化工学报 ›› 2025, Vol. 76 ›› Issue (9): 4425-4439.DOI: 10.11949/0438-1157.20241439

黄正宗1( ), 刘科成1, 李泽方1, 曾平生2, 刘永富2, 闫红杰1, 刘柳1(

), 刘科成1, 李泽方1, 曾平生2, 刘永富2, 闫红杰1, 刘柳1( )

)

收稿日期:2024-12-12

修回日期:2025-01-09

出版日期:2025-09-25

发布日期:2025-10-23

通讯作者:

刘柳

作者简介:黄正宗(1995—),男,博士研究生,z.z.huang@csu.edu.cn

基金资助:

Zhengzong HUANG1( ), Kecheng LIU1, Zefang LI1, Pingsheng ZENG2, YongFu LIU2, Hongjie YAN1, Liu LIU1(

), Kecheng LIU1, Zefang LI1, Pingsheng ZENG2, YongFu LIU2, Hongjie YAN1, Liu LIU1( )

)

Received:2024-12-12

Revised:2025-01-09

Online:2025-09-25

Published:2025-10-23

Contact:

Liu LIU

摘要:

砖砌式换热室是塔式锌精馏炉的关键设备,主要用于预热入炉空气和回收烟气余热。由于砖砌式换热室的结构限制,其存在气体流速分布不均、换热效率低等问题。因此,以锌精馏炉砖砌式换热室为研究对象,利用CFD技术对换热室进行全面的数值研究,并基于场协同理论,以积分中值协同角、体积加权平均协同角、综合强化传热性能系数等为评价指标,评估并获得了结构优化方案。研究表明,烟气侧速度分布不均的现象集中在换热流程的连接口,空气侧流速不均的现象集中在底层空气道;结构优化应重点关注底层东侧空气道;拓宽空气道入口可有效强化筒形砖内空气流量的均匀性,相对标准偏差仅为17.5%,并改善换热室的综合传热性能;底层东侧空气道入口的最佳宽度为435 mm。

中图分类号:

黄正宗, 刘科成, 李泽方, 曾平生, 刘永富, 闫红杰, 刘柳. 锌精馏炉砖砌式换热室数值模拟与场协同优化[J]. 化工学报, 2025, 76(9): 4425-4439.

Zhengzong HUANG, Kecheng LIU, Zefang LI, Pingsheng ZENG, YongFu LIU, Hongjie YAN, Liu LIU. Numerical simulation and field synergy optimization of brick-built heat exchange chamber in zinc refining furnace[J]. CIESC Journal, 2025, 76(9): 4425-4439.

