 2022, 42(9): 135-144. |

| Zhou C L, Liu X H, Zhang Y J, et al. Influence of inclusions in steel on hydrogen diffusion behavior[J]. Natural Gas Industry, 2022, 42(9): 135-144. | |

| [5] | Takeyama Y, Ueno M, Uejima M, et al. Development of carbon nanotube/rubber composite materials with excellent high pressure hydrogen characteristics[J]. Kobunshi Ronbunshu, 2019, 76(4): 288-296. |

| [6] | Zhou C L, Liu X H, Zheng Y R, et al. A comprehensive review of hydrogen-induced swelling in rubber composites[J]. Composites Part B: Engineering, 2024, 275: 111342. |

| [7] | Jung J K, Lee J H, Jeon S K, et al. Correlations between H2 permeation and physical/mechanical properties in ethylene propylene diene monomer polymers blended with carbon black and silica fillers[J]. International Journal of Molecular Sciences, 2023, 24(3): 2865. |

| [8] | Yamabe J, Nishimura S, Koga A. A study on sealing behavior of rubber O-ring in high pressure hydrogen gas[J]. SAE International Journal of Materials and Manufacturing, 2009, 2(1): 452-460. |

| [9] | Zhou C L, Huang Y L, Zheng Y R, et al. Hydrogen permeation behavior of rubber sealing materials for hydrogen infrastructure: recent advances and perspectives[J]. International Journal of Hydrogen Energy, 2024, 59: 742-754. |

| [10] | Chen Q, Peng W Z, Yang M M, et al. Numerical simulation of hydrogen diffusion in rubber O-rings containing a cavity defect based on thermomechanical coupling equivalent model[J]. International Journal of Hydrogen Energy, 2025, 139: 846-853. |

| [11] | Li Y L, Shin Y, Kuang W B, et al. Phase field modeling of hydrogen release in nitrile-butadiene rubber composites after high-pressure hydrogen exposure[J]. International Journal of Hydrogen Energy, 2024, 59: 833-844. |

| [12] | Zhou C L, Zheng Y R, Hua Z L, et al. Recent insights into hydrogen-induced blister fracture of rubber sealing materials: an in-depth examination[J]. Polymer Degradation and Stability, 2024, 224: 110747. |

| [13] | Schrittesser B, Pinter G, Schwarz T, et al. Rapid gas decompression performance of elastomers-a study of influencing testing parameters[J]. Procedia Structural Integrity, 2016, 2: 1746-1754. |

| [14] | Briscoe B J, Savvas T, Kelly C T. “Explosive decompression failure” of rubbers: a review of the origins of pneumatic stress induced rupture in elastomers[J]. Rubber Chemistry and Technology, 1994, 67(3): 384-416. |

| [15] | Fujiwara H, Yamabe J, Nishimura S. Evaluation of the change in chemical structure of acrylonitrile butadiene rubber after high-pressure hydrogen exposure[J]. International Journal of Hydrogen Energy, 2012, 37(10): 8729-8733. |

| [16] | Yamabe J, Matsumoto T, Nishimura S. Internal crack initiation and growth behavior and the influence of shape of specimen on crack damage of EPDM for sealing high-pressure hydrogen gas[J]. Journal of the Society of Materials Science, Japan, 2010, 59(12): 956-963. |

| [17] | Yamabe J, Nishimura S. Nanoscale fracture analysis by atomic force microscopy of EPDM rubber due to high-pressure hydrogen decompression[J]. Journal of Materials Science, 2011, 46(7): 2300-2307. |

| [18] | Yamabe J, Nishimura S. Influence of fillers on hydrogen penetration properties and blister fracture of rubber composites for O-ring exposed to high-pressure hydrogen gas[J]. International Journal of Hydrogen Energy, 2009, 34(4): 1977-1989. |

| [19] | Kane-Diallo O, Castagnet S, Grandidier J, et al. Morphology of damage occurring during decompression in a hydrogen-exposed EPDM[M]//Constitutive Models for Rubbers IX. Boca Raton: CRC Press, 2015: 345-350. |

| [20] | Kane-Diallo O, Castagnet S, Nait-Ali A, et al. Time-resolved statistics of cavity fields nucleated in a gas-exposed rubber under variable decompression conditions—support to a relevant modeling framework[J]. Polymer Testing, 2016, 51: 122-130. |

| [21] | Castagnet S, Mellier D, Nait-Ali A, et al. In-situ X-ray computed tomography of decompression failure in a rubber exposed to high-pressure gas[J]. Polymer Testing, 2018, 70: 255-262. |