| 材料 | 密度/(kg/m3) | 比热容/(J/(kg∙K)) | 热导率/(W/(m∙K)) | 吸收系数/m-1 | 散射系数/m-1 |

|---|---|---|---|---|---|

| 墙体 | 2200 | 750 | 1.5 | 3.7 | 50.88 |

表1 锌精馏炉墙体的物性参数

Table 1 Physical parameters of the wall of a zinc refining furnace

| 材料 | 密度/(kg/m3) | 比热容/(J/(kg∙K)) | 热导率/(W/(m∙K)) | 吸收系数/m-1 | 散射系数/m-1 |

|---|---|---|---|---|---|

| 墙体 | 2200 | 750 | 1.5 | 3.7 | 50.88 |

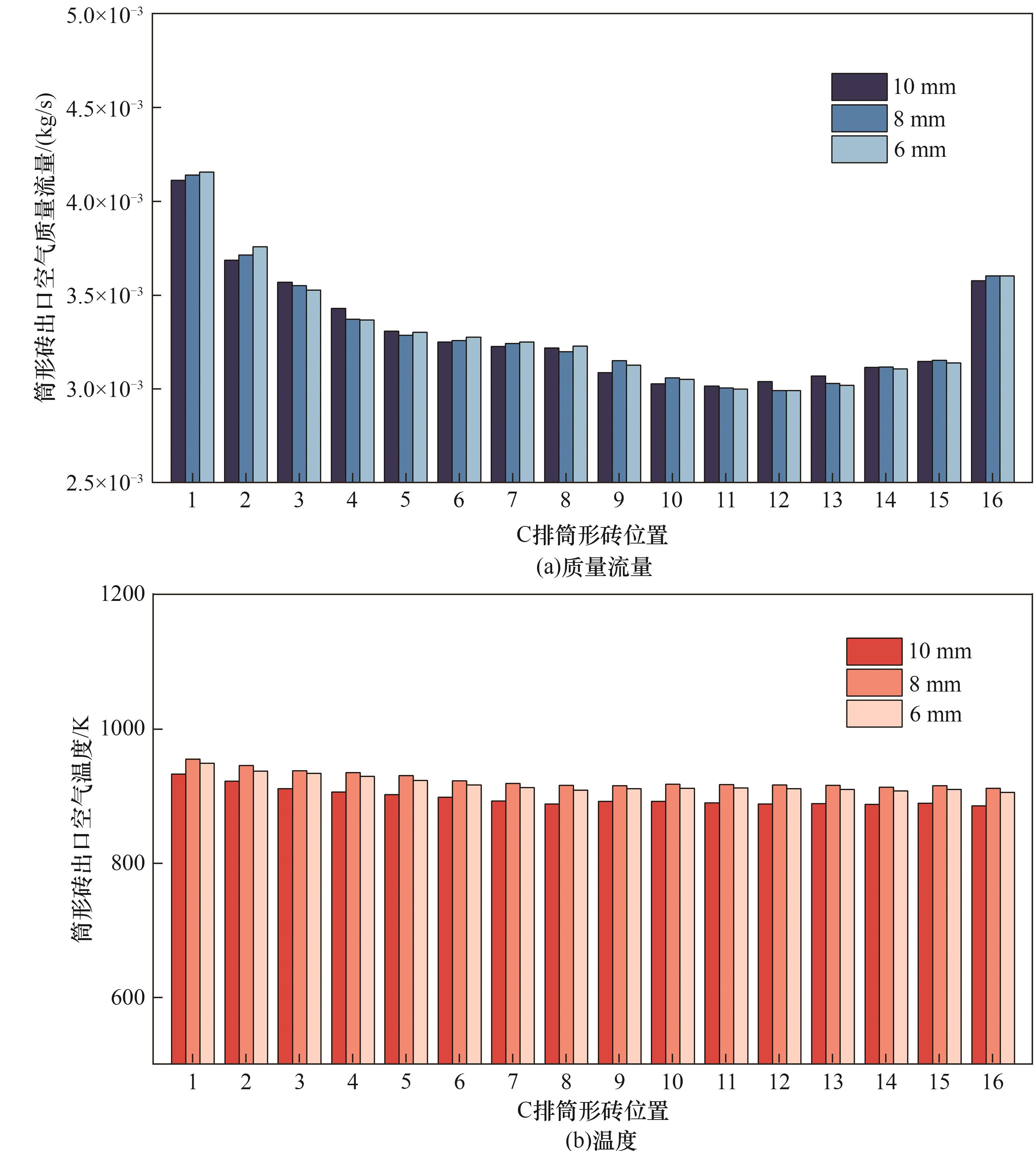

图3 换热室C排筒形砖空气出口的质量流量与温度的柱状图

Fig.3 Histogram of the mass flow and temperature at the air outlet of the chimney checker in row C for the heat exchange chamber

| 序号 | 测点位置 | 测试值/K | 计算值/K | 相对误差/% |

|---|---|---|---|---|

| 1 | 换热室烟气出口 | 825.13 | 882.46 | 6.9 |

| 2 | 换热室空气出口 | 1070.85 | 1001.23 | 6.5 |

表2 换热室烟气及空气温度计算值与测试值对比

Table 2 Comparison of calculated and measured flue gas and air temperatures in the heat exchange chamber