| [22] | Simmons K L. H-Mat: science-based advancement of polymeric materials for hydrogen technologies[R/OL]. Pacific Northwest National Laboratory(2020) [2025-04-28]. . |

| [23] | Kulkarni S S, Choi K S, Kuang W B, et al. Damage evolution in polymer due to pressurization-depressurization cycles of hydrogen gas[R/OL]. Pacific Northwest National Laboratory(2020) [2025-04-28]. . |

| [24] | Simmons K L, Marchi C S. H-Mat overview: polymers[R/OL]. Pacific Northwest National Laboratory(2021) [2025-04-28]. . |

| [25] | Kulkarni S S, Choi K S, Kuang W B, et al. Damage evolution in polymer due to exposure to high-pressure hydrogen gas[J]. International Journal of Hydrogen Energy, 2021, 46(36): 19001-19022. |

| [26] | Simmons K L. H-Mat material compatibility considerations for hydrogen[R/OL]. Pacific Northwest National Laboratory(2022) [2025-04-28]. . |

| [27] | Kulkarni S S, Choi K S, Simmons K. Coupled diffusion-deformation-damage model for polymers used in hydrogen infrastructure[C]//ASME 2022 17th International Manufacturing Science and Engineering Conference、West Lafayette, Indiana, USA, 2022. |

| [28] | Simmons K L, Marchi C S. H-Mat overview: polymers[R/OL]. Pacific Northwest National Laboratory(2022) [2025-04-28]. . |

| [29] | Kulkarni S S, Shin Y, Choi K S, et al. Investigation of desorption of hydrogen gas from polymer matrix using thermal desorption analysis and finite element modeling[J]. Polymer, 2023, 282: 126182. |

| [30] | Kulkarni S S, Choi K S, Menon N, et al. A diffusion–deformation model with damage for polymer undergoing rapid decompression failure[J]. Journal of the Mechanics and Physics of Solids, 2023, 178: 105348. |

| [31] | Castagnet S, Grandidier J C, Comyn M, et al. Mechanical testing of polymers in pressurized hydrogen: tension, creep and ductile fracture[J]. Experimental Mechanics, 2012, 52(3): 229-239. |

| [32] | Yang L M, Shim V P W, Lim C T. A visco-hyperelastic approach to modelling the constitutive behaviour of rubber[J]. International Journal of Impact Engineering, 2000, 24(6/7): 545-560. |

| [33] | Shim V P W, Yang L M, Lim C T, et al. A visco-hyperelastic constitutive model to characterize both tensile and compressive behavior of rubber[J]. Journal of Applied Polymer Science, 2004, 92(1): 523-531. |

| [34] | Ogden R W. Large deformation isotropic elasticity: on the correlation of theory and experiment for compressible rubberlike solids[J]. Proceedings of the Royal Society of London A Mathematical and Physical Sciences, 1972, 328(1575): 567-583. |

| [35] | Castagnet S, Ono H, Benoit G, et al. Swelling measurement during sorption and decompression in a NBR exposed to high-pressure hydrogen[J]. International Journal of Hydrogen Energy, 2017, 42(30): 19359-19366. |

| [36] | Ono H, Fujiwara H, Nishimura S. Penetrated hydrogen content and volume inflation in unfilled NBR exposed to high-pressure hydrogen—what are the characteristics of unfilled-NBR dominating them?[J]. International Journal of Hydrogen Energy, 2018, 43(39): 18392-18402. |

| [37] | Fujiwara H, Ono H, Nishimura S. Effects of fillers on the hydrogen uptake and volume expansion of acrylonitrile butadiene rubber composites exposed to high pressure hydrogen: property of polymeric materials for high pressure hydrogen devices (3)[J]. International Journal of Hydrogen Energy, 2022, 47(7): 4725-4740. |

| [38] | Zhou C L, Zheng J Y, Gu C H, et al. Sealing performance analysis of rubber O-ring in high-pressure gaseous hydrogen based on finite element method[J]. International Journal of Hydrogen Energy, 2017, 42(16): 11996-12004. |

| [39] | Ono H, Nait-Ali A, Kane Diallo O, et al. Influence of pressure cycling on damage evolution in an unfilled EPDM exposed to high-pressure hydrogen[J]. International Journal of Fracture, 2018, 210(1): 137-152. |