| 序号 | 测点位置 | 测试值/K | 计算值/K | 相对误差/% |

|---|---|---|---|---|

| 1 | 换热室烟气出口 | 825.13 | 882.46 | 6.9 |

| 2 | 换热室空气出口 | 1070.85 | 1001.23 | 6.5 |

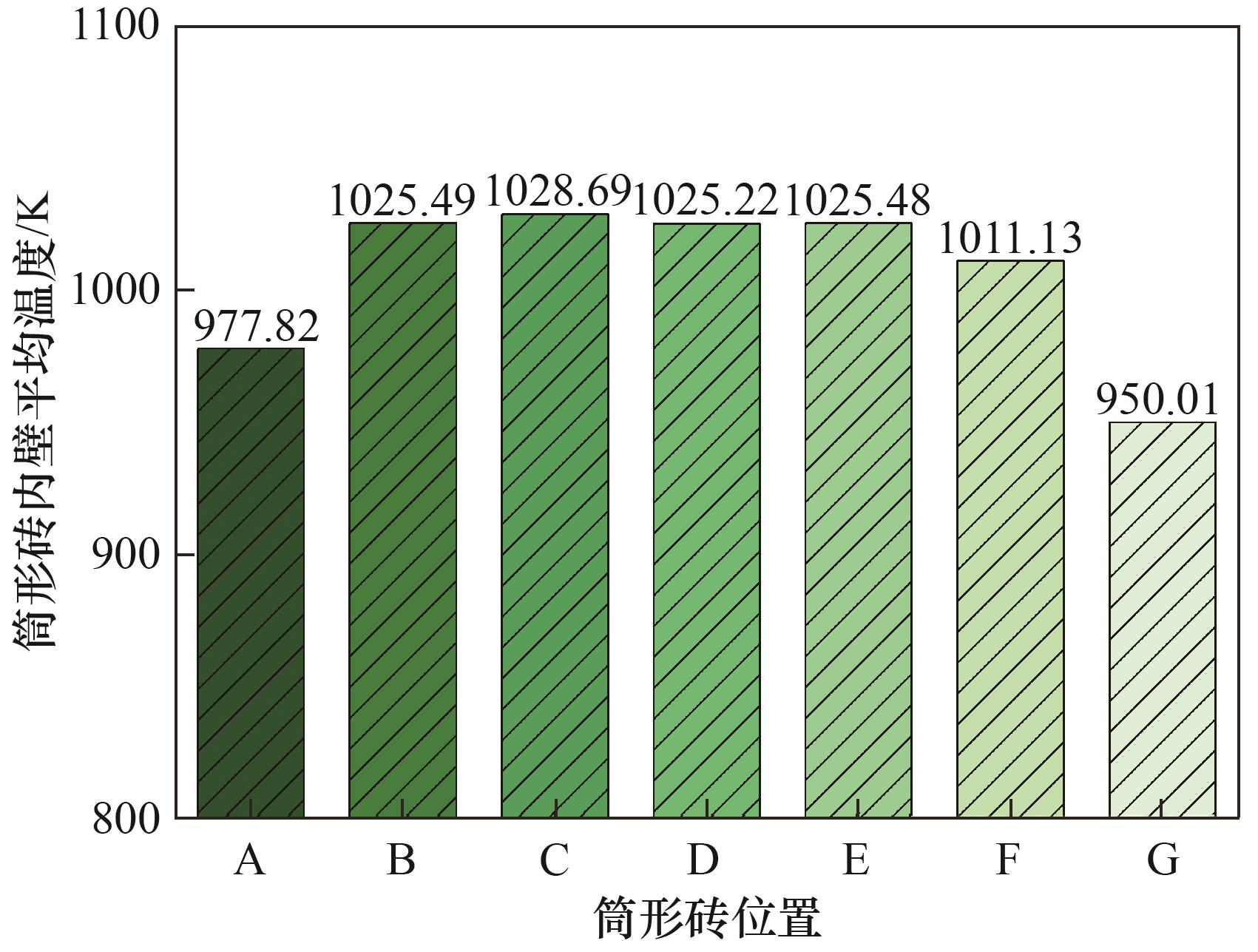

图10 砖砌式换热室不同排筒形砖内壁面的平均温度柱状图

Fig.10 Average temperature histogram of the inner wall surfaces of different rows of the chimney checker in the brick-built heat exchange chamber

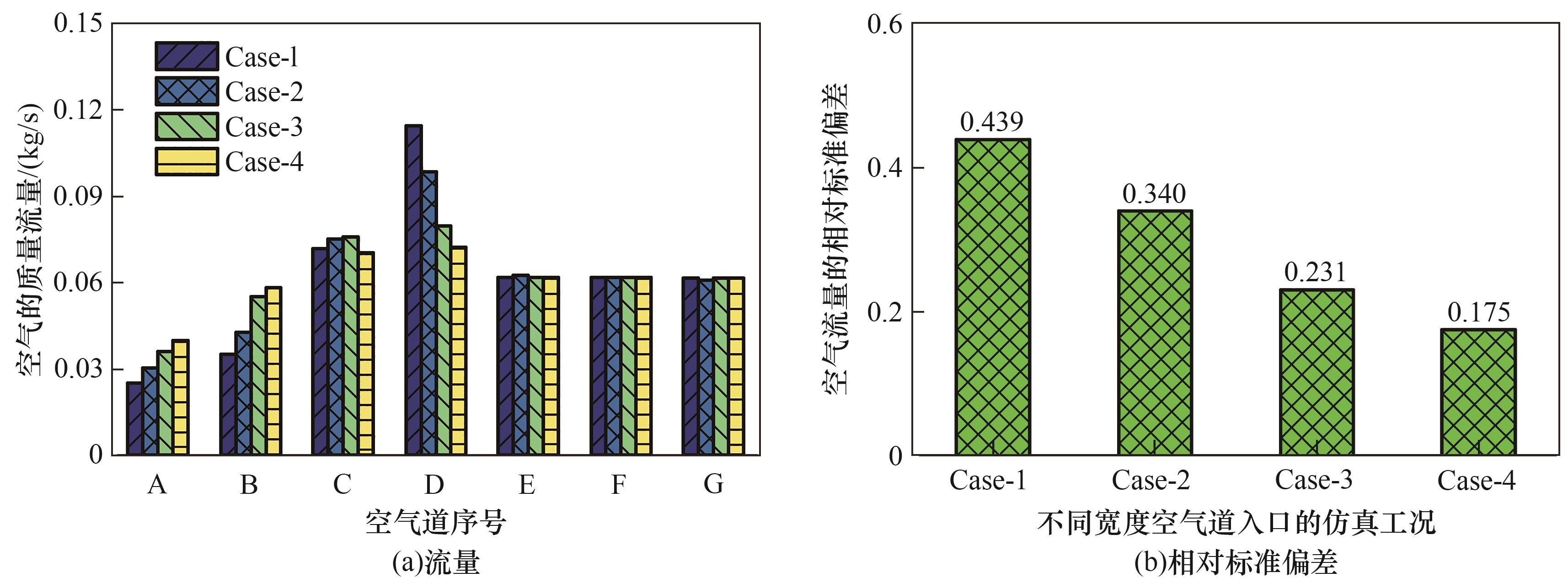

| 工况 | Case-1 | Case-2 | Case-3 | Case-4 |

|---|---|---|---|---|

| 数值/mm | 240 | 305 | 370 | 435 |

表3 底层东侧空气道入口的水平宽度

Table 3 Horizontal width of air duct inlet on east side at bottom layer

| 工况 | Case-1 | Case-2 | Case-3 | Case-4 |

|---|---|---|---|---|

| 数值/mm | 240 | 305 | 370 | 435 |

图13 空气道不同入口宽度时不同排筒形砖的空气质量流量及其相对标准偏差的柱状图

Fig.13 Histograms of air mass flows and their relative standard deviations for different rows of chimney checkers at different inlet widths of air duct