| [40] | Jeon S K, Kwon O H, Tak N H, et al. Relationships between properties and rapid gas decompression (RGD) resistance of various filled nitrile butadiene rubber vulcanizates under high-pressure hydrogen[J]. Materials Today Communications, 2022, 30: 103038. |

| [41] | Wang L L, Zhang L Q, Tian M. Mechanical and tribological properties of acrylonitrile-butadiene rubber filled with graphite and carbon black[J]. Materials & Design, 2012, 39: 450-457. |

| [42] | He X Z, Shi X Y, Hoch M, et al. Mechanical properties of carbon black filled hydrogenated acrylonitrile butadiene rubber for packer compounds[J]. Polymer Testing, 2016, 53: 257-266. |

| [43] | Zhou C L, Yan X W, Zheng Y R, et al. Hydrogen permeation behavior and mechanisms in nitrile butadiene rubber composites for hydrogen sealing[J]. Polymer Degradation and Stability, 2024, 229: 110969. |

| [1] | 彭建斌, 李明, 谢军龙, 陈建业. 液氢接收终端液氢泄漏扩散及爆炸超压研究[J]. 化工学报, 2025, 76(S1): 453-461. |

| [2] | 段浩磊, 陈浩远, 梁坤峰, 王林, 陈彬, 曹勇, 张晨光, 李硕鹏, 朱登宇, 何亚茹, 杨大鹏. 纯电动车热管理系统低GWP工质替代方案性能分析与综合评价[J]. 化工学报, 2025, 76(S1): 54-61. |

| [3] | 丁昊, 王林, 刘豪. R290/R245fa汽液相平衡混合规则对比研究[J]. 化工学报, 2025, 76(S1): 9-16. |

| [4] | 王俊鹏, 冯佳琪, 张恩搏, 白博峰. 曲折式与阵列式迷宫阀芯结构内流动与空化特性研究[J]. 化工学报, 2025, 76(S1): 93-105. |

| [5] | 赵子祥, 段钟弟, 孙浩然, 薛鸿祥. 大温差两相流动诱导水锤冲击的数值模型[J]. 化工学报, 2025, 76(S1): 170-180. |

| [6] | 黄灏, 王文, 贺隆坤. LNG船薄膜型液货舱预冷过程模拟与分析[J]. 化工学报, 2025, 76(S1): 187-194. |

| [7] | 汪思远, 刘国强, 熊通, 晏刚. 窗式空调器轴流风机的风速非均匀分布特性及其对冷凝器流路优化设计的影响规律[J]. 化工学报, 2025, 76(S1): 205-216. |

| [8] | 曹庆泰, 郭松源, 李建强, 蒋赞, 汪彬, 耑锐, 吴静怡, 杨光. 负过载下多孔隔板对液氧贮箱蓄液性能的影响研究[J]. 化工学报, 2025, 76(S1): 217-229. |

| [9] | 孙九春, 桑运龙, 王海涛, 贾浩, 朱艳. 泥水盾构仓体内射流对泥浆输送特性影响研究[J]. 化工学报, 2025, 76(S1): 246-257. |

| [10] | 何婷, 黄舒阳, 黄坤, 陈利琼. 基于余热利用的天然气化学吸收脱碳-高温热泵耦合流程研究[J]. 化工学报, 2025, 76(S1): 297-308. |

| [11] | 刘奕扬, 邢志祥, 刘烨铖, 彭明, 李玉洋, 李云浩, 沈宁舟. 加氢站液氢泄漏扩散特性与安全监测数值模拟研究[J]. 化工学报, 2025, 76(9): 4694-4708. |

| [12] | 邹家庆, 张肇钰, 张建国, 张博宇, 刘定胜, 毛庆, 王挺, 李建军. 碱水制氢电解槽极板通道中气泡的生成及演化性质[J]. 化工学报, 2025, 76(9): 4786-4799. |

| [13] | 黄正宗, 刘科成, 李泽方, 曾平生, 刘永富, 闫红杰, 刘柳. 锌精馏炉砖砌式换热室数值模拟与场协同优化[J]. 化工学报, 2025, 76(9): 4425-4439. |

| [14] | 贾志勇, 沈宪琨, 蓝晓程, 王铁峰. 气体密度对高压流态化影响的CFD-DEM模拟[J]. 化工学报, 2025, 76(9): 4383-4397. |

| [15] | 杨开源, 陈锡忠. 颗粒破碎的离散元及有限离散元模拟方法比较[J]. 化工学报, 2025, 76(9): 4398-4411. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号