图15 空气道不同入口宽度时换热室局部传热协同角云图的对比

Fig.15 Comparison of local heat transfer synergy angle contours of the heat exchanger chamber for different inlet widths of the air channel

| [1] | 赵浩然, 黄嗣罗, 林梅. 余热锅炉入口管箱底面沉积特性[J]. 化工学报, 2024, 75(10): 3464-3476. |

| Zhao H R, Huang S L, Lin M. Sedimentation characteristics of the bottom surface of the inlet pipe box of a waste heat boiler[J]. CIESC Journal, 2024, 75(10): 3464-3476. | |

| [2] | Guo X Y, Jiang B C, Chen J H, et al. Effect of oxygen lance seat arrangement on flow characteristics of large-scale copper smelting bottom-blown furnace[J]. Journal of Central South University, 2023, 30(8): 2542-2555. |

| [3] | 曹健, 钱红亮, 冯新, 等. 热力学视角下的碳中和三问[J]. 化工学报, 2024, 75(11): 4378-4384. |

| Cao J, Qian H L, Feng X, et al. Three questions on carbon neutrality from the perspective of thermodynamics[J]. CIESC Journal, 2024, 75(11): 4378-4384. | |

| [4] | 张岭, 蔡晖, 张乐如. ISP技术能耗分析[J]. 世界有色金属, 2021(12): 148-150. |

| Zhang L, Cai H, Zhang L R. Energy consumption of ISP technology[J]. World Nonferrous Metals, 2021(12): 148-150. | |

| [5] | 曾平生, 黄正宗, 郑关平, 等. 塔式锌精馏炉热工诊断与节能分析[J]. 中国有色冶金, 2022, 51(6): 45-53. |

| Zeng P S, Huang Z Z, Zheng G P, et al. Thermal diagnosis and energy saving analysis of a tower-type zinc refining furnace[J]. China Nonferrous Metallurgy, 2022, 51(6): 45-53. | |

| [6] | 陈杰. 锌精馏工艺中铅塔燃烧室内温度场研究[D]. 沈阳: 东北大学, 2011. |

| Chen J. Temperature field study of zinc refining process in plumbean tower burner[D]. Shenyang: Northeastern University, 2011. | |

| [7] | 李泽方. 基于场协同的锌精馏过程余热高效利用技术研究[D]. 长沙: 中南大学, 2023. |

| Li Z F. Research on the waste heat recovery technology of zinc refining process based on field synergy principle[D]. Changsha: Central South University, 2023. | |

| [8] | Khaled M, Mortada M, Faraj J, et al. Effect of airflow non-uniformities on the thermal performance of water-air heat exchangers: experimental study and analysis[J]. Energies, 2022, 15(21): 8120. |

| [9] | Yan H J, Xie H Y, Zheng W Y, et al. Numerical simulation of combustion and melting process in an aluminum melting furnace: a study on optimizing stacking mode[J]. Applied Thermal Engineering, 2024, 245: 122840. |

| [10] | Yan H J, Huang Z Z, Hu M, et al. Numerical modeling of gas-solid two-phase flow in a plasma melting furnace[J]. Powder Technology, 2022, 412: 117967. |

| [11] | 李杰, 胡国林, 朱永红, 等. 隧道窑烟气换热器肋板强化传热的数值研究[J]. 陶瓷学报, 2014, 35(3): 318-321. |

| Li J, Hu G L, Zhu Y H, et al. Numerical study on finned enhanced heat transfer used in a tunnel kiln's flue gas heat exchanger[J]. Journal of Ceramics, 2014, 35(3): 318-321. | |

| [12] | 何金桥, 赵华庚, 曾丹, 等. 基于多孔介质模型的低质燃气燃烧排放特性数值模拟[J]. 长沙理工大学学报(自然科学版), 2017, 14(2): 80-84. |

| He J Q, Zhao H G, Zeng D, et al. Numerical simulation of low-quality gas emission characteristics based on porous medium model[J]. Journal of Changsha University of Science & Technology (Natural Science), 2017, 14(2): 80-84. | |

| [13] | Xiong Q G, Izadi M, Shokri rad M, et al. 3D numerical study of conical and fusiform turbulators for heat transfer improvement in a double-pipe heat exchanger[J]. International Journal of Heat and Mass Transfer, 2021, 170: 120995. |

| [14] | 鄂加强, 邢德跃, 王曙辉, 等. 柴油机高压喷油嘴喷射过程空化效应数值模拟[J]. 湖南大学学报(自然科学版), 2013, 40(2): 45-51. |

| E J Q, Xing D Y, Wang S H, et al. Numerical simulation of cavitation effect in the injection process of high pressure injector nozzle in diesel[J]. Journal of Hunan University (Natural Sciences), 2013, 40(2): 45-51. | |

| [15] | Huang Z Z, Liu L, Chen L, et al. Numerical modeling and parameter optimization of the combustion chamber in a tower-type zinc refining furnace[J]. Case Studies in Thermal Engineering, 2024, 64: 105450. |

| [16] | Yan H J, Huang Z Z, Zeng P S, et al. CFD-based burner parameter optimization of a sintering ignition furnace[J]. Applied Thermal Engineering, 2024, 241: 122430. |

| [17] | 曾平生, 黄正宗, 江新辉, 等. 铅锌冶炼烧结点火炉点火过程数值模拟[J]. 中国有色金属学报, 2024, 34(1): 254-267. |

| Zeng P S, Huang Z Z, Jiang X H, et al. Numerical simulation on the ignition process of sintering ignition furnace in lead-zinc smelting[J]. The Chinese Journal of Nonferrous Metals, 2024, 34(1): 254-267. | |

| [18] | 曹天明, 李保运. 马钢特钢电炉余热回收系统改造实践[J]. 冶金动力, 2022, 41(4): 119-123. |

| Cao T M, Li B Y. Practice of electric furnace waste heat recovery system renovation of masteel[J]. Metallurgical Power, 2022, 41(4): 119-123. | |

| [19] | Szwaja S, Zajemska M, Szwaja M, et al. Integration of waste biomass thermal processing technology with a metallurgical furnace to improve its efficiency and economic benefit[J]. Clean Technologies and Environmental Policy, 2023, 25(2): 577-587. |

| [20] | Delpech B, Axcell B, Jouhara H. Experimental investigation of a radiative heat pipe for waste heat recovery in a ceramics kiln[J]. Energy, 2019, 170: 636-651. |

| [21] | Hatami M, Jafaryar M, Ganji D D, et al. Optimization of finned-tube heat exchangers for diesel exhaust waste heat recovery using CFD and CCD techniques[J]. International Communications in Heat and Mass Transfer, 2014, 57: 254-263. |

| [22] | Soundararajan S, Selvaraj M. Investigations of protracted finned double pipe heat exchanger system for waste heat recovery from diesel engine exhaust[J]. Thermal Science, 2023, 27(5 Part A): 3783-3793. |

| [23] | Siva T, Chaitanya P S. Optimization of shell and tube heat exchanger used in a rankine cycle of exhaust gas waste heat recovery system using CFD[J]. International Journal of Chemical Sciences, 2016, 14(4): 2247-2258. |

| [24] | 李逸飞. 基于烟气余热回收的蒸发冷凝型换热器性能研究及优化[D]. 太原: 太原理工大学, 2023. |

| Li Y F. Research and optimization of evaporative condensing heat exchanger based on flue gas waste heat recovery[D]. Taiyuan: Taiyuan University of Technology, 2023. | |

| [25] | Duan Y R, Zhang X Y, Han Z Y, et al. Numerical investigation of coupled heat transfer and flow characteristics in helical coil heat exchanger for mine water waste heat recovery[J]. International Journal of Thermal Sciences, 2024, 202: 109089. |

| [26] | Wang L M, Lei Y G, Jing S L. Performance of a double-tube heat exchanger with staggered helical fins[J]. Chemical Engineering & Technology, 2022, 45(5): 953-961. |

| [27] | Yu C, Shao M Z, Zhang W B, et al. Enhancing heat transfer efficiency in corrugated tube heat exchangers: a comprehensive approach through structural optimization and field synergy analysis[J]. Heliyon, 2024, 10(9): e30113. |

| [28] | 李雪雪. 柱翼型散热器传热过程数值模拟与场协同优化研究[D]. 太原: 太原理工大学, 2023. |

| Li X X. Numerical simulation of heat transfer process and field collaborative optimization of cylindrical airfoil radiators[D]. Taiyuan: Taiyuan University of Technology, 2023. | |

| [29] | 李德涛, 安亚中, 张灵东, 等. 管壳式换热器折流板开孔流场特征及场协同分析[J]. 江西化工, 2024, 40(3): 105-109. |

| Li D T, An Y Z, Zhang L D, et al. Flow field characteristics and field synergy analysis of the orifices in the baffles of shell and tube heat exchangers[J]. Jiangxi Chemical Industry, 2024, 40(3): 105-109. | |

| [30] | 王福军. 计算流体力学分析—CFD软件原理与应用[M]. 北京: 清华大学出版社, 2004. |

| Wang F J. Computational Fluid Dynamics Analysis—CFD Software Principles and Applications[M]. Beijing: Tsinghua University Press, 2004. | |

| [31] | Launder B E, Spalding D B. Lectures in mathematical model of turbulence[D]. New York: Academic Press, 1972. |

| [32] | 刘伟, 刘志春, 马雷. 多场协同原理在管内对流强化传热性能评价中的应用[J]. 科学通报, 2012, 57(10): 867-874. |

| Liu W, Liu Z C, Ma L. Physical quantity application of a multi-field synergy principle in the performance evaluation of convective heat transfer enhancement in a tube[J]. Chinese Science Bulletin, 2012, 57(10): 867-874. | |

| [33] | 费凤繁, 陈亚平, 吴嘉峰, 等. 半圆柱空间异形孔板换热器热工水力性能的数值模拟[J]. 热能动力工程, 2023, 38(3): 126-132. |

| Fei F F, Chen Y P, Wu J F, et al. Numerical simulation of thermal and hydraulic performance of heat exchanger with orifice baffles in half cylindrical space[J]. Journal of Engineering for Thermal Energy and Power, 2023, 38(3): 126-132. | |

| [34] | 曹穆霁. 新型折流板管壳式换热器的传热研究[D]. 杭州: 浙江科技学院, 2022. |

| Cao M J. Study on heat transfer of a new baffled shell and tube heat exchanger[D]. Hangzhou: Zhejiang University of Science and Technology, 2022. | |

| [35] | 蒋屹. 铅铋合金-超临界二氧化碳换热器流动换热特性研究[D]. 北京: 华北电力大学(北京), 2022. |

| Jiang Y. Study on the heat transfer characteristics of lead bismuth eutectic and supercritical carbon dioxide in heat exchanger[D]. Beijing: North China Electric Power University (Beijing), 2022. | |

| [36] | Goyal M, Chakravarty A, Atrey M D. Experimental investigations and validation of two dimensional model for multistream plate fin heat exchangers[J]. Cryogenics, 2017, 82: 83-91. |

| [37] | Grzywacz R, Teper M. Experimental validation of a CFD model of a ground heat exchanger with slinky coils[J]. Polish Journal of Chemical Technology, 2024, 26(2): 86-91. |

| [38] | 田元. 大型循环流化床锅炉风室与布风板联合布风均匀性数值模拟与试验研究[D]. 重庆: 重庆大学, 2018. |

| Tian Y. Numerical simulation and experimental investigation of air flow uniformity in the windbox of large-scale CFB boiler[D]. Chongqing: Chongqing University, 2018. | |

| [39] | 王华东, 姚来军, 王金辉, 等. 等压送风在小吨位锅炉设计上的应用[J]. 电器工业, 2004(7): 38-39. |

| Wang H D, Yao L J, Wang J H, et al. Application of isobaric air supply in the design of small tonnage boilers[J]. China Electrical Equipment Industry, 2004(7): 38-39. | |

| [40] | 孟继安. 基于场协同理论的纵向涡强化换热技术及其应用[D]. 北京: 清华大学, 2003. |

| Meng J A. Enhanced heat transfer technology of longitudinal vortices based on field-coordination principle and its application[D]. Beijing: Tsinghua University, 2003. | |

| [41] | 包晓琳. 幂律流体螺旋管内流场与温度场协同优化研究[D]. 济南: 山东建筑大学, 2020. |

| Bao X L. Study on collaborative optimization of flow field and temperature field of power-law fluid in spiral tube[D]. Jinan: Shandong Jianzhu University, 2020. | |

| [42] | 周俊杰, 陶文铨, 王定标. 场协同原理评价指标的定性分析和定量探讨[J]. 郑州大学学报(工学版), 2006, 27(2): 45-47. |

| Zhou J J, Tao W Q, Wang D B. Qualitative analysis and quantitative discussion of index for field synergy principle[J]. Journal of Zhengzhou University (Engineering Science), 2006, 27(2): 45-47. |

| [1] | 赵子祥, 段钟弟, 孙浩然, 薛鸿祥. 大温差两相流动诱导水锤冲击的数值模型[J]. 化工学报, 2025, 76(S1): 170-180. |

| [2] | 黄灏, 王文, 贺隆坤. LNG船薄膜型液货舱预冷过程模拟与分析[J]. 化工学报, 2025, 76(S1): 187-194. |

| [3] | 黄博, 黄灏, 王文, 贺隆坤. 薄膜型LNG船液货舱温度场计算分析[J]. 化工学报, 2025, 76(S1): 195-204. |

| [4] | 汪思远, 刘国强, 熊通, 晏刚. 窗式空调器轴流风机的风速非均匀分布特性及其对冷凝器流路优化设计的影响规律[J]. 化工学报, 2025, 76(S1): 205-216. |

| [5] | 曹庆泰, 郭松源, 李建强, 蒋赞, 汪彬, 耑锐, 吴静怡, 杨光. 负过载下多孔隔板对液氧贮箱蓄液性能的影响研究[J]. 化工学报, 2025, 76(S1): 217-229. |

| [6] | 孙九春, 桑运龙, 王海涛, 贾浩, 朱艳. 泥水盾构仓体内射流对泥浆输送特性影响研究[J]. 化工学报, 2025, 76(S1): 246-257. |

| [7] | 石一帆, 柯钢, 陈浩, 黄孝胜, 叶芳, 李成娇, 郭航. 大型高低温环境实验室温度控制仿真[J]. 化工学报, 2025, 76(S1): 268-280. |

| [8] | 孔繁臣, 张硕, 唐明生, 邹慧明, 胡舟航, 田长青. 二氧化碳直线压缩机气体轴承模拟[J]. 化工学报, 2025, 76(S1): 281-288. |

| [9] | 何婷, 黄舒阳, 黄坤, 陈利琼. 基于余热利用的天然气化学吸收脱碳-高温热泵耦合流程研究[J]. 化工学报, 2025, 76(S1): 297-308. |

| [10] | 何婷, 张开, 林文胜, 陈利琼, 陈家富. 沼气超临界压力低温脱碳-液化耦合流程研究[J]. 化工学报, 2025, 76(S1): 418-425. |

| [11] | 沙鑫权, 胡然, 丁磊, 蒋珍华, 吴亦农. 空间用单机两级有阀线性压缩机研制及测试[J]. 化工学报, 2025, 76(S1): 114-122. |

| [12] | 孙浩然, 吴成云, 王艳蒙, 孙静楠, 胡仞与, 段钟弟. 热对流影响下液滴蒸发特性模型与实验研究[J]. 化工学报, 2025, 76(S1): 123-132. |

| [13] | 燕子腾, 詹飞龙, 丁国良. 空调用套管式分流器结构设计及分流效果验证[J]. 化工学报, 2025, 76(S1): 152-159. |

| [14] | 段浩磊, 陈浩远, 梁坤峰, 王林, 陈彬, 曹勇, 张晨光, 李硕鹏, 朱登宇, 何亚茹, 杨大鹏. 纯电动车热管理系统低GWP工质替代方案性能分析与综合评价[J]. 化工学报, 2025, 76(S1): 54-61. |

| [15] | 王俊鹏, 冯佳琪, 张恩搏, 白博峰. 曲折式与阵列式迷宫阀芯结构内流动与空化特性研究[J]. 化工学报, 2025, 76(S1): 93-105. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号